|

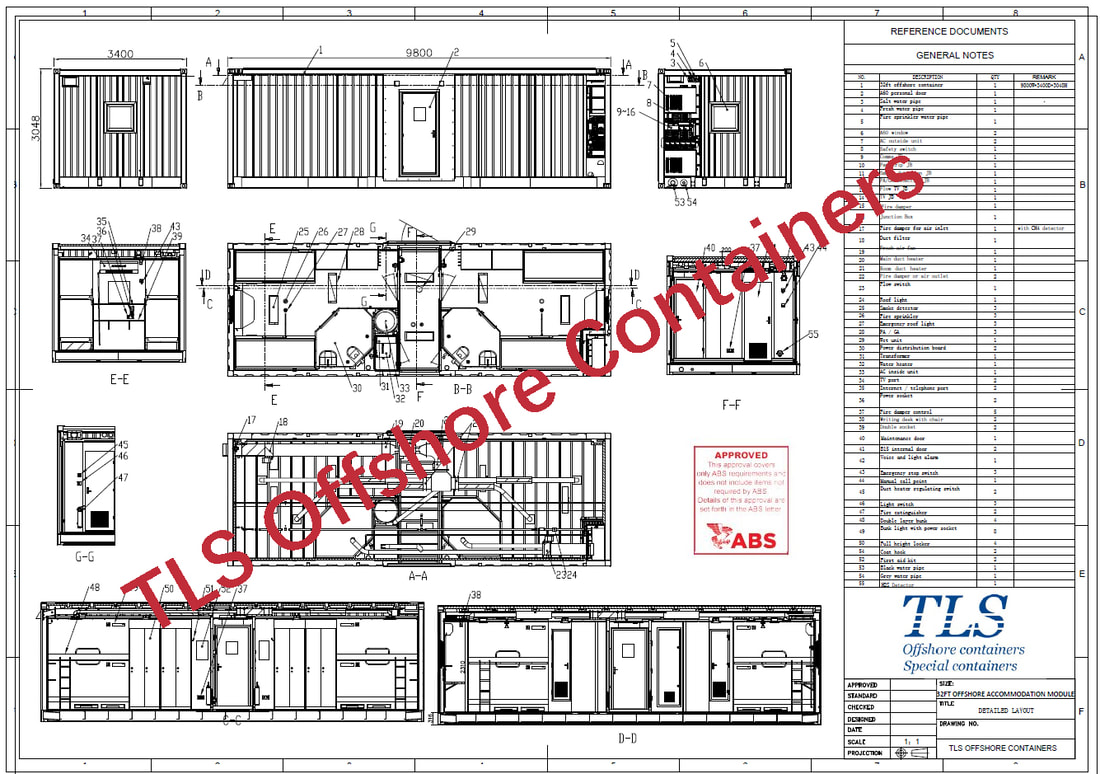

ABS guildline for portable offshore accommodation modules The installation of modular buildings for use as living quarters, industrial spaces, and workshops has become increasingly prevalent in recent years. Irrespective of the amount of time that portable modules are installed onboard, the potential risks to personnel within these buildings can be comparable to those within a traditional living quarters structure. Due to the transient nature of portable accommodation modules, it is possible that the buildings may be installed on a number of different types of vessels and offshore units over their life. In recognizing that the ABS class requirements differ based on the type of host vessel or facility, this Guide has been created to outline the process for the design and survey of the modules and to establish the requirements for modules which can be used on any category of offshore drilling unit, production facility, barge, steel vessel, or high speed craft. Class Approval Process The ABS approval process for accommodation modules is a four-step process as outlined below: • Design Review of the Module • Survey of the Module at Fabrication Facility • Design Review for Installation Approval • Survey onboard Host Vessel The ABS review process of the module commences with drawings and documentation detailing the module’s general arrangements, structural fire protection, electrical configuration, structural design, and machinery and piping systems being submitted to the ABS technical office for review. Upon completion of the review, drawings will be returned to the submitter and forwarded to the attending ABS Surveyor. Receipt of the drawings by the ABS Surveyor permits the physical survey of the module at the fabrication facility to be commenced. Once a host vessel for the module is determined, design review for installation approval can be commenced. Upon receipt of the documentation detailing the module and the proposed location onboard the host vessel, the ABS technical office can review the arrangements. Once the ABS engineers have determined that the proposed location onboard the host vessel is suitable for the subject module, stamped drawings will be returned to the submitter and made available to the attending ABS Survey office. Upon receipt of these drawings, the attending ABS Surveyor may attend the vessel and confirm that the installation of the modules is in accordance with the approved arrangements. The manufacturer is to assign a unique serial number to identify all modules being reviewed to this Guide. The initial submission of drawings is to specifically indicate the serial number of modules to be built in accordance with the drawings. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please contact [email protected] for more information. mud logging unit, mud logging cabin, A60 pressurised container, 20ft standard mud loggint cabin1/22/2021

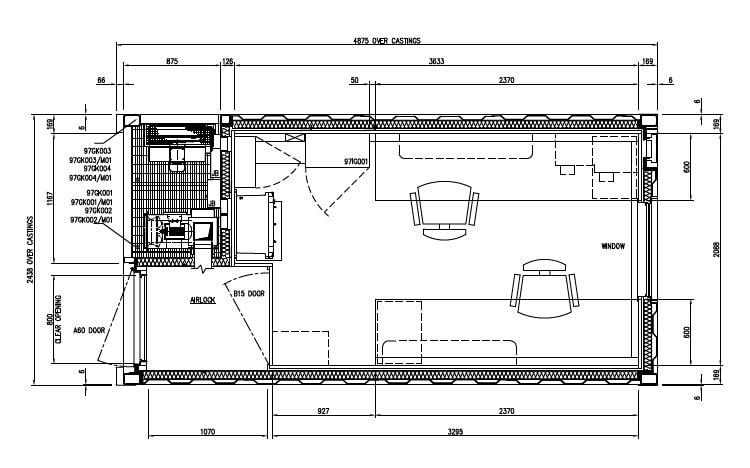

20ft Mud Logging cabin standard specifications Description: A60 rated, Zone1/zone 2 cabin (for offshore application) External dimension: 6058*2438*2591mm (L*W*H) Structural Rating: DNV 2.7-1/ EN12079 Hazardous Area Classification: Zone1 / zone 2 Designed, manufactured, and certified as per DNV 2.7-1 standard, IEC60079-13

Fire Rating: Walls, roof and floor will be insulated to A60 rating.

Electrical:

Air Conditioning:

Detection and Alarm system: 1 no. Combined Pressurization on Fire and Gas (CPFG) detection panel for Zone1. System includes gas detection for H2S and CH4, smoke detection MAC, emergency stop push button, Pressurization fan, loss of pressure alarm, flow switch, pressure switch, solenoid valve and all piping and cabling. Telephone/PA/speakers/data:

Furniture:

Finish Paint:

Certification: All products are produced to international standards meaning they are fit for the Purpose and meet your quality requirements. The following certification Standards apply:

Lifting Set: Sling Wire Rope Steel/Galvanized 4 legs / with master link assembly. Legs ending in thimble eye Flemish spliced with steel ferrules. Certified in line with DNV 2.7 -1 Warranty: One year Please contact [email protected] for inquires. TLS offshore pressurised containers are designed, manufactured and tested in accordance with requirements of the following latest editions standards and regulations.

Applications

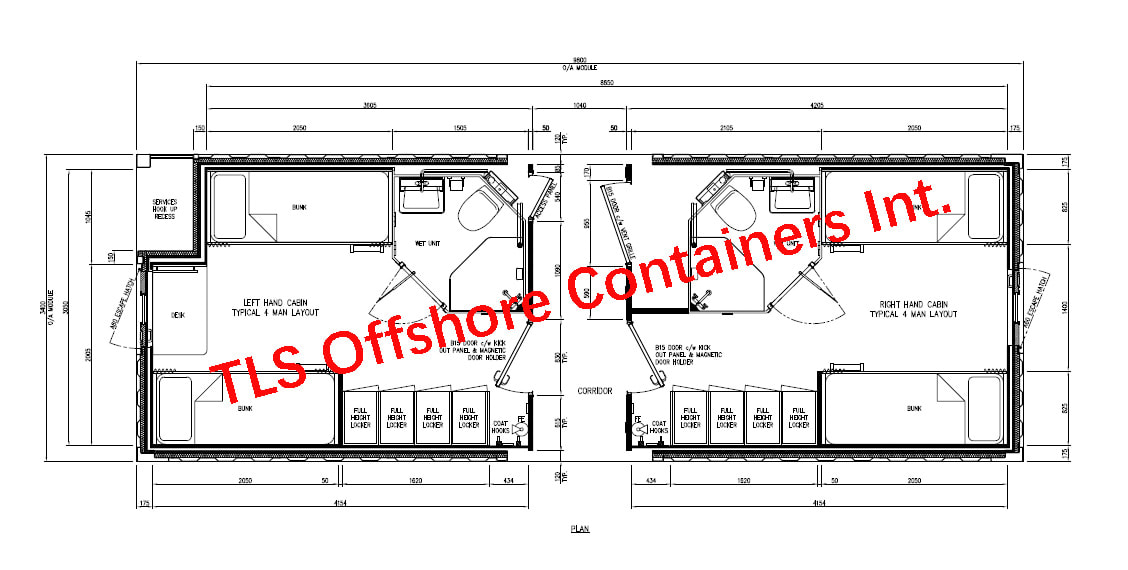

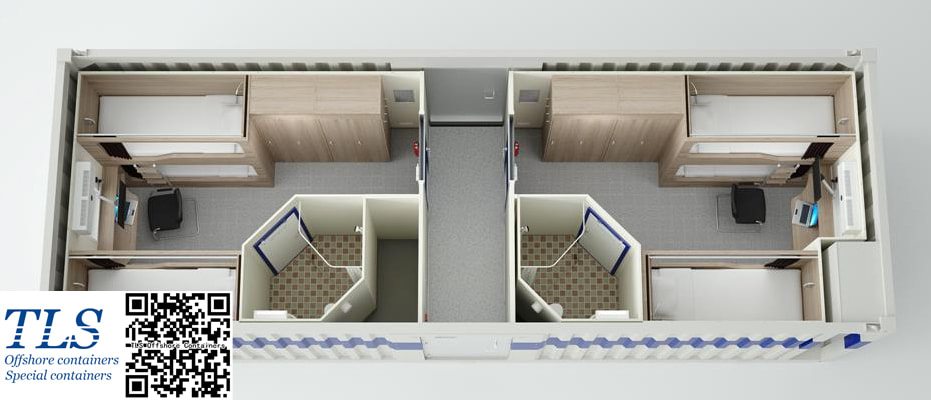

Please contact [email protected] for any inquires. A60 offshore accommodation module offering safe and comfortable living space for 1, 2, 3, 4 or 8 personnel Description:

In addition compliance with offshore oil & gas requirements as following,

Features:

Services

Weight Less than 17.5 Tons. Lifting

Furnitures

A60 offshore accommodation modules are manufactured and designed according to ABS guildline. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please contact [email protected] for more information. Our office containers are manufactured in house to meet the highest industry standards. All units are designed to optimize workspace efficiency, meet environment and acoustic requirements, and house your specialist equipment and resources in a safe and comfortable environment. Our Office containers can be outfitted and modified to perform any number of functions to suit your specific project requirements. These functional containers provide a high quality for clients. Features and benefits

Technical specifications

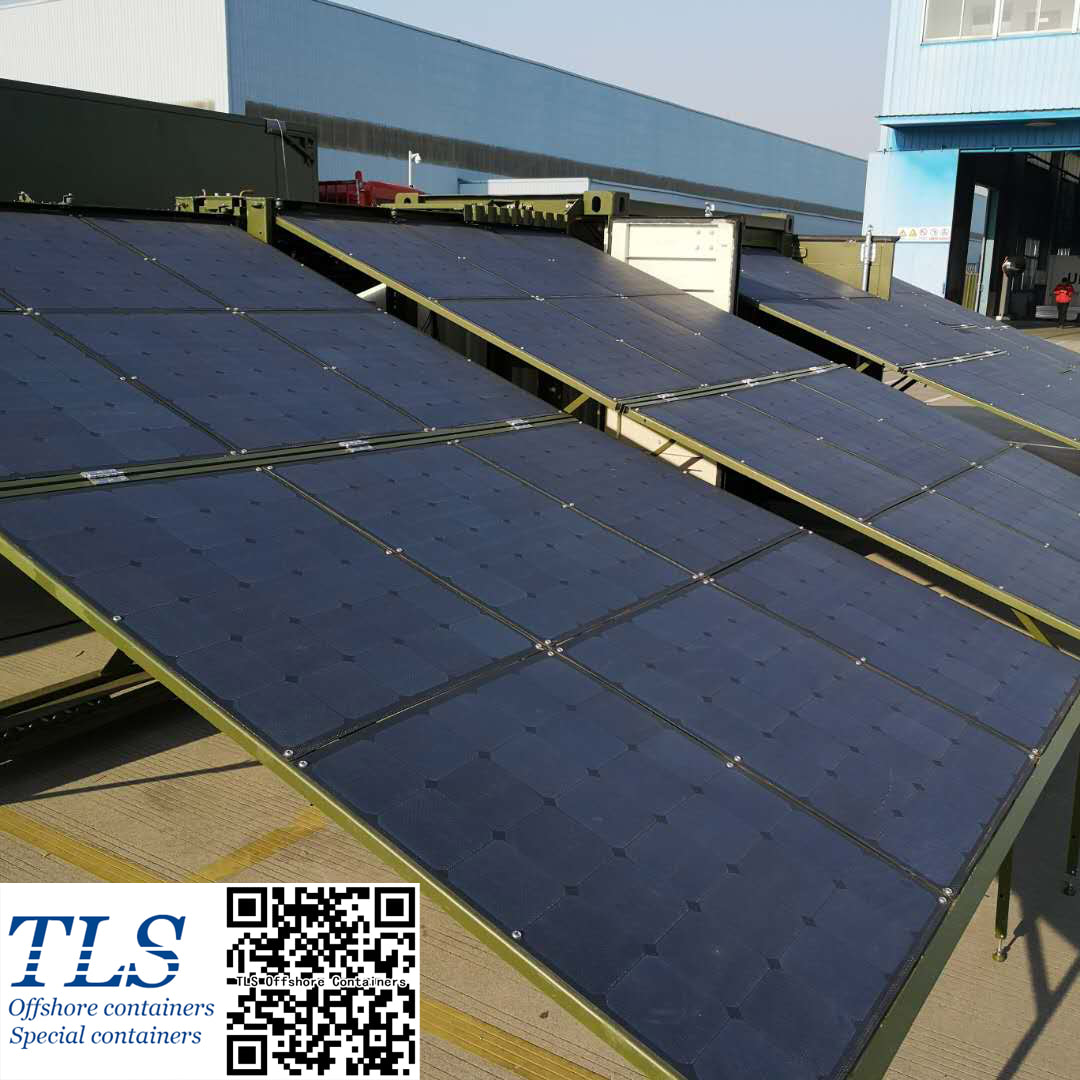

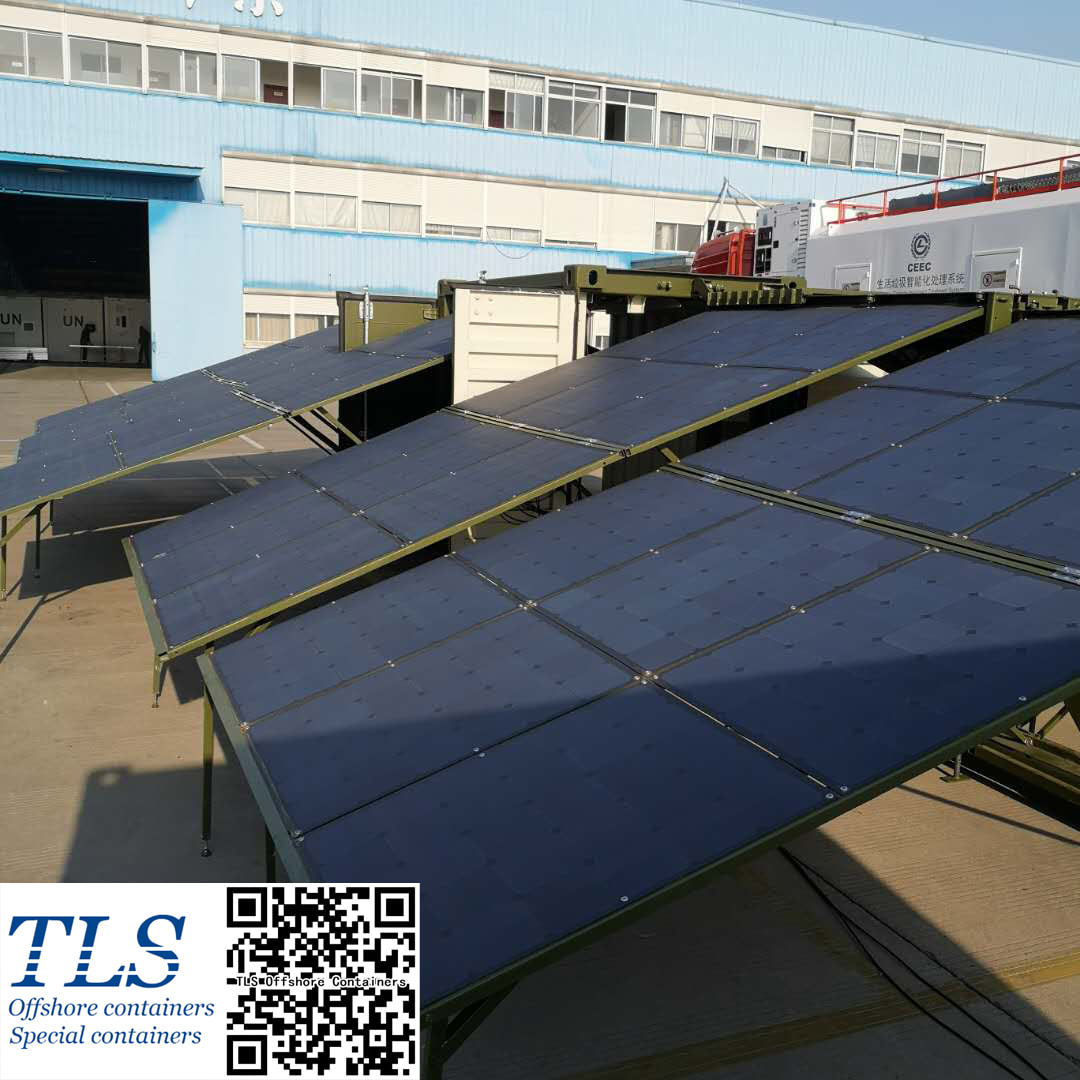

Electrical Connection Connection is 380-690Vac, 3Ph+E, 50/60Hz. Module is supplied with a 30m power cable as standard. Global compliance ATEX, IECEx, CSC, EN 12079, DNV 2.7-1, A60 SOLAS Lithium battery fires are mainly the result of the decomposition and burning of electrolyte, which is a kind of hydrocarbon gas burning fire. In the case of battery overheating, excessive charging and discharging, battery design defects and short circuits caused by raw material defects, chemical reactions occur between battery materials inside the battery, and the electrolyte decomposes to generate a large amount of heat and gas, resulting in thermal runaway of the battery. The thermal runaway is the main reason for the burning of the electrolyte. Once thermal runaway occurs, the battery temperature rises rapidly, directly causing the battery material to burn. When the concentration of flammable gas produced by the decomposition and combustion of the lithium battery electrolyte reaches a certain level, it will explode when it encounters an open flame. In large-scale battery energy storage containers, the battery packs have the characteristics of high density and centralized distribution. The lithium battery modules are connected in series to form a single battery pack and multiple battery packs. A large-capacity energy storage unit is formed in parallel, which not only increases the probability of lithium battery failure, but also increases the fire spread channel because the battery cannot be cut off in the event of a fire. There are a large number of auxiliary electrical equipment in the lithium battery energy storage container. The unsafe use of these equipment also increases the overall fire risk of the storage container, such as accidental high voltage and large current (lighting, surge) intrusion. High voltage and high current invade the lithium battery energy storage container. On the one hand, the electronic equipment in the lithium battery energy storage container is highly integrated, which reduces its resistance to high voltage and high current; on the other hand, the system uses a large number of communication lines have added channels for high voltage and high current intrusion. At the same time, the failure of the protection element is also one of the important causes of fire. Long-term heating and ultra-high temperature caused oxidation and corrosion of some electrical components in the cabinet, and aging of some insulating materials. The overcurrent protection in the battery, the DC fuse and the overcurrent fuse in the battery failed to effectively isolate the short circuit fault and could not meet the original design resistance and insulation. Therefore, the overall electrical safety of the lithium battery energy storage container system has a large hidden danger, and it will cause the spread of fire. When a lithium battery burns, a large amount of gas is generated, mainly organic gases such as hydrogen, carbon monohydride, carbon dihydride, methane, benzene, and toxic gases such as hydrogen chloride and hydrogen fluoride. In the event of a fire, the hydrogen, carbon monohydride and other combustible gases released by the lithium battery inside the lithium battery energy storage container under high temperature conditions cannot be effectively controlled, which may cause the fire to spread rapidly or even explode, endangering the main electrical equipment, and causing property damage. The fire extinguishing system in Lithium battery energy storage container adopts non-conductive suspension type, cabinet type or pipe network type heptafluoropropane (HFC) fire extinguishing system. At the same time, a nitrogen fire extinguishing system is also arranged. The lithium battery energy storage container gas fire extinguishing system consists of heptafluoropropane (HFC) fire extinguishing device, pressure relief device, gas fire extinguishing controller, fire detector and controller, emergency start stop button and isolation module, smoke detector, sound and light alarm, etc. to realize automatic detection, alarm, and fire protection functions in the protection zone. In the containerized lithium battery energy storage system, each container is a protection area, when smoke or temperature change is detected, the sound and light alarm will immediately respond to the fire. Extinguishing the fire in the early stage ensures the safety of the energy storage container. At the same time, considering the processing method of the collected signals, to increase the number of audible and visual alarms and arrange them in places where there are frequent patrols and guards. At the same time, considering that lithium battery energy storage containers are prone to explosion, according to the characteristics of different lithium batteries, the corresponding explosion-proof system is configured according to the characteristics of different lithium batteries. The fire extinguishing system is also inter-connected with the controller, the fan, power supply, etc. and transmit the fire signal to the fire control centers. All solar panels can be folderable and put into the standard ISO dimension container, which is very conveninent for transporation and quick for unfold at the site. All other accessories including battery, inverter, etc are also installed inside the container.

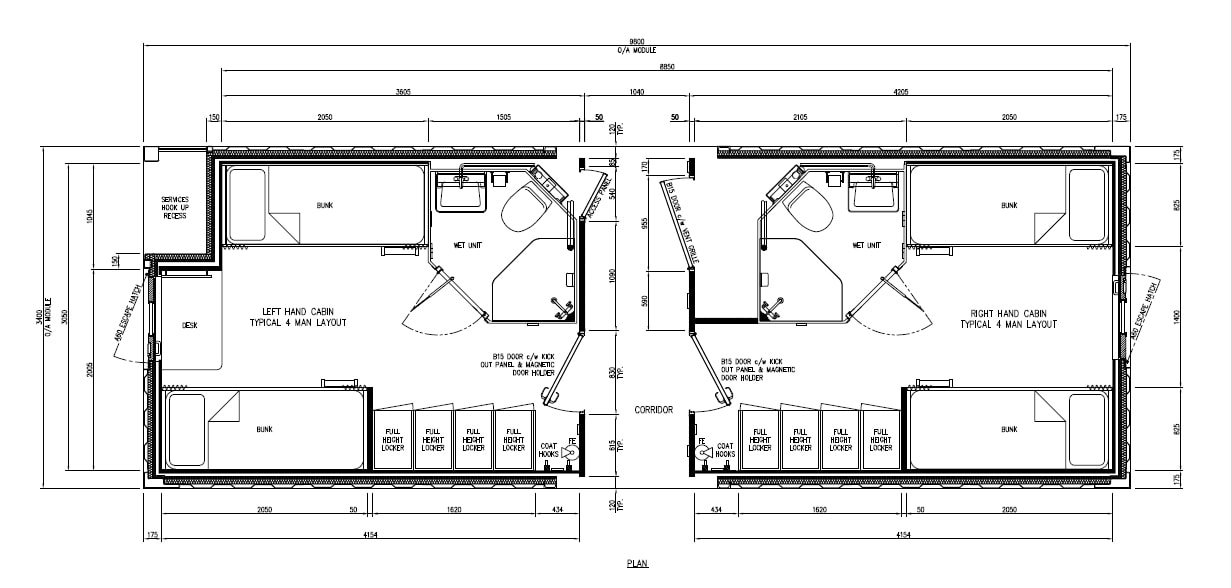

if you have any inquiries on the solar panel containers, please don't hesitate to contact us. TLS Offshore Containers International designs and produces lab containers, crane containers, workshop containers, rigging loft containers, ROV control containers, etc. in compliance with the customer technical specifications and according to the relevant standards, such as DNV 2.7-1, NORSOK and ATEX, including SOLAS/ IMO regulatory requirements.  ABS approved 8 man accommodation cabin installed on ABS classed mobile offshore drilling units, offshore barge or vessels ABS approved 8 man accommodation cabin installed on ABS classed mobile offshore drilling units, offshore barge or vessels Services Each Module has an Accessible Service Area Which Contains Hot Water Heater, Transformer & General Electrical Equipment Which Can be Easily Serviced. External Paint Specification Each Module is Shot Blasted to SA 2.5 and DNV approved, 3 Coat Paint System Applied, Giving a Total of 250 Microns Paint Thickness. Modules Shall be Painted “RAL 9003 Signal White” As Standard, However Client Can Change Color & Add Company Markings Where Required. Weight Not Exceed Weight of 17.5 Tons. Lifting All modules, as well as being DNV certified, also have certified lifting eyes included in the design structure and each module is supplied with a certified sling (included in the price). The units are designed for lifting on and off fixed platforms and other types of floating installations. Installation & Linking Each Module Comes Complete with Twist Locks & Pads for Deck Mounting & Linking Kits for Structural, Mechanical & Architectural Linking of Modules. Accommodation Module Contains 2 Cabins & Each Cabin Includes the Following Items:

In addition, compliance with offshore oil& gas requirements as follows:

Unit specification: As per ABS guideline for offshore accommodation module. modules fitness as three stacking level manned during floating / elevating condition meeting weather criteria in addition to compliance with ILO/MLC. ABS guildline for the design and survey of portable accommodation modules installed onboard ABS-classed Mobile Offshore Drilling Units (MODUs), and Mobile Offshore Units (MOUs), Offshore Installations (fixed or floating), Steel Barges, and Steel Vessels. Please don't hesitate to contact us [email protected] |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|