|

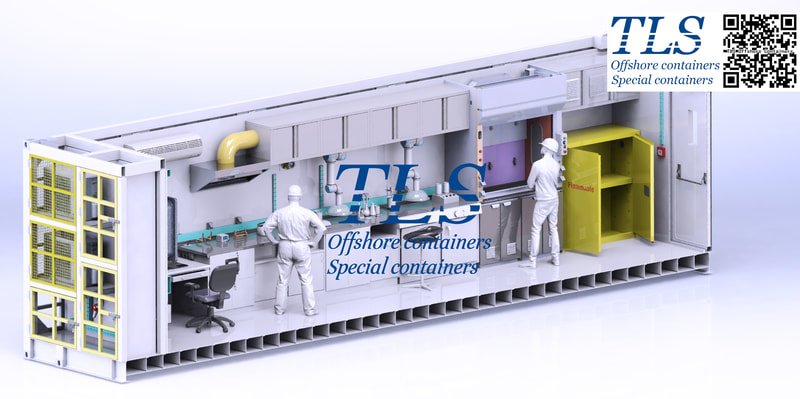

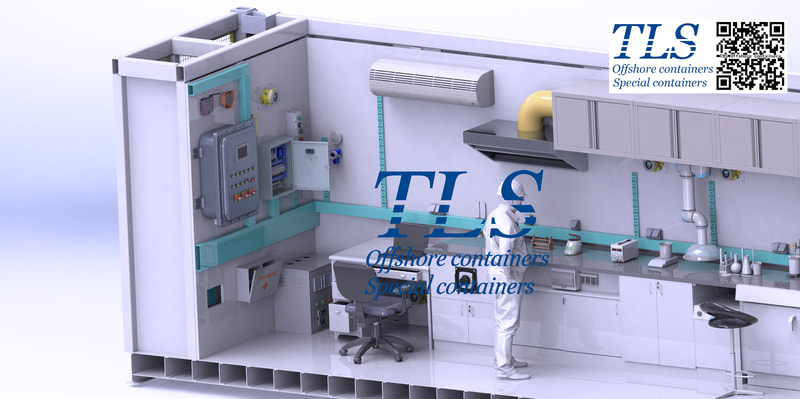

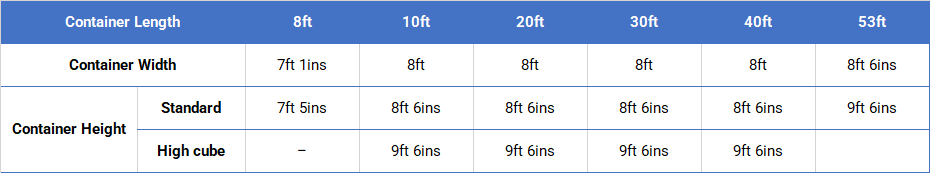

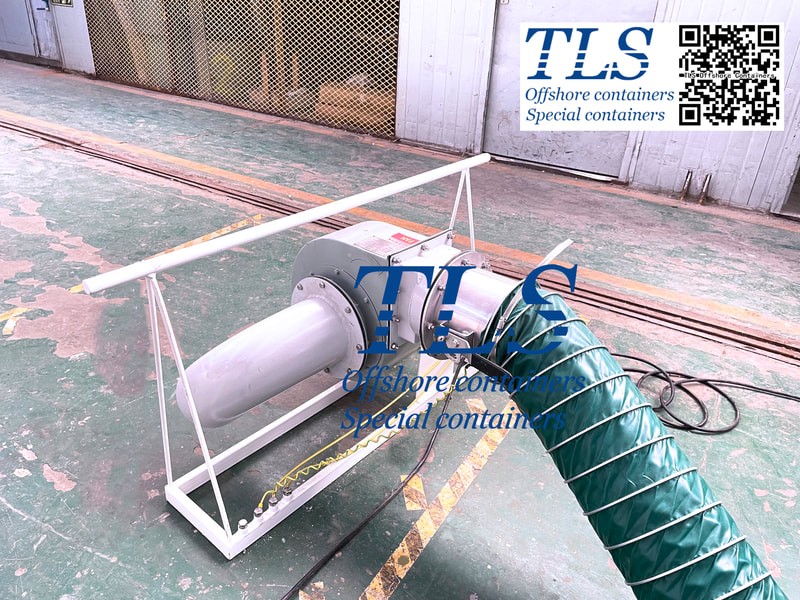

As we all know, offshore pressurized containers are widely used in offshore platforms/FPSOs or ships. When containers are used in zone 1 zone 2, it can keep our container safe environment. The positive pressure system provided by TLS is mainly composed of container body, CPFG control cabinet, positive pressure air system, explosion-proof centrifugal fan unit, fire alarm system, lighting system, alarm system, explosion-proof air conditioner, air valve control system and explosion-proof isolation switch box. The design and construction meet the IEC60079-13 2010 specification, DNV2.7-1 and SOLAS 2009. Explosion-proof appliances meet the CNEX or ATEX explosion-proof standards. TLS Offshore Containers/TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world, TLS can help you. Please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #pressurised container #ATEX #IECEx #offshore container #workshop container #TLS #explosion-proof #CPFG #air blower fan #Laboratory container #TLS offshore containers Taking the 1MW/1MWh battery energy storage system as an example, the system is generally composed of energy storage battery system, monitoring system, battery management unit, special fire protection system, special air conditioning system, power conversion system (PCS) and isolation transformer, and finally integrated in a container. The battery system is mainly composed of battery cells in series and parallel: first, a dozen groups of battery cells are connected in series and parallel to form a battery pack, then the battery boxes are connected in series to form a battery string to increase the system voltage, and finally the batteries are connected in series and parallel to increase the system capacity, and are integrated in inside the battery container. The monitoring system mainly enables the functions of external communication, network data monitoring and data acquisition, analysis and processing to be realized, ensuring accurate data monitoring, high voltage and current sampling accuracy, data synchronization rate and fast execution speed of remote control commands; the battery management unit has high precision The single-cell voltage detection and current detection functions ensure the voltage balance of the battery modules and avoid circulating currents between the battery modules, which will affect the system operation efficiency. In order to ensure the safety of the system, the container is equipped with a special fire protection and air conditioning system. The fire protection system senses the fire through smoke sensors, temperature sensors, humidity sensors, emergency lights and other safety equipment, and automatically extinguishes the fire; the special air conditioning system is based on the external ambient temperature. The cooling and heating system of the air conditioner is controlled through the thermal management strategy to ensure that the temperature in the container is in a suitable range and prolong the service life of the battery. The Power Conversion System(PCS) is an energy conversion unit that converts battery direct current to three-phase AC and can operate in grid-connected and off-grid modes. In grid-connected mode, the converter interacts with the power grid according to the power instruction from the upper dispatching. In off-grid mode, energy storage converters can provide voltage and frequency support for plant loads, and provide black start power for some renewable energy sources. The outlet of the energy storage converter is connected with the isolation transformer, so that the electrical insulation of the primary side and the secondary side is completely isolated, to ensure the safety of the container system to the greatest extent. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Modules are strictly regulated in all operating environments involving offshore drilling, MWD or LWD. In ZONE 1 and ZONE 2, select different modules for different purposes. Our portable modules are manufactured according to the International Maritime Organization safety of Life at Sea (SOLAS). Our design and manufacturing processes, including design and inspection, are certified by other third party classification societies Many portable accommodation and industrial modules are designed for use in zone 1 or zone 2 areas. The two areas are classified as follows: Zone 1 refers to "the combustible concentration of flammable gases or vapors that may be present under normal operating conditions". Zone 2 refers to "an environment where such flammable concentrations are unlikely under normal conditions, but if they do occur, they occur only for a short time". We have extensive experience and knowledge in providing safe and highly customized solutions to our customers in the offshore drilling industry. Our modules are available in a variety of configurations and sizes to meet the needs of various customer platforms, including weight limits and space limitations. If you want to know more about our products, please contact us for further information. The 53ft container has been widely used for road and rail transportation in North America since 1989. It is a type of intermodal container. A 53ft container is constructed similarly to a 40ft container. They are classified as tall cube containers. From the outside, the tall cube storage container is 9 feet 6 inches tall. They are a foot taller than standard dry containers. They measure 8 feet 6 inches, 6 inches wider than a standard container. A 53ft intermodal container provides roughly 50% more interior storage space than a standard 40'container. You can pack more cargo into a 53ft container than a 40ft container. Normally, goods in 20ft or 40ft containers imported from abroad are likely to be transferred to 53ft containers and then shipped to the destination. 53ft containers will be directly transported to the designated place after arriving at the destination port. After unloading at the port, inland trucks are not required to be replaced for shipment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. There are many ways to secure containers on the ground/deck, or to stably stack containers together. Each method requires different types of twist lock. Here are some common ways for your reference: 1. Vertical Locks (Stacked on top of each other) a. Shipping Container Twist Lock & Base It is used to stack containers vertically. Dovetail twist locks are suitable for flat surfaces and can be welded to the base or bolted to a metal surface. To use this lock, simply place the lock in place, load the container on top, move the handle from left to right, and it's secured. b. Shipping Container Manual Twist Lock It is used to hold two containers stacked vertically. In this lock there is a left-to-right lock, to fix two containers, just move the handle to the neutral position, load the container on the upper part, and then move the handle to the locked position. c. Shipping Container Semi-automatic twist lock It is used to hold two containers stacked vertically. It's similar to a manual twist lock, except that instead of a handle, the lock is spring-loaded. The advantage is that the spring stops when the lock is accidentally unlocked. When using it, simply pull the spring into the neutral position and insert the upper container. d. Shipping Container Manual Twist Lock Weld Type for Chassis It is generally welded to the container chassis trailer. When unlocked, the lock head is stuck inside. After loading the container, twist the handle to lock 2. Horizontal Locks a. Horizontal Container Twist Lock/Connector It is used to connect containers side by side. They cannot be connected vertically, only on the sides. Insert the latch into the side of the container and twist the latch. Attach the second container to it and lock it. b. Bridge Fittings Clamp When shipping containers, especially on barges, it is easier to prevent them from tipping or falling if they are tied together. Fortunately, steel bridge fittings can do the job. These heavy-duty fittings hold containers together, combine their weight and make them harder to move, spill or dump in transit. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #Dry Containers #Reefer Container #Refrigerated Container #Positive Pressure Container #Negative Pressure Container #Energy Storage System (#ESS) #Lab Container|Workshop Container #Accommodation Container #Temporary shelter #Temporary #refuge shelter ( #TR) #Sewage Treatment Container The advent of battery energy storage systems (BESS) reduces fuel dependence, reduces carbon emissions, and optimises the environment. The electrical enclosures of traditional battery energy packs are often located outdoors and exposed to extreme temperatures, severe weather, humidity, dirt and dust. Like most heat-sensitive electrical equipment, operating at high and low temperatures reduces power output and service life over time. When the battery storage is placed in a container designed for storage systems, it is isolated from the harsh external environment, while closed-loop cooling removes excess heat and protects sensitive components, improving the efficiency and reliability of associated electronics. It can be used in power stations, islands, offshore areas, communities, schools, scientific research institutions or factories and other areas.

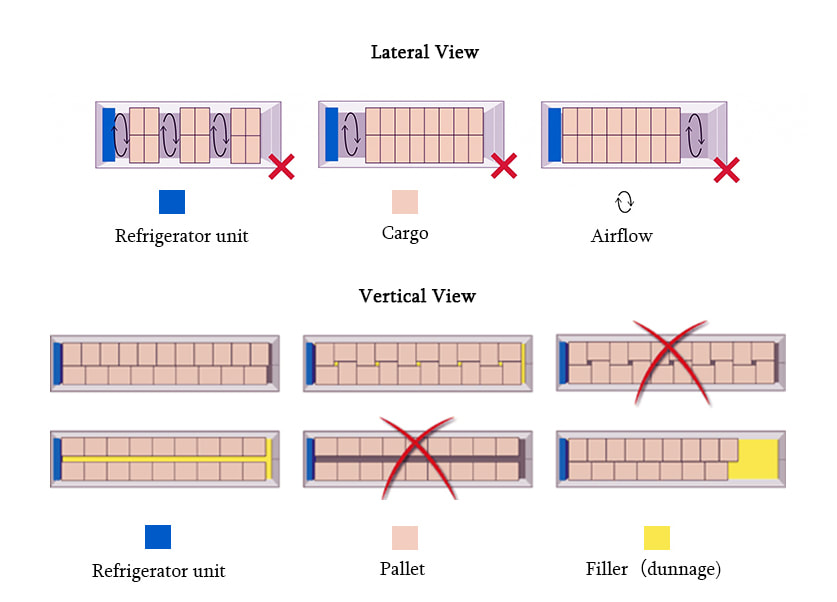

Any inquiries on BESS containers, please download the checklist and send it together with your inquiry. Don’t hesitate to contact us. How does the refrigerated container work? The purpose of the reefer container is not to cool the product, but to maintain the temperature of the product. So instead of adding cool air, the refrigeration process removes heat from the air inside the container. The reefer container distributes cold air from the floor through the T-deck. Precautions for the use of reefer containers

Make a preliminary judgment based on the following: Do your containers need to be placed in hazardous areas (ZONE1, ZONE 2)?

b) If the equipment in the container is non-explosion-proof, you need to choose an A60 fireproof and explosion-proof positively pressurized container (the air supply volume is greater than the exhaust volume. The indoor air is in a positive pressure state. Combined with the air conditioning unit, the cleanliness of the air sent into the container can be guaranteed.)

Key words: #DNV #BV #LR #ABS #SGS #DNV2.7-1 #A60 fire rating #explosion-proof #LAB # workshop container #TLS offshore containers #ZONE0 #ZONE1 #ZONE 2 What is DNV certification? DNV (Det Norske Veritas), a Norwegian classification society, merged with Germanischer Lloyd (GL) in September 2013 to form the world's largest classification society DNV GL Group. As a classification society, DNV GL sets standards for the offshore, maritime, energy and oil and gas industries. The purpose of these standards is to provide users, operators and engineers with requirements, principles and acceptance criteria. Two common standards are:

DNV2.7-1 and DNV2.7-3 in common

Difference between DNV2.7-1 and DNV2.7-3 Apart from the difference in standard details, the biggest difference is that the maximum gross weight (MGW) of dnV2.7-1 certified container is less than 25,000 kgs, and the MGW of DNV2.7-3 certified container is greater than 25,000 kgs. Although DNV2.7-1 and DNV2.7-3 standards are set by DNV Classification Society, they are also recognized by other classification societies (BV, LRs, etc), which will issue corresponding certificates according to the same standards. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|