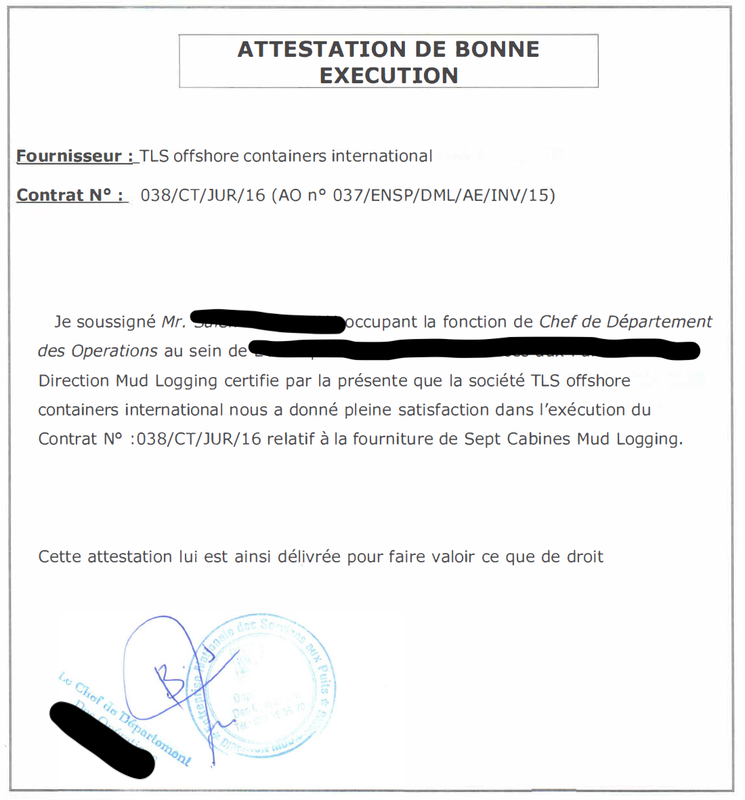

The COVID-19 pandemic has spread with alarming speed, infecting millions and bringing economic activity to a near-standstill as countries imposed tight restrictions on movement to halt the spread of the virus. As the health and human toll grows, the economic damage is already evident and represents the largest economic shock the world has experienced in decades. TLS teams are happy to get the full satisfaction feedback from an oil & gas client that 7 units mud logging cabins we supplied to them fully meet their expectation. The client is one of the subsidiaries of SONATRACH, which is known today to be the largest company in Africa, and often referred as the first African oil "major". ------ TLS teams In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations could provide an ignition source, due to electrical arcing, or high temperature. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations. A light switch may cause a small, harmless spark when switched on or off. In an ordinary household this is of no concern, but if a flammable atmosphere is present, the arc might start an explosion. In many industrial, commercial, and scientific settings, the presence of such an atmosphere is a common, or at least commonly possible, occurrence. Equipment can be designed or modified for safe operation in hazardous locations. The two general approaches are: 1. Intrinsic safety Intrinsic safety, also called non-incendive, limits the energy present in a system, such that it is insufficient to ignite a hazardous atmosphere under any conditions. This includes low both power levels, and low stored energy. Common with instrumentation. 2. Explosion proof Explosion-proof or flame-proof equipment is sealed and rugged, such that it will not ignite a hazardous atmosphere, despite any despite sparks or explosion within. Several techniques of flame-proofing exist, and they are often used in combination:

Explosive Atmospheres - Part 13: Equipment Protection By Pressurized Room "P" And Artificially Ventilated Room "V" IEC 60079-13:2017(E) gives requirements for the design, construction, assessment, verification and marking of rooms used to protect internal equipment by pressurization or artificial ventilation or both as applicable when located in an explosive gas atmosphere or combustible dust atmosphere hazardous area with or without an internal source of a flammable gas or vapour. It also includes a room located in a non-hazardous area that has an internal source of release of a flammable gas or vapour. This document deals with rooms that are partially constructed in a manufacturer’s facility and intended to have the final installation completed on-site, as well as rooms that are constructed completely on-site. Rooms partially constructed in a manufacturer’s facility may include third-party verification. For rooms built on-site, this document can be used by plant operators as a guide for assessment of those facilities. This document represents a major technical revision of the requirements for equipment protection by pressurized room "p" and artificially ventilated room "v" and should be considered as introducing all new requirements. This second edition cancels and replaces the first edition published in 2010. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - modification of the title of this document to include artificially ventilated room "v" in addition to pressurized room "p"; - addition of types of protection "pb", "pc", and "vc" and removal of types of protection "px", "py", "pz" and "pv"; - definition of the differences between pressurization and artificial ventilation types of protection; - removal of protection of rooms with an inert gas or a flammable gas from the scope of this document; - addition of an informative annex to include examples of applications where types of protection pressurization or artificial ventilation or pressurization and artificial ventilation can be used and associated guidelines. Keywords: marking of rooms used to protect internal equipment, pressurized room “p”, artificially ventilated room “v” IECEx System Objective

The objective of the IECEx System is to facilitate international trade in equipment and services for use in explosive atmospheres. while maintaining the required level of safety:

, reduced testing and certification costs to manufacturer , reduced time to market , international confidence in the product assessment process , one international database listing , maintaining International Confidence in equipment and services covered by IECEx Certification What is an Ex area? Ex areas can be known by different names such as "Hazardous Locations·. "Hazardous Areas· "Explosive Atmospheres·. and the like and relate to areas where flammable liquids, vapors, gases or combustible dusts are likely to occur in quantities sufficient to cause a fire or explosion. The modern day automation of industry has meant an increased need to use equipment in Ex areas. Such equipment is termed "Ex equipment" Where do you commonly find Ex equipment? Ex equipment in such areas include: , Automotive refuelling stations or petrol stations , Oil refineries, rigs and processing plants , Chemical processing plants , Printing industries, paper and textiles , Hospital operating theatres , Aircraft refuelling and hangars , Surface coating industries , Underground coal mines , Sewerage treatment plants , Gas pipelines and distribution centers , Grain handling and storage , Woodworking areas , Sugar refineries , Metal surface grinding, especially aluminum dusts and particles IECEx International Certification System In addition to the preparation of International Standards, the IEC facilitates the operation of Conformity Assessment Systems. One such System is the IECEx System The IECEx System comprises the following: , The IECEx Certified Equipment Scheme , The IECEx Certified Service Facilities Scheme , The IECEx Conformity Mark Licensing System , The IECEx Certification of Personnel Competencies Hazardous zone classification

This Technical Measures Document refers to the classification of plant into hazardous areas, and the systematic identification and control of ignition sources. The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) provide for the first time a specific legal requirement to carry out a hazardous area study, and document the conclusions, in the form of zones. General PrinciplesHazardous Area Classification for Flammable Gases and VapoursArea classification may be carried out by direct analogy with typical installations described in established codes, or by more quantitative methods that require a more detailed knowledge of the plant. The starting point is to identify sources of release of flammable gas or vapour. These may arise from constant activities; from time to time in normal operation; or as the result of some unplanned event. In addition, inside process equipment may be a hazardous area, if both gas/vapour and air are present, though there is no actual release. Catastrophic failures, such as vessel or line rupture are not considered by an area classification study. A hazard identification process such as a Preliminary Hazard Analysis (PHA) or a Hazard and Operability Study (HAZOP) should consider these abnormal events. The most commonly used standard in the UK for determining area extent and classification is BS EN 60079 part 101, which has broad applicability. The current version makes clear the direct link between the amounts of flammable vapour that may be released, the ventilation at that location, and the zone number. It contains a simplistic calculation relating the size of zone to a rate of release of gas or vapour, but it is not helpful for liquid releases, where the rate of vaporisation controls the size of the hazardous area. Other sources of advice, which describe more sophisticated approaches, are the Institute of Petroleum Model Code of Practice (Area Classification Code for Petroleum Installations, 2002), and the Institution of Gas Engineers Safety Recommendations SR25, (2001). The IP code is for use by refinery and petrochemical type operations. The IGE code addresses specifically transmission, distribution and storage facilities for natural gas, rather than gas utilisation plant, but some of the information will be relevant to larger scale users. ZoningHazardous areas are defined in DSEAR as "any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers". In this context, 'special precautions' is best taken as relating to the construction, installation and use of apparatus, as given in BS EN 60079 -10. Area classification is a method of analysing and classifying the environment where explosive gas atmospheres may occur. The main purpose is to facilitate the proper selection and installation of apparatus to be used safely in that environment, taking into account the properties of the flammable materials that will be present. DSEAR specifically extends the original scope of this analysis, to take into account non-electrical sources of ignition, and mobile equipment that creates an ignition risk. Hazardous areas are classified into zones based on an assessment of the frequency of the occurrence and duration of an explosive gas atmosphere, as follows:

When the hazardous areas of a plant have been classified, the remainder will be defined as non-hazardous, sometimes referred to as 'safe areas'. The zone definitions take no account of the consequences of a release. If this aspect is important, it may be addressed by upgrading the specification of equipment or controls over activities allowed within the zone. The alternative of specifying the extent of zones more conservatively is not generally recommended, as it leads to more difficulties with equipment selection, and illogicalities in respect of control over health effects from vapours assumed to be present. Where occupiers choose to define extensive areas as Zone 1, the practical consequences could usefully be discussed during site inspection. As an example:A proposal was made to zone an aircraft hanger as Zone 1, although the use of fuels handled above their flash point would be a rare event. It proved difficult to obtain a floor-cleaning machine certified for Zone 1 areas, though the floor needed sweeping regularly. The option of writing out an exception to normal instructions to allow a non Ex-protected machine to be used regularly is not recommended. Instead, a more realistic assessment of the zones is needed, and special instructions issued for the rare event of using more volatile fuels. A hazardous area extent and classification study involves due consideration and documentation of the following:

The results of this work should be documented in Hazardous Area Classification data sheets, supported by appropriate reference drawings showing the extent of the zones around (including above and below where appropriate) the plant item. Selection of EquipmentDSEAR sets out the link between zones, and the equipment that may be installed in that zone. This applies to new or newly modified installations. The equipment categories are defined by the ATEX equipment directive, set out in UK law as the Equipment and Protective Systems for Use in Potentially Explosive Atmospheres Regulations 1996. Standards set out different protection concepts, with further subdivisions for some types of equipment according to gas group and temperature classification. Most of the electrical standards have been developed over many years and are now set at international level, while standards for non-electrical equipment are only just becoming available from CEN. The DSEAR ACOP describes the provisions concerning existing equipment. There are different technical means (protection concepts) of building equipment to the different categories. These, the standard current in mid 2003, and the letter giving the type of protection are listed below. Zone 0Zone 1Zone 2 Category 1Category 2Category 3 'ia' intrinsically safe EN 50020, 2002'd' - Flameproof enclosure EN 50018 2000Electrical Type 'n' - EN 50021 1999 Non electrical EN 13463-1, 2001 Ex s - Special protection if specifically certified for Zone 0'p' - Pressurised EN 50016 2002 'q' - Powder filling EN 50017, 1998 'o' - Oil immersion EN 50015, 1998 'e' - Increased safety EN 50019, 2000 'ib' - Intrinsic safety EN 50020, 2002 'm' - Encapsulation EN 50028, 1987 's' - Special protection Correct selection of electrical equipment for hazardous areas requires the following information:

T1450>450 T2300>300 T3200>200 T4135>135 T5100>100 T685>85 If several different flammable materials may be present within a particular area, the material that gives the highest classification dictates the overall area classification. The IP code considers specifically the issue of hydrogen containing process streams as commonly found on refinery plants. Consideration should be shown for flammable material that may be generated due to interaction between chemical species. Ignition Sources - Identification and ControlIgnition sources may be:

Instead, safety should be achieved by a combination of a high standard of integrity of fuel and process pipelines, together with a means of rapid detection and isolation of any pipes that do fail. The consequences of the failure of a pipe carrying process materials within the furnace should be considered in any HAZOP study. Other processes (such as hot oil heating circuits) may handle products above their auto-ignition temperature. Any such processes should be specifically identified in a safety case. Again, area classification is not a suitable means of controlling the ignition risks, and the same considerations apply, as with fired heaters. Lightning ProtectionProtection against lightning involves installation of a surge protection device between each non-earth bonded core of the cable and the local structure. Further guidance can be found in BS 6651:19991 - (Code of practice for protection of structures against lightning). Ignitions caused by lightning cannot be eliminated entirely, particularly with floating roof tanks, where vapour is usually present around the rim seal. In these circumstances, measures to mitigate the consequences of a fire should be provided. VehiclesMost normal vehicles contain a wide range of ignition sources. These will include electrical circuits; the inlet and exhaust of any internal combustion engine; electrostatic build up; overheating brakes, and other moving parts. Site rules should be clear where normal road vehicles may be taken, and areas where they must be excluded. Standard EN 17551 sets out the requirements for diesel powdered ATEX category 2 or 3 lift trucks. Electric powered vehicles can also be built using a combination of this standard and the normal electrical standards. No specification is available for vehicles with spark ignition engines, and it is unlikely that such an engine could be built economically. Vehicles certified to ATEX requirements are however expensive, and for many applications an unprotected type has to be extensively rebuilt. Consequently, many employers are likely to try and justify not zoning storage compounds, where lift trucks handle flammable liquids or gases in containers. In some stores, perhaps with limited use of a vehicle, this may be acceptable. Discussions have been held with the British Chemical Distributors and Traders Association, with the objective of clarifying when storage areas should be classified as zone 2. The conclusions from this exercise will be made available in due course. Discussions are also ongoing, about vehicles with gas detection systems, designed to shut the engine and isolate other sources of ignition in the event of a gas release. At present these are sold without any claim for ATEX compliance, but with the suggestion they may be useful in cases of remote risk. For the purposes of COMAH, an assessment is needed of the risk that an ignition within a storage compound will produce a major accident, either directly or because a fire or explosion spreads to involve other materials. If this is possible, it is more appropriate to provide controls to prevent the spread, rather than simply apply more conservative zoning, and more restrictive rules on the equipment used in the store. Where specialist vehicles (e.g. cranes) are needed during maintenance operations, proper controls and plant isolation may allow the normal zones to be suspended. Typically these will involve written instructions, as specified in DSEAR schedule 1, or a formal permit to work system. Many sites will have operations of filling and emptying road tankers with flammable materials. Controls will be needed to prevent or minimise the release of gas or vapour but controls over ignition sources are also needed. Hazardous areas may be considered to exist during the transfer operation, but should not be present once the transfer is complete. Safe systems of work are needed to ensure safety where such 'transient' zones exist. Factors for Assessor of a Safety Case to Consider

DSEAR requires that hazardous area classification for flammable dusts should be undertaken in the same manner as that for flammable gases and vapours. Zoning as described above may be applied, replacing 'gas atmosphere' with 'dust/air mixtures'. The zone numbers used are 20, 21 and 22, corresponding to 0,1 and 2 used for gases/vapours The only relevant standard to help people zone their plant is BS EN 50281 part 3, 20021, which is an adaptation of the IEC equivalent. Where toxic dusts are processed, releases into the general atmosphere should be prevented, and the extent of any zone 21 or 22 outside the containment system should be minimal or non-existent. The inside of different parts of the plant may need to be zoned as 20, 21 or 22, depending on the conditions at particular locations. Classification of dusts relating to autoignition and minimum ignition current is undertaken similarly to gases/vapours, but involves additional complications. The explosibility of dusts is dependent upon a number of factors:

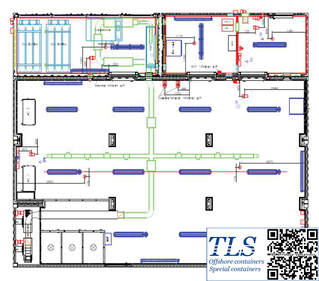

Ignition due to a hot surface is possible, but the temperature needed to ignite a dust layer depends on layer thickness and contact time. For COMAH sites with toxic dusts, the most likely hazard would arise in drying processes, if substantial quantities were held for extended periods hot enough to start self heating or smouldering combustion. Status of GuidanceExisting codes of practice provide information with respect to good practice for hazardous area classification. The standards detailing selection of appropriate electrical apparatus have been updated to take into consideration ventilation effects. European equipment standards may become 'harmonised' when a reference to them is published in the Official Journal of the European Community. A list of ATEX harmonised standards can be checked on the EU web site: Equipment built to such a harmonised standard may assume automatic conformity with those essential safety requirements of relevant directives that are covered by the standard. The EPS regulations describe the conformity assessment procedures that apply to different types of equipment. MWD CABIN, MUD LOGGING CABIN, PRESSURISED CONTAINER Download offshore pressurised mud logging cabin brochure for reference. • All units are designed, manufactured and certified to the latest DNV 2.7-1 and EN 12079 Offshore Container Standard and/ or DNV 2.7-2 Offshore Service Modules Standard, ABS Rules, ATEX, IEC and/ or SOLAS standards • Built for Safe Area or Hazardous Area Operation - Zone 1 and Zone 2 • Pressurised Control Module/ Cabin create a safe area environment for personnel and equipment, with built in HVAC and power control systems. • All modules are designed, built and completely fitted out as per customer's specifications and requirements • A60 Fire Rating complete with Certificate • Units designed and built complete with Fire & Gas Detection System, HVAC System and Communication System • Factory Acceptance Test and Pre-commissioning for all electrical and instrumentation Temporary refuge definition

The temporary refuge (TR) is a safe and sealed area for the people protection during environmental contamination from poisonous gases which can be present in operating areas where oil and/or gas research, extraction and pre-production are performed. This contamination could be related to the escape of gas from drilling wells, from piping or storage / production facilities or to the production of toxic gases due to an explosion in the surrounding area. The environmental conditions inside TR are constantly monitored to avoid the presence of contaminated air. The TR facility needs to be designed with the following minimal characteristics:

This is achieved inside the sealed TR. Area as follow:

The following equipment are installed inside TR:

To maintain the correct required oxygen ration and to prevent the increase of carbon dioxide ratio inside TR, a reserve of breathable air and oxygen and a CO2 reduction system are installed inside the TR. The TR consists in:

TR will be equipped with the following safety systems:

More information about TR shelter, TGR Don’t hesitate to contact us for more information about the temporary refuge shelter and toxic gas refuge. We are eager to explain the possibilities for your applications. A motor control center (MCC) is an assembly to control some or all electric motors in a central location. It consists of multiple enclosed sections having a common power bus and with each section containing a combination starter, which in turn consists of motor starter, fuses or circuit breaker, and power disconnect. A motor control center can also include push buttons, indicator lights, variable-frequency drives, programmable logic controllers, and metering equipment. It may be combined with the electrical service entrance for the building. MCC's are typically found in large commercial or industrial buildings where there are many electric motors that need to be controlled from a central location, such as a mechanical room or electrical room. A motor control center panel (MCC Panel) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. As those electric elements inside MCC panels are not EX approved, In some conditions, such as hazardous zones in FPSO, MCC panels have to be put in pressurised enclosure / containers for safely work. Pressurised containers are composed of CPFG, fire & gas detectors, pressurised blower fan, pressure difference gauge, control panels, etc. which will create a positive pressure working environment inside for the MCC panels by blowing fresh air when the MCC panels are installed inside. TLS offshore containers international is a professional containerised solution provider with tens of years’ experience in this area. TLS teams are eager to give professional support to worldwide clients by providing premium quality containerised solutions. Please contact us [email protected] for more information. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|