|

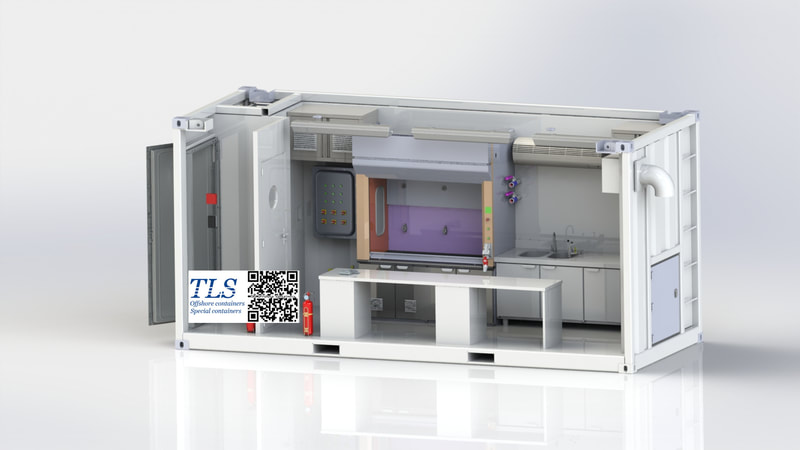

The negatively pressurized laboratory container is a specialized container that is designed to create a controlled laboratory environment where the air pressure inside the container is lower than the pressure outside the container. This creates a negative pressure differential that helps to prevent the release of hazardous or contaminated materials from the container into the surrounding environment. Negatively pressurized laboratory containers are used in a wide range of industries, including healthcare, pharmaceuticals, and oil and gas exploration and production. They are commonly used to test and analyze materials or substances that are potentially hazardous or contagious, such as biological or chemical samples. These containers are typically constructed with high-quality materials and are designed to withstand harsh environmental conditions, such as extreme temperatures and high humidity. They may also be equipped with specialized ventilation systems and air filtration systems that help to control the air quality and prevent the release of any hazardous or contaminated materials. Negatively pressurized laboratory containers may come in different sizes and configurations, depending on the specific needs of the user. Some containers may be designed to be portable, while others may be designed to be permanently installed in a fixed location. Overall, negatively pressurized laboratory containers play a critical role in ensuring the safety of personnel and protecting the environment from potential hazards in a variety of industries.

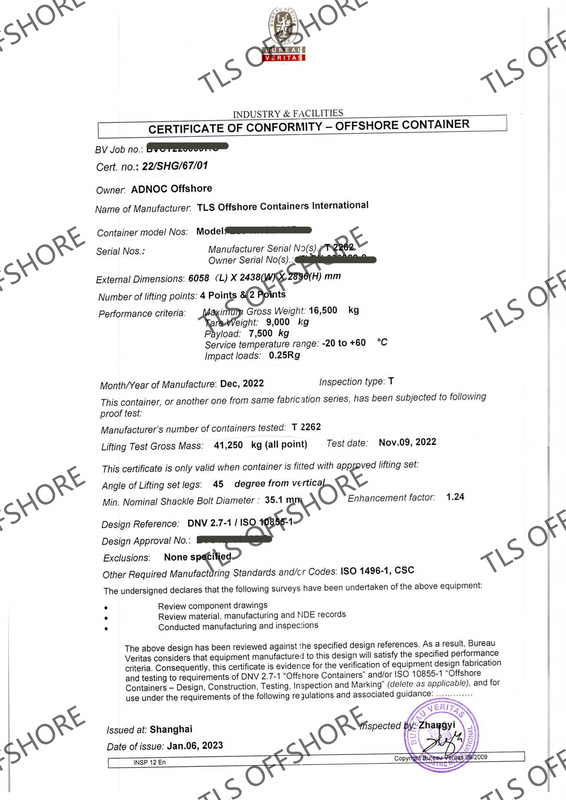

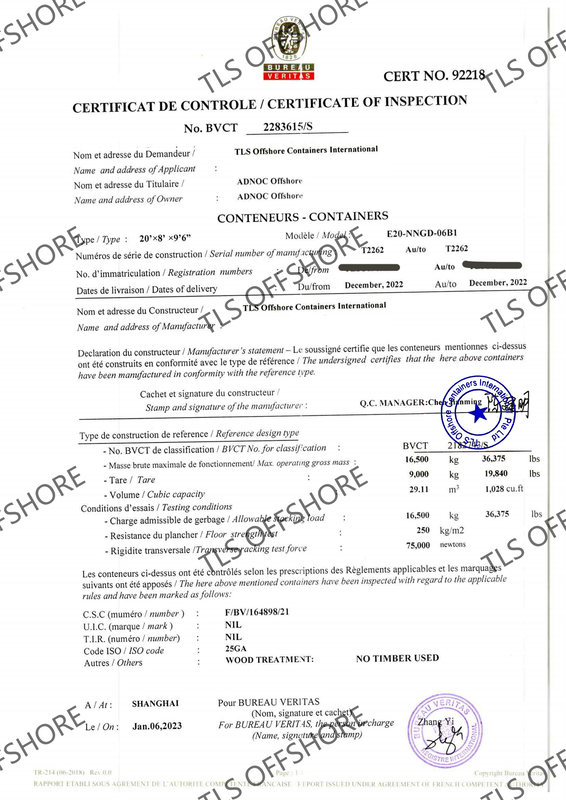

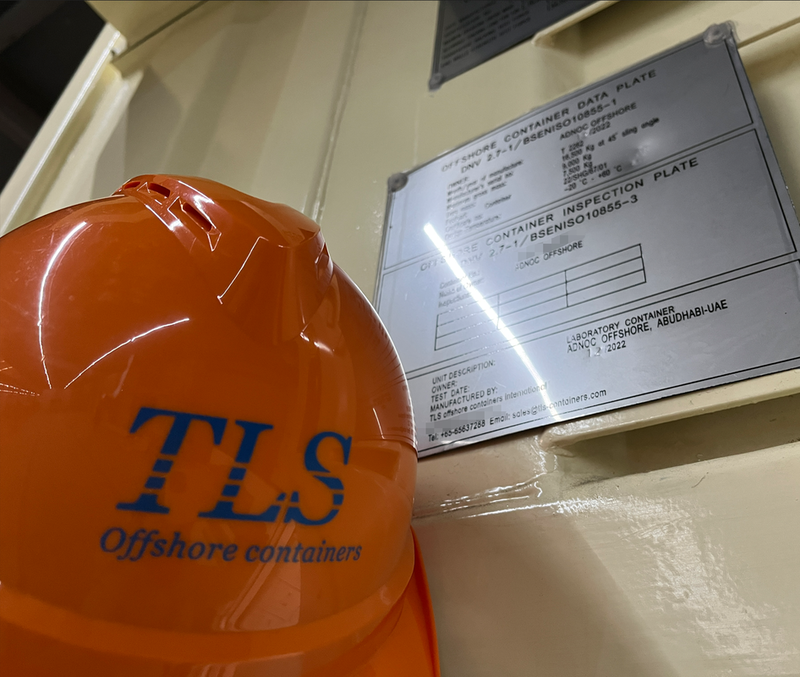

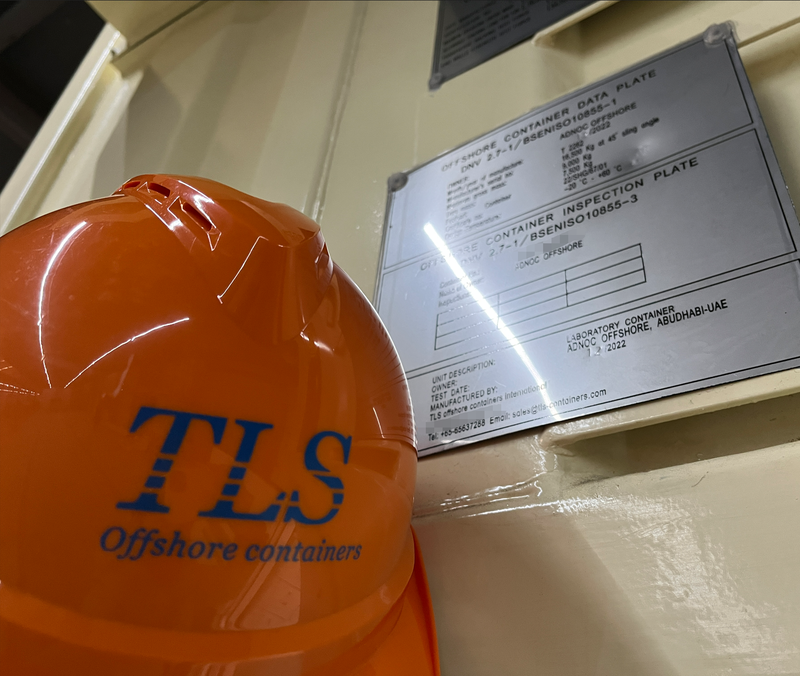

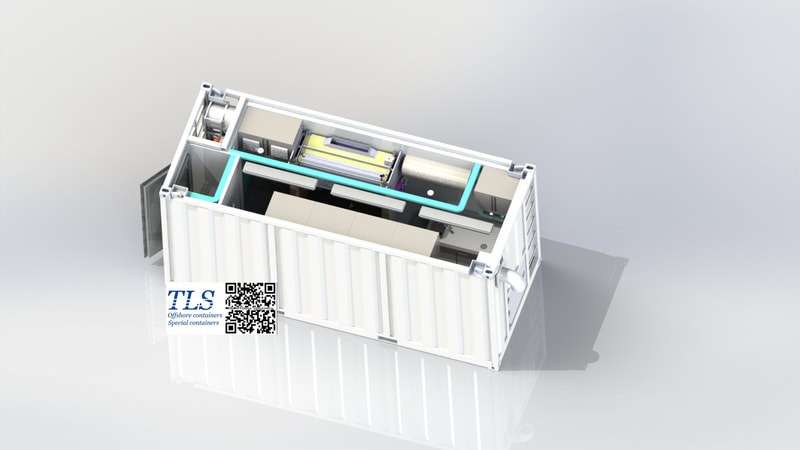

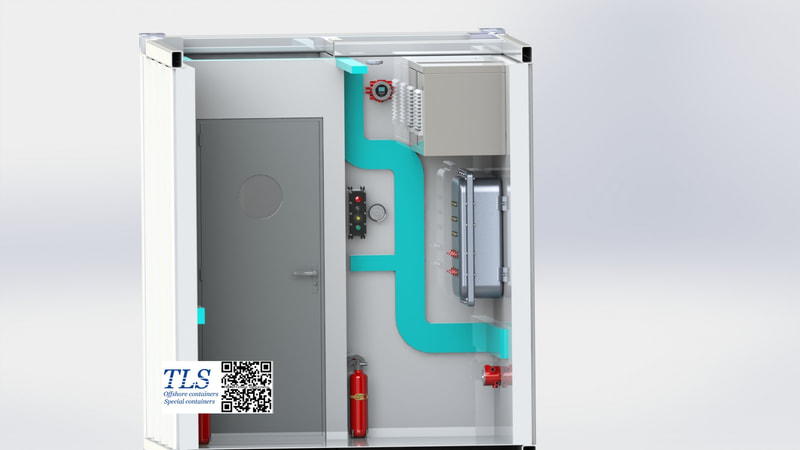

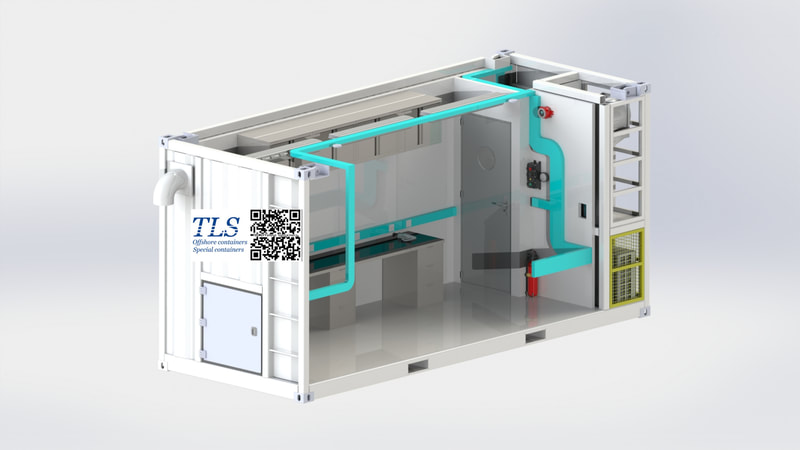

TLS Offshore Containers specializes in the design and manufacture of high-quality offshore containers for a wide range of industries. One of our most innovative products is laboratory container, which is specifically designed to meet the unique requirements of scientists and researchers who need to do experiments in remote or challenging environments. The TLS laboratory container is a self-contained unit that includes all the equipment and facilities needed to conduct scientific experiments in the field. It is made from high-quality materials and is built to withstand the toughest conditions, including extreme temperatures, high winds, and heavy rain. The container is also designed to be easily transportable, with fork pockets and lifting lugs for easy movement and placement. The laboratory container is designed to be completely self-sufficient, with a built-in generator for power, air conditioning for temperature control, and water and waste storage tanks for hygiene and safety. The container also includes a range of laboratory equipment, such as workstations, fume hoods, and storage cabinets, as well as a range of safety features, including emergency lighting, eye wash stations, and fire suppression systems. One of the key features of the TLS laboratory container is its flexibility. It can be customized to meet the specific needs of the user, with a range of options for equipment, layout, and size. This means that it can be adapted for use in a wide range of scientific disciplines, from environmental monitoring and soil analysis to microbiology and molecular biology. The laboratory container is also designed to be highly secure, with robust locking systems and tamper-proof features. This makes it ideal for use in remote or sensitive locations, where the security of the equipment and data is paramount. In conclusion, the TLS laboratory container is an innovative and highly practical solution for scientists and researchers who need to do experiments in challenging environments. Its self-contained design, flexible customization options, and robust security features make it an ideal choice for a wide range of scientific disciplines, and its durable construction ensures that it will provide many years of reliable service. Written by OliverDNV 2.7-1 is an international certification standard for offshore containers, including mud logging cabins and laboratory containers, used in the oil and gas industry. This standard ensures that the containers meet specific safety and quality requirements for use in harsh offshore environments. In the case of laboratory containers for ADNOC, this certification provides assurance to users that the containers are manufactured and maintained to meet the highest standards of safety and performance. The DNV 2.7-1 standard covers various aspects of the design, manufacturing, testing, and maintenance of offshore containers, including laboratory containers. This includes requirements for structural integrity, corrosion protection, equipment compatibility, and safety features such as fire protection and emergency escape routes. The certification process involves regular inspections and audits to ensure continued compliance with the standard. Having a DNV 2.7-1 certificate for an offshore container, such as a mud logging cabin or laboratory container for ADNOC, demonstrates a commitment to quality and safety in the industry. It also provides assurance to customers and regulators that the containers meet the necessary standards and requirements for use in the demanding offshore environment. In conclusion, obtaining a DNV 2.7-1 certificate for an offshore container, such as a mud logging cabin or laboratory container for ADNOC, is a key requirement for companies operating in the oil and gas industry. It demonstrates a commitment to quality, safety, and compliance, and provides assurance to customers and regulators that the containers are fit for purpose and meet the necessary standards. Offshore lab containers are specialized containers that are designed and built to meet the unique needs of laboratories operating in offshore environments. These containers typically include features such as climate control, electrical and plumbing systems, and safety equipment to ensure that laboratory personnel can work comfortably and safely. Offshore lab containers can be used for a variety of purposes, such as testing and analysis, research and development, and sample preparation. They can be equipped with various types of laboratory equipment, including analytical instruments, microscopes, and centrifuges, to support a wide range of scientific and technical activities. Offshore lab containers are typically constructed from durable, corrosion-resistant materials and are designed to withstand harsh offshore conditions such as high winds, saltwater, and extreme temperatures. They are also typically equipped with safety features such as fire suppression systems and emergency lighting to ensure the safety of laboratory personnel. Because of their durability, flexibility, and safety features, offshore lab containers are becoming increasingly popular among offshore operators in the oil and gas, renewable energy, and mining industries. They can be deployed on a temporary or permanent basis, and can be easily transported and installed on offshore platforms, ships, and other floating structures. Overall, Offshore lab containers are a cost-effective and efficient solution for companies looking to conduct laboratory work in offshore environments and they are designed to provide a safe, secure and comfortable working environment for the lab personnel. ADNOC, or Abu Dhabi National Oil Company, is a state-owned oil company based in Abu Dhabi, United Arab Emirates. It is the largest oil and gas company in the UAE and one of the largest in the world, with a production capacity of over 3 million barrels of oil and 10.5 billion cubic feet of natural gas per day. ADNOC is a key player in the global oil and gas industry and is actively involved in exploration, production, refining, marketing, and distribution of oil and gas products. We have previously had the pleasure of providing offshore functional containers to ADNOC and are proud to say that our products have been accepted and utilized by the company.

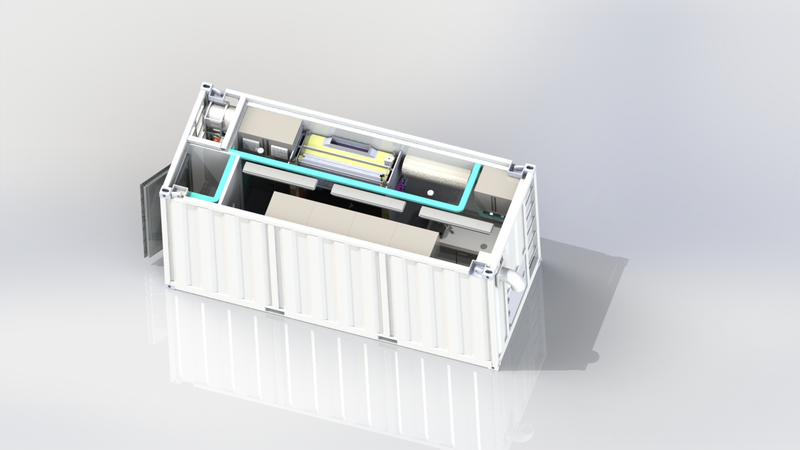

About the lab container The lab containers are fully insulated suitable for operation in all extremes of climatic conditions. The laboratory operating area in negative pressure is air conditioned with extracted air filtered and returned to maintain a comfortable working environment and to reduce operating costs. Applications for the laboratories can be fully operational within hours of arriving on site. So it can be used on exploration projects for the primary sizing of samples or as an on-site mining laboratory potentially saving millions in analysis and setup costs. Please download laboratory container brochure for reference. About the BESS container The battery energy storage system (BESS) containers are based on a modular design. They can be configured to match the required power and capacity requirements of client’s application. The battery energy storage systems are based on standard sea freight containers starting from kW/kWh (single container) up to MW/MWh (combining multiple containers). The containerised energy storage system allows fast installation, safe operation and controlled environmental conditions. The energy storage system (BESS) containers are designed for neighbourhoods, public buildings, medium to large businesses and utility scale storage systems, weak- or off-grid, e-mobility or as backup systems. The energy storage system containers make it possible to store the energy produced by photovoltaics, wind turbines, or CHP. Due to its high cycle lifetime, The energy storage system containers are also used for peak-shaving, thereby reducing the electricity bill. Our containerised energy storage system (BESS) is the perfect solution for large-scale energy storage projects. The energy storage containers can be used in the integration of various storage technologies and for different purposes. If you have any inquiries on BESS containers, please download the check list and send it together with your inquiry. Don’t hesitate to contact us for more information about the battery energy storage system container, We are eager to explain the possibilities for your applications. Please download Energy Storage System (ESS) Containers brochure for reference. The lab containers are fully insulated suitable for operation in all extremes of climatic conditions. The laboratory operating area in negative pressure is air conditioned with extracted air filtered and returned to maintain a comfortable working environment and to reduce operating costs. Applications for the laboratories can be fully operational within hours of arriving on site. So it can be used on exploration projects for the primary sizing of samples or as an on-site mining laboratory potentially saving millions in analysis and setup costs. Specification: • All units are designed, manufactured and certified to the latest DNV 2.7-1 and EN 12079 Offshore Container Standard and or ATEX, IEC and / or SOLAS standards • Built for Safe Area or Hazardous Area Operation Zone 1 and Zone 2 • Pressurised Control Module / Cabin create a safe area environment for personnel and equipment, with built in HVAC and power control systems. • All modules are designed, built and completely fitted out as per customer's specifications and requirements • A60 Fire Rating complete with Certificate • Units designed and built complete with Fire & Gas Detection System, HVAC System and Communication System • Factory Acceptance Test and Pre-commissioning for all electrical and instrumentation Please download laboratory container brochure for reference. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|