|

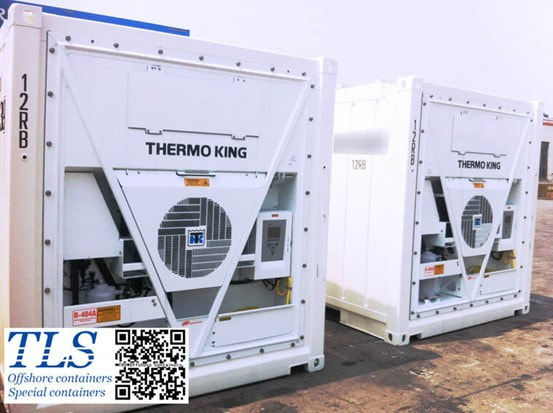

In the intricate world of international trade, the safe transportation of perishable goods remains a top priority. Enter TLS Reefer Containers, the epitome of reliability and precision in preserving temperature-sensitive cargo. Designed to meet the stringent demands of offshore operations, TLS Reefer Containers stand as a beacon of assurance for industries ranging from agriculture to pharmaceuticals. Let's delve deeper into why TLS Reefer Containers are the ultimate choice for safeguarding your valuable goods. Unrivaled Temperature Control TLS Reefer Containers boast a temperature range between -20°C and +2°C, ensuring optimal conditions for a diverse array of perishable items. Equipped with renowned refrigeration units from DAIKIN, Carrier, or Thermo King, these containers provide steadfast climate control, regardless of external conditions. From succulent fruits to delicate pharmaceuticals, your cargo remains impeccably preserved throughout its journey. Customized Solutions No two cargo needs are alike, and TLS understands this implicitly. With offerings in 10ft, 20ft, 40ft sizes, and the flexibility for customized dimensions, TLS Reefer Containers cater to the unique requirements of every shipment. Need adjustable ventilation or specialized shelving? TLS has you covered, ensuring that your cargo receives tailored care at every stage of the voyage. Robust Construction for Offshore Environments Operating in offshore settings demands equipment that can withstand the harshest elements. TLS Reefer Containers, constructed in accordance with DNV2.7-1/EN 12079 standards, embody durability and resilience. Featuring stackable design and integrated forklift pockets, these containers facilitate seamless loading and unloading operations, even in challenging offshore conditions. Advanced Control and Monitoring Maintaining precise temperature and humidity levels is paramount in preserving perishable cargo. TLS Reefer Containers come equipped with state-of-the-art electronic control panels and data loggers, enabling real-time monitoring and adjustment of environmental conditions. With flashing strobe beacons signaling operational status and see-through lockable control panels for added security, you can rest assured knowing your cargo is in capable hands. Certified Peace of Mind Compliance and certification are non-negotiable in the world of cargo transport. TLS Reefer Containers adhere to DNV2.7-1, EN12079, and CSC standards, underscoring their commitment to quality and safety. Whether navigating international waters or traversing remote offshore locations, TLS Reefer Containers provide a certified seal of trust for your valuable shipments. Conclusion In the dynamic landscape of global commerce, TLS Reefer Containers emerge as a beacon of reliability and innovation. With unrivaled temperature control, customizable solutions, robust construction, advanced monitoring capabilities, and certified compliance, TLS sets the standard for safeguarding temperature-sensitive cargo. Elevate your logistics strategy with TLS Reefer Containers, where precision meets peace of mind on every journey. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference Key words: #Temperature-controlled containers #TLS Reefer Containers #Refrigeration units #Temperature-sensitive cargo #Offshore logistics #DNV2.7-1 certification #EN12079 certification #CSC certification #Customized container solutions #Reefer container sizes #Stackable containers Written by OliverIn today's global marketplace, the transportation of temperature-sensitive goods presents a significant challenge. From pharmaceuticals to perishable foods, maintaining the integrity of these products during transit is paramount. This challenge has spurred the development of advanced solutions, including customized refrigerated shipping containers equipped with sophisticated control and monitoring systems. The Importance of Temperature Control in Shipping Temperature-sensitive goods, such as vaccines, fresh produce, and certain chemicals, require precise temperature control throughout the entire supply chain to prevent spoilage, degradation, or loss of potency. Even minor temperature fluctuations can compromise the quality and safety of these products, leading to significant financial losses and potential health risks. Customized Refrigerated Shipping Containers: A Solution for Precise Control Customized refrigerated shipping containers offer a tailored solution for transporting temperature-sensitive goods across long distances. Unlike standard containers, these units are equipped with advanced temperature control and monitoring systems designed to maintain a consistent and optimal environment for the cargo. Key Features of Customized Refrigerated Containers 1. Temperature Control Systems: Advanced refrigeration units installed in customized containers allow for precise temperature regulation. These systems can maintain temperatures within a narrow range, ensuring that the cargo remains stable throughout the journey. 2. Remote Monitoring Capabilities: State-of-the-art monitoring systems enable real-time tracking of temperature and humidity levels inside the container. Integrated sensors provide continuous data feedback to logistics managers, allowing them to remotely monitor conditions and intervene promptly if any deviations occur. 3. Data Logging and Reporting: Customized containers are equipped with data logging capabilities, which record temperature variations and other relevant parameters during transit. This data can be analyzed post-transit to assess the integrity of the cargo and identify any potential issues in the supply chain. 4. Alarm Systems: In the event of temperature excursions or system malfunctions, customized containers are equipped with alarm systems that alert stakeholders immediately. These alerts enable swift corrective actions to be taken, minimizing the risk of product loss or damage. Advantages of Customized Containers

Conclusion In an increasingly interconnected world, the demand for reliable and efficient transportation solutions for temperature-sensitive goods continues to grow. Customized refrigerated shipping containers equipped with advanced control and monitoring systems offer a viable solution to this challenge. By leveraging technology to maintain precise temperature conditions, businesses can safeguard the integrity of their products throughout the supply chain, ensuring customer satisfaction and regulatory compliance. As innovation in this field continues to evolve, the future of temperature-controlled shipping looks promising, promising safer, more reliable, and more efficient transportation of perishable goods around the globe. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference Key Words: #Temperature-sensitive goods #Refrigerated shipping containers #Control and monitoring systems #Temperature control #Perishable goods #Logistics #Supply chain #Refrigeration units #Remote monitoring #Data logging #Alarm systems Written by OliverIn today's dynamic shipping landscape, the demand for precision and reliability has never been higher, making these specialized containers a crucial asset for industries worldwide. In this article we will delve into the fascinating world of specialty reefer containers - the pioneers of temperature-controlled cargo transportation. Understanding Special Reefer Containers Special reefer containers are not your average shipping units; they are tailored to meet the unique requirements of diverse cargos. From pharmaceuticals and perishables to delicate electronics, these containers offer advanced features designed to maintain optimal conditions throughout the journey. Tailored Temperature and Humidity Controls One of the defining features of special reefer containers is their ability to provide precise temperature and humidity controls. Unlike standard containers, which offer generic settings, these specialized units allow for customized adjustments to meet the specific needs of the cargo. Whether it's pharmaceuticals requiring stringent temperature regulation or delicate flowers needing optimal humidity levels, special reefer containers ensure that goods arrive at their destination in prime condition. Dynamic Monitoring and Adjustments Equipped with sophisticated monitoring systems, special reefer containers go beyond basic temperature checks. These systems continuously analyze the internal environment, making real-time adjustments to maintain desired conditions. This proactive approach minimizes the risk of cargo spoilage and ensures uninterrupted quality throughout the transportation process. Insulation Innovations and Customizable Solutions Special reefer containers feature state-of-the-art insulation materials and technologies, enhancing temperature and humidity control while promoting energy efficiency. Moreover, these containers offer customizable solutions to accommodate a wide range of cargo types, from oversized machinery to hazardous materials, ensuring that each shipment receives the tailored care it deserves. Real-World Applications and Innovations In real-world scenarios, special reefer containers play a pivotal role in preserving the integrity of sensitive cargo. For instance, biotechnology firms rely on these containers to maintain precise environmental conditions for shipping genetically modified organisms (GMOs), safeguarding their viability throughout the journey. Looking to the Future As we peer into the future of cargo transportation, exciting innovations await special reefer containers. The integration of blockchain technology promises enhanced transparency and traceability, while AI-driven predictive maintenance systems ensure the reliability of these specialized units. Additionally, advanced remote monitoring capabilities, coupled with satellite technology, will provide stakeholders with real-time insights into cargo conditions, further revolutionizing the shipping industry. Conclusion: Shaping the Future of Cargo Transportation In conclusion, special reefer containers represent a technological marvel in the world of cargo transportation. With their precision, customization, and innovation, they stand at the forefront of ensuring the safe and secure transit of diverse cargo types. As we embrace the possibilities of blockchain integration, AI-driven maintenance, and enhanced remote monitoring, it's clear that these containers are not just vessels but guardians of goods that demand the utmost care and sophistication. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference Key Words: #Special Reefer Containers #Temperature-Controlled Cargo #Refrigerated Containers #Temperature and Humidity Controls #Cargo Transportation #Pharmaceutical Logistics #Perishable Goods Transport #Delicate Cargo Handling #Insulation Innovations #Advanced Monitoring Systems #Customizable Solutions Written by OliverOptimizing Refrigerated Container Transport for Fresh Goods: A Guide to Effective Ventilation12/22/2023

Introduction: When it comes to transporting frozen and refrigerated goods in reefer containers, the right ventilation strategy can make all the difference. In this article, we'll explore the importance of proper ventilation and how it can positively impact the quality and shelf life of perishable items during transit. Optimizing Ventilation for Different Goods: Whether you're transporting frozen goods or fresh produce like fruits and vegetables, understanding the role of ventilation is crucial. For frozen items, it's recommended to keep the vents closed, while for refrigerated items, opening the vents at the right time is key. This strategic approach helps control the levels of CO2 and ethylene gas within the container, contributing to optimal conditions for the transported goods. How Ventilation Works: Reefer containers utilize evaporator fans to force cold air into the enclosure. The suction port of the refrigerated container ventilator is designed to communicate with the evaporator fan's suction port. As the fan operates, negative pressure draws air from outside the container, continuously introducing fresh air. Simultaneously, the ventilator discharge port connects with the external environment, allowing the air inside the container to be effectively discharged, achieving proper ventilation. Balancing Ventilation for Refrigerated Items: When transporting refrigerated items, it's essential not to open the air vents excessively for cooling effects. Striking the right balance ensures that the controlled atmosphere inside the container is maintained, preventing unnecessary temperature fluctuations that may impact the quality of the goods. Advantages of Effective Ventilation:

Conclusion: Incorporating proper ventilation practices into refrigerated container transport is a vital aspect of ensuring the integrity and freshness of perishable goods. By understanding and implementing these ventilation strategies,TLS can optimize the transportation process, providing customers with high-quality products that have undergone controlled and secure transit. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference Key words: #Reefer containers #Ventilation in shipping #Refrigerated transport #Controlled atmosphere shipping #CO2 and ethylene gas control #Fresh produce transport #Perishable goods logistics #Evaporator fan in reefer containers #Temperature-controlled shipping #Transit time optimization Written by OliverIntroduction: In the dynamic world of global trade, the efficient and reliable transportation of perishable goods is crucial. As industries expand and markets become increasingly interconnected, the demand for a seamless cold chain solution is more significant than ever. Refrigerated containers, also known as reefer containers, have emerged as the ultimate choice for transporting perishable goods, ensuring their freshness and quality are preserved throughout the journey. Why Refrigerated Containers? Refrigerated containers are specially designed containers equipped with an integrated cooling system that regulates the temperature inside. These containers are the go-to solution for the transportation of perishable items such as fruits, vegetables, dairy products, pharmaceuticals, and more. Let's explore why refrigerated containers are considered the ultimate choice for maintaining the integrity of perishable goods during transportation.

Conclusion: In the realm of perishable goods transportation, refrigerated containers stand out as the ultimate choice for businesses seeking a reliable and efficient cold chain solution. From maintaining precise temperature control to extending the shelf life of goods, reefer containers offer a comprehensive solution for the diverse needs of various industries. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference #Refrigerated containers #Reefer containers #Perishable goods transportation #Cold chain logistics #Temperature-controlled shipping #Precise temperature control #Controlled atmosphere transport #Fresh produce logistics #Extended shelf life #Cargo preservation Written by OliverIntroduction: In the realm of modern logistics, the transportation of temperature-sensitive goods has become a critical aspect of supply chain management. Whether it's pharmaceuticals, perishable foods, or other sensitive materials, maintaining a specific temperature throughout the shipping process is paramount. This is where refrigerated shipping containers, often referred to as reefer containers, play a pivotal role, standing as the pinnacle of cold chain logistics. Understanding the Cold Chain: The cold chain is a temperature-controlled supply chain that ensures the integrity of goods from production to consumption. Refrigerated shipping containers are designed to maintain precise temperature conditions, safeguarding products that are highly sensitive to temperature fluctuations. The cold chain is essential for various industries, including pharmaceuticals, agriculture, and the food sector. Key Features of Refrigerated Shipping Containers:

Benefits of Refrigerated Shipping Containers:

Conclusion: Refrigerated shipping containers represent the zenith of cold chain logistics, providing a reliable and efficient solution for transporting temperature-sensitive goods. With advancements in technology and a growing emphasis on the quality and safety of products, these containers have become indispensable in today's globalized supply chain. Investing in refrigerated shipping containers is not just a necessity; it's a strategic move that ensures the seamless and secure transportation of perishable and sensitive goods across the world. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference #Refrigerated shipping containers #Reefer containers #Cold chain logistics #Temperature-controlled supply chain #Perishable goods transportation #Precision temperature control #Insulation technology #Monitoring and tracking systems #Air circulation and ventilation #Global cold chain Written by OliverTLS freezer containers are revolutionizing temperature-sensitive material preservation. In today's world, maintaining precise and ultra-low temperatures is essential across various sectors, including biomedical research, pharmaceuticals, genetics, and the food industry. In this condensed article, we will explore the mechanics of super freezer containers, their distinctive features, and their profound impact on multiple industries. Section 1: The Working Principle of Super Freezer Containers Super freezer containers excel at reaching and maintaining ultra-low temperatures, often dipping below -80°C (-112°F). They are crucial for preserving sensitive materials like biological samples, vaccines, genetic specimens, and gourmet ingredients. These containers employ advanced temperature control mechanisms and high-efficiency insulation to achieve ultra-low temperatures. Their powerful refrigeration systems, consisting of compressors, evaporators, and condensers, work swiftly to cool the interior. This combination of refrigeration technology and insulation prevents heat exchange with the external environment. Section 2: The Role of Insulation in Maintaining Ultra-Low Temperatures Super freezer containers require top-tier insulation to minimize heat transfer between the interior and the external surroundings. This insulation ensures stability in ultra-low temperatures, even when external conditions fluctuate. Conventional household refrigerators, designed to maintain around -18°C (0°F), have less insulation since they do not require extreme temperatures like super freezer containers. The latter's insulation is engineered to keep temperatures below -80°C (-112°F) without excessive energy consumption. Section 3: The Cooling System Super freezer containers employ state-of-the-art refrigeration systems for efficient cooling. Compressors, evaporators, and condensers work together to achieve rapid temperature reduction. The compressor plays a vital role by compressing refrigerant gas, releasing heat, and converting it into a high-pressure, high-temperature gas. This gas then condenses into a liquid, further releasing heat and maintaining the desired low temperature. Section 4: Distinctive Features of Super Freezer Containers The key difference between super freezer containers and regular freezers lies in the range of temperatures they can reach and maintain. Regular household refrigerators maintain temperatures around -18°C (0°F), sufficient for everyday frozen items. Super freezer containers, in contrast, can reach temperatures as low as -80°C (-112°F) or even lower. This capability is essential for preserving highly sensitive materials. Section 5: Professional Applications and Precise Temperature Control Super freezer containers find critical applications in various industries:

These containers offer precise temperature control through advanced control panels. Integrated monitoring systems track internal temperatures and provide real-time alerts to ensure the integrity of sensitive materials. Section 6: Energy Efficiency and Sustainability Despite their extreme cooling capabilities, super freezer containers prioritize energy efficiency. Advanced compressor technology optimizes energy consumption, and premium insulation minimizes heat transfer, reducing the need for constant cooling. Many manufacturers also embrace sustainable practices, using eco-friendly refrigerants and energy-efficient designs. Conclusion In summary, super freezer containers are at the forefront of refrigeration technology. Their ability to reach and maintain ultra-low temperatures, coupled with advanced insulation, refrigeration systems, precise controls, and specialized applications, sets them apart. They play a pivotal role in preserving sensitive materials across various industries, contributing to scientific progress, and upholding quality standards in the food industry. These super freezer containers empower professionals and researchers with precision cooling solutions that are here to stay. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference #Super freezer containers #Ultra-low temperature storage #Precision cooling #Refrigeration technology #Temperature-sensitive materials #Advanced insulation #Refrigeration systems #Temperature control mechanisms #Biomedical research preservation #Pharmaceutical storage Written by OliverIntroduction: Perishable goods, including fresh produce, dairy, meat, and seafood, are essential in our daily lives. The storage and transportation of these goods are critical for maintaining quality. TLS's refrigeration sea containers offer an innovative approach to storing perishables, creating a controlled environment that ensures optimal conditions. In this article, we delve into the factors influencing the storage duration of perishable cargo within refrigerated sea containers, recommended storage times for different goods, and strategies for optimizing storage duration. Factors Influencing Storage Duration: Several factors impact the quality and shelf life of perishable goods stored in refrigerated sea containers. These factors encompass temperature control, humidity management, and effective air circulation. Temperature Control: Precise temperature control is key to preserving perishables. Different goods require specific temperature ranges to retain freshness. For instance, fruits and vegetables typically need temperatures between 32°F and 55°F (0°C to 13°C), while dairy and seafood may demand slightly lower temperatures. Maintaining a consistent temperature is vital, as fluctuations can hasten spoilage. Humidity Management: Humidity levels play a pivotal role in preserving perishables. Some goods are sensitive to high humidity (e.g., leafy greens), while inadequate humidity can lead to dehydration (e.g., meat). Maintaining recommended humidity levels ensures product freshness and texture. Air Circulation and Ventilation: Proper air circulation within refrigeration sea containers is crucial. Adequate airflow prevents temperature irregularities and ensures even cooling. Additionally, ventilation regulates gas concentrations, preventing the buildup of harmful gases and removing ethylene gas, which accelerates spoilage. Recommended Storage Periods for Different Goods: Fresh Fruits and Vegetables:

Dairy Products:

Meat, Poultry, and Seafood:

Factors Beyond Container Conditions: Other factors impacting storage life include:

Conclusion: TLS's refrigeration sea containers offer a solution for preserving perishable goods' quality and safety. By understanding influencing factors, maintaining temperature and humidity control, ensuring proper air circulation, and following best practices, shelf life can be extended. Monitoring, quality control, and inspection ensure consumers receive top-quality goods, minimizing waste and maximizing profit in the perishable goods industry. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 #Perishable goods storage #Refrigeration sea containers #Storage duration of perishables #Controlled environment storage #Temperature-controlled storage #Humidity management for perishables #Air circulation in storage containers #Fresh produce preservation #Dairy product storage guidelines #Meat and seafood shelf life Written by OliverHow Can You Optimize Offshore Reefer Containers? Unlocking the Secrets to Usage and Maintenance6/16/2023

Offshore reefer containers play a crucial role in preserving the freshness and quality of goods during maritime transportation. To ensure optimal performance and proper functioning of these containers, it is essential to follow key usage guidelines and maintenance practices. This blog presents a concise guide on using and maintaining offshore reefer containers effectively.

Remember that proper usage and maintenance are key to unlocking the full potential of offshore reefer containers for sea transport. Following these best practices will help protect the integrity of goods, prolong the lifespan of the containers, and minimize the risk of disruptions and damages. The Ultimate Guide to Selecting the Perfect Refrigerated Shipping Container for Perishable Goods6/2/2023

Introduction: As the global market continues to expand and interconnect, the transportation of perishable goods over long distances has become increasingly vital. To ensure the freshness and quality of these products, choosing the right refrigerated shipping container is of paramount importance. This comprehensive guide will delve into the intricate details of selecting the ideal container for your specific needs, providing you with valuable insights and guidance. Section 1: Essential Considerations for Choosing a Refrigerated Shipping Container 1. Product Type and Temperature Requirements:

2. Temperature Range:

3. Product Dimensions and Weight:

4. Transit Time:

5. Shipping Regulations and Requirements:

Section 2: Exploring Different Types of Refrigerated Transport Containers 1. Refrigerated Containers:

2. Insulated Containers:

3. Refrigerated Trailers:

4. Cryogenic Containers:

Section 3: Additional Features to Consider 1. Cooling Unit Types:

2. Insulation Thickness:

3. Flooring and Ventilation Options:

4. Security Features:

Conclusion: Selecting the perfect refrigerated shipping container for your perishable goods involves a comprehensive assessment of factors like product type, temperature requirements, dimensions, transit time, shipping regulations, container types, additional features, and supplier reliability. By meticulously considering these elements, you can ensure the safe and efficient transport of your perishable products, preserving their quality and freshness until they reach their final destination. Remember to conduct thorough research, seek recommendations, and engage with trusted suppliers to make an informed decision that aligns with your specific needs. Any more information, please download TLS offshore reefer containers brochure for your reference TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 #Refrigerated shipping container #Perishable goods #Temperature control #Product requirement #Transit time #Shipping regulations #Container type #Temperature range #Insulation thickness #Cooling unit type Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|