|

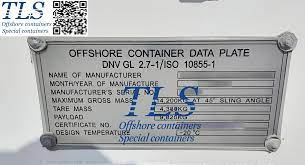

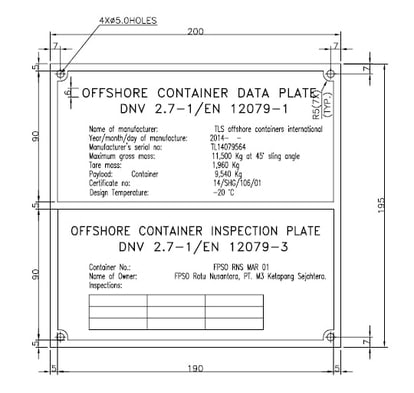

In the dynamic landscape of offshore and onshore operations, the demand for robust, reliable, and safe storage solutions is paramount. TLS Offshore Containers leads the forefront in this sector, offering a cutting-edge solution with its pressurized containers. Engineered to meet the rigorous demands of various industries, these containers set a new standard in safety, efficiency, and durability. ### What are Pressurized Containers? Pressurized containers are specialized storage units designed to hold gases or liquids at a higher pressure than the ambient atmosphere. These are critical in industries like oil and gas, chemicals, and pharmaceuticals, where controlling the pressure of stored substances is essential for safety and quality control. ### The TLS Advantage TLS Offshore Containers stands out in the manufacturing of pressurized containers, boasting full advanced production lines dedicated to these units. This not only underscores our commitment to excellence but also ensures that every container meets the highest standards of quality and safety. #### Cutting-Edge Technology Our state-of-the-art production lines are equipped with the latest in manufacturing technology. This allows for precision engineering of containers that can withstand extreme pressures, ensuring the safe storage and transport of sensitive materials. #### Customization and Compliance Understanding the diverse needs of our clients, TLS offers customizable pressurized containers. Whether it's varying sizes, pressure ratings, or specific fittings and features, we tailor solutions to meet precise requirements. Additionally, all containers are designed and manufactured in compliance with international standards, including DNV 2.7-1, EN12079, and ISO standards, ensuring global operability and acceptance. #### Safety and Durability At TLS, safety is paramount. Our pressurized containers are subjected to rigorous testing and quality checks to ensure they offer maximum protection against leaks, bursts, and other potential hazards. The use of high-grade materials and advanced welding techniques further enhances their durability, offering an extended service life even in the harshest environments. #### Eco-friendly Solutions In line with our commitment to sustainability, TLS pressurized containers are designed with eco-friendliness in mind. By ensuring efficient use of resources and minimizing emissions during production, we contribute to a healthier planet. ### Industries Served TLS pressurized containers are versatile and find applications across a wide range of industries, including: - **Oil and Gas:** For the safe transport and storage of hydrocarbons and chemicals. - **Chemicals:** Ideal for handling pressurized chemical compounds. - **Pharmaceuticals:** Ensuring the integrity of pressurized medicinal gases. - **Energy:** For hydrogen storage and transport in renewable energy projects. With advanced production lines and a relentless focus on quality, TLS Offshore Containers is at the vanguard of pressurized container manufacturing. Our dedication to innovation, safety, and environmental stewardship makes us the preferred choice for businesses seeking reliable and efficient pressurized storage solutions. Explore how TLS can support your operational needs and drive success through superior container solutions. More information about offshore pressurised container/cabin Don’t hesitate to contact us for more information about the offshore pressurised container. Our skilled engineers are eager to explain the possibilities for your applications. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Are you seeking top-tier offshore accommodation solutions that prioritize safety, comfort, and functionality? Look no further than TLS – your trusted partner in offshore shelter manufacturing. Our state-of-the-art accommodation shelters are meticulously crafted to meet the stringent standards of DNV2.7-1/EN 12079 and ABS, ensuring unparalleled quality and reliability in every unit. Setting New Standards in Offshore Living: TLS takes pride in revolutionizing offshore living with our innovative accommodation shelters. Here's why our shelters stand out:

Experience Unrivaled Comfort with TLS: At TLS, we understand the importance of comfortable and safe living spaces in offshore operations. With our cutting-edge accommodation shelters, we redefine offshore living, offering unmatched comfort, convenience, and peace of mind. Elevate your offshore experience with TLS – where excellence meets innovation in every shelter we produce. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. Key words: #Offshore accommodation #Offshore shelter #Offshore living quarters #Modular accommodation #Accommodation units #DNV certified shelters #ABS approved accommodation #Offshore safety standards #Customizable accommodation #Offshore construction shelters #Offshore workforce housing #Offshore accommodation solutions Written by OliverIntroduction: Battery Energy Storage Systems (BESS) have emerged as vital components in modern energy infrastructure, facilitating renewable energy integration, grid stabilization, and ensuring reliable power supply. Within the BESS container, every component plays a crucial role, and one such component often overlooked is the Bus-bar. In this blog, we delve into the significance of Bus-bars in BESS containers and how they contribute to optimizing energy storage efficiency. Understanding Bus-bars: Bus-bars are metallic strips or bars used to conduct and distribute electrical currents within electrical equipment, such as BESS containers. In the context of BESS, Bus-bars serve as the backbone of the electrical system, connecting various components like batteries, inverters, and transformers. Their primary function is to efficiently transmit high currents with minimal power loss, ensuring the smooth operation of the energy storage system. Importance of Bus-bars in BESS Containers:

Optimizing Bus-bar Design for Enhanced Performance:

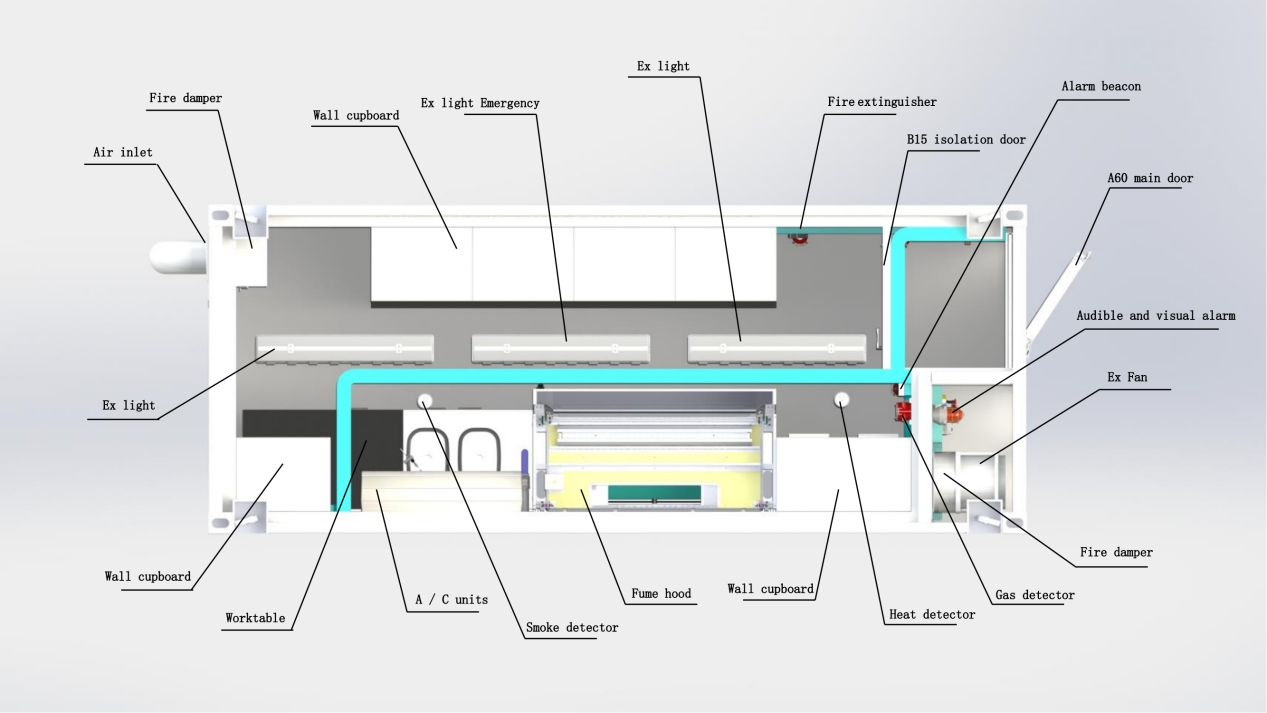

Conclusion: In the realm of Battery Energy Storage Systems, Bus-bars play a critical role in ensuring efficient energy transmission, heat dissipation, and system reliability within the container. Understanding the importance of Bus-bars and implementing optimized design practices can significantly enhance the performance, longevity, and cost-effectiveness of BESS installations. As the demand for energy storage continues to grow, investing in high-quality Bus-bar solutions becomes imperative for maximizing the efficiency and sustainability of modern energy infrastructure. By prioritizing Bus-bar optimization in BESS container design and deployment, stakeholders can unlock the full potential of energy storage technologies, paving the way for a cleaner, more resilient energy future. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #Bus-bar design for BESS #Electrical components #Bus-bar optimization techniques #BESS container electrical efficiency #Bus-bar materials #Current distribution in BESS systems #Voltage drop reduction in BESS containers #Bus-bar scalability and flexibility #Thermal management #Bus-bar insulation and protection #Optimizing bus-bars for BESS performance Written by OliverIn the dynamic realm of offshore operations, safety and efficiency are paramount concerns. As industries push the boundaries of exploration and research, the need for reliable infrastructure, including laboratory facilities, becomes increasingly crucial. Enter TLS, a pioneer in offshore container solutions, offering cutting-edge technology to meet diverse industry needs. Among TLS's innovations is the offshore lab container, fortified with advanced ventilation systems, particularly the fume hood, ensuring a safe and productive working environment even in the most challenging offshore conditions. Understanding Offshore Lab Containers Offshore lab containers are bespoke units designed to provide on-site laboratory capabilities in remote offshore locations. These containers serve a diverse range of industries, including oil and gas exploration, environmental research, and marine biology, among others. Their compact yet comprehensive design allows for the execution of critical tests, experiments, and analyses without the need for extensive onshore facilities. The Crucial Role of Ventilation Systems Within the confined space of offshore lab containers, effective ventilation is imperative. Proper ventilation not only ensures the comfort of personnel but, more importantly, mitigates the risks associated with hazardous fumes, chemicals, and contaminants commonly found in laboratory settings. TLS understands this necessity and has engineered a ventilation system tailored to the specific challenges of offshore environments. Introducing the Fume Hood At the heart of TLS's ventilation system is the fume hood—a sophisticated apparatus designed to contain and remove harmful airborne substances generated during laboratory procedures. The fume hood operates on the principle of negative pressure, wherein air is drawn into the unit, capturing contaminants, and then safely vented outside the container. Key Features and Benefits

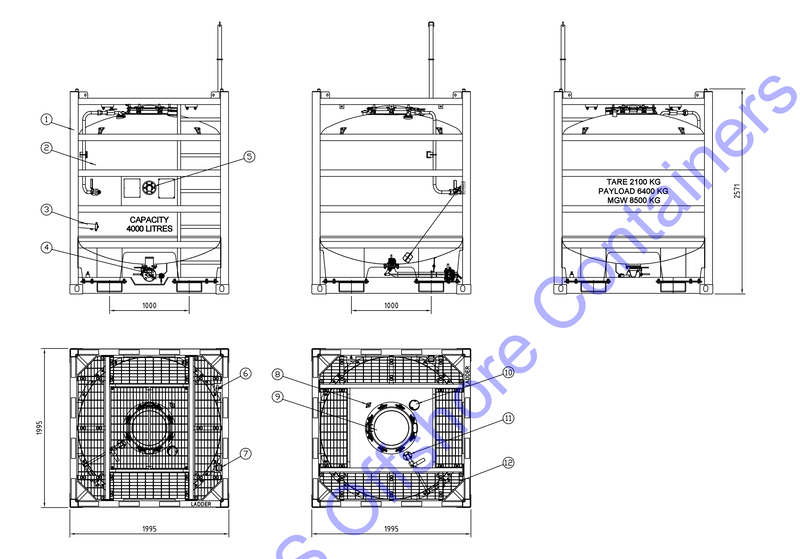

Conclusion In the fast-paced world of offshore industries, safety and efficiency are non-negotiable. TLS's offshore lab containers, featuring state-of-the-art ventilation systems centered around the innovative fume hood, represent the pinnacle of engineering excellence and dedication to excellence. By prioritizing the well-being of personnel and the integrity of operations, TLS continues to redefine standards and inspire confidence in offshore endeavors worldwide. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Offshore lab containers #Ventilation systems #Fume hood #Offshore safety #Environmental safety #Offshore operations #Industrial ventilation #Offshore exploration #Laboratory containers #Ventilation technology #Airflow optimization Written by OliverIn the ever-evolving landscape of chemical and aviation fuel storage, the quest for tanks that offer unmatched safety, durability, and compliance with international standards has led to significant innovations. At the forefront of this revolution are transportable chemical and aviation fuel tanks, engineered to meet the rigorous demands of the industry while ensuring environmental protection and operational efficiency. #### Designed for Compliance and Versatility Our transportable offshore tanks are meticulously crafted in compliance with the most stringent international standards, including the International Maritime Dangerous Goods Code (IMDG), the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR), DNV 2.7-1, EN12079, and BS7072. This adherence guarantees the highest levels of safety and reliability for the transportation and storage of hazardous materials. The versatility of our tank lineup is unparalleled, catering to a wide range of products and capacities. From stainless steel tanks available in 1400 to a whopping 520,000-liter capacities, to specialized designs like vertical, horizontal, and compact tanks, as well as lined tanks for corrosive or acidic substances, we have a solution for every need. #### Innovative Features for Enhanced Usability Ease of handling and operational efficiency are at the core of our design philosophy. Our tanks are engineered for easy maneuverability with forklifts or cranes, and most models are stackable, maximizing storage space without compromising safety. Access to critical components like the vent valve is designed for ground level, simplifying operations and maintenance tasks. A three-stage closure system is standard on outlet assemblies, ensuring secure containment of contents. For monitoring and quality assurance, a sample take-off point is integrated, making it effortless to sample contents without exposing personnel to hazardous materials. The 460mm swing bolt-type manlid further facilitates easy inspection and cleaning, promoting longevity and hygiene. #### Setting New Standards in Chemical and Aviation Fuel Storage The evolution of chemical and aviation fuel storage demands solutions that not only meet current safety and environmental standards but also anticipate the future needs of the industry. Our transportable chemical and aviation fuel tanks represent the pinnacle of this innovation, offering unparalleled safety, efficiency, and versatility. Embrace the future of storage with tanks designed to exceed expectations and propel your operations to new heights of success. In the relentless pursuit of offshore safety and efficiency, TLS Offshore Containers emerges as a beacon of reliability and innovation. Central to their arsenal of offerings are Positive Pressurised Containers, meticulously crafted to mitigate risks and ensure a secure environment in the most challenging offshore conditions. Let's delve deeper into the features and applications of TLS Positive Pressurised Containers, and how they elevate offshore safety to unprecedented levels. ### Understanding Positive Pressurised Containers Positive Pressurised Containers are the backbone of offshore safety, engineered to maintain internal pressure higher than the surrounding environment. This critical differential acts as a barrier against the ingress of explosive gases, safeguarding both personnel and sensitive equipment. TLS Positive Pressurised Containers stand out for their robust construction, advanced safety features, and compliance with rigorous industry standards. ### Advanced Safety Features 1. **Fire and Gas Detection Systems:** TLS Positive Pressurised Containers are equipped with cutting-edge fire and gas detection systems, providing early warning alerts to swiftly mitigate potential hazards. 2. **Compliance with Industry Standards:** These containers adhere to stringent safety standards such as ATEX, IECEx, and NFPA, ensuring optimal performance and reliability. 3. **Durable Construction:** Built to withstand the harsh offshore environment, TLS containers are constructed with high-quality materials to ensure long-term durability and resilience. 4. **Continuous Pressure Monitoring:** TLS containers feature continuous pressure monitoring systems, ensuring optimal pressure levels are maintained at all times. ### Applications Across Offshore Ventures TLS Positive Pressurised Containers find versatile applications across a spectrum of offshore operations: 1. **MUD Logging Units:** Vital for monitoring and analyzing drilling fluids, TLS containers provide a safe environment for critical well integrity assessments. 2. **Living Quarters:** TLS containers offer secure and comfortable living spaces for offshore personnel, fostering morale and well-being during extended offshore stays. 3. **Laboratories:** Ideal for safe sample handling and analysis in hazardous environments, TLS containers support essential research and data collection efforts. ### Elevating Offshore Safety and Efficiency With TLS Positive Pressurised Containers, offshore operators experience a seamless blend of safety, reliability, and efficiency. These containers not only protect personnel and equipment but also empower operators to maximize productivity and achieve operational excellence in challenging offshore environments. ### A Testament to Reliability and Excellence Backed by years of industry expertise and a proven track record, TLS Offshore Containers has earned the trust of offshore operators worldwide. Their Positive Pressurised Containers are a testament to reliability, delivering on the promise of safety and performance in the most demanding offshore conditions. ### Partnering for a Secure Future In the ever-evolving landscape of offshore operations, TLS Offshore Containers stands as a trusted partner, dedicated to enhancing safety, reliability, and efficiency. By leveraging the advanced features and unmatched performance of TLS Positive Pressurised Containers, offshore ventures can navigate hazardous environments with confidence, knowing that TLS has their safety and success at heart. For more information on TLS Positive Pressurised Containers and how they can elevate your offshore operations, visit [TLS Offshore Containers](https://www.tls-containers.com/pressurised-container.html). Maximizing Efficiency and Safety in Energy Storage: The Crucial Role of Thermal Management3/27/2024

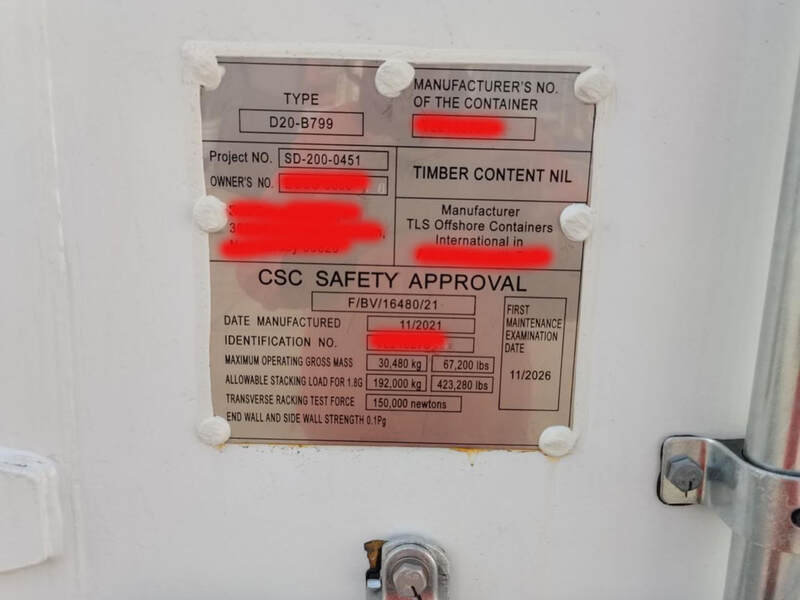

In the quest for sustainable development and meeting the escalating demands for energy, the innovation and research in energy storage technology have taken center stage in the new energy sector. Notably, Battery Energy Storage Systems (BESS) stand out for their high efficiency, renewable nature, and environmental benefits. Yet, the performance and longevity of energy storage solutions, including lithium-ion, lead-acid, and cutting-edge solid-state batteries, are significantly impacted by temperature. This highlights the indispensable need for proficient thermal management within energy storage systems. Understanding the Need for Thermal Management in Energy Storage Energy storage devices undergo thermal fluctuations during the charging and discharging cycles, generating heat that, if not effectively dissipated, can elevate battery temperatures to detrimental levels. Such scenarios not only degrade battery performance but also elevate the risk of thermal runaway, fires, or explosions. Implementing robust thermal management practices ensures batteries operate within their optimal temperature range, enhancing energy utilization, extending service life, and mitigating potential safety hazards. Mechanisms of Thermal Management in Energy Storage A comprehensive thermal management system encompasses thermal sensors, cooling systems (leveraging either liquid or gas mediums), heat exchangers, and control units, among other components: - **Sensors** play a pivotal role in monitoring individual cell temperatures within the battery pack, feeding real-time data to the control unit for optimal thermal regulation. - **Cooling Mediums** are selected based on their thermal conductivity, safety, and cost-effectiveness, with air cooling, liquid cooling (such as water/glycol mixtures), and phase change materials being prevalent choices. - **Heat Exchangers** facilitate the transfer of heat from the batteries to the cooling medium, ensuring rapid and efficient heat dissipation. - **Control Units** dynamically adjust cooling system operations based on sensor data, maintaining battery operations within the ideal temperature range for maximum efficiency and safety. The Significance of Optimal Temperature Regulation The optimal temperature range for the majority of batteries is approximately 20°C to 25°C, albeit with variations across different types and manufacturers. Within this thermal window, batteries can achieve peak performance, characterized by stable and uniform chemical reactions, low self-discharge rates, and thereby, high energy efficiency and extended lifespan. Thermal Management Technologies: Passive vs. Active Cooling - **Passive Cooling Technologies** rely on natural heat dissipation processes, such as conduction, radiation, and convection, without external energy input. Insulating materials and heat sinks are commonly utilized to achieve passive cooling. - **Active Cooling Technologies** enhance heat removal through external energy sources, including fans and liquid pumps, offering a more controlled temperature management solution, especially under conditions of high operational loads or ambient temperatures. Environmental and Cost Implications of Thermal Management Systems Efficient thermal management systems not only curb energy loss attributable to excessive heat but also boost the overall energy efficiency of storage systems. This leads to reduced maintenance and replacement expenses, prolongs battery lifespan, and minimizes waste, contributing to environmental sustainability. Additionally, the integration of energy-efficient and sustainable materials in thermal management designs emphasizes a commitment to eco-friendly practices. By advancing thermal management techniques, the energy storage sector can significantly improve the performance, safety, and environmental footprint of battery systems, marking a pivotal step toward achieving a sustainable energy future. A Battery Management System (BMS) is a technology dedicated to supervising a battery pack, a configuration of battery cells organized in a matrix of rows and columns for electrical arrangement. This setup enables the provision of a target range of voltage and current over a period for anticipated load situations. The supervision offered by a BMS typically includes: - Monitoring the entire battery pack - Providing battery protection - Estimating the battery's operational state - Continuously optimizing battery performance - Reporting operational status to external devices however, monitoring and control functions specifically apply to individual cells or groups within the battery pack, known as modules. Lithium-ion rechargeable batteries, known for their high energy density, are the standard choice for battery packs in a wide range of consumer goods from laptops to electric vehicles. While they perform excellently, lithium-ion batteries can be unforgiving if operated outside their typically stringent Safety Operating Area (SOA), with consequences ranging from degraded battery performance to outright dangerous outcomes. The job description of a BMS undoubtedly presents challenges, with its overall complexity and supervision scope potentially involving multiple disciplines such as electrical, digital, control, thermal, and hydraulic engineering. How Does a Battery Management System Work? There is no fixed or unique standard that a Battery Management System must adhere to. The technical design scope and features implemented are typically related to: - The battery pack's cost, complexity, and size - The application of the battery and any concerns regarding safety, lifespan, and warranty - Certification requirements of various governmental regulations, where the costs and penalties are crucial if functional safety measures are not in place BMS designs encompass many functionalities, with battery pack protection management and capacity management being two fundamental aspects. This article discusses how these two functionalities work. Battery pack protection management covers two key areas: electrical protection, which means preventing damage to the battery by not allowing it to be used outside of its SOA, and thermal protection, which involves passive and/or active temperature control to maintain or bring the battery pack into the SOA. Types of Battery Management Systems Battery Management Systems vary from simple to complex and can adopt different technologies to fulfill their primary directive of “caring for the battery.” However, these systems can be categorized based on their topology, which relates to how they are installed and operate across the battery or modules within the entire battery pack. The Importance of Battery Management Systems In BMS, functional safety is paramount. Preventing any battery or module under supervision control from exceeding specified SOA limits for voltage, current, and temperature during charging and discharging operations is crucial. Exceeding these limits for any length of time can not only affect the potentially expensive battery pack but may also result in dangerous thermal runaway conditions. Furthermore, for the protection of lithium-ion batteries and functional safety, lower voltage threshold limits are strictly monitored. If lithium-ion batteries remain in such a low voltage state, copper dendrites may eventually grow on the anode, which can increase the self-discharge rate and pose potential safety issues. The high energy density of lithium-ion power systems comes with the cost of having virtually no room for errors in battery management. Thanks to BMS and improvements in lithium-ion batteries, it is one of the most successful and safest battery chemistries available today. Benefits of a Battery Management System A complete battery energy storage system, often referred to as BESS, can be composed of dozens, hundreds, or even thousands of lithium-ion batteries strategically assembled together, depending on the application. The rated voltage of these systems may be less than 100V but can go up to 800V, with battery pack supply currents ranging up to 300A or more. Any mismanagement of high-voltage battery packs could lead to life-threatening catastrophic disasters. Therefore, a BMS is crucial for ensuring safe operation. The benefits of a BMS can be summarized as follows: - Functional Safety: Particularly prudent and necessary for large-sized lithium-ion battery packs. However, it's well-known that even smaller formats used in laptops can catch fire and cause immense destruction. There's virtually no room for battery management errors regarding the personal safety of users of products containing lithium-ion power systems. - Lifespan and Reliability: Battery pack protection management, both electrical and thermal, ensures that all batteries are used within the declared SOA requirements. This delicate supervision ensures the safe use of batteries through rapid charging and discharging cycles, inevitably producing a stable system capable of providing years of reliable service. - Performance and Range: BMS battery pack capacity management, where inter-battery balancing is employed to equalize the SOC across adjacent cells in the battery pack component, allows for optimal battery capacity. Without this BMS functionality to account for variations in self-discharge, charging/discharging cycles, temperature effects, and general aging, the battery pack could ultimately become useless. - Diagnostics, Data Collection, and External Communication: The supervisory task includes continuous monitoring of all battery units, where data logging itself can be used for diagnostics but is usually employed for computing tasks to predict the SOC across all batteries in the component. This information is used for balancing algorithms but can also be forwarded to external devices and displays to indicate the available residing energy, estimate expected range or lifespan based on current usage, and provide the health status of the battery pack. - Reduced Costs and Warranty: Introducing a BMS into a BESS adds cost, as battery packs are expensive and have potential hazards. The more complex the system, the higher the safety requirements, thus more BMS supervision needed. However, the protection and preventative maintenance offered by a BMS in terms of functional safety, lifespan and reliability, performance and range, diagnostics, etc., ensure that it will lower overall costs, including those associated with warranty. Simulation is a valuable ally in BMS design, especially when applied to explore and resolve design challenges in hardware development, prototyping, and testing. With accurate lithium-ion battery models, the simulated model of the BMS architecture is recognized as an executable specification for virtual prototypes. Moreover, simulation allows for the painless investigation of variants of BMS supervisory functions against different battery and environmental operating scenarios. Implementation issues can be discovered and investigated early, allowing for verification of performance and functional safety improvements before actual hardware prototype implementation. This reduces development time and helps ensure that the first hardware prototype is robust. Moreover, many authentication tests can be conducted on the BMS and battery pack, including worst-case scenarios, when applied in embedded systems applications. Battery Energy Storage Systems (BESS) containers, when used for transportation or shipping, generally need to comply with certain regulations and standards to ensure safety and compatibility with international shipping requirements. The Convention for Safe Containers (CSC) is one such regulation that applies to containers used in international transport. The CSC ensures that containers meet specific safety standards, and it requires containers to be examined at intervals appropriate to operating conditions. For BESS containers: 1. **CSC Certificate**: If the BESS container is designed to be shipped internationally as a part of cargo or equipment, it would likely need a CSC certification. This certification confirms that the container has been inspected and meets the safety standards required for international transport. The CSC certification involves checking the structural integrity of the container and ensuring it is fit for transport. 2. **Specific Approvals for BESS**: Beyond the CSC, BESS containers might require additional approvals or certifications depending on their specific technology, the materials they contain (like lithium batteries), and their intended use. These could involve standards related to electrical safety, hazardous materials, and fire safety, among others. 3. **Local and International Regulations**: Compliance with local regulations in the country of use and international standards like those from the International Maritime Organization (IMO) or the International Electrotechnical Commission (IEC) might also be necessary. These standards can include safety, testing, and performance criteria specific to energy storage systems. 4. **Periodic Inspections and Maintenance**: Ensuring ongoing compliance with CSC and other relevant standards means that the containers should be subject to periodic inspections and maintenance checks. This is to ensure that they continue to meet safety and operational standards throughout their lifecycle. Given the specialized nature of BESS containers, especially those containing lithium-ion batteries or other hazardous materials, additional safety and operational considerations might apply. It's recommended to consult with regulatory experts or certification bodies to ensure full compliance with all relevant standards and regulations for your specific BESS containers. The CSC (Container Safety Convention) nameplate, also known as the CSC safety approval plate, is a standardized identification plate required on all containers used in international trade. It certifies that the container has been inspected and found to meet specific safety standards. The CSC nameplate plays a critical role in ensuring the safety and integrity of containerized goods during transport. Here’s a breakdown of what is typically included on a CSC nameplate and what each part means: 1. **CSC Nameplate Description** - **Owner Name**: The legal owner of the container. - **Technical Data**: Key specifications of the container, such as dimensions, type, manufacture date, and maximum operating gross weight. - **Approval Number**: A unique identifier given to containers that pass the CSC inspection. - **Manufacture Date**: When the container was produced. - **Identification Number**: A unique number assigned to the container, often including the owner's code and a serial number. - **Max Gross Weight**: The maximum weight the container can safely carry, including the tare (empty) weight plus the maximum cargo weight. - **Tare Weight**: The empty weight of the container. - **Payload**: Maximum cargo weight the container can carry, calculated by subtracting the tare weight from the maximum gross weight. - **CSC Safety Approval**: A statement that the container has been inspected in accordance with the standards of the CSC and is deemed safe for transport. 2. **CSC Safety Approval** This is a certification that the container meets the requirements of the International Convention for Safe Containers (CSC). It signifies that the container has passed inspections and tests for strength, durability, and suitability for safe handling and transport in the global intermodal transport system. The CSC safety approval is critical for containers moving across different modes of transport, such as from ship to rail or truck. 3. **Approved for Transport Under Customs Seal** This phrase indicates that the container is approved to be sealed by customs authorities for international transport. The seal is a critical security feature, ensuring that the container's contents have not been tampered with since it was inspected and sealed by customs. Transport under customs seal helps in maintaining the integrity of the container's contents, facilitating smoother customs clearance. Importance of CSC Nameplate and Safety Approval - **Legal Requirement**: Having a CSC nameplate is a legal requirement for containers used in international shipping, ensuring they meet global safety standards. - **Safety**: Ensures that containers are structurally sound, minimizing risks to cargo, handlers, and transport operators. - **Efficiency in Customs**: Containers approved for transport under customs seal can move more quickly through customs, reducing delays and costs. In summary, the CSC nameplate and safety approval are fundamental to the international transport of goods, ensuring that containers are safe, secure, and suitable for the rigors of international trade. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|