|

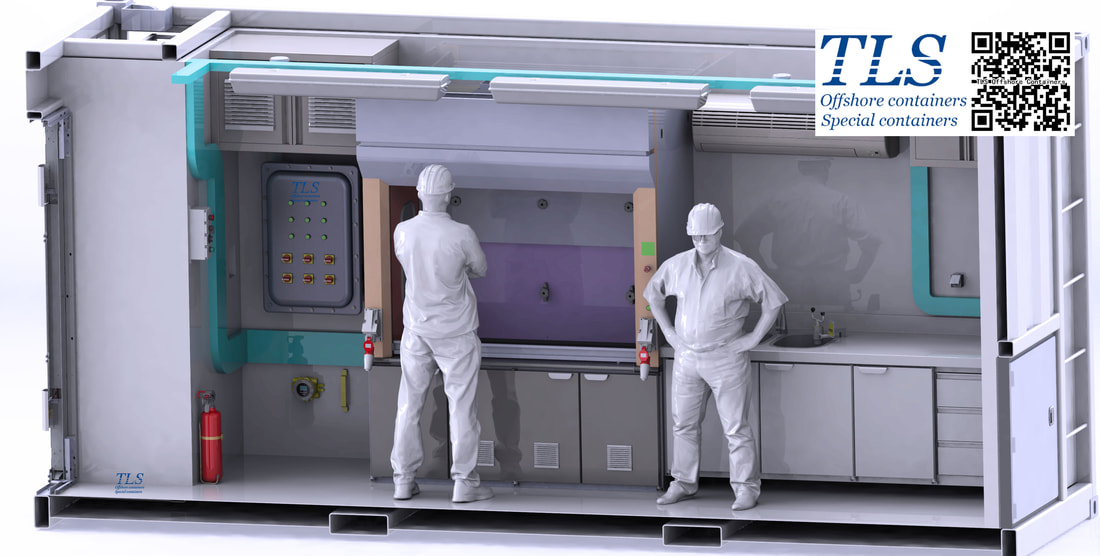

The maritime and offshore industry constantly evolves, necessitating robust and reliable solutions for various operational challenges. One such innovation is the A60 offshore workshop container, a versatile and essential asset for offshore projects. This blog explores the features, benefits, and applications of the A60 offshore workshop container manufactured by TLS, a leading provider in the industry. What is an A60 Offshore Workshop Container? An A60 offshore workshop container is a specially designed and certified container that meets the stringent A60 fire rating standards. These containers are engineered to withstand extreme offshore conditions, providing a safe and functional workspace for various activities, including maintenance, repair, and storage. Key Features of TLS A60 Offshore Workshop Containers

Benefits of Using A60 Offshore Workshop Containers

Applications of TLS A60 Offshore Workshop Containers

Why Choose TLS for A60 Offshore Workshop Containers?

Conclusion A60 offshore workshop containers by TLS are a vital asset for the maritime and offshore industry. With their robust construction, advanced safety features, and versatile applications, these containers provide reliable and efficient solutions for various offshore needs. Choosing TLS means investing in quality, safety, and performance, ensuring the success of your offshore operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Key words: #A60 offshore workshop container #Offshore workshop solutions #Durable offshore containers #Custom offshore containers #DNV 2.7-1 containers #Marine workshop container #Secure offshore storage solutions #Offshore control room container #A60 compliant containers #Offshore living quarters containers #Modular offshore workshop Written by OliverIn the dynamic landscape of offshore industries, efficiency, and safety are paramount. With the demand for reliable equipment that can withstand harsh environments, TLS introduces the A60 Offshore Pressurized Container, revolutionizing offshore operations. In this blog post, we delve into the features, benefits, and significance of this innovative solution in enhancing productivity and mitigating risks in offshore settings. Understanding the A60 Offshore Pressurized Container The A60 Offshore Pressurized Container by TLS is a cutting-edge solution engineered to meet the rigorous demands of offshore environments. Designed to withstand extreme conditions such as high pressure, corrosive elements, and adverse weather, this container sets a new standard in reliability and durability. Key Features and Benefits

Applications in Offshore Industries The versatility of the A60 Offshore Pressurized Container makes it indispensable across a wide range of offshore applications, including:

Conclusion In the ever-evolving landscape of offshore industries, the A60 Offshore Pressurized Container by TLS emerges as a game-changer, combining innovation, reliability, and safety to optimize operations and mitigate risks. With its robust construction, advanced features, and customizable configurations, this container offers unmatched versatility and performance in demanding offshore environments. Embrace the future of offshore operations with TLS and experience the difference with the A60 Offshore Pressurized Container. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Offshore industry #Oil and gas #Marine engineering #Subsea operations #Rigging solutions #Containerization #Hazardous materials #Seismic exploration #Remote locations #Modular design #Environmental protection #Logistics management Written by OliverEnsuring Safety at Sea: The Crucial Role of A60 Fire Rating for Offshore and Marine Containers5/24/2024

In the dynamic world of offshore and marine industries, safety stands as the paramount concern. Amidst the vast expanse of open water or the rugged environments of offshore drilling rigs, ensuring the safety of personnel and equipment is non-negotiable. One pivotal aspect of this safety framework is the A60 fire rating for containers, which plays a vital role in safeguarding against fire hazards in offshore and marine applications. Understanding A60 Fire Rating: A60 fire rating refers to a specific classification system that determines the fire resistance capability of a structure or material. In the context of containers used in offshore and marine settings, the A60 rating signifies the ability to withstand fire for a defined period, typically 60 minutes, without compromising its structural integrity or allowing the fire to spread to the adjacent areas. The Importance in Offshore and Marine Environments:

Choosing the Right A60 Fire-Rated Containers: Selecting suitable A60 fire-rated containers requires careful consideration of various factors, including:

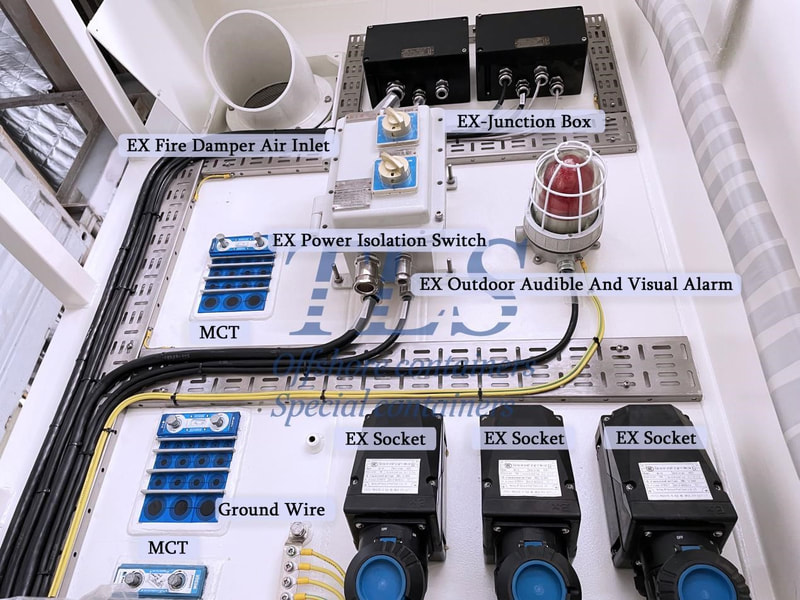

Conclusion: In the demanding environments of offshore and marine operations, safety is paramount, and fire prevention is a top priority. A60 fire-rated containers play a critical role in mitigating fire risks, ensuring regulatory compliance, protecting personnel and assets, and sustaining operational continuity. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Key words: #A60 fire rating #Offshore containers #Marine applications #International Maritime Organization (IMO) #SOLAS compliance #Offshore platform safety #Marine vessel fire prevention #Safety standards for offshore equipment #Fire hazard mitigation #Regulatory compliance in maritime industry Written by OliverIntroduction: In the complex and demanding landscape of offshore industries, the efficiency and reliability of operations are paramount. The Multi-Cable Transit (MCT) module emerges as a critical component, addressing the challenges associated with cable management in offshore containers. This article explores the pivotal role of the MCT module in ensuring organized and secure cable transit systems for offshore applications. Understanding the Multi-Cable Transit (MCT) Module: The MCT module is an advanced cable management system designed specifically for offshore containers. This innovative solution facilitates the organized and secure passage of multiple cables through container walls, ensuring a streamlined approach to power distribution, communication, and control systems in offshore environments. Key Features and Benefits:

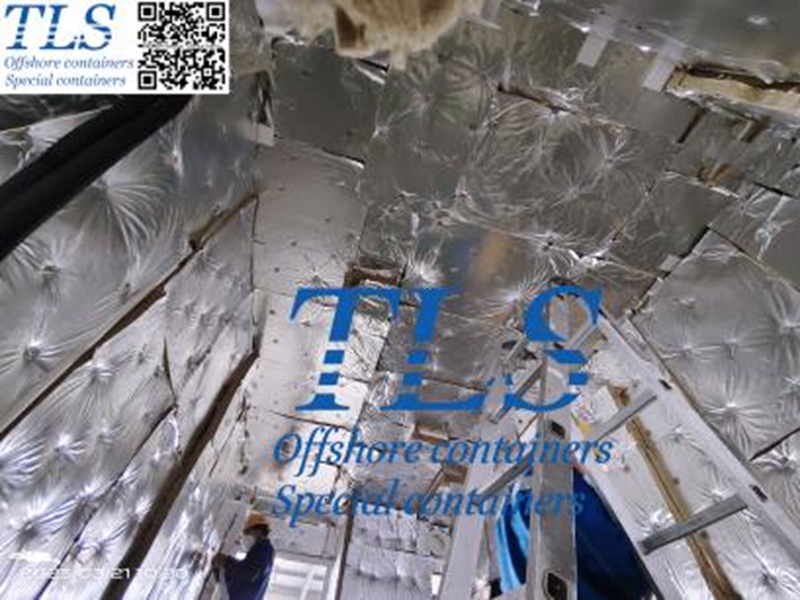

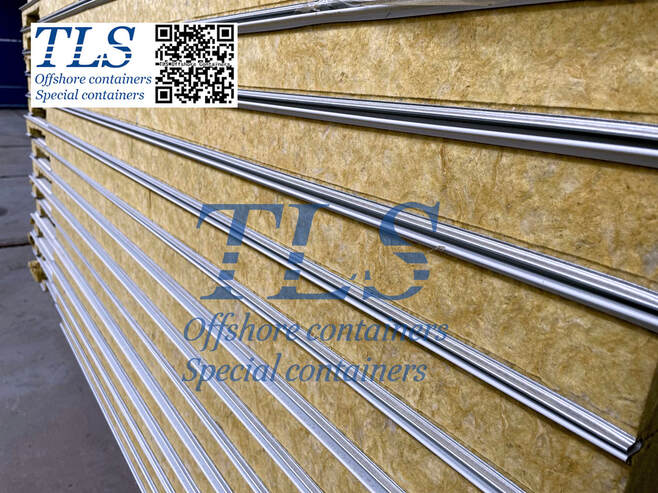

Conclusion: As offshore industries continue to push technological boundaries, the Multi-Cable Transit (MCT) module emerges as a key enabler for efficient and reliable cable management in containers. Its ability to organize cable routing, provide modularity and flexibility, offer environmental protection, ensure fire resistance, and enhance time and cost efficiency positions it as an indispensable solution for the evolving needs of offshore applications. By utilizing MCT modules in offshore containers, TLS not only solves the compelling challenge of cable management, but also prepares for future offshore operations by providing a scalable and adaptable solution. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Multi-Cable Transit #Cable Management #Offshore Containers #Cable Routing #Modular Cable Systems #Offshore Operations #Containerized Cable Solutions #Cable Transit Points #Environmental Protection #Fire Resistance Written by OliverContainer heat insulation and fire protection design involves creating a system within a container to safeguard its contents from external temperature fluctuations and fire hazards. This system typically incorporates insulation materials such as rock wool, glass wool, and polyurethane, along with fireproof materials like fireproof boards and coatings. TLS offshore containers are engineered to meet the A60 fire protection standard, typically utilizing rock wool as an insulating material. Rock wool, composed of basalt or lava mineral fibers, offers several advantageous properties:

Employing rock wool as an insulation material in containers offers benefits in terms of thermal insulation, fire resistance, soundproofing, and environmental sustainability. When designing an insulation system, it's crucial to consider factors like insulation requirements, cost, and durability to determine the appropriate rock wool thickness and density. Additionally, compliance with relevant fire protection and environmental standards must be adhered to during installation. In container heat insulation and fire protection design, several key aspects should be considered:

Container heat insulation and fire protection design is a multifaceted endeavor, requiring a holistic approach to factors like insulation, fire protection, fire prevention systems, and operator safety. Throughout the design process, factors like cargo type, container characteristics, and budget constraints must be thoughtfully considered to determine the most suitable heat insulation and fire protection scheme. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Rock wool #Fireproof boards #Fireproof coatings #Thermal insulation #Fire resistance #Sound absorption #Environmental protection #Safety #A60 fire protection standard #Temperature stability Written by OliverUnderstanding A60 Fire Rating Standard and A60 Fireproof Materials for Offshore Containers8/31/2023

In order to fully enable offshore containers to fulfill various functions such as transporting perishable goods, providing living quarters, and accommodating workspaces, it becomes essential to undertake modifications that adhere to the container's thermal insulation and fire protection prerequisites. Typically, the containers offered by TLS are designed to meet the A60 standard, ensuring compliance with stringent safety regulations. Key Specifications for A60 Classification Society Standard:

Characteristics of A60 Fireproof Materials: The chosen fireproof material should exhibit both rigidity and the ability to withstand fire for a minimum of 1 hour, all while preserving its structural integrity to thwart the passage of smoke and flames. Rock wool and ceramic fiber wool stand out as two distinct alternatives for insulation materials in A60 fire protection applications. However, it is imperative that both materials receive official endorsement from the pertinent classification society to ensure adherence to safety standards and regulations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #A60 fire rating #A60 fireproof material #Offshore containers #Thermal insulation #Fire protection #Classification society standards #Steel thickness #Anti-flexion reinforcement #Non-combustible materials #Average temperature rise Written by OliverIntroduction: Container heat insulation and fire protection play a crucial role in safeguarding goods from external temperature fluctuations and fire hazards during transportation. This comprehensive guide outlines the essential aspects of designing an efficient heat insulation and fire protection system inside containers to ensure optimal safety and protection. Discover the key insulation materials, fireproof options, and the significance of meeting A60 fire protection standards for offshore containers. Section 1: Benefits of Rock Wool Insulation in Containers Rock wool, crafted from basalt or lava mineral fibers, emerges as an exceptional insulation material with several advantages:

Section 2: Choosing the Ideal Rock Wool Thickness and Density Designing an effective insulation scheme necessitates a comprehensive consideration of insulation requirements, cost, and durability. The appropriate thickness and density of rock wool should be determined based on these factors, taking care to adhere to relevant fire protection and environmental standards. Section 3: Designing the Insulation and Fire Protection Layers Consider the following aspects when designing the insulation and fire protection layers within containers:

Section 4: Implementing a Comprehensive Fire Protection System The container's fire protection system is a critical element, comprising fire water sources, fire sprinklers, smoke detectors, and more. These components work together to detect and combat fire outbreaks promptly, minimizing potential damage to goods. Section 5: Prioritizing Operator Safety Ensure the safety and well-being of operators by incorporating essential features like efficient lighting and ventilation systems within the container. Adequate lighting ensures clear visibility, while proper ventilation prevents the accumulation of harmful gases. Conclusion: Container heat insulation and fire protection design is a multifaceted project that demands a holistic approach. By considering factors like cargo characteristics, container properties, and budget constraints, you can develop a tailored and efficient heat insulation and fire protection scheme. Opting for rock wool insulation, meeting A60 fire protection standards, and implementing a comprehensive fire protection system will enhance the safety and security of goods during transportation, mitigating risks and potential damages. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Container heat insulation #Container fire protection #Heat insulation materials #Fireproof materials #Rock wool insulation #A60 fire protection standard #TLS offshore containers #Container insulation design #Fireproof boards #Fireproof coatings Written by OliverIntroduction: The offshore industry operates in some of the most challenging and hazardous environments. To ensure the safe transportation and storage of equipment, materials, and personnel, it relies on specialized containers designed to withstand extreme conditions. Among these containers, the A60 rated offshore container stands out as a reliable and highly effective solution. In this article, we will explore in detail the features, benefits, and applications of A60 rated offshore containers, highlighting their crucial role in enhancing safety and efficiency in offshore operations. Section 1: Understanding A60 Rating and its Significance A60 rating refers to the fire protection and insulation capabilities of offshore containers. The "A" stands for fire protection, while "60" signifies the container's ability to withstand high temperatures for up to 60 minutes. This rating is of utmost importance as it ensures the containment of fires and minimizes the risk of their spread, protecting both personnel and valuable assets in offshore operations. Compliance with international standards and regulations, such as those set by the International Maritime Organization (IMO), is necessary to meet safety requirements. Section 2: Key Features of A60 Rated Offshore Containers 2.1 Robust Construction:

2.2 Fire-Resistant Properties:

2.3 Watertight and Weatherproof:

2.4 Modular Design:

Section 3: Applications of A60 Rated Offshore Containers 3.1 Offshore Oil and Gas Industry:

3.2 Renewable Energy Sector:

3.3 Marine and Shipping Industry:

3.4 Research and Exploration Projects:

Section 4: Benefits of A60 Rated Offshore Containers 4.1 Enhanced Safety:

4.2 Reliable Equipment Storage:

4.3 Flexibility and Versatility:

4.4 Cost-Effectiveness:

4.5 Compliance and Peace of Mind:

Section 5: Maintenance and Inspection Considerations

Conclusion: A60 rated offshore containers are indispensable assets in the offshore industry, ensuring the safety and efficiency of operations in challenging environments. Their robust construction, fire-resistant properties, and adaptability make them a preferred choice for the storage and transportation of valuable equipment, materials, and personnel. By adhering to international standards, conducting regular maintenance, and procuring A60 rated containers from reputable suppliers, offshore operators can achieve the highest levels of safety, compliance, and operational excellence. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #A60 rated offshore container #Offshore containers #Fire protection #Insulation #Compliance #International standards #Robust construction #Fire-resistant properties #Watertight #Weatherproof Written by OliverAs industries and businesses continue to expand, the need for safe and reliable shipping of goods and equipment becomes increasingly important. One way to ensure this safety is through the use of containers. Specifically, containers with an A60 fire rating are becoming more and more popular. What is an A60 fire rating? An A60 fire rating is a classification that signifies the ability of a container to withstand fire. The rating means that the container can withstand temperatures of up to 1,000 degrees Celsius for up to 60 minutes. This rating is particularly important for offshore and marine applications, where the risk of fire is high due to the presence of flammable materials and gases. Why choose a container with an A60 fire rating? Containers with an A60 fire rating offer several advantages, including:

Where are A60 containers commonly used? A60 containers are commonly used in offshore and marine applications, such as oil and gas platforms and drilling rigs. They are also used for military and industrial applications that require high levels of fire protection. In addition to their fire-resistant properties, A60 containers can also be customized to meet specific industry requirements. For example, containers can be outfitted with HVAC systems, lighting, and electrical systems to meet the needs of different industries. Conclusion Choosing a container with an A60 fire rating is a wise choice for businesses and industries that require reliable and safe shipping of goods and equipment. These containers offer a high level of protection against fire, and can help prevent damage to equipment and loss of goods. They also help protect workers and the environment, and ensure compliance with industry standards. Whether used for offshore and marine applications or for military and industrial uses, A60 containers are a durable and reliable option for transporting goods and equipment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #A60 fire rating, #containers, #offshore, #marine, #fire protection, #safety, #compliance, #durability Written by OliverWhat is the A60 fire rating standard? What kind of A60 fireproof material will be put into use?9/29/2022

For the functions of sea containers, such as transporting refrigerated, living or working, etc., it is necessary to carry out modifications to meet the requirements of thermal insulation and fire protection of the container. Normally, the sea land containers provided by TLS can comply with the A60 standard.

Classification society standard A60 level specific requirements:

What type of refractory material is A60 fireproof? The material is required to have a certain rigidity and fire resistance for more than 1 hour, during which time the integrity is maintained to prevent the passage of smoke and flame. Rock wool and ceramic fiber wool are two different materials, both of which can be used as insulation materials for A60 fire protection but must be approved by the relevant classification society. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|