|

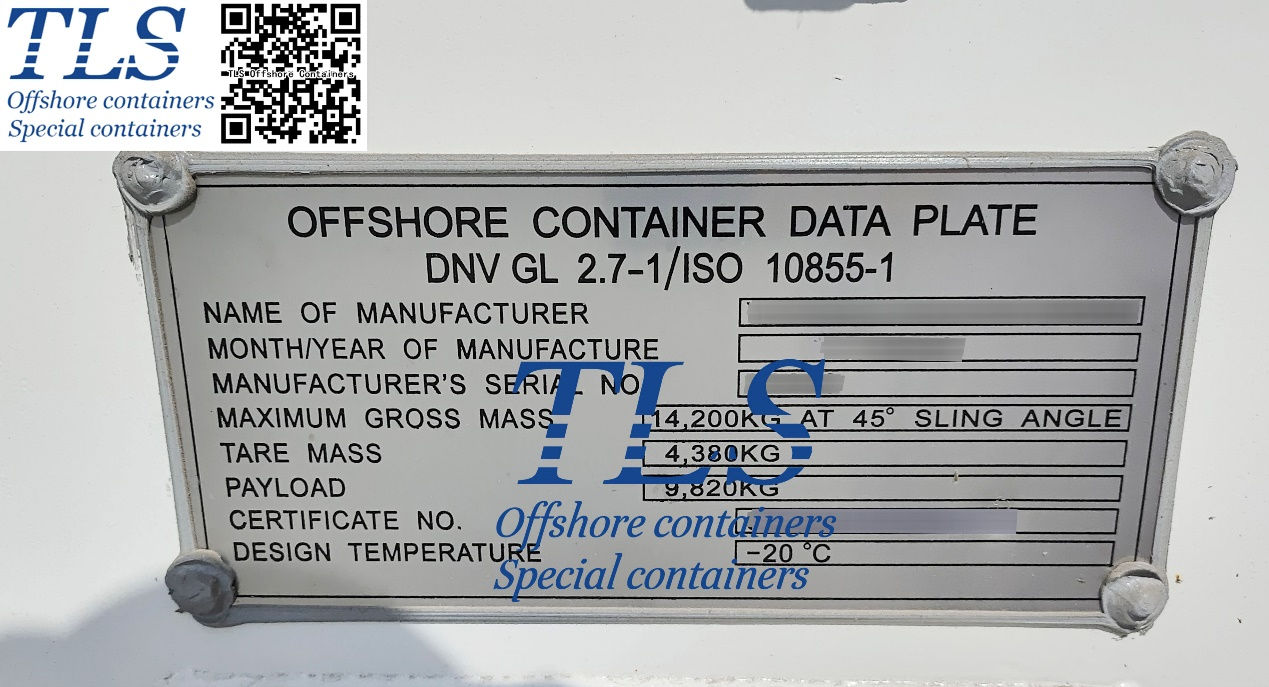

In the realm of offshore operations, safety and efficiency are paramount. One critical aspect that significantly contributes to these factors is the use of certified offshore containers. Among these, the DNV 2.7-1 standard stands out as a benchmark for quality and reliability. In this blog, we'll delve into what DNV 2.7-1 containers are, why they are essential, and how they enhance offshore operations. What is a DNV 2.7-1 Container? DNV 2.7-1 is a standard set by Det Norske Veritas (DNV), a leading international certification body. This standard specifically addresses the design, manufacturing, and certification of offshore containers. An offshore container is any portable unit, used for the transport and storage of goods and equipment, that is frequently handled in open seas and harsh environments. The DNV 2.7-1 standard ensures that these containers can withstand the extreme conditions encountered offshore, including rough handling, high winds, and corrosive saltwater. To meet this standard, containers must pass rigorous tests for structural integrity, safety, and durability. Key Features of DNV 2.7-1 Containers

Benefits of Using DNV 2.7-1 Containers in Offshore Operations

Applications of DNV 2.7-1 Containers

Conclusion The adoption of DNV 2.7-1 containers in offshore operations is a testament to the industry's commitment to safety, efficiency, and regulatory compliance. By investing in these high-quality, certified containers, offshore operators can ensure the protection of their personnel, equipment, and the environment, while also optimizing their operational processes. Whether for transporting goods, storing hazardous materials, or providing temporary living spaces, DNV 2.7-1 containers are the gold standard in offshore container solutions. As the offshore industry continues to evolve, the reliance on robust and certified containers will only grow, making DNV 2.7-1 an indispensable part of modern marine operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Key words: #DNV 2.7-1 containers #Offshore containers #Marine operations safety #Durable offshore containers #Marine container safety #Compliance #Offshore storage solutions #Hazardous materials storage offshore #Safety in offshore operations #Regulatory compliance offshore containers Written by OliverMovable container modules are becoming more and more popular in both offshore and onshore work areas. Because of its mobility, security, customizability, durability and cost-effectiveness, it can better meet people's needs.

Take the workshop container as an example.

This type of container workshop is windproof, waterproof and fireproof, has good sealing, can be easily transferred, and is easy to install. As a tool workshop| storage container workshop, it is cost-effective and provides more convenience for work and life. Any related needs, please feel free to contact us. What is negative pressure? When the exhaust air volume in the space is greater than the air intake volume, the space is in a negative pressure state, the air outside flows into the interior and is discharged through the exhaust outlet for centralized treatment. When to choose negative pressure? When the external environment is safe, but toxic and harmful gases are generated inside, negative pressure is preferred.

NEGATIVELY PRESSURISED CONTAINERS PROVIDED BY TLS

TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions.

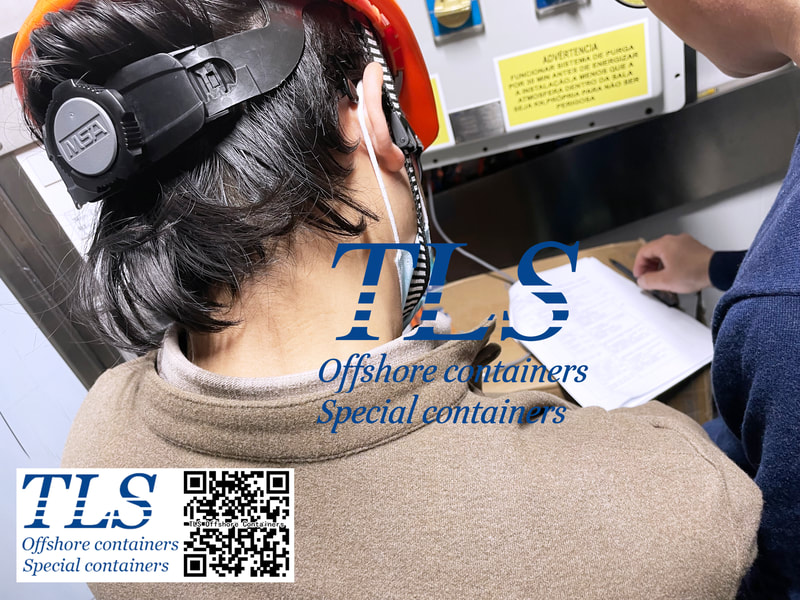

Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #pressurised #ATEX #IECEx #offshore CARBIN #workshop container #TLS #EX-proof #CPFG #air blower fan #Laboratory container #TLS offshore This is a positive pressure explosion-proof, fire grade A60 laboratory container, which can be used from -25 ℃ to +50℃, with good sealing, rain resistance, sand resistance, suitable for land oil exploration and offshore oil exploration in hazardous areas and desert areas. The design and construction meet the IEC60079-13 2010 specification, DNV2.7-1 and SOLAS 2009. Explosion-proof appliances meet the CNEX or ATEX explosion-proof standards. The positive pressure test container is integrated with CPFG control cabinet, positive pressure air path system, explosion-proof centrifugal air unit, safe power supply system, fire alarm system, lighting system, alarm system, explosion-proof air conditioner, air valve control system and explosion-proof isolation switch box. In order to meet the various conditions for the products to be used in Petrobras, TLS insists on strictly controlling the quality of the products in every step, from preprocessing of sheet and section steel to welding and assembly, from painting and decoration to debugging and installation, from label and decal to cleaning and packing. In addition to professional certification certificates, professional detection methods, real and convincing data and several measured operation results are the quality assurance that TLS believes should be provided to customers. TLS is an international company that can customize onshore | offshore special containers for you. Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #Petrobras #brazil #oil & #offshore standard #brazil oil #pressurised container #laboratory container #IEC60079-13 #DNV2.7-1 #CNEX #TLS offshore containers TLS pressurised laboratory container brochure can be downloaded here. Key words: #DNV #BV #DNV2.7-1 #ESS #BESS #A60 fire rating #explosion-proof #LAB # workshop container #TLS offshore containers #laboratory container Key words: #pressurised container #ATEX #IECEx #offshore container #workshop container #TLS #explosion-proof #CPFG #air blower fan #Laboratory container #TLS offshore containers Customized offshore container module | workshop container is ready for shipment. Before the shipment, we carry out a system check to ensure that the equipment is in good condition when it arrives at the customer. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|