Revolutionizing Energy Storage: Advanced Thermal Management for TLS Air-Cooled BESS Containers7/25/2024

Introduction Battery Energy Storage Systems (BESS) are rapidly becoming essential components of the modern energy landscape. As the demand for reliable, efficient energy storage grows, so does the need for innovative solutions to optimize the performance and longevity of these systems. TLS, a leader in energy storage solutions, is at the forefront of developing advanced thermal management systems specifically for their air-cooled BESS containers. The Importance of Thermal Management in BESS Effective thermal management is crucial for BESS performance for several reasons:

Advanced Thermal Management Systems for TLS Air-Cooled BESS Containers TLS has integrated several cutting-edge technologies into their air-cooled BESS containers to address these thermal challenges:

Benefits of TLS's Approach TLS's advanced thermal management systems offer several key advantages:

The Future of BESS Thermal Management As BESS technology continues to evolve, so too will thermal management systems. TLS is committed to ongoing research and development in this area, with a focus on even more efficient, intelligent, and sustainable solutions. The integration of renewable energy sources and energy storage is transforming the way we power our world, and advanced thermal management plays a vital role in ensuring the success of this energy revolution. Conclusion TLS's advanced thermal management systems for air-cooled BESS containers are a testament to the company's commitment to innovation and energy efficiency. By prioritizing the longevity, performance, and safety of their BESS solutions, TLS is helping to pave the way for a more sustainable and reliable energy future. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Keywords: #BESS #battery energy storage systems #thermal management #air-cooled containers #TLS #energy efficiency #battery lifespan #energy storage #renewable energy Written by OliverTLS 20ft Offshore Accommodation Containers: The Essential Solution for Oil Platform Housing7/25/2024

Introduction: In the demanding world of offshore oil and gas operations, providing safe and comfortable living quarters for personnel is paramount. That's where TLS 20ft offshore accommodation containers have emerged as a game-changer. These modular units are designed to withstand the harsh offshore environment while offering a high quality of life for those working on oil platforms. Why TLS 20ft Offshore Accommodation Containers Are the Industry Standard:

Benefits for Oil and Gas Operations:

TLS: A Leader in Offshore Accommodation TLS (TLS Offshore Containers & TLS Energy) has established itself as a trusted provider of offshore accommodation solutions. Our commitment to quality, safety, and innovation has earned us a reputation for excellence in the industry. Conclusion: If your oil and gas operation requires reliable, safe, and comfortable housing for offshore personnel, look no further than TLS 20ft offshore accommodation containers. Our combination of durability, functionality, and customizability makes us the ideal choice for the demanding conditions of the oil platform environment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. Keywords: #offshore accommodation container #oil platform housing #TLS containers #offshore housing solutions #DNV 2.7-1 certified containers #EN 12079 containers #modular offshore housing #oil rig housing #offshore living modules Written by OliverUnveiling the Significance of TLS 40ft MCC Shelters in Hazardous Areas: A Comprehensive Insight7/25/2024

Introduction: In industries operating in hazardous zones, the safety and reliability of electrical equipment are paramount. A 40ft MCC (Motor Control Center) shelter, especially those engineered by TLS, offers a robust solution to protect sensitive electrical components from the risks posed by flammable gases, vapors, dust, and other hazardous substances. What are 40ft MCC Shelters? MCC shelters are essentially specialized containers designed to house motor control centers. These shelters provide a controlled environment for MCC, ensuring their optimal performance and longevity, even in challenging conditions. TLS, a renowned manufacturer in this field, is known for our high-quality and innovative MCC shelter solutions. Why are 40ft MCC Shelters Essential in Hazardous Areas?

Key Features of TLS 40ft MCC Shelters:

Applications of 40ft MCC Shelters:

Choosing the Right 40ft MCC Shelter: When selecting a 40ft MCC shelter, consider factors like:

Conclusion: 40ft MCC shelters, especially those manufactured by TLS, are indispensable in safeguarding electrical equipment and personnel in hazardous environments. Investing in a high-quality MCC shelter ensures regulatory compliance, enhances safety, and ultimately contributes to the smooth operation of critical industrial processes. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Keywords: #40ft MCC shelter, #TLS, #hazardous areas, #electrical equipment, #explosion-proof, #intrinsically safe, #pressurised container Written by OliverIn the demanding environment of offshore operations, ensuring the comfort and safety of crew members is paramount. TLS Offshore Containers offers a range of ABS approved accommodation modules that not only meet but exceed industry standards for safety, functionality, and comfort. Designed to be stacked and linked seamlessly, these modules provide a robust and adaptable solution for various offshore accommodation needs. #### Exceptional Safety and Compliance Safety is a critical concern in offshore environments. TLS Offshore Containers' accommodation modules are certified to DNV2.7-1 and EN 12079 standards, ensuring they meet rigorous international safety requirements. Each module is equipped with a PLC-based fire and gas detection system, category II lighting with low brightness to minimize eye strain, and an HVAC system with individual thermostatic control. The modules also include certified lifting eyes and slings, making them safe and easy to install on fixed platforms and floating installations. #### Robust and Adaptable Design The design of these modules prioritizes both durability and adaptability. Constructed with ISO corner blocks, the modules can be easily stacked to create multi-level accommodation complexes. Linking kits maintain A60 integrity and provide a watertight barrier, ensuring the modules remain secure in harsh weather conditions. Each module is designed for quick and easy hookup to onboard services, further enhancing their practicality. #### Comfortable Living Spaces Comfort is not sacrificed for safety in these accommodation modules. Each unit includes two sets of bunk beds or single beds, complete with FR mattresses and blackout curtains to ensure restful sleep. The en-suite shower rooms feature integral hot water systems, and high-quality fixtures and fittings are used throughout the living spaces. Additionally, modules come with desks and workspaces, operator chairs on lockable castors, and 32” LED TVs, providing a comfortable and functional environment for crew members. #### Comprehensive Facilities TLS Offshore Containers' accommodation modules are fully equipped to meet the needs of offshore workers. Each module includes essential facilities such as fresh and sea water supply connections, black and grey water drainage pipes, and socket outlets suitable for 240V. Emergency electrical lighting and a PAGA/TV/Tel socket connection ensure that communication and safety systems are always operational. #### Easy Installation and Integration The modules are designed for ease of installation and integration. Each unit comes complete with twist locks and pads for deck mounting, and the linking kits facilitate structural, mechanical, and architectural connections between modules. The design also ensures that all external connections comply with ZONE 2 requirements, providing an additional layer of safety. #### Conclusion TLS Offshore Containers' ABS approved accommodation modules offer an unparalleled combination of safety, comfort, and practicality for offshore environments. With their robust design, high-quality facilities, and ease of installation, these modules are an excellent choice for enhancing the living conditions of offshore workers. By prioritizing both safety and comfort, TLS Offshore Containers ensures that crew members can perform their duties efficiently while enjoying a secure and comfortable living space. For more information on our accommodation modules and other offshore container solutions, visit us. Introduction: In the rapidly evolving world of renewable energy, Battery Energy Storage Systems (BESS) are playing a critical role in grid stabilization and the integration of intermittent sources like solar and wind power. At the heart of these advanced BESS solutions lie the Power Conversion System (PCS) and the Battery Management System (BMS). Today, we're shining a spotlight on TLS, a pioneering company in the BESS industry, and the advanced technology behind their PCS and BMS. The PCS: The Powerhouse of the BESS The PCS is the workhorse of any BESS container. It's responsible for converting the direct current (DC) power stored in the batteries into alternating current (AC) power that can be fed into the grid or used to power homes and businesses. TLS's PCS stands out for its:

The BMS: The Brain of the BESS The BMS is the intelligent control system that monitors and manages the health and performance of the batteries within the BESS container. TLS's BMS is a marvel of engineering, offering:

TLS's Commitment to Safety and Reliability Safety is paramount in the design of any BESS container. TLS takes this responsibility seriously, incorporating advanced safety features into both the PCS and BMS:

Conclusion TLS BESS containers are a testament to the power of innovation in the energy storage sector. The advanced PCS and BMS technologies integrated into our systems ensure efficient, reliable, and safe operation. As the world transitions towards a cleaner energy future, companies like TLS are paving the way for a more sustainable and resilient grid. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Keywords: #TLS #BESS #Battery Energy Storage System #PCS #Power Conversion System #BMS #Battery Management System #energy storage #renewable energy #grid stability Written by OliverIn industries that deal with hazardous substances, safety and compliance are paramount. When working in Zone 1 & 2 areas, where the risk of explosive atmospheres is present, the choice of equipment becomes critical. This is where specialized laboratory containers, like those manufactured by TLS, offer a vital solution. Understanding Zone 1 & 2 Hazardous Areas Zone 1 & 2 areas are classified based on the frequency and duration of the presence of flammable gases, vapors, or dust.

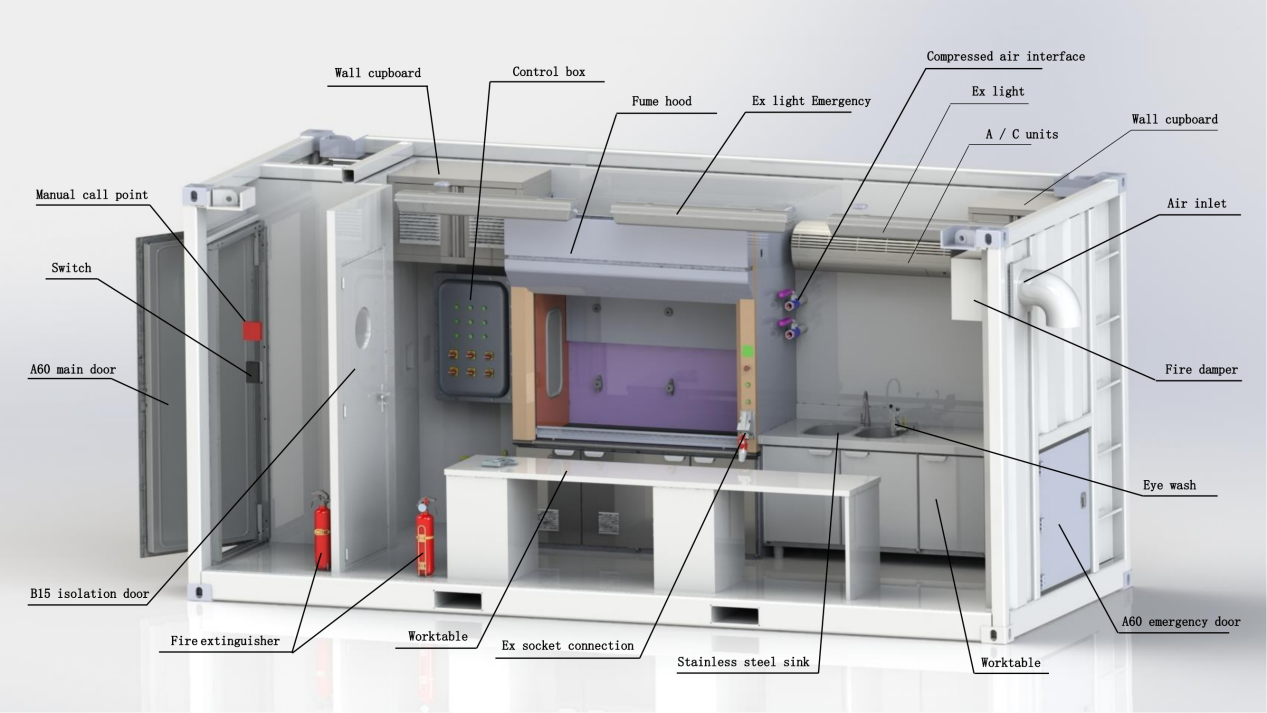

Why Specialized Laboratory Containers are Essential In these hazardous environments, standard laboratory containers are not suitable. The risk of ignition from electrical components or sparks is too high. Specialized containers address these risks by incorporating:

TLS Laboratory Containers: Engineered for Safety and Performance TLS is a leader in the design and manufacture of hazardous area equipment. Their laboratory containers are engineered to meet the stringent safety requirements of Zone 1 & 2 environments. Key Features of TLS Laboratory Containers:

Benefits of Choosing TLS Laboratory Containers:

Who Can Benefit from TLS Laboratory Containers?

Investing in Safety Protecting your personnel and assets is not just a responsibility; it's an investment in the future of your operations. With TLS laboratory containers, you're not just buying equipment; you're investing in a safer, more productive work environment. Let TLS be your partner in navigating the complexities of working in hazardous areas. Contact us today to discuss your laboratory container needs. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #laboratory containers Zone 1 & 2 #hazardous area laboratory containers #explosion-proof laboratory containers #TLS laboratory containers #Zone 1 laboratory #Zone 2 laboratory #laboratory containers for hazardous areas #safety laboratory containers #ATEX laboratory containers #IECEx laboratory containers #modular laboratory containers Written by OliverIntroduction In the world of offshore research and exploration, safety and precision are paramount. Enter TLS's negative pressure offshore lab containers – innovative solutions designed to create controlled environments for scientific work on oil rigs, vessels, and other offshore platforms. In this blog post, we'll delve into the benefits, features, and applications of these cutting-edge containers. The Importance of Negative Pressure in Offshore Labs Negative pressure environments are crucial for:

TLS's Negative Pressure Lab Containers: Setting the Standard TLS is a pioneer in offshore container technology, and their negative pressure lab containers stand out for several reasons:

Applications of TLS Negative Pressure Offshore Lab Containers These versatile containers are ideal for a wide range of offshore applications, including:

The Future of Offshore Research As offshore activities continue to expand, the demand for safe and reliable lab spaces will only grow. TLS is at the forefront of this movement, developing innovative solutions that empower scientists and researchers to push the boundaries of knowledge in challenging environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Keywords: #Negative pressure lab container #Offshore lab container #TLS lab container #Offshore research container #Oil rig lab container #Vessel lab container #Scientific container #Containment container #HEPA filtration container #Customizable lab container Written by OliverIn the dynamic and demanding environment of offshore industries, ensuring the comfort and safety of crew members is paramount. TLS Offshore Containers International understands this necessity and offers superior solutions through its 20ft offshore accommodation containers. These containers are designed to provide a safe, comfortable, and efficient living space for personnel working in challenging offshore conditions. #### Premium Quality and Robust Design TLS Offshore Containers International's 20ft accommodation containers are manufactured to the highest standards, ensuring durability and reliability. Constructed with high-grade materials and advanced engineering techniques, these containers are built to withstand the harshest marine environments. They are fully compliant with international standards, including DNV 2.7-1 / EN 12079, ensuring they meet rigorous safety and quality benchmarks. #### Comfortable and Functional Living Spaces These 20ft offshore accommodation containers are meticulously designed to offer a homely and functional living space. Each container is equipped with essential amenities to ensure the comfort of the crew. The interiors are thoughtfully designed with climate control systems, high-quality insulation, and noise reduction features, creating a conducive living environment. Additionally, these containers are fitted with fire and gas detection systems, ensuring the safety of the occupants. #### Customization and Versatility Understanding the diverse needs of offshore projects, TLS Offshore Containers International offers customization options for their 20ft accommodation containers. Clients can choose from a range of configurations and interior layouts to suit specific requirements. Whether it's a single living quarter, multi-person accommodation, or combined living and workspace, these containers can be tailored to meet various needs. #### Easy Transportation and Installation One of the standout features of the 20ft offshore accommodation containers is their ease of transportation and installation. Designed with portability in mind, these containers can be easily transported to different offshore locations. Their standardized size ensures compatibility with various transportation modes, including shipping, road, and air freight. Moreover, the installation process is streamlined to ensure quick and hassle-free deployment, minimizing downtime and ensuring that the crew can be accommodated promptly. #### Eco-friendly and Sustainable Solutions TLS Offshore Containers International is committed to sustainability and environmental responsibility. The 20ft accommodation containers are designed with energy-efficient systems, reducing the overall carbon footprint. The materials used in construction are selected for their durability and environmental impact, ensuring that these containers are a sustainable choice for offshore accommodation. #### Comprehensive Support and Services Choosing TLS Offshore Containers International means more than just purchasing a product. It means partnering with a company that offers comprehensive support and services. From initial consultation and design to transportation, installation, and maintenance, TLS provides end-to-end solutions to ensure the seamless operation of their accommodation containers. Their dedicated team of experts is always on hand to provide support and address any concerns, ensuring complete customer satisfaction. #### Conclusion The 20ft offshore accommodation containers from TLS Offshore Containers International represent the pinnacle of offshore living solutions. Combining robust construction, comfortable living spaces, customization options, and eco-friendly features, these containers are designed to meet the demanding needs of offshore industries. Trust TLS Offshore Containers International to provide reliable and high-quality accommodation solutions that prioritize the safety and comfort of your crew. Invest in the best with TLS Offshore Containers International and ensure your crew's well-being in any offshore environment. Empowering Energy Storage with TLS Semi-Integrated BESS Containers: The Future of Sustainable Power7/11/2024

Introduction The global shift towards renewable energy sources like solar and wind power is undeniable. However, their intermittent nature demands efficient energy storage solutions. This is where Battery Energy Storage Systems (BESS) play a crucial role. TLS, a leader in container solutions, has taken BESS technology to the next level with their innovative semi-integrated BESS containers. What are Semi-Integrated BESS Containers? Semi-integrated BESS containers combine the enclosure and some of the core components, such as battery racks and air ducts, in a standard container. This approach streamlines installation and reduces on-site integration complexities. TLS's semi-integrated BESS containers are designed for flexibility, allowing customization to meet specific project requirements. Key Advantages of TLS Semi-Integrated BESS Containers

Applications of TLS Semi-Integrated BESS Containers

Why Choose TLS for Your BESS Needs? TLS has a proven track record in delivering high-quality container solutions for various industries. Their commitment to innovation, quality, and customer satisfaction makes them a trusted partner for your BESS projects. With a global reach and a focus on sustainability, TLS is well-positioned to support the transition towards a cleaner, more reliable energy future. Conclusion TLS's semi-integrated BESS containers represent a significant advancement in energy storage technology. Their flexibility, efficiency, and sustainability make them a compelling choice for a wide range of applications. As the world continues to embrace renewable energy sources, BESS technology will play an increasingly critical role. With TLS as your partner, you can be confident that you're investing in a solution that will empower your energy storage needs and contribute to a more sustainable future. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #semi-integrated BESS container #BESS system #TLS BESS container #sustainable energy storage #solar energy storage #wind energy storage #grid stability #lithium-ion battery #energy transition #TLS container solutions Written by OliverIntroduction In the demanding world of oil, gas, and renewable energy industries, reliable Motor Control Centers (MCCs) are the backbone of electrical systems. Ensuring their protection and functionality is paramount, especially in challenging environments. This is where TLS Offshore Containers steps in, offering cutting-edge MCC shelters designed to withstand the harshest conditions while optimizing operational efficiency. What are MCC Shelters? MCC shelters are specialized enclosures designed to house and protect Motor Control Centers, which are essential for controlling and distributing electrical power in industrial settings. These shelters safeguard MCCs from environmental hazards, ensuring the uninterrupted operation of critical processes. Why Choose TLS Offshore Containers' MCC Shelters?

Key Benefits of TLS MCC Shelters:

TLS Offshore Containers: Your Trusted Partner With decades of experience in the offshore industry, TLS Offshore Containers has established a reputation for excellence in engineering and manufacturing. Their commitment to quality, innovation, and customer satisfaction is evident in every MCC shelter they produce. Conclusion In industries where reliability and safety are non-negotiable, TLS Offshore Containers' MCC shelters are the ultimate solution. Their robust construction, customization options, and unwavering commitment to safety make them the preferred choice for protecting critical electrical infrastructure in the harshest conditions. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #TLS Offshore Containers #Offshore MCC shelter #Motor Control Center shelte #Hazardous area shelter #Explosion-proof shelter #Customizable MCC shelter #Oil and gas shelter #Petrochemical shelter #MCC shelter for harsh environments #MCC shelter for harsh environments Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|