Unlocking the Future: Key Technologies for Battery Energy Storage System (BESS) Integration1/26/2024

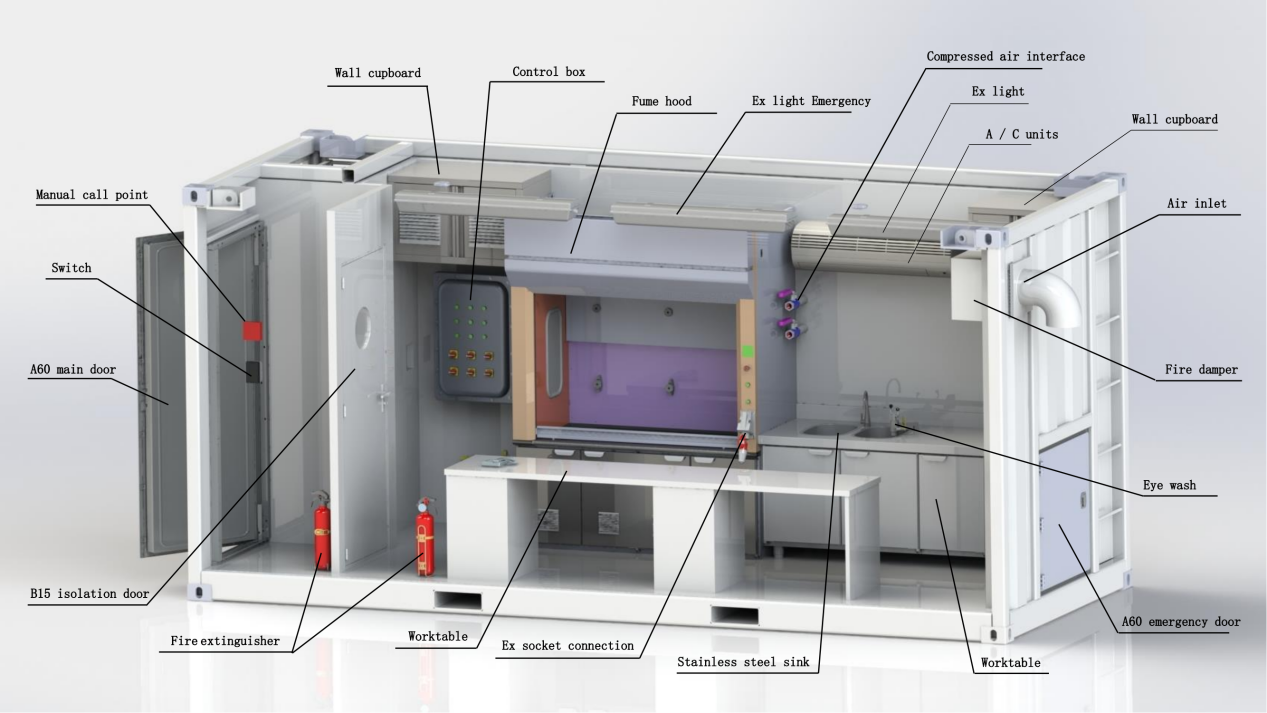

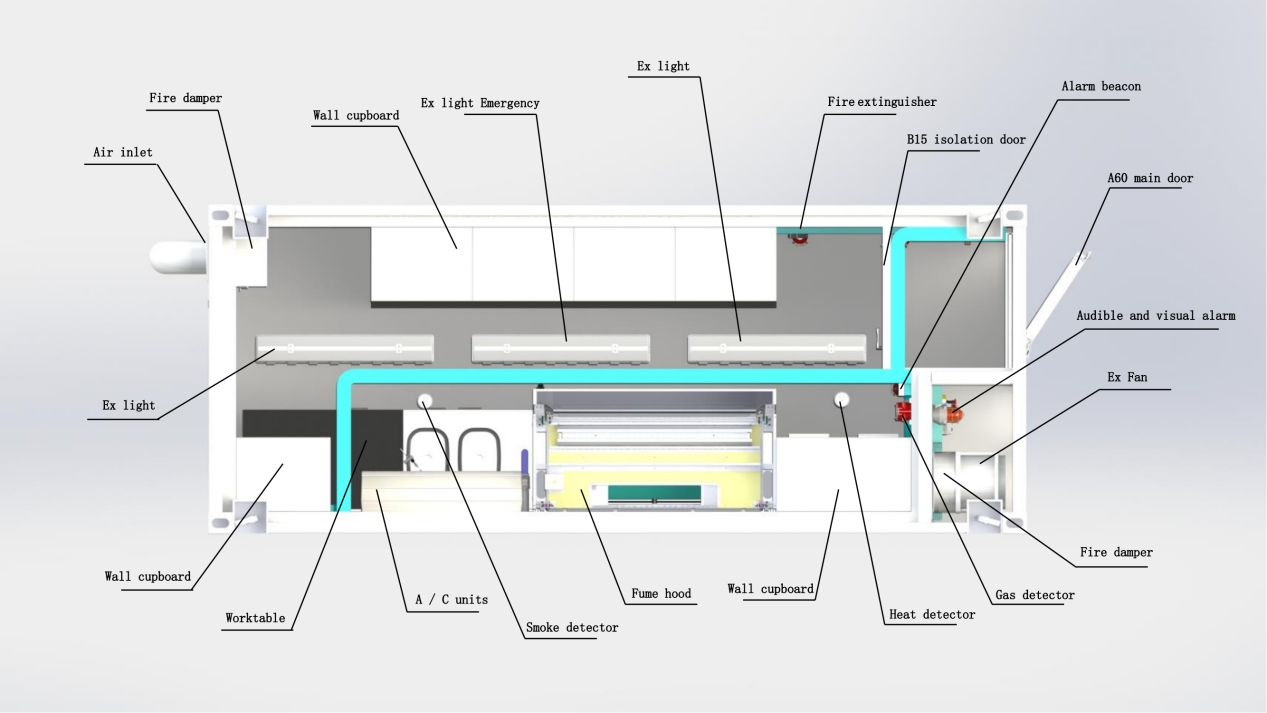

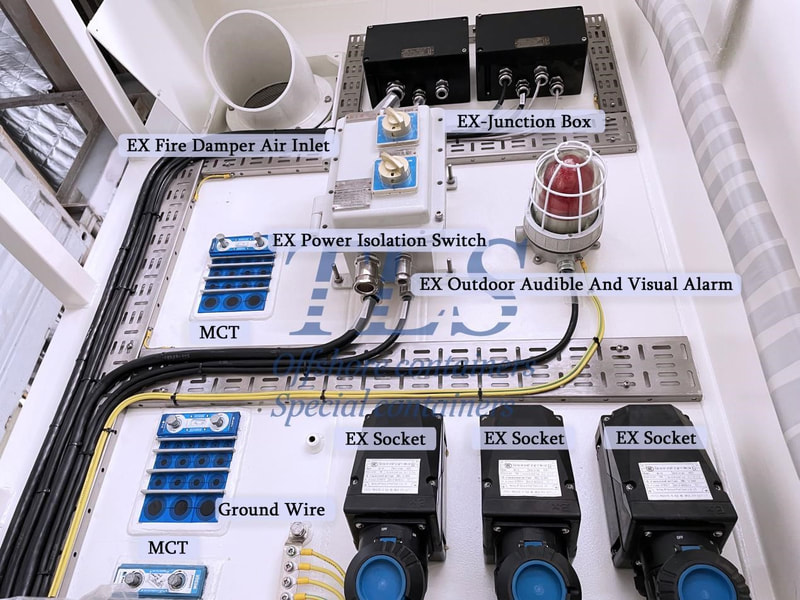

In the realm of modern energy systems, the integration of battery energy storage systems (BESS) stands as a pivotal technology, heralding advancements in smart grids, new energy generation, grid connections, and power load management. Among the various technologies driving this evolution, lithium-ion batteries emerge as the frontrunners, owing to their high energy density, minimal self-discharge rates, stable discharge voltages, and extended cycle lives. The widespread adoption of lithium-ion batteries underscores their indispensable role in large-scale power storage, marking a definitive trajectory in technological progress. However, the seamless integration and optimal operation of lithium-ion BESS demand a comprehensive approach encompassing efficient management, meticulous optimization, and rigorous control mechanisms. To this end, key technologies have been identified to ensure the safe, reliable, and enduring application of BESS within the energy landscape. 1. Advanced Battery Management Technology Central to the efficacy of BESS integration is the deployment of advanced battery management technology. This encompasses sophisticated algorithms and systems designed to monitor and regulate various aspects of battery performance, including charging rates, voltage levels, and overall health. By leveraging real-time data and predictive analytics, battery management technology optimizes battery usage, mitigates degradation, and safeguards against critical failures, thereby maximizing system efficiency and longevity. 2. Temperature Monitoring and Management Technology Temperature fluctuations exert a profound influence on battery performance and longevity. In the context of BESS integration, temperature monitoring and management technology assume paramount importance. Through the implementation of sensors and thermal regulation systems, BESS can effectively mitigate the adverse effects of temperature extremes, preventing overheating, thermal runaway, and other thermal-induced complications. By maintaining optimal operating temperatures, this technology enhances system reliability and minimizes the risk of thermal-related hazards. 3. State of Health (SOH) Monitoring Technology The ability to accurately assess the state of health (SOH) of battery systems is indispensable for ensuring long-term reliability and performance. SOH monitoring technology facilitates the continuous evaluation of battery condition, tracking parameters such as capacity degradation, internal resistance, and aging patterns. By proactively identifying signs of deterioration or inefficiency, SOH monitoring technology enables timely intervention, proactive maintenance, and strategic replacement strategies, thereby optimizing resource utilization and prolonging battery lifespan. 4. System Integration Technology At the core of BESS integration lies the imperative of seamless system integration. This encompasses the harmonious amalgamation of diverse components, subsystems, and interfaces to form a cohesive and interoperable system architecture. System integration technology encompasses a spectrum of disciplines, ranging from electrical and mechanical engineering to software development and automation. By fostering interoperability, scalability, and modularity, system integration technology ensures the holistic functionality of BESS, facilitating seamless communication, efficient operation, and streamlined maintenance protocols. Conclusion: In conclusion, the convergence of advanced technologies holds the key to unlocking the full potential of battery energy storage systems within the contemporary energy landscape. Through the judicious deployment of battery management, temperature monitoring, SOH assessment, and system integration technologies, stakeholders can realize the promise of large-scale power storage while ushering in a new era of sustainability, resilience, and energy autonomy. As the momentum towards renewable energy intensifies and the imperatives of grid modernization become increasingly pronounced, the role of BESS integration technologies assumes unparalleled significance, propelling the transition towards a more resilient, efficient, and sustainable energy ecosystem. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #Smart grid #Grid connection #Power load shifting #Valley filling #Battery management technology #Temperature monitoring #State of health (SOH) monitoring #System integration technology #Advanced algorithms #Predictive analytics #Thermal regulation #Overheating prevention #Thermal runaway #State of health assessment Written by OliverIn the dynamic landscape of energy storage solutions, TLS Energy emerges as a beacon of innovation with its Semi-Integrated Approach. As the world grapples with the challenges of sustainable energy management, TLS Energy's Battery Energy Storage System (BESS) containers redefine the norms, offering a comprehensive solution that goes beyond mere storage. Traditionally, energy storage containers have been seen as static units, primarily focusing on storing energy without much consideration for the complexities of energy management. However, TLS Energy's BESS containers disrupt this notion by incorporating a semi-integrated approach that sets them apart from the competition. At the heart of TLS Energy's Semi-Integrated Approach lies the recognition that energy storage goes beyond mere capacity. It involves intricate systems and processes that require careful consideration and efficient management. Here's what makes TLS Energy's approach truly unique: 1. Essential Component Integration: Unlike standard containers, TLS Energy's BESS containers are equipped with essential components such as HVAC systems, fire fighting systems, and efficient lighting. This integration ensures that the containers are not just storage units but fully functional systems capable of handling diverse environmental conditions and safety requirements. 2. Holistic Energy Management: The semi-integrated approach adopted by TLS Energy allows for holistic energy management within a single unit. By integrating essential components directly into the container, TLS Energy streamlines the deployment process while enhancing operational efficiency. This holistic approach minimizes the need for additional infrastructure, reducing both costs and complexity. 3. Flexibility and Scalability: TLS Energy's Semi-Integrated Approach offers unmatched flexibility and scalability, catering to the evolving needs of energy storage projects. Whether deployed in remote locations or integrated into existing energy infrastructure, TLS Energy's BESS containers adapt seamlessly, providing reliable and resilient storage solutions. 4. Enhanced Reliability and Safety: By incorporating advanced safety features and robust design elements, TLS Energy's BESS containers ensure enhanced reliability and safety standards. From temperature regulation to fire suppression systems, every aspect is meticulously engineered to mitigate risks and safeguard critical assets. 5. Optimized Performance: The semi-integrated approach enables TLS Energy to optimize the performance of its BESS containers, maximizing energy efficiency and overall system reliability. Through advanced monitoring and control systems, operators gain real-time insights, allowing for proactive management and optimization of energy resources. In an era defined by the urgent need for sustainable energy solutions, TLS Energy's Semi-Integrated Approach stands as a testament to innovation and forward-thinking. By reimagining the traditional concept of energy storage, TLS Energy paves the way for a more resilient and efficient energy future. In conclusion, the semi-integrated approach adopted by TLS Energy represents a paradigm shift in the realm of energy storage solutions. With its focus on integration, flexibility, and performance optimization, TLS Energy sets a new standard for excellence in the industry. As the world continues its transition towards renewable energy sources, TLS Energy's BESS containers emerge as a beacon of hope, offering a scalable and sustainable solution to the complex challenges of energy management. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #TLS Energy #Semi-Integrated Approach #Sustainable Energy #Innovation #Holistic Energy Management #Flexibility #Scalability #Reliability #Safety Features #Efficiency #Advanced Monitoring #Performance Optimization Written by OliverIntroduction: In the fast-evolving landscape of laboratory safety, innovation is key to ensuring the well-being of researchers and maintaining the integrity of experiments. One such groundbreaking solution is the Negative Pressure Laboratory Containers by TLS Offshore Containers. In this blog post, we'll delve into the significance of negative pressure environments, the features of TLS Offshore Containers' cutting-edge solutions, and how they are transforming laboratory safety. Why Negative Pressure Matters: Negative pressure environments are crucial in laboratories where the containment of hazardous substances is of paramount importance. These environments help prevent the escape of harmful contaminants, ensuring the safety of researchers and the surrounding environment. Negative pressure laboratory containers create a controlled atmosphere where air flows into the container but doesn't escape, effectively containing any potential dangers within. TLS Offshore Containers' Innovative Solution: TLS Offshore Containers, a leading name in the industry, has engineered state-of-the-art negative pressure laboratory containers that set new standards for safety and efficiency. Here are some key features that make our containers stand out:

Benefits for Laboratories:

Conclusion: In the ever-evolving landscape of laboratory safety, TLS Offshore Containers emerges as a trailblazer with its negative pressure laboratory containers. By prioritizing safety, customization, and user-friendly design, TLS is revolutionizing the way laboratories approach containment and experimentation. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Negative Pressure Laboratory Containers #Laboratory Safety Solutions #Hazardous Substance Containment #Advanced Filtration Systems #HEPA and Carbon Filtration #Customizable Laboratory Containers #Biohazard Containment #Pharmaceutical Research Safety #Cutting-edge Laboratory Technology #Regulatory Compliance in Laboratories Written by OliverBESS Container Solutions by TLS Energy International: Revolutionizing Energy Storage and Delivery1/21/2024

In the dynamic world of energy storage and delivery, TLS Energy International stands out with its innovative approach to Battery Energy Storage System (BESS) containers. These semi-integrated solutions, designed and delivered by TLS Energy, are not just containers – they are the embodiment of efficiency, safety, and technological advancement. This article delves into the unique features of TLS Energy’s BESS containers, highlighting the integration of HVAC systems, fire fighting mechanisms, lighting solutions, and more. The Essence of BESS Containers Battery Energy Storage Systems (BESS) have become pivotal in the modern energy sector, offering a means to store energy for later use. This technology is crucial for balancing grid loads, harnessing renewable energy, and providing emergency power. TLS Energy International elevates this concept by housing these systems in specially designed containers, offering a portable, durable, and efficient solution to energy storage and delivery. TLS Energy’s Semi-Integrated Approach The uniqueness of TLS Energy’s BESS containers lies in their semi-integrated approach. Unlike standard containers, these units come equipped with essential components such as HVAC systems, fire fighting systems, and efficient lighting. This integration means that the containers are not just storage units but are equipped to handle the nuances of energy management. 1. HVAC Systems in BESS Containers The integration of Heating, Ventilation, and Air Conditioning (HVAC) systems in BESS containers by TLS Energy cannot be overstated. These systems ensure that the batteries operate within their optimal temperature range, thus enhancing efficiency and prolonging their lifespan. The HVAC units installed by TLS are tailored to the specific needs of the BESS, ensuring that irrespective of the external environmental conditions, the internal climate is always ideal for battery operation. 2. Advanced Fire Fighting Systems Recognizing the potential risks associated with energy storage, TLS Energy has incorporated state-of-the-art fire fighting systems in its BESS containers. These systems are designed to detect and extinguish fires swiftly, ensuring the safety of the equipment and personnel. The use of advanced sensors and firefighting agents guarantees a rapid response to any thermal event, minimizing damage and ensuring continuity of operations. 3. Efficient and Safe Lighting Solutions Lighting within these containers is another aspect where TLS Energy shines. The use of energy-efficient and durable lighting ensures that maintenance and operational costs are kept to a minimum. Furthermore, the lighting systems are designed to be safe and reliable, providing adequate illumination for maintenance and monitoring activities without posing any risk to the battery systems. Customization and Delivery A key strength of TLS Energy International is its ability to customize BESS containers according to client requirements. Whether it’s adjusting the size of the container, the capacity of the HVAC system, or the layout of the internal components, TLS Energy ensures that each container is tailored to meet the specific needs of the client. The delivery process of these containers is handled with utmost care and professionalism. From the initial design phase to the final delivery, TLS ensures that every step is executed flawlessly, guaranteeing that the clients receive a product that is not just functional but also exceeds their expectations in terms of quality and performance. Environmental Impact and Sustainability TLS Energy’s BESS containers are not just about efficient energy storage; they are also a testament to the company's commitment to sustainability. By enabling the effective use of renewable energy sources and reducing reliance on fossil fuels, these containers contribute significantly to reducing the carbon footprint. Additionally, the use of eco-friendly materials and processes in the construction of these containers further underscores TLS Energy’s dedication to environmental stewardship. Conclusion TLS Energy International’s BESS containers represent a significant leap in the field of energy storage and delivery. With their semi-integrated solutions, including HVAC, fire fighting systems, and efficient lighting, these containers are redefining what it means to store and manage energy efficiently and safely. As the world moves towards more sustainable energy solutions, TLS Energy International stands at the forefront, leading the charge with its innovative, reliable, and environmentally-friendly BESS containers. Introduction: Battery Energy Storage Systems (BESS) play a crucial role in the modern energy landscape, providing flexibility, stability, and resilience to the power grid. Within these energy storage solutions, the Power Conversion System (PCS) serves as the linchpin, managing the bidirectional flow of energy between the battery and the grid. This article explores the significance of PCS within BESS containers, its functionalities, and its impact on the overall efficiency and performance of energy storage systems. Understanding PCS in BESS Containers: A BESS container is a self-contained unit that houses the various components of an energy storage system, including the battery modules, power electronics, and control systems. At the heart of this container lies the Power Conversion System, which acts as the bridge between the DC (direct current) output of the batteries and the AC (alternating current) required for integration with the grid. Key Functions of PCS in BESS Containers:

Benefits of Advanced PCS in BESS Containers:

Conclusion: Power Conversion Systems are indispensable components of Battery Energy Storage Systems housed in containers. Their efficient operation and advanced functionalities not only enable the seamless integration of BESS with the grid but also contribute to the overall stability, reliability, and longevity of the energy storage system. As technology continues to advance, the role of PCS in BESS containers will play a pivotal role in shaping the future of the energy storage industry, unlocking new possibilities for a cleaner and more resilient energy future. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key Words: #Power Conversion System (PCS) #DC to AC conversion #Grid integration #Voltage regulation #Frequency regulation #Efficiency optimization #Bidirectional energy flow #Ancillary services #Advanced control algorithms #Renewable energy integration #Flexibility in applications #Peak shaving Written by OliverUnveiling Excellence: The Superiority of TLS Offshore Containers' Negative Pressure Lab Containers1/19/2024

Introduction: In the ever-evolving landscape of laboratory technology, the demand for cutting-edge solutions is more prominent than ever. When it comes to ensuring the safety and precision of lab processes, TLS Offshore Containers stands out as a beacon of innovation. In this blog post, we delve into the unparalleled quality of TLS Offshore Containers' Negative Pressure Lab Containers and how we set a new standard in the industry.

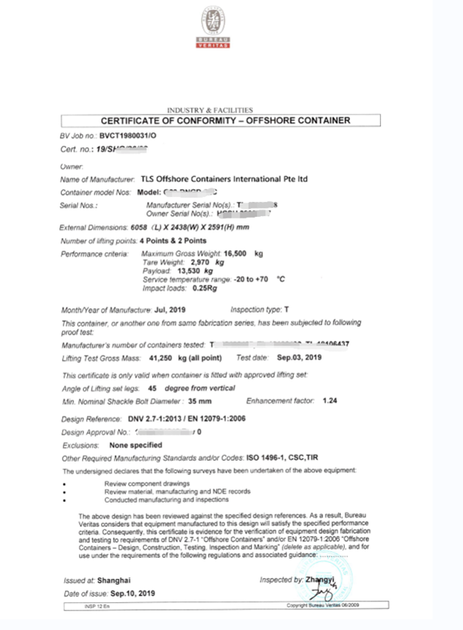

Conclusion: In the realm of laboratory equipment, TLS stands out as a pioneer in the design and manufacturing of Negative Pressure Lab Containers. Our commitment to advanced technology, precision engineering, durability, safety compliance, customization options, cost-effectiveness, and environmental responsibility makes us the go-to choice for laboratories aiming for excellence. With TLS Offshore Containers, labs can elevate their standards, ensuring a future-proof and reliable environment for scientific endeavors. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key Words: #Precision Engineering #Durability #Robust Construction #Safety Standards #Customization Options #Cost-Effective Solutions #Environmental Responsibility #Scientific Innovation #Controlled Environment #Hazardous Substance Containment #Green Practices #Laboratory Technology Written by OliverIn the ever-evolving landscape of global industry, the need for cutting-edge solutions and innovative technologies is paramount. Enter TLS Offshore Containers, a company at the forefront of providing specialized containers tailored to meet the unique demands of various industries. Recently, TLS made waves by sending a 20-foot Lab Container to Dubai, marking a significant milestone in offshore logistics. TLS Offshore Containers has long been recognized for our commitment to delivering state-of-the-art solutions for industries such as oil and gas, renewable energy, and research. Our expertise in designing and manufacturing specialized containers has enabled us to cater to the diverse and complex needs of our clients. The 20-foot Lab Container, equipped with advanced technology and safety features, represents a leap forward in offshore research and development capabilities. This container is not just a conventional shipping unit; it is a mobile laboratory, designed to facilitate scientific experiments and data collection in the challenging offshore environments that are characteristic of the industry. TLS Offshore Containers International designs and produces lab containers, crane containers, workshop containers, rigging loft containers, ROV control containers, and more, all built to customer specifications and compliant with standards such as DNV 2.7-1, NORSOK, and ATEX/IECEx, including SOLAS/IMO regulatory requirements. Our functional containers are fully insulated, capable of operating in any climate, and feature air conditioning with filtered air extraction and return, creating a comfortable working environment while reducing operating costs. Our containers can be fully operational within hours of arriving on site. TLS Offshore Containers International also provides a range of additional services to meet customer requirements. These include customised design and production of functional containers, testing and certification, and on-site installation and commissioning. Our team of experienced engineers and technicians are available to provide advice and support on all aspects of container design, production and installation. We can also provide technical advice on the selection of appropriate materials and components, and on the use of the latest technologies to ensure that the containers are designed and produced to the highest standards. Our commitment to customer service and quality ensures that all containers are delivered on time and to the customer's exact specifications. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #TLS Offshore Containers #20-foot Lab Container #Offshore logistics #Innovation #Global industry #Specialized containers #Research and development #Cutting-edge technology #Offshore environments #Security measures #Industrial collaboration Written by OliverIntroduction: Battery Energy Storage Systems (BESS) play a crucial role in modern energy management, providing a reliable solution for storing excess energy and balancing the power grid. Within BESS containers, the choice between air-cooled and liquid-cooled systems is a critical decision that impacts efficiency, performance, and overall system reliability. In this article, we will delve into the advantages of both air-cooled and liquid-cooled systems in the context of BESS containers. Air-Cooled Systems:

Liquid-Cooled Systems:

Conclusion: The choice between air-cooled and liquid-cooled systems for BESS containers depends on various factors, including project requirements, budget constraints, and environmental considerations. While air-cooled systems offer cost-effective and simple solutions, liquid-cooled systems provide superior thermal performance and efficiency. Ultimately, the decision should be based on a careful evaluation of the specific needs of the energy storage project, with a focus on achieving optimal performance, reliability, and cost-effectiveness. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #BESS #cooling systems #Thermal management #Energy storage solutions #Efficiency in energy storage #High-power applications #Battery module density #Maintenance requirements #Environmental considerations #Heat dissipation #Temperature control Written by OliverIntroduction: In the challenging environment of offshore operations, protecting precision equipment is paramount. The use of positive-pressure explosion-proof containers in ZONE 2 areas has emerged as a crucial safety measure. These containers are designed to ensure the safety of personnel and the integrity of sensitive equipment in potentially hazardous locations. In this article, we delve into the significance of positive-pressure explosion-proof containers and how they contribute to safeguarding precision equipment in offshore ZONE 2 environments. Understanding ZONE 2: In the context of hazardous areas in the oil and gas industry, ZONE 2 refers to locations where flammable gases or vapors are present, but not in sufficient quantities to be classified as ZONE 0 or ZONE 1. Despite the lower risk, these areas still demand strict safety measures to prevent accidents and protect critical assets. Positive-Pressure Explosion-Proof Containers: Positive-pressure explosion-proof containers are engineered to create a controlled environment that prevents the intrusion of hazardous gases or vapors. These containers maintain a higher internal pressure than the surrounding atmosphere, effectively containing any potential explosion within the unit. This proactive approach significantly reduces the risk of ignition and minimizes the impact on nearby equipment and personnel. Key Benefits:

Conclusion: In conclusion, the use of positive-pressure explosion-proof containers in offshore ZONE 2 environments plays a pivotal role in safeguarding precision equipment. These containers not only enhance safety by containing potential explosions but also create a controlled environment that preserves the integrity and functionality of critical devices. As the offshore industry continues to evolve, investing in such safety measures becomes imperative to ensure the well-being of personnel and the longevity of precision equipment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #Offshore ZONE 2 safety #Precision equipment protection #Hazardous area safety measures #Oil and gas industry safety #Controlled environment solutions #Explosion-proof container benefits #ZONE 2 compliance #Offshore equipment safeguarding #Precision equipment longevity #Explosion mitigation solutions #Offshore equipment maintenance #Precision equipment integrity Written by OliverIntroduction: In the realm of offshore operations, ensuring the safety and reliability of equipment is paramount. One key aspect that underscores this commitment to safety is the DNV 2.7-1 certification for offshore containers. This certification, issued by DNV (Det Norske Veritas), signifies compliance with international standards and plays a pivotal role in safeguarding both personnel and assets in the challenging offshore environment. Understanding DNV 2.7-1 Certification: DNV 2.7-1 is a standard developed by DNV to establish minimum requirements for offshore containers. These containers are widely used to transport goods, equipment, and materials to and from offshore platforms and vessels. The certification process involves a rigorous assessment of the container's design, manufacturing, and maintenance processes to ensure they meet stringent safety and quality standards. Key Elements of DNV 2.7-1 Certification:

Benefits of DNV 2.7-1 Certification:

Conclusion: In the complex and demanding world of offshore operations, the importance of DNV 2.7-1 certification for offshore containers cannot be overstated. This certification provides a robust framework for ensuring the safety, reliability, and regulatory compliance of containers, ultimately contributing to the success and sustainability of offshore projects. Companies that prioritize DNV 2.7-1 certification are not only investing in the well-being of their personnel but also in the longevity and efficiency of their offshore operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #DNV 2.7-1 certification #Offshore containers #Offshore operations #Safety standards #International regulations #Structural integrity #Material quality #Welding standards #Design assessment #Testing requirements Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|