|

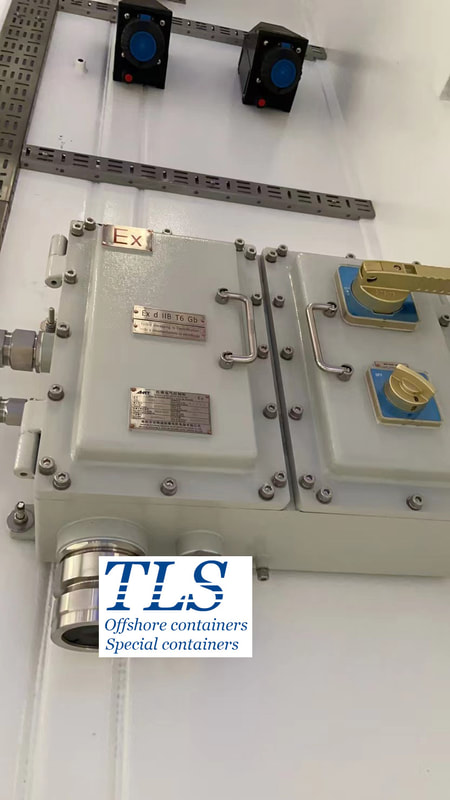

When the modular container needs fire and explosion protection and external cables need to be connected to the container, how to do it? Use MCT (the multi-cable transit system) to ensure that the container meets the air tightness and pressure requirements. MCT features:

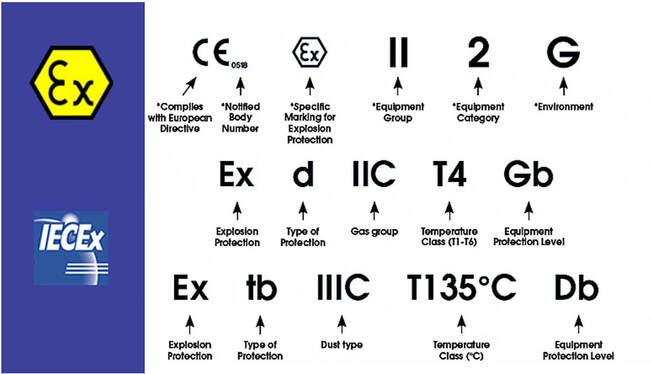

Key words: #MCT #pressurised container #ATEX #IECEx #offshore container #workshop container #TLS #explosive atmospheres What is ATEX? The name ATEX comes from the French ATmosphère EXplosibles, describing the equipment and use of a product to be located in an explosive atmosphere. The ATEX directive applies to a wide range of equipment, generally including offshore platforms, petrochemical plants, flour mills and other equipment used in potentially explosive atmospheres. The Directive also applies to safety devices beneficial to the safety of equipment, which may be used outside potentially explosive atmospheres. What is IECEx? IEC Scheme for Certification to Standards for Electrical Equipment for Explosive atmospheres, referred to as IECEx explosion-proof certification, was established in 1996 and is an international explosion-proof certification organization for explosion-proof electrical products. The IECEx Directive refers to the certification of electrical equipment specially used in industrial sectors such as petroleum, chemical, coal mining, textile, food processing and military industries that may accumulate explosive gases, vapors, dust or fibers and other explosive hazards. Difference between ATEX and IECEx

Key words:

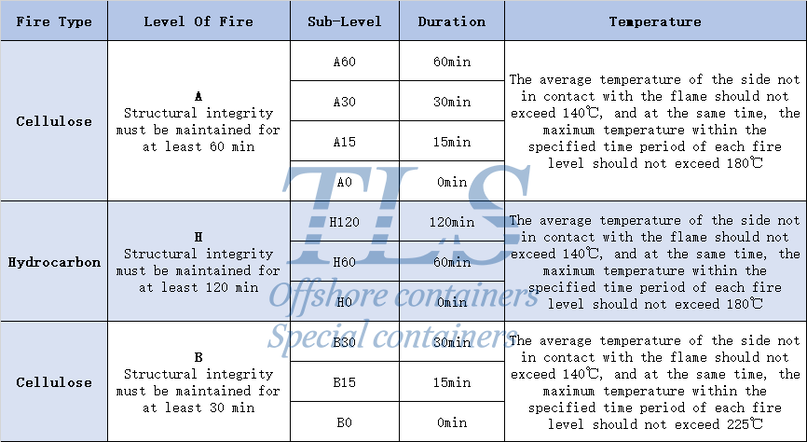

#pressurised container #ATEX #IECEx #offshore container #workshop container #TLS #explosive atmospheres Fire ratings such as A60 and H120 indicate the duration the doors and walls must be able to withstand a particular type of fire. A diagram shows you the container fire rating. In view of the above fire protection requirements, how is the container usually insulated and fireproof in structure?

Key words: #A60 fire rating #H120 #insulate #fireproof #rock wool #sandwich panel Battery energy storage system containers Taking the 1MW/1MWh energy storage system container as an example, the system generally consists of an energy storage battery system, a monitoring system, a battery management unit, a special fire protection system, a special air conditioner system, an energy storage converter and an isolation transformer, and is finally integrated in a 40-foot container. The battery system is mainly composed of cells in series and parallel: first, a dozen groups of cells are connected in series and parallel to form a battery box, then the battery boxes are connected in series to form a battery string and increase the system voltage, and finally the battery strings are connected in parallel to increase the system capacity, and Integrated installation in the battery cabinet. The monitoring system mainly monitors the functions of external communication, network data monitoring and data acquisition, analysis and processing, ensuring accurate data monitoring, high voltage and current sampling accuracy, data synchronization rate and fast execution speed of remote control commands; the battery management unit has high-precision monomers. The voltage detection and current detection functions ensure the voltage balance of the battery modules and avoid circulating currents between the battery modules, which affects the operating efficiency of the system. In order to ensure the safety of the system, the container is equipped with a special fire protection and air conditioning system. The fire protection system senses the fire through smoke sensors, temperature sensors, humidity sensors, emergency lights and other safety equipment, and automatically extinguishes the fire; the special air conditioning system according to the external environment temperature, The cooling and heating system of the air conditioner is controlled by the thermal management strategy to ensure that the temperature in the container is in a suitable range and prolong the service life of the battery. The energy storage converter is an energy conversion unit that converts battery DC power into three-phase AC power, which can operate in grid-connected and off-grid modes. In grid-connected mode, the converter interacts with the power grid according to the power command dispatched by the upper layer; in off-grid mode, the energy storage converter can provide voltage and frequency support for the plant load, and provide black-start power for some renewable energy sources. The outlet of the energy storage converter is connected to the isolation transformer, so that the electricity of the primary side and the secondary side is completely insulated, and the safety of the container system is guaranteed to the greatest extent. Mobile energy storage systems have been widely used in power system transmission, distribution and other fields due to their outstanding flexibility and convenience. Compared with the traditional fixed energy storage power station, the modular design of the container energy storage system adopts the internationally standardized container size, which allows ocean and road transportation, and can be hoisted by overhead cranes, with strong mobility and no geographical restrictions. In addition, the container energy storage system can be produced in a factory, and can be assembled and debugged directly in the workshop, which greatly saves the construction and operation and maintenance costs of the project, and monitors accident isolation. It is believed that with the continuous breakthrough of battery technology, the energy density of mobile energy storage systems will be further improved, and the cost will be greatly reduced. The actual value of mobile energy storage systems will continue to be reflected, and the scope of application will continue to expand. It will become an important carrier to promote the revolution of energy production and consumption, and it is a technology and industry with great development prospects in the energy Internet. Key words: #BESS container #BESS TLS Offshore containers follow DNV2.7-1 standard to do test for offshore containers, the container should be lifted with a sling at a certain angle in the vertical direction according to the specification of DNV2.7-1. ALL POINT LIFTING TEST: The weight (2.5R-T) is placed inside the box and the deformation of the bottom frame is measured simultaneously. After 5 minutes of static lifting of the container, measure the deformation of the bottom frame. 2- point LIFTING TEST: Reduce the weight inside the box to (1.5R-T), and measure the deformation of the bottom frame. FORK POCKET LIFTING TEST(If the container has pockets): Adjust the weight inside the box to (1.6R-T), and measure the deformation of the bottom frame at the same time. Fix the fork arm with angle pieces or jack the container up and stand still for 5 minutes, then measure the line variation of the bottom frame (for the small container, directly lift the container with forklift and stand still for 5 minutes, then test and record the data). VERTICAL IMPACT TEST: Adjust the weight in the container to R-T state. Appropriate Shackle and Wire Rope Sling should be installed on the four lifting points according to the design requirements of the drawing, and the lifting point of the Wire Rope should be adjusted appropriately to confirm that the container has a certain slope, and then the container should be unloaded quickly between the hook of the crane and the Wire Rope, and the container should be pulled by the Rope during lifting to prevent the container from swinging randomly. Lift the container to the cement surface, adjust the tilt angle of the bottom side beam of the box by 5° (ensure that the highest point of the bottom frame can't be higher than the lowest point 400 mm), and ensure that the lowest point of the bottom frame of the container is more than 5 cm free naked distance from the ground to operate quick shackle, so that the container free fall. Inspect all structural parts of the container for cracks or damage immediately after the drop sample is completed. Key words: #container test #drop test #lifting test To withstand the test of various climates, the coating of the container must have very good application performance. One of the important indicators is excellent anti-corrosion performance, including long-term corrosion resistance of marine climate, good water resistance, salt water resistance, oil resistance, humidity and heat resistance, chemical resistance, etc. The film thickness of the paint is an important indicator to detect the performance of the container coating, which will directly affect the anti-corrosion performance of the paint film. Containers with different functions have different requirements for paint film thickness. TLS will give professional suggestions according to the specific needs of customers. For the manufacturing process of containers, TLS will follow up and monitor the whole process, including the detection of film thickness. Key words: #container painting #painting thickness #TLS offshore #painting test #container NDT #NDT inspection |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|