|

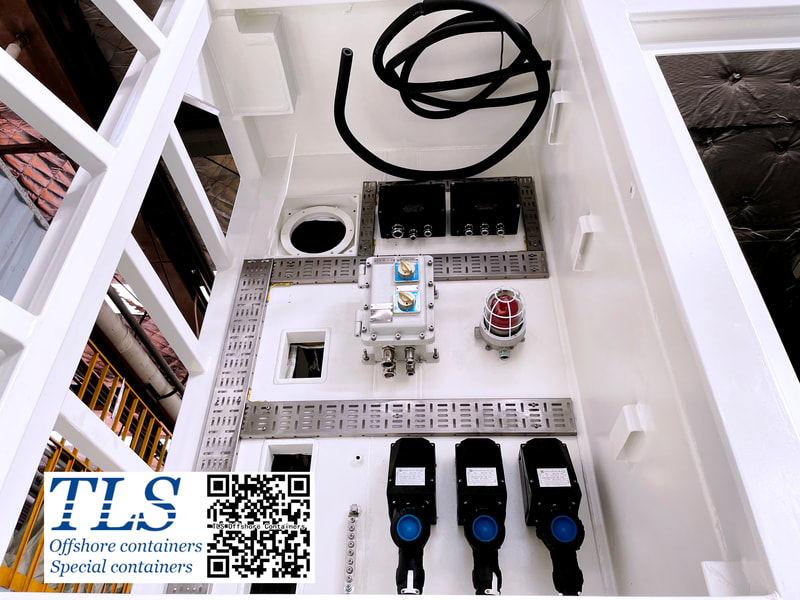

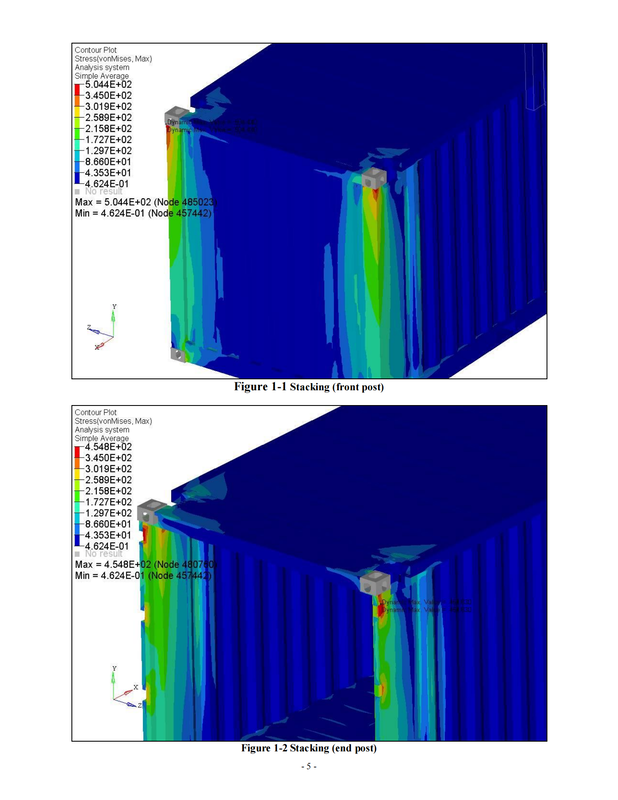

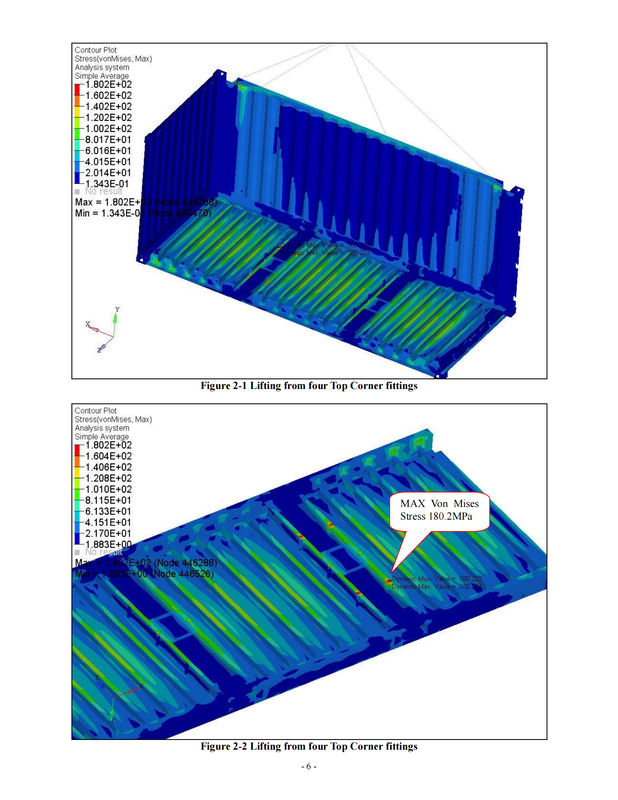

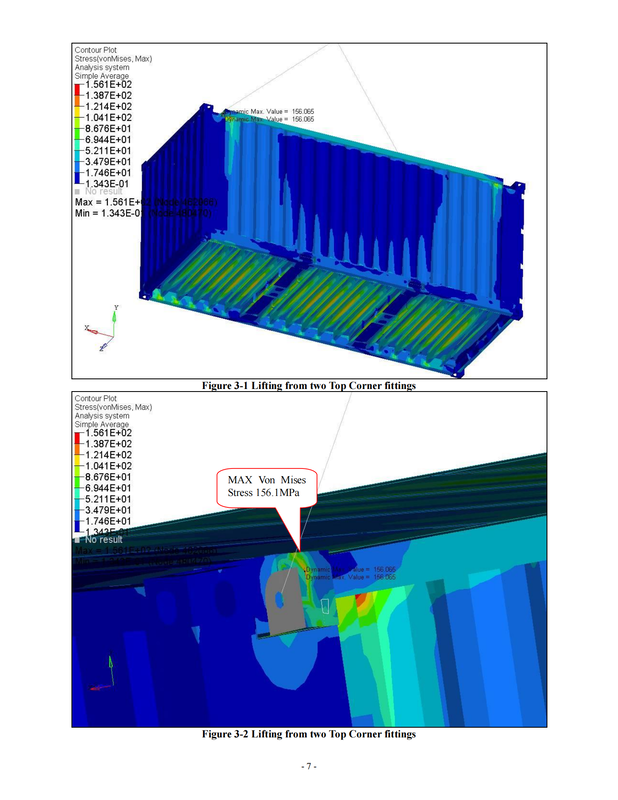

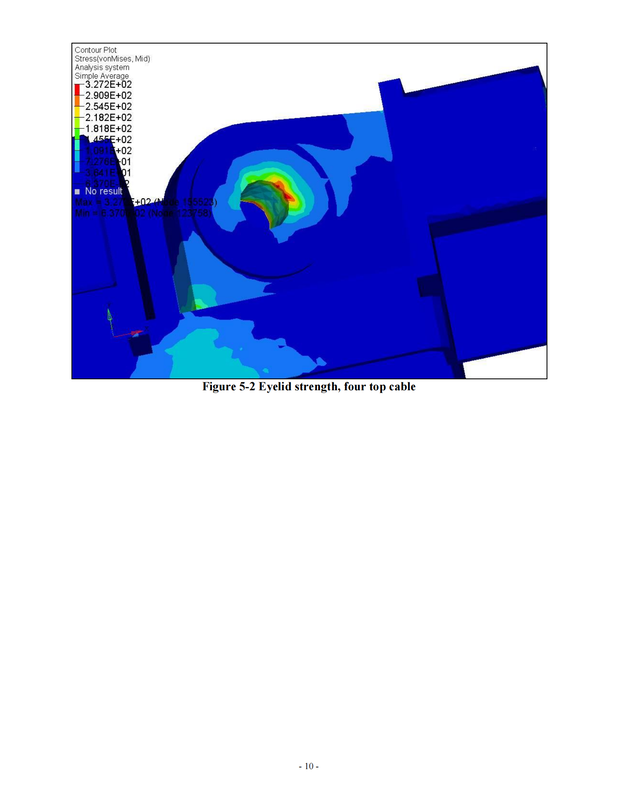

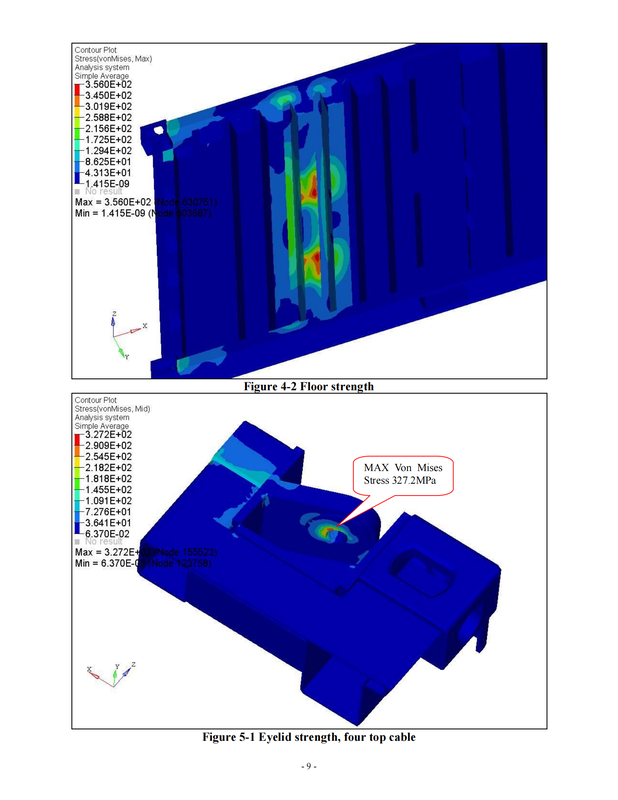

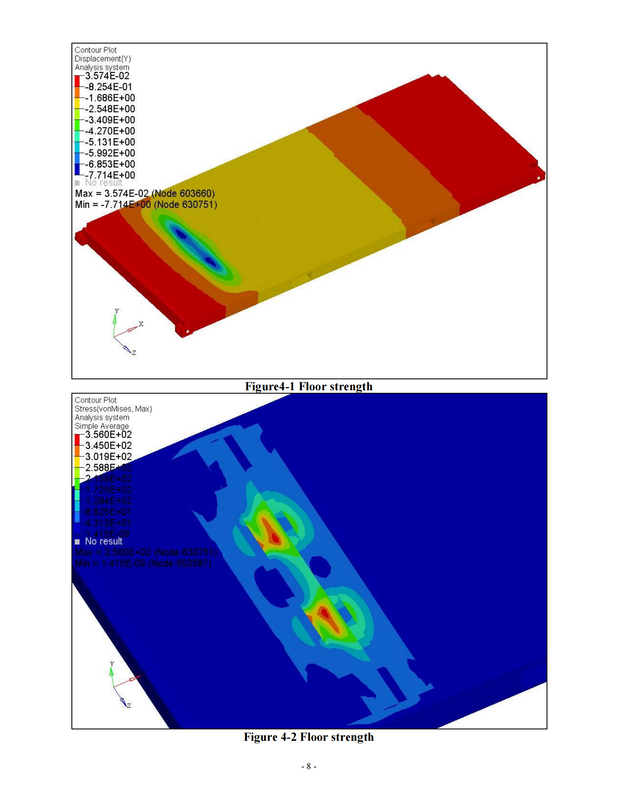

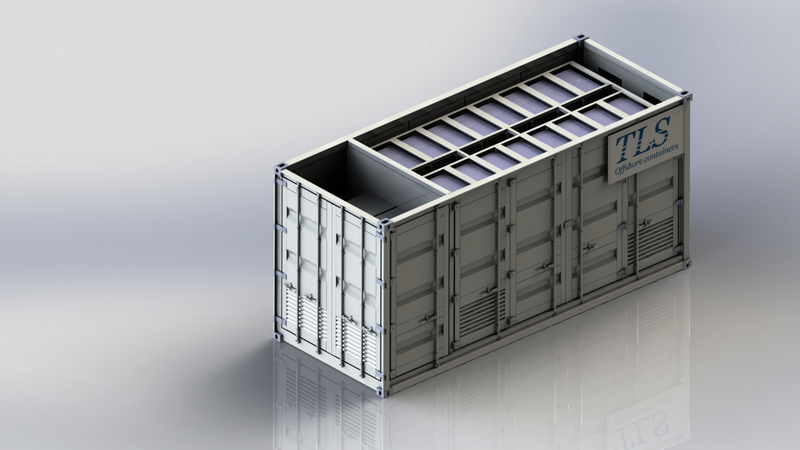

Hazardous environments, such as offshore oil and gas exploration, chemical processing plants, and mining operations, pose a significant risk to the workers in these industries. Explosive gases and substances present a constant danger, making it crucial to ensure the safety of workers in these environments. One company that is leading the way in revolutionizing safety in hazardous industries is TLS Offshore Containers, with positive pressurized ex-proof container. This container is designed to maintain a positive pressure inside, preventing explosive gases or substances from entering the container. It is equipped with an air filtration system that circulates clean, dry air inside the container, ensuring a safe working environment for workers. The importance of TLS Offshore Containers' positive pressurized ex-proof container cannot be overstated. It provides enhanced safety features, such as preventing any spark or ignition source from entering the container and maintaining a positive pressure inside. This makes it a game-changer in the world of industrial safety. The container is also highly customizable, allowing it to be tailored to meet the specific needs of different industries and applications. It can be equipped with various safety features, such as fire suppression systems, gas detection systems, and emergency shut-off systems, ensuring the utmost safety of workers. Positive pressurized ex-proof containers have a wide range of applications in hazardous industries. They are commonly used in offshore oil and gas exploration, chemical processing plants, and mining operations, to provide a safe and secure storage solution for explosive gases and substances. In conclusion, TLS Offshore Containers' positive pressurized ex-proof container is a crucial tool in ensuring the safety of workers in hazardous environments. It provides enhanced safety features, is highly customizable, and has a wide range of applications in various industries. It is a game-changer in the world of industrial safety and is leading the way in revolutionizing safety in hazardous industries. Written by OliverOffshore containers are used in the oil and gas industry to transport equipment, supplies, and materials to offshore platforms and drilling sites. These containers are designed to withstand harsh weather conditions, rough handling during transportation, and high loads during lifting and stacking. TLS Offshore Containers International is a leading provider of offshore container solutions, and their containers undergo rigorous Finite Element Analysis (FEA) structure analysis to ensure their safety and durability. FEA is a computational method that analyzes the behavior of structures under various conditions by dividing the structure into small, interconnected elements. Each element is analyzed individually, and the results are combined to obtain the overall behavior of the structure. FEA is widely used in engineering design and analysis to optimize designs, reduce costs, and improve performance. TLS Offshore Containers International uses FEA to analyze their offshore containers to ensure they meet the strict safety and performance requirements of the oil and gas industry. FEA enables them to evaluate the structural integrity of the containers under various loads, including lifting, stacking, and impact loads. This analysis helps them identify potential weaknesses in the design and make necessary modifications to improve the container's strength and durability. The FEA process starts with creating a 3D model of the container in a computer-aided design (CAD) software. The model includes all the components of the container, such as the frame, walls, roof, floor, and door. The model is then divided into small elements, and the material properties of each element are specified. The loads that the container is expected to experience during transportation and handling are also specified. The FEA software then solves equations based on the specified loads and material properties to calculate the stresses and deformations in each element of the container. These results are combined to obtain the overall stress and deformation of the container. The results are compared to the allowable stress and deformation limits specified by industry standards and regulations, such as DNV 2.7-1, EN 12079, and CSC. If the stress and deformation values are within the allowable limits, the container design is deemed safe and suitable for use. If the values exceed the allowable limits, modifications are made to the design to improve the container's strength and durability. These modifications may include changes to the material properties, thickness, or geometry of the container components. FEA enables TLS Offshore Containers International to optimize their container designs to meet the specific needs of their customers while ensuring their safety and durability. The use of FEA also reduces the need for physical testing, which saves time and costs in the design and development process. Furthermore, FEA allows for rapid iteration of designs, enabling TLS Offshore Containers International to quickly evaluate different design options and choose the most optimal one. In conclusion, FEA is a powerful tool that enables TLS Offshore Containers International to analyze and optimize their offshore container designs for safety and durability. The use of FEA ensures that their containers meet the strict industry standards and regulations and can withstand the harsh conditions of the oil and gas industry. By leveraging FEA, TLS Offshore Containers International can continue to provide innovative and reliable offshore container solutions to their customers. Safe and Comfortable Offshore Accommodation Containers by TLS Offshore Containers International2/27/2023

Offshore accommodation containers made by TLS Offshore Containers International are designed to provide safe and comfortable living and working conditions for offshore and onshore use. These modules are manufactured to meet the highest industry standards, including DNV 2.7-1/EN12079 and A60 fire-rated insulation standards. These standards ensure that the modules are suitable for use in the offshore industry and meet the necessary safety requirements. In addition to meeting safety standards, the offshore accommodation containers are equipped with advanced features that provide comfort and convenience. The modules come with air-conditioning units, lockers, en-suite shower rooms, and high-quality fixtures and fittings. These features provide a comfortable and functional living and working environment for offshore personnel. The offshore accommodation containers are also designed for easy transport and installation. They come equipped with twist locks, pads for deck mounting, and linking kits for structural, mechanical, and architectural linking. These features ensure that the modules can be easily transported and installed on offshore platforms or vessels. TLS Offshore Containers International also offers other offshore module solutions, including FPSO living quarters, meeting rooms, offices, and workshops. These modules are also designed and manufactured to meet the highest industry standards, providing safe and comfortable solutions for offshore personnel. To ensure maximum safety, the offshore accommodation containers are equipped with state-of-the-art technology such as PLC-based fire and gas detection systems. This technology provides an additional layer of safety and ensures that any potential hazards are detected and addressed quickly. In summary, TLS Offshore Containers International provides high-quality offshore module solutions that are designed and manufactured to meet the highest industry standards. Their offshore accommodation containers are equipped with advanced features to provide comfort and convenience and are designed for easy transport and installation. With state-of-the-art safety technology, these modules provide a safe and comfortable living and working environment for offshore personnel. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. Forced air-cooling technology is mature, and air duct design is the key point. The main point of the design of forced air-cooling technology is to control the air duct to change the wind speed: due to the different energy density and capacity of the batteries in the energy storage system, the battery placement and arrangement structure are different, so the air duct inside the energy storage system needs to be customized design. The air duct can control the direction and path of the air flow, and conduct heat exchange on the surface of the basic battery cells by guiding the cold and warm air generated by the air conditioner and the fan into the interior of the battery module. At present, energy storage systems mostly adopt the thermal management scheme of air conditioning + cooling duct air supply. The air duct is mainly divided into serial ventilation and parallel ventilation, and the parallel ventilation has better uniformity. The air duct design includes: the main air duct connected to the outlet of the air conditioner, the wind baffle inside the main air duct, the air duct outlet and the wind baffles at both ends of the battery rack. The main air duct is used to transport the output airflow of the air conditioner to the outlets of each air duct: the windshield in the main air duct can distribute the gas flow of each air duct outlet to ensure that the flow of each outlet is consistent; the windshields at both ends of the battery rack are used to prevent airflow Escape from the gap between the battery rack and the inner wall of the container. The air cooler control system includes air conditioner control and battery module fan control: the air conditioner control determines the cooling and heating by judging the internal temperature of the container, and the battery module fan control can adjust the temperature of a single battery. Written by Mandy The use of Battery Energy Storage Systems (BESS) has become increasingly popular in recent years as a way to store excess renewable energy generated from wind turbines and solar panels. BESS can help to provide a more reliable and stable energy supply, reducing the need for traditional fossil fuel power plants. TLS Offshore Containers, a leading provider of offshore containers and equipment, has designed a BESS solution that can help to meet the growing demand for energy storage. The TLS BESS solution is a modular system that can be easily transported and installed on-site, making it a versatile option for a wide range of applications. The system is designed to be durable and weather-resistant, which ensures it can withstand harsh offshore environments. The BESS modules are also equipped with a battery management system that ensures optimal performance and extends the life of the batteries. One of the key features of the TLS BESS solution is its scalability. The system can be configured to meet the specific energy storage requirements of any project, with the ability to add or remove modules as needed. This flexibility allows the TLS BESS solution to be used in a wide range of applications. In addition to its energy storage capabilities, the TLS BESS solution also offers advanced monitoring and control features. The system can be remotely monitored and controlled using a web-based interface, allowing operators to quickly and easily monitor the system's performance and make any necessary adjustments. This helps to ensure that the system operates at peak efficiency and maximizes the benefits of energy storage. The TLS BESS solution also offers a number of safety features to protect both the system and the surrounding environment. The system is equipped with overcurrent and overvoltage protection, as well as temperature and short-circuit protection. The batteries are also equipped with a fire suppression system that uses a non-toxic, environmentally friendly extinguishing agent. Overall, the Battery Energy Storage System (BESS) designed by TLS Offshore Containers offers a versatile, scalable, and efficient solution for energy storage. The system's advanced features, including its lithium-ion batteries, battery management system, and monitoring and control capabilities, make it a valuable addition to any renewable energy project. With its durable and weather-resistant design, the TLS BESS solution is ideal for use in offshore environments, where reliability and performance are crucial. Written by OliverPressurized containers are a feature product of TLS, these containers are designed to use a positive pressure differential to keep the environment inside the shell safe. It has important applications in many industries, especially in hazardous environments, such as oil and gas industry, chemical processing plants, etc.

Intelligent pressure vessels help ensure the safe and efficient operation of equipment such as MWD/LWD and MCC, providing a reliable and safe environment for these critical components and workers. Written by Mandy Battery Energy Storage System (BESS) containers are a type of energy storage solution that use rechargeable batteries to store and manage energy. These containers are designed to be modular and scalable, allowing them to be easily expanded or downsized based on the specific needs of the energy project. BESS containers typically use lithium-ion batteries, which are known for their high energy density, long lifespan, and low maintenance requirements. The batteries are housed inside a container that is specifically designed to protect them from various environmental factors, such as extreme temperatures, humidity, and physical damage. The container is also equipped with various safety features, such as fire suppression systems and emergency shut-off switches, to ensure the safe and secure storage of energy. One of the main advantages of BESS containers is their flexibility. They can be easily transported and deployed in various locations, making them ideal for energy projects in remote or off-grid areas. They can also be easily integrated with other renewable energy technologies, such as solar panels or wind turbines, to create a comprehensive energy system. BESS containers are also highly efficient and cost-effective. They can be used to store energy during off-peak hours when energy prices are lower, and then release it during peak demand periods when prices are higher. This can help to reduce overall energy costs for consumers and increase energy affordability. In addition to their use in renewable energy projects, BESS containers can also be used in various other applications, such as backup power for critical infrastructure, emergency response, and electric vehicle charging stations. Overall, BESS containers are a versatile and effective solution for energy storage and management. As the demand for renewable energy continues to grow, the use of BESS containers is likely to become increasingly widespread as organizations seek to reduce their environmental footprint and transition to cleaner energy sources. Efficient On-Site Workstations: The Workshop Container designed by TLS Offshore Containers2/23/2023

The Workshop Container is designed to be a self-contained workspace that can be deployed quickly and easily, even in remote or challenging environments. The container is constructed from high-quality steel and features a weatherproof and fire-resistant design, ensuring that equipment and personnel are protected from the elements and potential hazards. Inside the container, there is ample space for workstations, tools, and equipment, as well as storage for materials and supplies. The Workshop Container can be customized to meet the specific needs of each customer, with options for lighting, ventilation, electrical outlets, and other features. One of the key advantages of the Workshop Container is its mobility. The container can be easily transported to different job sites, and its compact design allows it to be maneuvered into tight spaces or difficult terrain. This makes it an ideal solution for industries such as construction, oil and gas, mining, and renewable energy. In addition to its mobility, the Workshop Container is also designed for ease of use. The container can be set up and taken down quickly, and its modular design allows for easy expansion or customization as needed. The Workshop Container is also built to last, with a rugged and durable design that can withstand the demands of heavy use and harsh conditions. TLS Offshore Containers also places a strong emphasis on safety and environmental responsibility in their designs. The Workshop Container features multiple safety features, including fire suppression systems and emergency lighting, to ensure that personnel are protected at all times. The container is also designed to be environmentally friendly, with options for solar power and energy-efficient lighting to reduce its carbon footprint. Overall, the Workshop Container designed by TLS is a versatile and durable solution for on-site workstations and storage. Its mobility, ease of use, and safety features make it an ideal choice for a wide range of industries and applications. Written by OliverMarine energy storage container is a kind of equipment that uses energy storage technology to realize the power supply of ships and can also be used as an emergency backup power supply. It is an emerging technology in the shipping industry that can provide sustainable, clean energy solutions for ships. Its advantages are as follows:

Written by Mandy Offshore workshop containers are specialized containers used in offshore oil and gas operations for conducting maintenance, repair, and other workshop-related activities. These containers are designed to be durable and withstand the harsh offshore environment. TLS is a leading manufacturer of offshore containers and provides a range of offshore containers that meet various industry standards. The offshore workshop containers made by TLS are designed to comply with DNV2.7-1 standard, which is the international standard for offshore containers. The offshore workshop containers for Halliburton made by TLS are equipped with various features such as a lifting crane, workbench tables, air-conditioner, ex-proof control panels, ex-proof electric sockets, vices, etc. These containers are specifically designed to meet the needs of Halliburton, which is a leading provider of oilfield services to the energy industry. Halliburton operates in more than 70 countries and offers a range of services such as drilling, cementing, well completion, and production optimization. TLS Offshore Containers Int. is a leading manufacturer of offshore containers and offers a wide range of container solutions for various industries such as oil and gas, and renewable energy. TLS is committed to providing high-quality and reliable offshore containers that meet the industry's stringent safety and quality standards. TLS is an ISO 9001 certified company and ensures that its products are designed and manufactured to the highest standards. In summary, the offshore workshop containers for Halliburton made by TLS are designed to meet the specific needs of the offshore oil and gas industry. These containers are equipped with various features that are essential for conducting maintenance and repair activities in the offshore environment. TLS is a leading manufacturer of offshore containers and ensures that its products meet the highest safety and quality standards. Halliburton is a leading provider of oilfield services and operates in more than 70 countries.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|