DNV 2.7-1 standard for offshore containers |

DNV 2.7-1 Standard for Certification was first published in May, 1989 as "DNV Certification note 2.7-1 Offshore Freight Containers". It was prepared because other regulations at the time, whether international codes, national requirements or rules published by Det Norske Veritas (DNV).

The Standard for Certification is concerned with certification of all types of offshore containers as transport units. The three typical phases of transport are: shoreside (e.g. by fork lift truck), by supply vessel and lifting to and from offshore installations. The Standard for Certification includes design requirements related to all three phases. Under conditions in which offshore containers are often transported and handled, the "normal" rate of wear and tear is high, and damage necessitating repair will occur. However, containers designed and certified according to this Standard for Certification should have sufficient strength to withstand the normal forces encountered in offshore operations, and not suffer complete failure even if subject to more extreme loads. Please download DNV 2.7-1 standard for offshore containers. |

EN 12079 for Offshore Containers and Associated Lifting Sets |

In 1991, the European Committee for standardisation, CEN, started developing a European Standard (EN) on offshore containers. The committee prepared EN 12079 which was originally issued in 1999 and revised and replaced with 2006 edition. The requirements for design, testing and production of offshore containers in EN 12079 are directly based on DNV Standard for Certification 2.7-1.

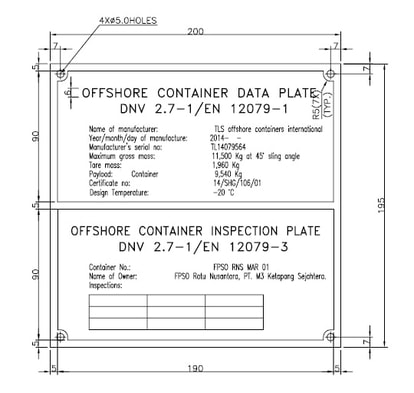

EN 12079 consists of three parts. Offshore containers and lifting sets certified to comply with DNV 2.7-1 also comply fully with EN 12079 parts 1 and 2. This is reflected on our container offshore certificates Please download EN 12079 standard for offshore containers. |

International convention for safe containers (CSC) |

The International Maritime Organization (IMO) has issued both the International Convention for Safe Containers (CSC) and the International Maritime Dangerous Goods code (IMDG). Both of these are mandatory international regulations. IMO has recognized that the CSC convention is not directly applicable for offshore containers that are handled in the open seas and has issued circular MSC/Circ. 860 with the applicable guidelines. Containers certified to DNV 2.7-1 are also certified to MSC/Circ. 860 and it is noted on their certificates.

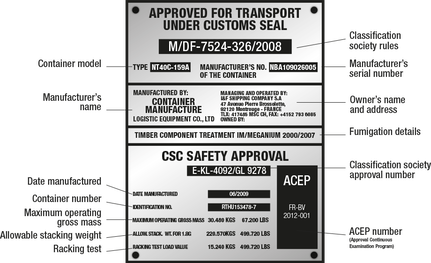

Every container used for international transport needs a valid CSC plate to ensure a good condition for safety reasons. The International Maritime Organisation (IMO) undertook a study to find about more about the safety of containerization as the number of containers increased over the years. The container itself emerged as the most important safety reason for humans working around it which led to the foundation of the Convention for Safe Containers (CSC) by the United Nations and the IMO in 1972 with two main goals to maintain the highest level of safety in transportation and logistics and facilitate international container transport by providing standards. Nowadays every container used for international cargo transport must have a valid CSC approval. Doesn’t matter if COC or SOC Container, it would not be able to move the equipment for international maritime transport without a valid CSC plate. However, be advised that DNV 2.7-1 containers are not required to be certified and plated CSC. For a container to be CSC plated, a separate set of criteria and testing must be met. Our containers are both DNV 2.7-1 and CSC certified. Containers that are intended for ocean voyages on container ships are normally designed to applicable parts of International Organisation for Standardisation (ISO). Containers that are certified to CSC are in general also designed as ISO containers. Our containers are designed and certified according to ISO as well. Every shipping container used for international maritime transport must have a valid CSC plate bolted to the outside of the left door. It shall take the form of a permanent, non-corrosive, fireproof rectangular plate measuring at least 20x10cm. Fastened at the time of manufacture, each plate must contain a certain level of information (see graphics below), either in English or French and it shall be durable in a colour contrasting with the one of the containers. The words “CSC SAFETY APPROVAL” are prominently placed in the middle of every plate alongside the country of approval and reference number. Additional information includes: Please download CSC standard for offshore containers. |

ISO 1161 standard for container corner fittings |

ISO1161 standard and guidelines provide requirements applying to container corner fittings to be used for the fabrication of freight containers. The dimension of the container corner fittings dealt with in these requirements must comply with the latest edition of the international standard ISO1161.

Please download guidelines for container corner fittings - ISO1161. |

ATEX

|

You can download the text of the new ATEX 2014/34/EU on the following web sites :

|

Offshore DNV2.7-3 |

An offshore container is a unit with a maximum gross mass not exceeding 25000 kgs, for repeated use in the transport of goods or equipment, handled in open seas, to, from or between fixed and/or floating installations and ships. Offshore containers are also defined by the requirements given in DNV 2.7-1. While portable offshore unit gross mass is over 25000 kgs, the portable offshore Unit’s main structure, supports for any permanent equipment and features will follow DNV 2.7-3 for the functionality during the transport phase.

|

A60 fire rating, fire protection |

A60 fire protection

“A” class divisions Divisions formed by bulkheads and decks which comply with the following: 1. they shall be constructed of steel or other equivalent material; 2. they shall be suitably stiffened; 3. they shall be so constructed as to be capable of preventing the passage of smoke and flame to the end of the one-hour standard fire test; 4. they shall be insulated with approved non-combustible materials such that the average temperature of the unexposed side will not rise more than 140 ×C above the original temperature, nor will the temperature, at any one point, including any joint, rise more than 180 ×C above the original temperature within 60 minutes. |

IEC 60079-13:2017 |

IEC 60079-13:2017 gives requirements for the design, construction, assessment, verification and marking of rooms used to protect internal equipment:

– located in a Zone 1 or Zone 2 or Zone 21 or Zone 22 explosive atmosphere without an internal source of gas/vapour release and protected by pressurisation; – located in a Zone 2 explosive atmosphere with or without an internal source of gas/vapour release and protected by artificial ventilation; – located in a non-hazardous area, containing an internal source of gas/vapour release and protected by artificial ventilation; – located in a Zone 1 or Zone 2 or Zone 21 or Zone 22 explosive atmosphere containing an internal source of gas/vapour release and protected by both pressurisation and artificial ventilation. |

ABS guildline for portable accommodation modules- updated on 2020

|

The ABS guildline for Portable Accommodation Modules has been developed to provide a consolidated set of requirements for portable accommodation modules that may be installed onboard a variety of vessels or offshore installations.

This Guide outlines the ABS requirements for the design and survey of accommodation modules installed onboard ABS-classed Mobile Offshore Drilling Units (MODUs), and Mobile Offshore Units (MOUs), Offshore Installations (fixed or floating), Steel Barges, and Steel Vessels. The Guide may be voluntarily applied to other type of portable modules. The requirements contained in this Guide are for design, construction, installation, and survey of accommodation modules and are based on the applicable ABS Rules and Guides, for the vessel type. No part of an accommodation module is to be designed and built to a lesser standard than a deckhouse on the same facility unless explicitly indicated in this ABS Guide. |