|

In today's global trade and logistics, refrigerated shipping containers play a crucial role in ensuring the safe transport of temperature-sensitive goods. Whether it's fresh food, pharmaceuticals, or other items requiring precise temperature control, properly managing and utilizing refrigerated containers is paramount. Below are key insights on how to efficiently manage and use these containers in ocean freight: 1. Cargo Loading and Stacking: Depending on the nature of frozen, chilled, or hazardous cargo, loading and stacking methods may vary. Ensure cargo is adequately packaged with no gaps between the cargo and container walls to facilitate even airflow. Follow block stacking principles to allow cold air to circulate uniformly, meeting the desired temperature requirements. 2. Temperature Monitoring: Regularly monitor the temperature inside refrigerated containers, typically checking at intervals of no more than six hours. Record temperature data and consider using an automated recording system to transmit real-time temperature data for continuous cargo status tracking. Especially when transporting hazardous refrigerated cargo, record temperatures every hour. 3. Refrigeration Unit and Maintenance: Conduct routine inspections of the mechanical and electrical systems of refrigerated containers to ensure they are in proper working condition. If any malfunctions occur, promptly inform specialized personnel for maintenance. Regular maintenance is crucial to equipment reliability. 4. Cargo Tracking: Implement cargo tracking technologies to monitor cargo location, status, and temperature data in real-time. This aids in the timely detection of issues and corrective actions to ensure cargo safety and quality. 5. Managing High-Performance Specialized Refrigerated Containers: High-performance specialized refrigerated containers are typically placed in the mid to aft sections of concealed deck vessels, avoiding the lower two tiers of containers on the ship's outermost sides. During transport, check the container's temperature three times a day and maintain records. When transporting hazardous refrigerated containers, record temperatures hourly. In case of equipment failure, promptly notify senior engineers for assessment and repairs. One hour before unloading at the port, record the temperature, disconnect the power supply, and secure the container. 6. Inspection Coordination: Before loading, conduct a comprehensive inspection of the refrigerated containers along with the chief engineer and electrical engineer. Ensure that all systems are operational. If the power has been disconnected, assess the equipment's status based on previous paper chart records. If any damages or malfunctions are detected, document them and promptly notify the yard management for inspection and repair. If the damage is significant and could affect product quality or if the fault cannot be rectified, consider rejecting the container. By adhering to these recommendations, you can ensure the efficient management and utilization of refrigerated shipping containers in ocean freight, preserving the quality and safety of your cargo, meeting customer demands, and maintaining a smooth supply chain operation. Success in international trade hinges on correct management and operation of the cold chain logistics, making refrigerated containers a vital component. In the dynamic landscape of Battery Energy Storage Systems (BESS), the role of battery racks is pivotal in ensuring the efficiency and durability of these containers. TLS Offshore Containers, a renowned name in container manufacturing, brings its expertise to the forefront in crafting battery racks tailored for BESS containers. In this article, we'll explore how TLS manufactures battery racks that are not only robust but also optimized for the demanding requirements of energy storage. Step 1: In-Depth Assessment The journey begins with a meticulous assessment of the specific needs of your BESS container. TLS collaborates closely with clients to understand the capacity, dimensions, and weight specifications of the batteries that will be accommodated within the racks. Environmental considerations, safety standards, and scalability are all taken into account during this initial phase. Step 2: Material Expertise TLS prides itself on material selection that ensures durability and performance. Battery racks must be constructed using materials that offer exceptional strength, corrosion resistance, and longevity. Typically, materials such as stainless steel, aluminum, or specially coated steel are employed to thwart corrosion effectively. Step 3: Precision in Design and Engineering The heart of a reliable battery rack is an impeccable design. TLS commits to several vital design considerations:

Step 4: Expert Manufacturing Process TLS employs a rigorous manufacturing process:

Step 5: Unyielding Quality Assurance TLS leaves no room for compromise when it comes to quality assurance. Each battery rack undergoes stringent checks to meet industry and safety standards. Load-bearing tests, corrosion resistance assessments, and weld quality inspections are routine to guarantee the highest quality. Step 6: Seamless Integration Once the battery racks pass rigorous quality assessments, TLS ensures seamless integration into the BESS container. Proper alignment, anchoring, and electrical connections are meticulously attended to. Step 7: Ongoing Maintenance Support TLS stands by its products with a commitment to ongoing maintenance and support. Regular inspections are conducted to identify wear and tear, corrosion, or anomalies, ensuring the sustained performance of the BESS container. In conclusion, TLS brings a wealth of expertise to the manufacturing of battery racks for BESS containers. Their dedication to precision, quality, and safety ensures that these battery racks not only meet but exceed the expectations of the dynamic energy storage industry. With TLS, you can trust in the reliability and durability of your BESS infrastructure. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. #Battery rack manufacturing #BESS container racks #Battery energy storage systems #Energy storage solutions #TLS Offshore Containers #Battery rack design #Battery rack construction #Battery rack materials #BESS container integration #Energy storage infrastructure Written by OliverThe Essential Guide to MCC (Motor Control Center) Shelter: Benefits, Design, and Maintenance9/22/2023

Introduction Motor Control Centers (MCC) are the nerve centers of industrial automation and electrical distribution systems, ensuring seamless operation of machinery and equipment. To protect these vital components from environmental factors and ensure uninterrupted functionality, MCC shelters play a crucial role. In this comprehensive guide, we'll delve into the world of MCC shelters, exploring their importance, design considerations, and maintenance practices. Why MCC Shelters Matter

Design Considerations When designing an MCC shelter, several factors must be taken into account to ensure optimal functionality and long-term reliability.

Maintenance Practices To keep your MCC shelter and its components in peak condition, regular maintenance is essential.

Conclusion MCC shelters are the unsung heroes of industrial automation and electrical distribution systems. They protect vital equipment, ensure safety, and help businesses meet regulatory requirements. By carefully considering their design and implementing a proactive maintenance regimen, you can ensure the longevity and reliability of your MCC shelter, minimizing downtime and maximizing productivity in your industrial operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Written by OliverContainer heat insulation and fire protection design involves creating a system within a container to safeguard its contents from external temperature fluctuations and fire hazards. This system typically incorporates insulation materials such as rock wool, glass wool, and polyurethane, along with fireproof materials like fireproof boards and coatings. TLS offshore containers are engineered to meet the A60 fire protection standard, typically utilizing rock wool as an insulating material. Rock wool, composed of basalt or lava mineral fibers, offers several advantageous properties:

Employing rock wool as an insulation material in containers offers benefits in terms of thermal insulation, fire resistance, soundproofing, and environmental sustainability. When designing an insulation system, it's crucial to consider factors like insulation requirements, cost, and durability to determine the appropriate rock wool thickness and density. Additionally, compliance with relevant fire protection and environmental standards must be adhered to during installation. In container heat insulation and fire protection design, several key aspects should be considered:

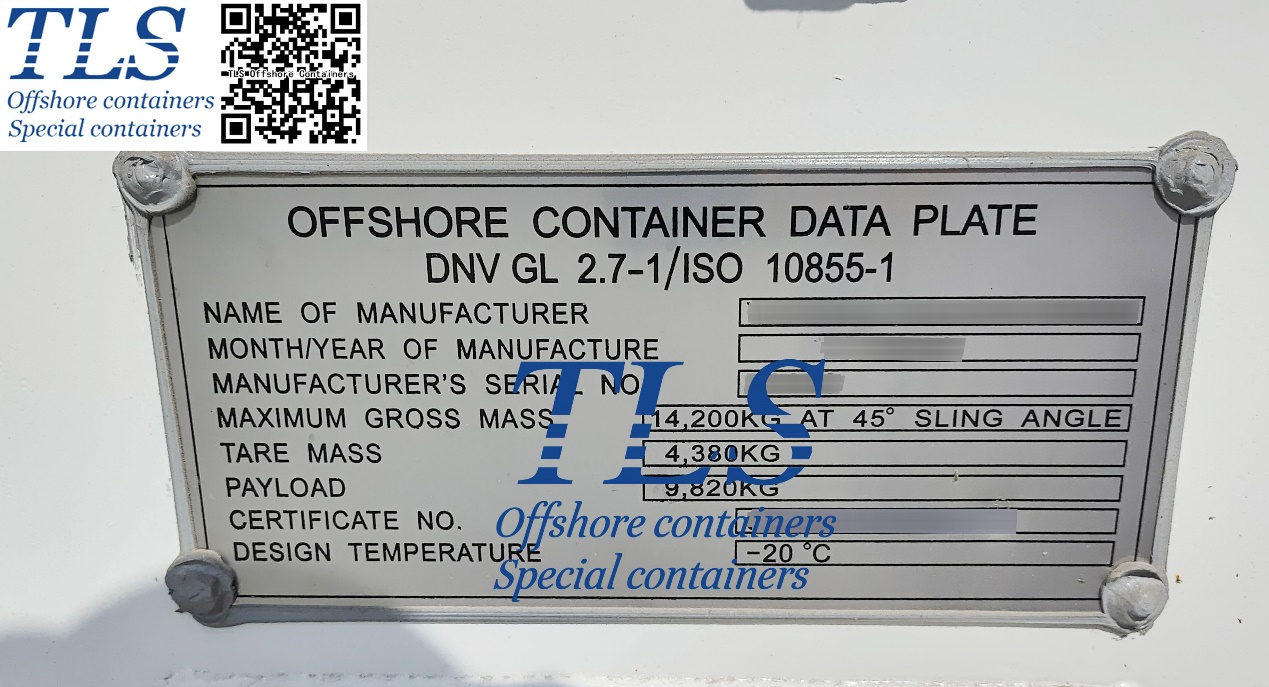

Container heat insulation and fire protection design is a multifaceted endeavor, requiring a holistic approach to factors like insulation, fire protection, fire prevention systems, and operator safety. Throughout the design process, factors like cargo type, container characteristics, and budget constraints must be thoughtfully considered to determine the most suitable heat insulation and fire protection scheme. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Rock wool #Fireproof boards #Fireproof coatings #Thermal insulation #Fire resistance #Sound absorption #Environmental protection #Safety #A60 fire protection standard #Temperature stability Written by OliverIn various industries, the transportation and storage of hazardous materials and flammable substances demand specialized containers that can guarantee safety. These containers, known as explosion-proof containers, play a vital role in minimizing the risks associated with the handling of dangerous goods. What Are Explosion-Proof Containers? Explosion-proof containers are specially designed for the transportation and storage of hazardous materials. They incorporate a range of unique design and engineering features aimed at reducing the risk of fires and explosions, thereby safeguarding individuals and the environment. Key Features of Explosion-Proof Containers Material Selection: Explosion-proof containers are typically constructed from materials that exhibit excellent resistance to corrosion and fire, helping them withstand chemical corrosion and heat sources. Structural Design: These containers have reinforced structural designs to withstand external pressure and reduce the spread of fires, ensuring their integrity in case of unforeseen incidents. Ventilation Systems: They are equipped with internal ventilation and ventilation systems to rapidly eliminate hazardous gases, thereby lowering the risk of explosions. Explosion Suppression Systems: Some explosion-proof containers come with explosion suppression systems, including explosion firefighting equipment and gas detectors, to control explosive events. Electrical Systems: Electrical systems need to adhere to explosion-proof standards to prevent electrical sparks from igniting fires or explosions. Sealing Performance: Effective sealing performance is crucial to prevent liquid or gas leaks and the spread of fires. Marking and Signage: Proper labeling and signage are essential for identifying the container's purpose, hazardous material classification, and other critical information. International and Domestic Regulations Designing and using explosion-proof containers necessitates compliance with relevant international and domestic regulations. These regulations cover various aspects of hazardous material transportation and storage, including container design, manufacturing, labeling, and transportation. Compliance is critical to ensuring that explosion-proof containers fulfill their role in the safe handling of hazardous materials. TLS can provide pressure containers, laboratory containers, mud logging, negative pressure laboratories, etc., that meet explosion-proof and A60 fire-proof requirements and can be used in ZONE1 and ZONE2 areas. For any inquiries, please feel free to contact us at any time. Introduction: DNV (Det Norske Veritas) plays a crucial role in ensuring safety at sea and on land through its certification and verification services. In this article, we'll explore the key characteristics and benefits of DNV 2.7-1 certified offshore containers, highlighting their importance in harsh offshore conditions. DNV 2.7-1 Certification: What Sets Them Apart DNV 2.7-1 certified offshore containers are purpose-built for dynamic hoisting, equipped with eye pad devices and DNV certified slings with shackles. These containers undergo rigorous checks throughout their lifecycle, including the design phase, material procurement, production, and final loading, as well as Non-Destructive Examination (NDE) testing. Testing and Quality Assurance Unlike standard containers, DNV 2.7-1 containers are subject to meticulous testing procedures. Prototypes are rigorously tested, and a specific number of units from each batch are randomly selected for testing, ensuring a level of scrutiny five times higher than ISO standard containers. Robust Construction One of the distinguishing features of DNV 2.7-1 containers is their solid steel structure, which includes reinforced floors. These containers are designed to withstand the challenges of rough seas, making them substantially heavier compared to ISO containers of the same size. This added weight is essential to keep them upright during transportation in adverse conditions. DNV Approved Slings and Materials DNV 2.7-1 containers are equipped with DNV-approved slings and incorporate stronger steel. The production process adheres to strict specifications to ensure the highest quality. All test documentation is readily available to demonstrate their reliability in offshore environments. Certification Process Classification societies play a vital role in certifying offshore containers. The process involves:

Conclusion: DNV 2.7-1 certified offshore containers are engineered to meet the demanding needs of offshore industries. Their robust construction, rigorous testing, and adherence to DNV standards ensure their reliability in the harshest offshore conditions, making them a vital asset for maritime safety and efficiency. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Shackles #Testing procedures #ISO standard containers #Robust construction #Steel structure #Offshore environments #Quality assurance #Manufacturing process #Welder qualifications #Non-destructive testing Written by OliverIn the realm of global logistics and cargo transportation, containers play an indispensable role. They are essential tools for moving goods from one location to another. However, different types of containers are suitable for different types of cargo and transportation needs. This article will explore the distinctions between side-opening containers and standard containers, as well as their respective advantages and application areas. Side-opening containers stand out due to their unique side panel design. Unlike standard containers, side-opening containers are equipped with full-length side doors, providing unprecedented flexibility in accessing and loading/unloading cargo. Whether dealing with oversized cargo or irregularly shaped items, side-opening containers excel. This design feature not only enhances accessibility but also ensures the structural integrity and security of cargo during transportation, effectively shielding it from external elements and potential theft. In contrast, standard containers find wide application across various cargo transportation scenarios. They feature sturdy structures and end-door designs, making them suitable for packaged goods, dry bulk materials, and equipment. Standard containers excel in safeguarding cargo, ensuring its safety throughout the transportation process. They are typically used for transporting consumer goods, electronics, furniture, and other items that can be easily loaded through end doors. So, what are the primary differences between side-opening containers and standard containers? Firstly, side-opening containers have side panels consisting of full-length doors, allowing cargo to be conveniently loaded and unloaded from the side. This is particularly crucial for large machinery, vehicles, building materials, and other items that require lateral access for efficient handling. This convenience makes side-opening containers highly popular in industries such as construction, automotive, and heavy equipment manufacturing. In contrast, standard containers feature end doors, limiting cargo access to these doors. This can pose challenges when dealing with large or irregularly shaped cargo. Nevertheless, standard containers excel in cargo protection and are suitable for various types of goods. Another significant distinction is that side-opening containers typically have a thinner structure compared to standard containers, which may make them slightly less robust. This implies that standard containers are more suitable for cases involving exceptionally heavy cargo or the need for multi-tier stacking. However, side-opening containers still possess adequate structural strength to meet most transportation requirements. Lastly, cost is also a factor to consider. Due to their unique design and greater accessibility, side-opening containers are generally more expensive than standard containers. Therefore, when choosing the appropriate container type, logistics professionals must strike a balance between cargo characteristics, transportation requirements, and budget constraints. In conclusion, side-opening containers and standard containers each have their own set of advantages and limitations. Side-opening containers offer greater accessibility and convenience, making them suitable for specialized scenarios requiring lateral cargo access. Standard containers, on the other hand, provide stronger structural protection and are suitable for a wide range of cargo types. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions.

Wherever you are in the world TLS can help you, please contact us. The Airlock Room: A Critical Component for Pressure Container Safety and Functionality Pressure containers are marvels of engineering, designed to maintain specific air pressure levels within their confines. This controlled environment is essential for various purposes, from research to offshore drilling and aerospace exploration. But have you ever wondered why there's an airlock room in these containers? What purpose does it serve, and why is it indispensable? In this article, we will explore the functions and necessity of the airlock room in pressure containers, revealing its crucial role in ensuring safety, efficiency, and comfort within these specialized environments. Function and Necessity of the Airlock Room in a Pressure Container The airlock room, located within the pressure container, is a vital space that plays several key roles: 1. Pressure Balance Maintenance: One of the primary functions of the airlock room is to maintain pressure balance. The interior of a pressure container typically operates at a specific air pressure, which may be higher or lower than the external environment. This pressure differential is crucial for various processes and safety measures. The airlock room serves as a transitional buffer zone, allowing individuals and equipment to enter or exit without compromising the pressure in the main chamber. 2. Safety First: Without the airlock room, opening the main door of a pressure container directly to the external environment could lead to rapid pressure equalization, resulting in potentially dangerous consequences. For example, if the main chamber's pressure is higher than the outside, a sudden release of pressure could harm people, equipment, or materials. Conversely, if the main chamber's pressure is lower, rapid exposure to external air could cause decompression sickness in individuals. 3. Pressure Monitoring: Within the airlock room, an inner door controls access between the main chamber and the external environment. Pressure monitoring devices in the container ensure that the pressure inside the main chamber stays within safe and specified limits during entry and exit procedures. 4. Emergency Escape: In cases of crisis or emergencies within the main chamber or the airlock area itself, escape doors can be strategically installed on walls away from the airlock area. These doors provide alternative exit routes for personnel, significantly enhancing safety within the pressure container. 5. Comfort and Efficiency: In environments with limited space and challenging conditions, such as offshore platforms, the airlock room contributes to the comfort and efficiency of personnel working inside the pressure container. It allows for controlled access and egress, minimizing discomfort or health risks associated with rapid pressure changes. In summary, the airlock room is a critical component of pressure containers, ensuring the safety and well-being of personnel and equipment by maintaining pressure differentials, providing controlled access, and offering emergency escape routes when necessary. Its multifaceted functions make it indispensable in various industries where maintaining precise pressure environments is a must. The next time you encounter a pressure container, remember the crucial role played by the unassuming airlock room within. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions.

Wherever you are in the world TLS can help you, please contact us. #PRESSURIZED CONTAINER #ZONE1 #ZONE2 #LAB CONTAINER #OFFICE CONTAINER #AIRLOCK ROOM #SPECIAL CONTAINERS Revolutionize Your Energy Strategy with TLS Offshore Containers' Grid-Tied Battery Storage Solution9/8/2023

In today's rapidly changing energy landscape, businesses and industries are constantly seeking innovative solutions to manage their energy needs efficiently, reduce costs, and minimize their environmental footprint. At the forefront of these innovations is TLS Offshore Containers, a company that has consistently delivered cutting-edge energy storage systems. Their latest offering, the Flexible Grid-Tied Battery Storage System, is a game-changer that promises to reshape how we approach energy management. Powering a Sustainable Future The demand for sustainable energy solutions is higher than ever, driven by a global commitment to reducing greenhouse gas emissions and combatting climate change. TLS Offshore Containers has taken up this challenge by developing a state-of-the-art Grid-Tied Battery Storage System that is both versatile and eco-friendly. With this system, you have the power to unlock a sustainable future. It's designed to cater to a wide range of applications, spanning from commercial and industrial setups to microgrid installations. Whether you're looking to optimize self-consumption of solar energy, reduce demand charges, perform peak shaving, or provide ancillary services to the grid, this solution has you covered. Safety as a Top Priority Safety is non-negotiable when it comes to energy storage systems, and TLS Offshore Containers understands this better than anyone. Their Grid-Tied Battery Storage System prioritizes safety with an IP67-rated battery pack. This means it's dust-tight and can withstand temporary immersion in water. Moreover, the double-layer construction and use of flame-retardant and explosion-proof materials provide an additional layer of security. The commitment to safety doesn't stop there. TLS proudly adheres to a slew of certifications, including UN38.3, CE, IEC62619, IEC 61000, IEC 62477, IEC 63056, UL1973, and UL 9540a, ensuring that their system meets the most stringent safety standards in the industry. Intelligence Meets Efficiency The Grid-Tied Battery Storage System is not just safe; it's incredibly intelligent and efficient. Its all-in-one modular design supports multiple operational modes, giving you the flexibility to adapt to changing energy demands. Whether you want to participate in virtual power plants, connect to the grid, or operate off-grid, this system has the capability. Advanced features, including intelligent balancing strategies and AI-driven early warning systems, ensure that your battery operates at its best throughout its life cycle. The core components are designed on a unified platform with standardized interfaces, streamlining production and testing processes for maximum efficiency. Optimal Performance with Liquid Cooling One standout feature of this system is its liquid cooling technology. This innovative approach ensures optimal performance across a wide temperature range. It's particularly beneficial for applications that require rapid transitions between charging and discharging states, such as peak shaving. By efficiently managing temperature, you can reduce electricity costs and alleviate stress on the electrical grid, making your energy usage more sustainable and cost-effective. Flexibility at Its Core Flexibility is embedded in the DNA of the Grid-Tied Battery Storage System. With an IP55 rating for the entire equipment and a C4 anti-corrosion level, it's rugged enough to thrive in outdoor environments. The standardized interface and flexible access points make installation and expansion a breeze. Thanks to its modular design and parallel connection capabilities, you can scale up your energy storage as your needs grow. This adaptability to various power and voltage ranges makes it a versatile choice for different scenarios. User-Friendly Operation and Maintenance While the system boasts cutting-edge technology, it's also designed for user-friendliness. It undergoes a rigorous 100% Factory Acceptance Test (FAT) to ensure high-quality delivery, minimizing on-site installation and commissioning time. Real-time leakage monitoring and intelligent refill mechanisms are integrated to reduce the need for on-site maintenance. The system's design specifications also lower the requirements for on-site engineering work, resulting in shorter recovery times. Cloud-based early warning capabilities enable remote monitoring and management, providing you with peace of mind and control over your energy storage. Conclusion: Embrace the Future with TLS Offshore Containers TLS Offshore Containers' Grid-Tied Battery Storage System is a versatile, safety-compliant, and highly adaptable solution designed to meet the multifaceted needs of modern energy management. Whether you're a business looking to optimize solar investments, manage energy costs, or contribute to grid stability, this system offers a robust and flexible platform to help you achieve your goals. Don't miss out on the energy revolution. Invest in TLS Offshore Containers' Grid-Tied Battery Storage System today and take a significant step towards a greener, more efficient future. Contact us to learn more about how you can transform your energy strategy with this innovative solution. Together, we can shape a sustainable tomorrow. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding the Commercial and industrial & microgrid energy storage system, please download Commerical and industrial microgrid tied energy storage system cabinet brochure for your reference #Grid-Tied Battery Storage #Flexible Energy Management #Sustainable Energy Solutions #Eco-friendly Battery Storage #Energy Storage System #Energy Efficiency #Battery Safety #Sustainable Energy Future #Renewable Energy Management #Liquid Cooling Technology Written by OliverIntroduction Container lifting is a crucial aspect of logistics and shipping operations worldwide. Efficient and safe container lifting ensures the seamless movement of goods from one location to another. Whether you're a seasoned professional or a newcomer to the industry, understanding the various techniques, equipment, and safety measures associated with container lifting is essential. In this comprehensive guide, we will delve into the world of container lifting, exploring its importance, methods, equipment, and safety considerations. Why Container Lifting Matters Container lifting is the process of raising and moving standardized cargo containers, which come in various sizes and configurations, such as 20-foot and 40-foot containers. Proper container lifting is vital for several reasons:

Container Lifting Techniques Several container lifting techniques are employed depending on the situation and equipment available. Here are some common methods:

Container Lifting Equipment To carry out container lifting effectively, the right equipment is essential. Key container lifting equipment includes:

Safety Considerations Container lifting can be hazardous without proper safety measures. Here are some crucial safety considerations:

Conclusion Container lifting is a fundamental aspect of the global logistics industry, ensuring the smooth flow of goods across the world. To maximize efficiency and safety in container lifting operations, it is crucial to understand the various techniques, equipment, and safety measures involved. By following best practices and adhering to safety guidelines, businesses can optimize their container handling processes and contribute to the success of the global supply chain. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Container lifting #Container handling #Container lifting techniques #Container lifting equipment #Container lifting methods #Container lifting safety #Container lifting best practices #Cargo container lifting #Container crane #Container spreader Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|