|

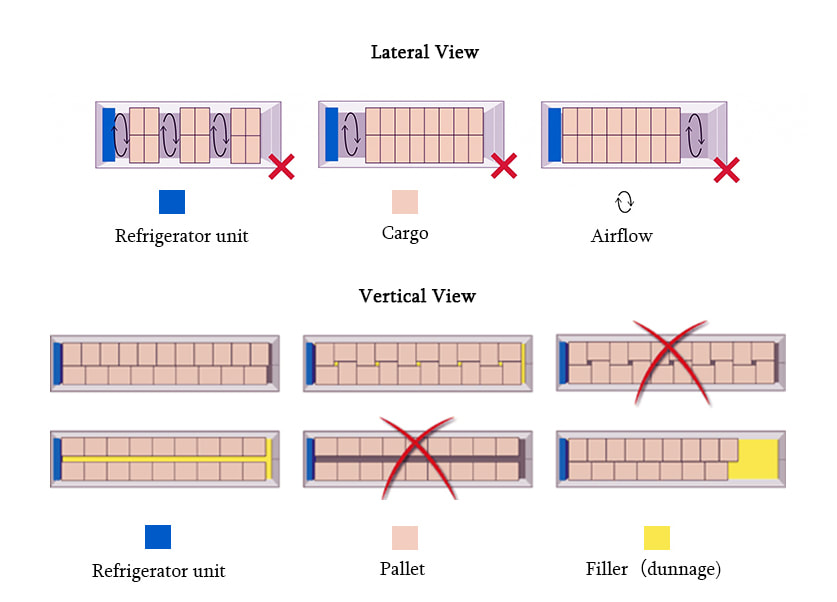

In today's global trade and logistics, refrigerated shipping containers play a crucial role in ensuring the safe transport of temperature-sensitive goods. Whether it's fresh food, pharmaceuticals, or other items requiring precise temperature control, properly managing and utilizing refrigerated containers is paramount. Below are key insights on how to efficiently manage and use these containers in ocean freight: 1. Cargo Loading and Stacking: Depending on the nature of frozen, chilled, or hazardous cargo, loading and stacking methods may vary. Ensure cargo is adequately packaged with no gaps between the cargo and container walls to facilitate even airflow. Follow block stacking principles to allow cold air to circulate uniformly, meeting the desired temperature requirements. 2. Temperature Monitoring: Regularly monitor the temperature inside refrigerated containers, typically checking at intervals of no more than six hours. Record temperature data and consider using an automated recording system to transmit real-time temperature data for continuous cargo status tracking. Especially when transporting hazardous refrigerated cargo, record temperatures every hour. 3. Refrigeration Unit and Maintenance: Conduct routine inspections of the mechanical and electrical systems of refrigerated containers to ensure they are in proper working condition. If any malfunctions occur, promptly inform specialized personnel for maintenance. Regular maintenance is crucial to equipment reliability. 4. Cargo Tracking: Implement cargo tracking technologies to monitor cargo location, status, and temperature data in real-time. This aids in the timely detection of issues and corrective actions to ensure cargo safety and quality. 5. Managing High-Performance Specialized Refrigerated Containers: High-performance specialized refrigerated containers are typically placed in the mid to aft sections of concealed deck vessels, avoiding the lower two tiers of containers on the ship's outermost sides. During transport, check the container's temperature three times a day and maintain records. When transporting hazardous refrigerated containers, record temperatures hourly. In case of equipment failure, promptly notify senior engineers for assessment and repairs. One hour before unloading at the port, record the temperature, disconnect the power supply, and secure the container. 6. Inspection Coordination: Before loading, conduct a comprehensive inspection of the refrigerated containers along with the chief engineer and electrical engineer. Ensure that all systems are operational. If the power has been disconnected, assess the equipment's status based on previous paper chart records. If any damages or malfunctions are detected, document them and promptly notify the yard management for inspection and repair. If the damage is significant and could affect product quality or if the fault cannot be rectified, consider rejecting the container. By adhering to these recommendations, you can ensure the efficient management and utilization of refrigerated shipping containers in ocean freight, preserving the quality and safety of your cargo, meeting customer demands, and maintaining a smooth supply chain operation. Success in international trade hinges on correct management and operation of the cold chain logistics, making refrigerated containers a vital component. In today's era of globalization and international trade, the transportation and preservation of frozen goods have become crucial challenges. Especially for temperature-sensitive commodities like meat, seafood, ice cream, and pharmaceuticals, maintaining their freshness and quality is of utmost importance. Fortunately, technological advancements have provided us with a solution, and the standout performer is the Super Freezer Container.

The Super Freezer Container is a high-tech container specifically designed for transporting frozen goods. Unlike ordinary containers, it is equipped with a specialized refrigeration system, capable of maintaining a constant low temperature, typically ranging from -60°C to -25°C. This makes it an ideal transportation tool for frozen goods, ensuring the perfect preservation of items such as seafood, meat, ice cream, and pharmaceuticals. Let's take a closer look at some of the features of the Super Freezer Container. It consists of a top plate, side panels, bottom plate, door, and refrigeration unit. The powerful refrigeration unit, located at the front of the container, can achieve cooling capacity as low as -60°C, guaranteeing that the cargo remains frozen throughout the journey. The four walls are made from robust aluminum panels, while the container's insulation layer uses ultra-low temperature foaming materials, ensuring excellent thermal insulation. The interior side panels and roof are equipped with corrugated ribs and inner columns, while the exterior side panels have several hat-shaped edges, providing a sturdy and stable structure. Moreover, the rear end of the container features a stepped design, sealed with rubber strips to prevent heat leakage. The door is equipped with multiple lip outer seals and double lip inner seals, further enhancing the container's sealing performance. Inside the top plate's insulation layer, there is a hat-shaped roof beam, improving the insulation effect. The advantages of the Super Freezer Container are numerous. Its reasonable structure, powerful refrigeration capacity, superior sealing, and insulation performance make it suitable for storing special items requiring ultra-low temperatures (-70°C to +25°C). Playing a vital role in protecting the quality and freshness of temperature-sensitive goods, such as pharmaceuticals, plasma, and seafood, the Super Freezer Container is a critical asset. These high-tech Super Freezer Containers serve diverse purposes across various fields. They are used for scientific research, low-temperature experiments with special materials, cold chain logistics, medical applications, electronic industries, and low-temperature preservation of seafood, among others. Blood stations, hospitals, health and epidemic prevention systems, research institutions, military enterprises, and more can rely on Super Freezer Containers to ensure the optimal condition of their cargo during transportation. In the tide of globalization and international trade, Super Freezer Containers are not only the guardians of maritime shipping but also crucial support for cold chain logistics. They provide a secure and efficient means of transporting perishable goods across the global supply chain. Whether it's sending delicious seafood across the ocean or preserving top-quality pharmaceuticals and plasma, Super Freezer Containers have made an indelible contribution to human life and health. In the future, we believe that Super Freezer Containers will continue to evolve and innovate, constantly enhancing their performance and scope of application. They will continue to play a pivotal role in the global logistics industry, providing consumers around the world with fresher and higher-quality frozen goods. Let us look forward to a bright future where Super Freezer Containers bring more convenience and assurance to cold chain logistics! The Importance of Temperature-Controlled Transport: Understanding Offshore Refrigerated Containers2/15/2023

An offshore refrigerated container is a type of container used to transport perishable goods that require temperature-controlled storage. These containers are equipped with refrigeration units that can be powered by electricity and can keep the temperature inside the container within a specific range. Offshore Refrigerated containers are commonly used to transport fresh and frozen foods such as fruits and vegetables, meat, dairy products, and seafood. They are also used to transport pharmaceuticals, chemicals, and other temperature sensitive products. Offshore Refrigerated containers are designed to be optimized for preserving perishable goods, with features such as insulation, temperature control systems, and ventilation to maintain the desired temperature and humidity levels. Some refrigerated containers are also equipped with a remote alarm system, which monitors the temperature, humidity, and other environmental factors in the refrigerated container in real time through remote communication technology and sends out an alarm signal when an abnormal situation occurs. The refrigerated container remote alarm system can not only protect the quality of refrigerated items, but also prevent unsafe conditions of refrigerated containers, such as abnormal temperature increase, refrigerated container door opening, etc. Offshore refrigerated containers are a regular product of TLS. It complies with DNV2.7-1 / EN12079 / CSC certificate and can be applied to multimodal transport. Welcome clients to customize in batches. Written by Mandy WHAT STANDARD OFFSHORE REFRIGERATED CONTAINER CAN TLS PROVIDE, IS THAT YOU ARE LOOKING FOR?8/5/2022

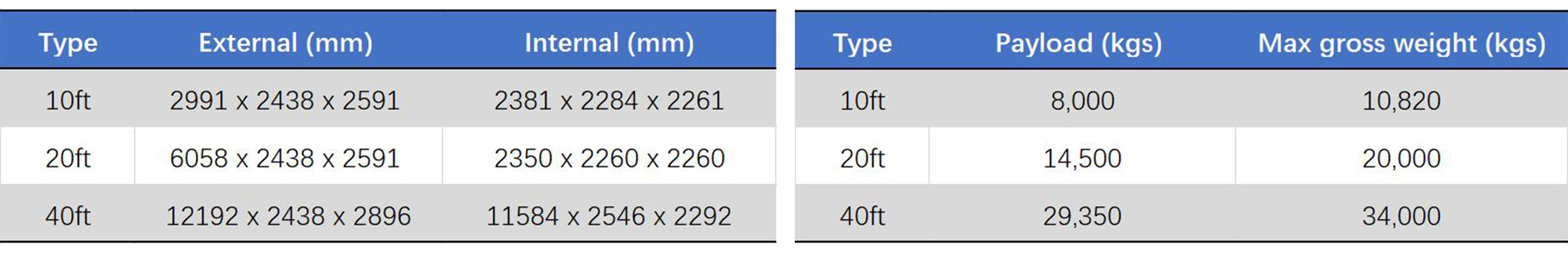

Offshore refrigerated containers provided by TLS are equipped with DAIKIN, CARRIER or THERMO KING refrigeration units to maintain the internal temperature between -20°C to +25°C. 10ft, 20ft, 40ft or customised size reefer container for option.

TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #DNV 2.7-1 #BV #LR #offshore reefer container #ISO #EN12079 #door curtains #shelving #lasing ring #Man-trap alarm #TLS How does the refrigerated container work? The purpose of the reefer container is not to cool the product, but to maintain the temperature of the product. So instead of adding cool air, the refrigeration process removes heat from the air inside the container. The reefer container distributes cold air from the floor through the T-deck. Precautions for the use of reefer containers

Reefer containers|refrigerated containers are used to transport or store goods that require temperature control. Fruit, vegetables, dairy products, meat and other products are typical goods transported or stored in such containers. At first glance, reefer containers look similar to traditional shipping containers, but they have many different features.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|