|

As the world races towards a sustainable future, the demand for efficient and eco-friendly energy storage solutions has skyrocketed. In this pursuit, TLS Offshore Containers, a pioneering company in the energy storage industry, has gained a foothold in the market with their cutting-edge Battery Energy Storage System (BESS) containers. This article delves into the innovative manufacturing process behind TLS Offshore Containers' BESS containers, shedding light on the key features and benefits that make them stand out in the renewable energy landscape. 1. Embracing Technological Excellence TLS Offshore Containers' BESS containers are the result of a meticulous manufacturing process that leverages state-of-the-art technologies. Utilizing advanced computer-aided design (CAD) software, the design team creates bespoke container solutions tailored to meet the specific requirements of clients. TLS's engineers work collaboratively to ensure that each container adheres to industry standards and safety regulations. 2. Quality Materials for Durability At the heart of every BESS container manufactured by TLS Offshore Containers lies the commitment to using high-quality materials. The containers are constructed with durable and sustainable materials that withstand the harshest environmental conditions. With a focus on longevity, TLS Offshore Containers ensures that their containers have a prolonged service life, reducing the need for frequent replacements and minimizing waste generation. 3. Customization and Scalability One of the standout features of TLS Offshore Containers' BESS containers is their adaptability. Recognizing that each energy storage project is unique, TLS offers a wide range of customization options. Whether it's a compact container for small-scale applications or a multi-container setup for a large-scale project, TLS Offshore Containers can tailor their solutions to match the precise requirements of the client. This flexibility allows businesses to scale their energy storage needs as demands evolve. 4. Precision Manufacturing Process TLS Offshore Containers follows a precision-driven manufacturing process that ensures each container is built to perfection. The fabrication process involves skilled technicians and engineers who oversee every stage of production with meticulous attention to detail. From the initial cutting of materials to the final assembly, quality checks are carried out at various intervals, guaranteeing a flawless end product. 5. Streamlined Assembly Line TLS boasts a modern and efficient assembly line that optimizes production time without compromising on quality. We have implemented lean manufacturing principles, minimizing waste and enhancing overall productivity. The streamlined assembly process enables us to meet tight deadlines and ensures timely delivery to clients. 6. Stringent Quality Assurance TLS Offshore Containers prioritizes safety and quality above all else. To meet stringent industry standards, each BESS container undergoes rigorous quality assurance checks. These evaluations include load testing, environmental simulations, and electrical performance assessments. The thorough quality control process guarantees that clients receive top-of-the-line BESS containers that deliver consistent and reliable performance. 7. Committed to Sustainability As a responsible corporate entity, TLS Offshore Containers is deeply committed to sustainability. Not only do our BESS containers contribute to renewable energy adoption, but the manufacturing process itself emphasizes eco-friendly practices. TLS seeks to minimize its carbon footprint by optimizing energy consumption, responsibly sourcing materials, and recycling waste wherever possible. Conclusion TLS Offshore Containers' Battery Energy Storage System containers are a testament to the relentless pursuit of innovation and excellence in the renewable energy sector. Their cutting-edge manufacturing process, focus on quality materials, customization options, and unwavering commitment to sustainability set them apart as leaders in the field. As the world transitions towards a greener future, TLS Offshore Containers' BESS containers are poised to play a pivotal role in shaping the renewable energy landscape for generations to come. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. #Battery Energy Storage System #BESS containers #Manufacturing process #Technological excellence #Computer-aided design (CAD) #Quality materials #Durability #Customization #Scalability #Precision manufacturing Written by OliverIntroduction: Container heat insulation and fire protection play a crucial role in safeguarding goods from external temperature fluctuations and fire hazards during transportation. This comprehensive guide outlines the essential aspects of designing an efficient heat insulation and fire protection system inside containers to ensure optimal safety and protection. Discover the key insulation materials, fireproof options, and the significance of meeting A60 fire protection standards for offshore containers. Section 1: Benefits of Rock Wool Insulation in Containers Rock wool, crafted from basalt or lava mineral fibers, emerges as an exceptional insulation material with several advantages:

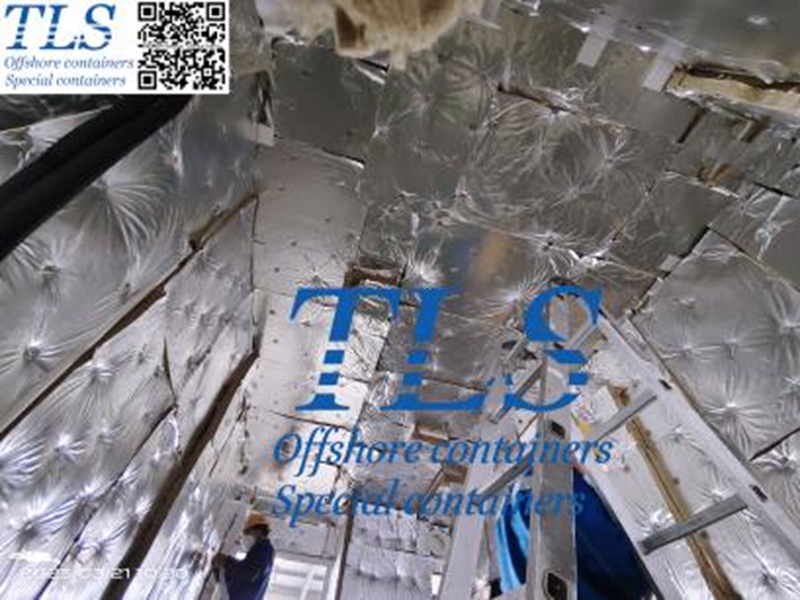

Section 2: Choosing the Ideal Rock Wool Thickness and Density Designing an effective insulation scheme necessitates a comprehensive consideration of insulation requirements, cost, and durability. The appropriate thickness and density of rock wool should be determined based on these factors, taking care to adhere to relevant fire protection and environmental standards. Section 3: Designing the Insulation and Fire Protection Layers Consider the following aspects when designing the insulation and fire protection layers within containers:

Section 4: Implementing a Comprehensive Fire Protection System The container's fire protection system is a critical element, comprising fire water sources, fire sprinklers, smoke detectors, and more. These components work together to detect and combat fire outbreaks promptly, minimizing potential damage to goods. Section 5: Prioritizing Operator Safety Ensure the safety and well-being of operators by incorporating essential features like efficient lighting and ventilation systems within the container. Adequate lighting ensures clear visibility, while proper ventilation prevents the accumulation of harmful gases. Conclusion: Container heat insulation and fire protection design is a multifaceted project that demands a holistic approach. By considering factors like cargo characteristics, container properties, and budget constraints, you can develop a tailored and efficient heat insulation and fire protection scheme. Opting for rock wool insulation, meeting A60 fire protection standards, and implementing a comprehensive fire protection system will enhance the safety and security of goods during transportation, mitigating risks and potential damages. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Container heat insulation #Container fire protection #Heat insulation materials #Fireproof materials #Rock wool insulation #A60 fire protection standard #TLS offshore containers #Container insulation design #Fireproof boards #Fireproof coatings Written by OliverThe Ultimate Guide to ISO Shipping Containers: Types, Uses, and Importance in Global Shipping7/27/2023

Introduction: ISO shipping containers play a pivotal role in the global shipping industry, facilitating the efficient transportation and storage of goods across oceans, roads, and railways. In this comprehensive guide, we explore the various types of ISO shipping containers and their versatile applications, highlighting their immense significance in the modern shipping landscape. I. Definition of ISO Shipping Container: ISO shipping containers are standardized units designed for the transportation and safekeeping of goods. Employed across ships, trains, and trucks, these containers have revolutionized the shipping sector, expediting the movement of goods across the globe. II. Types of ISO Shipping Containers: A. Standard Dry Cargo Container:

B. High Cubic Container:

C. Open Top Container:

D. Flat Rack Container:

E. Refrigerated Containers:

III. Uses of ISO Shipping Containers:

IV. Importance of Understanding ISO Shipping Containers:

Conclusion: ISO shipping containers form the backbone of the global shipping industry, offering standardized, efficient, and reliable methods for transporting and storing goods. Their versatility and importance in various sectors make them indispensable components of modern logistics. As international trade continues to flourish, ISO shipping containers will continue to play a pivotal role in facilitating seamless commerce across the globe. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #ISO shipping containers #Global shipping industry #Transportation of goods #Cargo containers #Standardized containers #Container dimensions #Dry cargo container #Refrigerated containers #Open top containers #High cubic container Written by OliverIn today's era of globalization and international trade, the transportation and preservation of frozen goods have become crucial challenges. Especially for temperature-sensitive commodities like meat, seafood, ice cream, and pharmaceuticals, maintaining their freshness and quality is of utmost importance. Fortunately, technological advancements have provided us with a solution, and the standout performer is the Super Freezer Container.

The Super Freezer Container is a high-tech container specifically designed for transporting frozen goods. Unlike ordinary containers, it is equipped with a specialized refrigeration system, capable of maintaining a constant low temperature, typically ranging from -60°C to -25°C. This makes it an ideal transportation tool for frozen goods, ensuring the perfect preservation of items such as seafood, meat, ice cream, and pharmaceuticals. Let's take a closer look at some of the features of the Super Freezer Container. It consists of a top plate, side panels, bottom plate, door, and refrigeration unit. The powerful refrigeration unit, located at the front of the container, can achieve cooling capacity as low as -60°C, guaranteeing that the cargo remains frozen throughout the journey. The four walls are made from robust aluminum panels, while the container's insulation layer uses ultra-low temperature foaming materials, ensuring excellent thermal insulation. The interior side panels and roof are equipped with corrugated ribs and inner columns, while the exterior side panels have several hat-shaped edges, providing a sturdy and stable structure. Moreover, the rear end of the container features a stepped design, sealed with rubber strips to prevent heat leakage. The door is equipped with multiple lip outer seals and double lip inner seals, further enhancing the container's sealing performance. Inside the top plate's insulation layer, there is a hat-shaped roof beam, improving the insulation effect. The advantages of the Super Freezer Container are numerous. Its reasonable structure, powerful refrigeration capacity, superior sealing, and insulation performance make it suitable for storing special items requiring ultra-low temperatures (-70°C to +25°C). Playing a vital role in protecting the quality and freshness of temperature-sensitive goods, such as pharmaceuticals, plasma, and seafood, the Super Freezer Container is a critical asset. These high-tech Super Freezer Containers serve diverse purposes across various fields. They are used for scientific research, low-temperature experiments with special materials, cold chain logistics, medical applications, electronic industries, and low-temperature preservation of seafood, among others. Blood stations, hospitals, health and epidemic prevention systems, research institutions, military enterprises, and more can rely on Super Freezer Containers to ensure the optimal condition of their cargo during transportation. In the tide of globalization and international trade, Super Freezer Containers are not only the guardians of maritime shipping but also crucial support for cold chain logistics. They provide a secure and efficient means of transporting perishable goods across the global supply chain. Whether it's sending delicious seafood across the ocean or preserving top-quality pharmaceuticals and plasma, Super Freezer Containers have made an indelible contribution to human life and health. In the future, we believe that Super Freezer Containers will continue to evolve and innovate, constantly enhancing their performance and scope of application. They will continue to play a pivotal role in the global logistics industry, providing consumers around the world with fresher and higher-quality frozen goods. Let us look forward to a bright future where Super Freezer Containers bring more convenience and assurance to cold chain logistics! What are the video inspections of explosion-proof pressure containers, which are usually checked?7/20/2023

During the video inspection of explosion-proof pressure containers, several critical aspects are thoroughly examined to ensure their safety and compliance with regulations. The inspection process includes the following key areas:

Check the functions of all modes, and the functional tests of all modes will be carried out one by one according to the regulations on the FAT file. Automatic mode: normal use in hazardous areas Bypass mode: can only be used in safe area Manual mode: for emergency use only In "bypass mode" and "manual mode", the explosion-proof fan can be started manually only when the air inlet and outlet valves are fully opened; when the air valve is not fully opened, the manual switch of the explosion-proof fan is invalid. TLS pays attention to every detail of the product, please feel free to contact us for any needs Introduction: In industries where hazardous conditions are prevalent, safety is of utmost importance. The A60 Ex-Proof MCC (Motor Control Center) shelter container is a vital solution for ensuring safety and efficiency in hazardous environments. These specially designed containers are built to withstand explosive atmospheres while providing a secure and controlled environment for critical electrical equipment. In this article, we will delve into the significance of A60 Ex-Proof MCC shelter containers, their features, and the benefits they offer in terms of safety and operational efficiency. Understanding A60 Ex-Proof MCC Shelter Containers: A60 Ex-Proof MCC shelter containers are engineered to house Motor Control Centers (MCCs) and related electrical equipment in hazardous environments such as oil and gas facilities, chemical plants, and refineries. These containers are designed to meet stringent safety standards and provide protection against explosive atmospheres, ensuring the safe operation of critical electrical systems. Key Features of A60 Ex-Proof MCC Shelter Containers:

Benefits of A60 Ex-Proof MCC Shelter Containers: Implementing A60 Ex-Proof MCC shelter containers in hazardous environments offers several key benefits:

Conclusion: A60 Ex-Proof MCC shelter containers are indispensable for ensuring safety and efficiency in hazardous environments. By employing their explosion-proof construction, robust design, and compliance with international standards, these containers offer a secure and controlled environment for critical electrical equipment. Incorporating A60 Ex-Proof MCC shelter containers in hazardous facilities not only mitigates risks but also contributes to enhanced operational efficiency, regulatory compliance, and long-term cost savings. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #A60 Ex-Proof MCC shelter containers #Ex-Proof MCC enclosures #Hazardous environment safety solutions #Explosion-proof electrical shelters #A60 shelter container features #Hazardous location protection #Robust MCC enclosure design #Compliance with ATEX standards #Electrical equipment safety in explosive atmospheres #Ventilation and cooling systems for MCC shelters Written by OliverIn the offshore industry, safety and efficiency are paramount. When it comes to accommodating personnel in offshore environments, ABS-approved A60 offshore accommodation containers are the gold standard. These containers are designed and certified to withstand extreme conditions while providing a secure and comfortable living space for offshore workers. In this article, we will explore the importance of ABS approval, the features of A60 offshore accommodation containers, and their benefits in ensuring safety and efficiency offshore. Understanding ABS Approval: The American Bureau of Shipping (ABS) is a leading classification society that sets industry standards for the design, construction, and maintenance of offshore structures and equipment. ABS approval signifies that a product or equipment complies with rigorous safety, quality, and environmental requirements. When it comes to offshore accommodation containers, ABS approval ensures that they meet the highest industry standards, guaranteeing the safety and welfare of personnel in offshore environments. Features of A60 Offshore Accommodation Containers: A60 offshore accommodation containers are specially designed to provide a safe and comfortable living environment in offshore installations such as oil rigs, platforms, and vessels. Here are some key features:

Benefits of ABS-Approved A60 Offshore Accommodation Containers: Investing in ABS-approved A60 offshore accommodation containers offers several benefits for offshore operations:

Conclusion: ABS-approved A60 offshore accommodation containers are an integral part of ensuring safety and efficiency in offshore operations. With their fire resistance, robust construction, insulation, and compliance with international regulations, these containers provide a secure and comfortable living environment for offshore personnel. Investing in ABS-approved containers not only mitigates risks and enhances safety but also contributes to increased productivity and overall operational efficiency. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS ABS approved offshore accommodation module brochure for reference. #ABS-approved offshore accommodation containers #A60 offshore containers #Offshore accommodation solutions #Offshore living quarters #Fire-resistant offshore containers #Offshore container certification #Offshore accommodation safety #ABS classification for offshore containers #A60 container features #Offshore accommodation standards Written by OliverUnderstanding the A60 Fire Standard in Offshore Containers: Ensuring Safety and Compliance7/14/2023

Offshore containers play a crucial role in the oil and gas industry, providing storage and transportation solutions for various materials and equipment. Safety is of paramount importance in these environments, which is why adherence to fire standards is essential. In this article, we will delve into the A60 fire standard in offshore containers, its requirements, and how TLS offshore containers Int. is leading the way in providing A60 standard offshore functional containers to global clients. Understanding the A60 Fire Standard The A60 fire standard, also known as the "A" class division, sets specific requirements for the construction and performance of bulkheads and decks within offshore containers. These divisions serve as barriers against the passage of smoke and flames during a one-hour standard fire test. Let's examine the key criteria that must be met: 1. Construction Material: To meet the A60 fire standard, bulkheads and decks must be constructed using steel or other equivalent materials. This ensures robustness and durability, enhancing their ability to withstand fire hazards. 2. Stiffening: Suitable stiffening techniques are employed to reinforce the bulkheads and decks, further enhancing their structural integrity. This reinforcement ensures the containers can withstand the extreme conditions associated with offshore operations. 3. Prevention of Smoke and Flame Passage: The A60 fire standard requires that bulkheads and decks be constructed in a manner that effectively prevents the passage of smoke and flames for the duration of the one-hour fire test. This is achieved through meticulous design and engineering, with a focus on sealing potential points of entry. 4. Insulation: Approved non-combustible materials are used to insulate the bulkheads and decks, ensuring that the average temperature of the unexposed side does not rise more than 140 °C above the original temperature. Additionally, no single point, including joints, should exceed a temperature rise of 180 °C above the original temperature within 60 minutes. TLS Offshore Containers Int. and A60 Standard Containers TLS offshore containers Int. stands at the forefront of providing A60 standard functional offshore containers to clients worldwide. With a wide range of offerings, including pressurized containers, BESS containers, lab containers, MCC containers, VFD containers, and more, TLS ensures that clients have access to top-quality containers that adhere to the A60 fire standard. Importance of A60 Standard Containers Investing in A60 standard containers offers numerous benefits. First and foremost, they provide a high level of fire resistance, minimizing the risk of fire-related incidents offshore. This not only protects personnel but also safeguards valuable equipment and materials. Additionally, A60 standard containers contribute to regulatory compliance, meeting the stringent requirements set by industry bodies and authorities. Understanding the A60 fire standard in offshore containers is crucial for ensuring safety and compliance in the oil and gas industry. TLS offshore containers Int. plays a pivotal role in providing A60 standard functional offshore containers to global clients, offering a wide range of options tailored to specific needs. By investing in A60 standard containers, companies can enhance safety, protect assets, and uphold regulatory requirements. Choose TLS offshore containers Int. for reliable and high-quality A60 standard containers that exceed expectations. Introduction: The offshore industry operates in some of the most challenging and hazardous environments. To ensure the safe transportation and storage of equipment, materials, and personnel, it relies on specialized containers designed to withstand extreme conditions. Among these containers, the A60 rated offshore container stands out as a reliable and highly effective solution. In this article, we will explore in detail the features, benefits, and applications of A60 rated offshore containers, highlighting their crucial role in enhancing safety and efficiency in offshore operations. Section 1: Understanding A60 Rating and its Significance A60 rating refers to the fire protection and insulation capabilities of offshore containers. The "A" stands for fire protection, while "60" signifies the container's ability to withstand high temperatures for up to 60 minutes. This rating is of utmost importance as it ensures the containment of fires and minimizes the risk of their spread, protecting both personnel and valuable assets in offshore operations. Compliance with international standards and regulations, such as those set by the International Maritime Organization (IMO), is necessary to meet safety requirements. Section 2: Key Features of A60 Rated Offshore Containers 2.1 Robust Construction:

2.2 Fire-Resistant Properties:

2.3 Watertight and Weatherproof:

2.4 Modular Design:

Section 3: Applications of A60 Rated Offshore Containers 3.1 Offshore Oil and Gas Industry:

3.2 Renewable Energy Sector:

3.3 Marine and Shipping Industry:

3.4 Research and Exploration Projects:

Section 4: Benefits of A60 Rated Offshore Containers 4.1 Enhanced Safety:

4.2 Reliable Equipment Storage:

4.3 Flexibility and Versatility:

4.4 Cost-Effectiveness:

4.5 Compliance and Peace of Mind:

Section 5: Maintenance and Inspection Considerations

Conclusion: A60 rated offshore containers are indispensable assets in the offshore industry, ensuring the safety and efficiency of operations in challenging environments. Their robust construction, fire-resistant properties, and adaptability make them a preferred choice for the storage and transportation of valuable equipment, materials, and personnel. By adhering to international standards, conducting regular maintenance, and procuring A60 rated containers from reputable suppliers, offshore operators can achieve the highest levels of safety, compliance, and operational excellence. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #A60 rated offshore container #Offshore containers #Fire protection #Insulation #Compliance #International standards #Robust construction #Fire-resistant properties #Watertight #Weatherproof Written by OliverIn the rapidly evolving energy sector, Battery Energy Storage Systems (BESS) have emerged as a pivotal technology, enabling efficient storage and utilization of power. The heart of these systems is the battery technology, and among the various types available, Lithium Iron Phosphate (LFP) batteries have gained significant attention. A key player in the provision of BESS containers is TLS Offshore Containers International, a company that has been instrumental in delivering these solutions worldwide. LFP batteries are a type of lithium-ion battery that uses lithium iron phosphate (LiFePO4) as the cathode material. They offer several advantages over other lithium-ion batteries, including longer cycle life, superior thermal stability, and enhanced safety features. These characteristics make LFP batteries an ideal choice for BESS applications, where safety, reliability, and longevity are paramount. LFP batteries in BESS can support a range of applications, from frequency regulation and peak shaving to energy reserve. They offer a stable discharge voltage, ensuring the reliable operation of energy storage systems. Furthermore, their high energy density allows for a compact and efficient design, optimizing the footprint and balance of system (BOP) cost. TLS Offshore Containers International, a global leader in offshore containers and modular equipment, has recognized the potential of LFP batteries and incorporated them into their BESS containers. The company's innovative module and rack design, featuring both passive and active thermal ventilation systems, are designed to optimize the performance of these batteries. The design also takes into account the need for proper aisle space in containerized solutions, ensuring easy maintenance and efficient operation. The company's platform design for energy, medium, and power solutions is flexible, catering to wide range of applications. This flexibility allows for customization based on specific energy needs, making it a versatile solution for various industries. TLS Offshore Containers International has a global footprint, providing BESS container solutions to clients worldwide. The company's commitment to quality, innovation, and customer satisfaction has earned it a strong reputation in the energy sector. Their BESS containers, equipped with LFP batteries, are not only efficient and reliable but also designed with the highest safety standards in mind. The integration of LFP batteries in BESS by TLS Offshore Containers International represents a significant advancement in energy storage technology. The company's innovative design and commitment to quality ensure that their BESS containers offer reliable, efficient, and cost-effective energy storage solutions. As the demand for sustainable and efficient energy storage continues to grow, the role of LFP batteries and the contribution of companies like TLS Offshore Containers International will undoubtedly become even more significant. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|