|

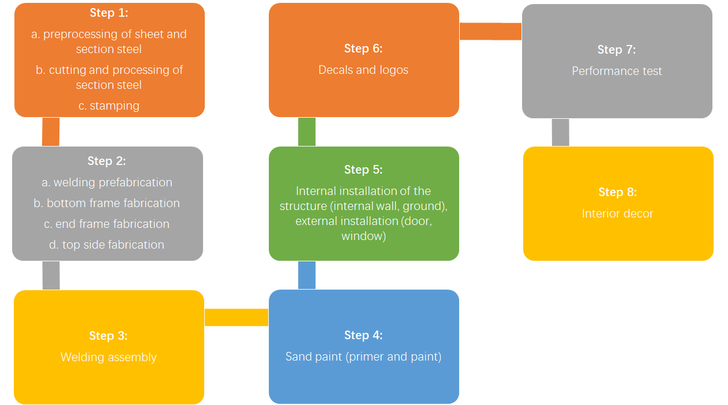

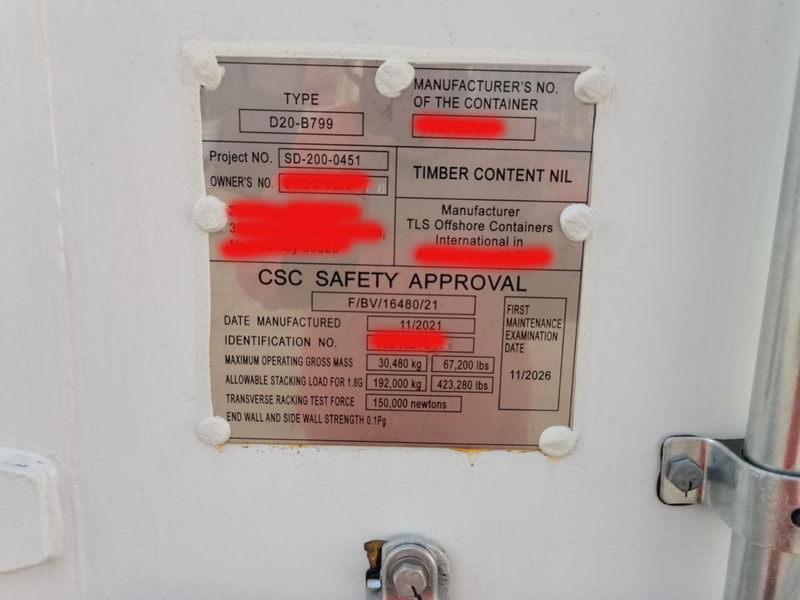

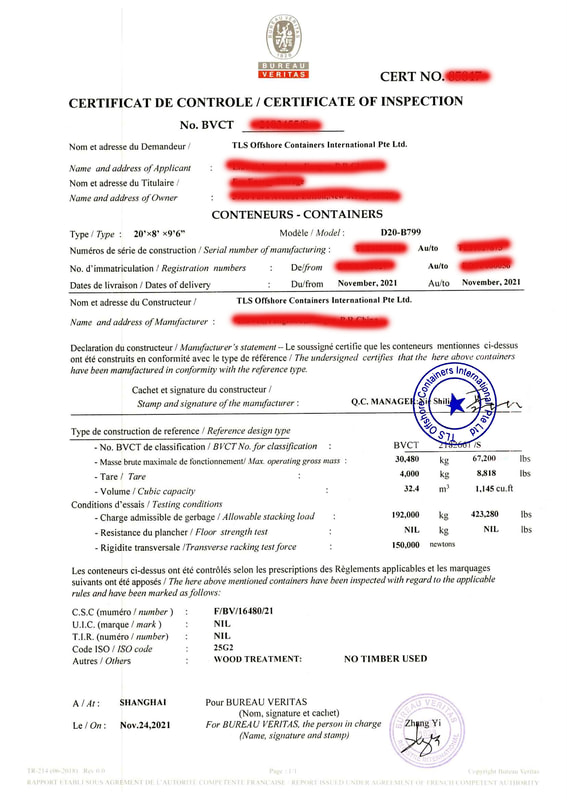

Welders of TLS offshore containers must have the corresponding welding qualification certificate, have the same type of container welding experience, and be approved by the production department manager and filed with the quality assurance department. The whole container assembly process is followed by QC to ensure that it passes the on-site inspection of the third-party classification society. Offshore containers provided by TLS are certified by third-party classification societies (BV, LR, DNV, ABS....), and the quality is trustworthy. Key words: #container welding #container third party inspection #third party classification societies #BV inspection THE PROCESS OF CONTAINER MANUFACTURING Step 1: a. preprocessing of sheet and section steel b. cutting and processing of section steel c. stamping Step 2: a. welding prefabricationb. bottom frame fabrication c. end frame fabricationd. top side fabrication Step 3: Welding assembly Step 4: Sand paint (primer and paint) Step 5: Internal installation of the structure (internal wall, ground), external installation (door, window) Step 6: Decals and logos Step 7: Performance test Step 8: Interior decor The customized ultra-wide laboratory container is being assembled, we will follow up every process in real time, and we will take every detail seriously. Rest assured, products tailored to your needs are sure to satisfy you. CSC, or the International Convention for Safe Containers, incorporates design requirements, minimum functionality requirements, and measurements of capacity, weight, and resistance to the forces containers are subjected to when they ship by sea or on land within ships, trains, or trucks. The goal of CSC is to formalize international safety requirements for structural design and consistent inspection and maintenance of cargo containers. Overall, CSC ensures containers are built safely and inspected on a consistent basis to keep workers as safe as possible. CSC is an international agreement dating to the 1972 International Convention for Safe Containers. Countries participating in CSC are contracting parties, and CSC is administered by contracting parties’ governments and organizations designated by them, such as the American Bureau of Shipping in the United States. CSC sets international standards in design-type approval and safety inspections so that containers operate globally under one set of safety regulations. Once a container design meets all CSC and International Standardization Organization (ISO) standards, it is assigned a CSC number. The number appears on a safety approval plate, or CSC plate, that must be attached to the container. The CSC plate indicates that the container passed specific tests, met minimum standards for capacity, weight, and resistance to shipping forces, and has been issued a four-digit alpha code that identifies the container owners and its intended use. WHAT IS THE CSC PLATE? The convention requires that any container used for international transport must be fitted with a valid safety approval plate (CSC Plate). The CSC plate is fastened to every shipping container at the time of manufacture and is typically riveted to the outside of the left door. Each CSC plate must contain a certain level of information, in either English or French. The words “CSC SAFETY APPROVAL” are prominent on the plate, along with the country of approval and the approval reference. The date of container manufacture, specifically the month and year, must be evident. As must the manufacturer’s container identification number or, in the case of an existing container without a manufacturer number, the Container Operator’s operational number (using a “BIC Code”) or the number allotted by the Administration. The container’s maximum weight-carrying capability (usually referred to as “Payload” or “max net mass”) in both kilograms and lbs must be inscribed, along with the stacking and racking test load value. NOTE: The CSC Plate is today typically included as part of a Combined Data Plate, which includes the other plates necessary for containers to be used in international trade, namely: l The Customs plate (referring to the Customs Convention for Containers (CCC) requirements) showing the certificate applicable to the container to allow transport under customs seal. l The timber treatment applied to the wood flooring of the container as required by the Australian agriculture authorities l Optionally, the Owner’s plate carrying the name of the container’s Operator and its operational number (using the “BIC Code”) CSC INSPECTIONS Container owners are responsible for maintaining containers in a safe condition and must ensure containers are inspected at intervals appropriate to operating conditions. However practical considerations, commercial practice, and contractual agreements mean that this responsibility is transferred to the party in control of the container. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions with a 150,000 square meters manufacturing base located in China, which allows TLS to provide the most cost-effective and complete containerised solutions to worldwide clients. Any requirements about Battery Energy Storage System Container |Accommodation Cabin |Workshop Container |Temporary refuge (TR) shelter |MWD/LWD cabin |Reefer container |Sewage treatment plant container etc, please don’t hesitate to contact us. We will provide professional design solutions and high-quality services. All the production process we will have a dedicated team to follow up to ensure product quality. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Customized offshore container module | workshop container is ready for shipment. Before the shipment, we carry out a system check to ensure that the equipment is in good condition when it arrives at the customer. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|