|

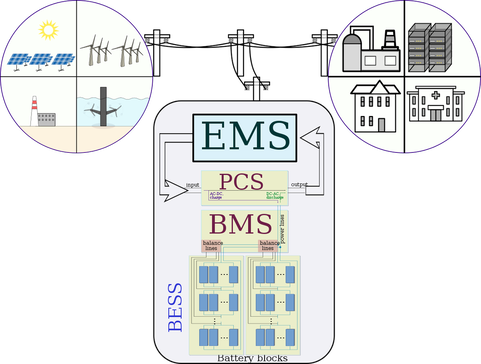

The Energy Management System (EMS) serves as the nerve center of Battery Energy Storage Systems (BESS), enabling these systems to meet diverse and dynamic grid requirements. In a rapidly evolving energy landscape that increasingly relies on renewable sources, the importance of an effective EMS cannot be overstated. Let's delve deeper into the nuanced functionalities and groundbreaking benefits that an EMS brings to BESS. Advanced Algorithms: The Brain Behind the Operations One of the standout features of an EMS is its use of sophisticated algorithms. These algorithms interpret data from various sensors and gauges, such as temperature, voltage, and current, to make real-time decisions that optimize the performance of the battery storage system. ### Machine Learning and Predictive Analytics Many modern EMS implementations are incorporating machine learning techniques to forecast grid behavior better. These predictive analytics capabilities allow the system to anticipate fluctuations in supply and demand, thus making more efficient use of stored energy. ### Adaptive Charging and Discharging The EMS is programmed to manage the charging and discharging cycles of the BESS dynamically. For instance, during periods of low demand and high renewable energy production, the EMS might command the BESS to store more energy. Conversely, during peak hours or low renewable energy output, the system discharges stored energy to maintain grid stability. Seamless Grid Integration: Harmonizing with Renewable Sources The integration of renewable energy sources like wind and solar presents several challenges for grid management. One minute the sun is shining, and the next, clouds could obscure it, causing sudden dips in energy production. Here's where an EMS shines: ### Renewable Energy Buffering The EMS can act as a buffer for renewable energy, absorbing excess production and releasing it when there's a shortfall. This buffering capability is critical for making renewable energy sources more reliable and easier to manage. ### Microgrid Operations For more localized energy solutions, an EMS can manage a microgrid, balancing energy production and storage within a smaller geographic area, such as a community or even a single building. This offers great advantages in terms of sustainability and resilience. Reliability and Safety: Non-Negotiables in Energy Management Safety and reliability are essential in any energy storage system, and the EMS plays a pivotal role in ensuring these factors. With built-in fail-safes and emergency protocols, the EMS can detect abnormalities that may indicate a malfunction, automatically taking the system offline for inspection or triggering other safety measures. Remote Monitoring and Control For system operators, the EMS offers the convenience of remote monitoring and control. Dashboards accessible via the internet provide real-time information and the ability to override automated systems if necessary, ensuring that control is never out of human reach. Long-Term Benefits: Sustainability and ROI Investing in a BESS with an advanced EMS yields long-term benefits. By optimizing the use of energy, it not only makes the grid more sustainable but also offers substantial cost savings over time, thus enhancing the return on investment. Wrapping Up: The Indispensable Role of EMS in BESS As we forge ahead into a future characterized by renewable energy and smart technology, the EMS will undoubtedly serve as the linchpin that holds complex electrical systems together. The dynamic capabilities, the focus on safety and reliability, and the adaptability to evolving energy landscapes make it a crucial part of any BESS setup. When it comes to integrating a BESS into your grid, having a well-designed EMS ensures that you are well-equipped to meet the challenges and opportunities of the modern energy world. As we navigate the challenges of an ever-evolving energy landscape, the need for stable, efficient, and reliable electrical grid systems has never been more critical. Solar farms, wind turbines, and other renewable energy resources are getting integrated into the grid, but these sources are not without their intermittent fluctuations. The answer to these problems lies in advanced Battery Energy Storage Systems (BESS). A leader in this industry, TLS Energy International offers state-of-the-art BESS containers designed to tackle a range of grid applications. From frequency response to peak shaving, these BESS solutions are your go-to for holistic grid management. Why BESS Containers are Crucial for the Modern Grid In today’s era of sustainable energy, BESS serves as the backbone for many modern grid systems. By storing excess energy and discharging it when needed, BESS enhances the overall functionality and efficiency of grids. TLS Energy International's BESS containers are designed to operate seamlessly with existing grid structures, paving the way for a more resilient energy future. Key Features of TLS Energy International's BESS Containers Before diving into how TLS Energy International's BESS containers meet various grid applications, it's essential to understand their key features: 1. **Scalability**: These containers can be scaled up or down to match grid requirements, making them highly versatile. 2. **Durability**: Built with robust materials and state-of-the-art engineering, they are designed for long-term operations. 3. **Efficiency**: High energy conversion rates mean less waste and more effective grid operation. 4. **Automation**: Equipped with intelligent systems, these containers can operate autonomously, making grid management hassle-free. Meeting Critical Grid Applications Now, let's explore how these BESS containers fulfill different grid needs. 1. FFR (Fast Frequency Response) FFR is crucial for the rapid stabilization of the grid in cases of sudden changes in frequency. TLS Energy International’s BESS containers can respond within a second, effectively acting as a quick countermeasure to fluctuations that could otherwise destabilize the grid. 2. FCR-N (Frequency Containment Reserve - Normal) In a perfect world, electrical grids would operate without any disturbances. However, minor adjustments are often needed to keep frequency within designated ranges. TLS Energy International’s BESS containers excel in this task, making them an ideal choice for FCR-N applications. 3. FCR-D Up & FCR-D Down (Frequency Containment Reserve - Disturbance Up and Down) Grid disturbances come unannounced and require swift action. Whether it's a matter of ramping up or scaling down output, these BESS containers provide dynamic responses to keep the grid stable during unexpected events. 4. aFRR (Automatic Frequency Restoration Reserve) Imagine a scenario where there is a sudden imbalance between energy supply and demand, leading to a frequency deviation. TLS Energy International’s BESS containers are equipped with aFRR capabilities, meaning they can automatically restore frequency to nominal levels. 5. mFRR (Manual Frequency Restoration Reserve) Automated systems are excellent but not infallible. For those instances where manual intervention is required, these BESS containers offer manual control options, providing a well-rounded solution for grid management. 6. Peak Shaving Utility companies often struggle with the increased demand during peak hours, leading to higher costs and grid strain. With peak shaving capabilities, TLS Energy International's BESS containers can release stored energy to alleviate this strain, subsequently reducing operational costs. 7. Reactive Power Applications Reactive power is essential for maintaining voltage levels within the grid. These BESS containers can either absorb or provide reactive power, ensuring that the voltage remains stable and within the desired limits. Real-world Applications and Case Studies What sets TLS Energy International apart is not just its state-of-the-art technology but also its proven track record. Whether it's managing frequency reserves for a city grid or providing peak shaving solutions for industrial complexes, the company’s BESS containers have shown exemplary performance. The Future is Bright and Stable with TLS Energy International In summary, as we transition towards more sustainable energy sources and as our power needs continue to evolve, BESS containers like those from TLS Energy International will play a more and more vital role. With their ability to tackle a range of applications, from frequency response to peak shaving and beyond, these systems offer a comprehensive solution for modern grid management. The future of energy is here, and it's intelligent, responsive, and efficient. Opt for TLS Energy International's BESS containers for a stable, resilient, and future-proof grid system. Because when it comes to energy, compromise is not an option. Choose quality, choose reliability, choose TLS Energy International. In today's era of increasing reliance on renewable energy sources and smart grids, Battery Energy Storage Systems (BESS) have emerged as a cornerstone. These BESS containers offer a viable solution for storing excess electrical energy and ensuring an uninterrupted power supply. However, with the advent of sophisticated technology comes the responsibility of securing these installations against potential hazards, notably fire. A comprehensive fire fighting system (FFS) is no longer an optional accessory; it's a necessity. This article delves into the intricacies of fire fighting systems specially designed for BESS containers. ## Components that Make Up a Robust Fire Fighting System One of the remarkable aspects of a modern FFS for BESS containers is the multitude of components that form an interconnected network for maximal efficiency and safety. Below are the crucial components that you should expect in a state-of-the-art FFS: ### Fire Detectors Fire detectors serve as the eyes of the system, constantly monitoring conditions to detect any abnormalities that could lead to a fire. ### Controllers Controllers act as the brain of the operation, interpreting signals from the fire detectors and determining the appropriate course of action. ### Storage Bottle Sets These bottles store the fire-extinguishing agents, ready to be released when activated. ### Sprinkler Heads In the event of a fire, sprinkler heads distribute the extinguishing agents to contain and suppress the fire. ### Pressure Relief Valves These valves regulate the pressure within the system, ensuring it operates within safe parameters. ### Audio-Visual Alarms These alarms provide both sound and light indications of a fire hazard, enabling quick reaction from personnel. ### Gas Discharge Indicator Lights These lights signal that the extinguishing agents have been discharged, offering an additional layer of safety communication. ### Emergency Start/Stop Buttons These buttons provide the flexibility for manual override, allowing trained personnel to take control in unique situations. All these components are designed to function cohesively, providing both manual and automatic switching capabilities. This dual-functionality ensures that the system can adapt to varying conditions and offer immediate and appropriate responses. ## A Comprehensive Three-Tiered Approach for Unparalleled Safety The FFS for BESS containers is uniquely developed to include a three-tiered approach, each aimed at tackling different levels of threats. ### Level 1: Proactive Early Warning System The first level primarily focuses on early detection and warning. When sensors detect low levels of hazardous gases like hydrogen (H₂) and carbon monoxide (CO), or notice minor fluctuations in smoke and temperature, audio-visual alarms are immediately triggered. These early warnings are invaluable, as they offer the first line of defense, giving personnel the opportunity to address issues before they escalate. ### Level 2: Intelligent Gas Dispersion Measures When the system escalates to Level 2, it signifies that gas concentrations have surpassed safe limits. At this point, the FFS activates exhaust fans to disperse and dilute the gases. This is a crucial middle step, serving as an intermediary measure to handle escalating but not yet critical situations. ### Level 3: All-Out Comprehensive Response This is the most advanced and critical stage of the fire fighting system. When conditions reach alarming levels—indicated by high concentrations of dangerous gases, smoke detection, and temperature anomalies—the system shifts into high gear. It deactivates exhaust fans, disconnects system switches, and releases aerosol extinguishing agents to swiftly neutralize the threat. ## Why Your BESS Container Needs a State-of-the-Art FFS With BESS containers playing an increasingly critical role in our energy infrastructure, their protection becomes a matter of national interest. Investing in a comprehensive fire fighting system is not just about meeting regulatory standards; it's about ensuring operational continuity and safeguarding human lives and valuable assets. As BESS containers become ubiquitous in renewable energy setups and grid systems, their vulnerability to fire hazards cannot be ignored. A robust, state-of-the-art fire fighting system serves as an integral part of a BESS setup, enhancing its reliability and longevity. With tiered response mechanisms, this system not only offers early warnings but can take decisive, life-saving actions. In today’s complex and ever-changing energy landscape, such an investment is not just a safety measure but a mandate for sustainable and responsible operation. By giving due attention to the various components and levels of a well-designed FFS, we can ensure that our BESS containers are not just efficient but also resilient and safe. This makes the subject of fire safety in BESS installations a critical topic for everyone, from policymakers and engineers to end-users. In today's fast-paced world, the energy landscape is in constant flux. Traditional energy sources are giving way to renewable energy, and energy consumers are increasingly looking for ways to reduce their carbon footprint while maintaining control over their energy costs. This shifting paradigm has given rise to the need for innovative solutions, and one such solution that is gaining prominence is the grid-tied battery storage system. A Multifaceted Solution Grid-tied battery storage systems offer a multifaceted approach to energy management. They are a dynamic and adaptable tool that can be customized to suit a variety of applications. One such system leading the way in this field is the Commercial and Industrial & Microgrid Energy Storage System from TLS. Let's delve deeper into its key features.

Conclusion: Embracing the Future of Energy Management In conclusion, the Commercial and Industrial & Microgrid Energy Storage System from TLS is not just a storage system; it's a comprehensive, safety-compliant, and highly adaptable solution designed to meet the multifaceted needs of modern energy management. Whether the goal is to optimize solar investments, manage energy costs, or contribute to grid stability, this system offers a robust and flexible platform for achieving these objectives. Embrace the future of energy management with TLS and experience the benefits of safety, intelligence, efficiency, and flexibility in one remarkable package. It's a solution that aligns perfectly with the ever-changing energy landscape. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding the Commercial and industrial & microgrid energy storage system, please download Commerical and industrial microgrid tied energy storage system cabinet brochure for your reference #Grid-tied battery storage system #Energy management solutions #Commercial energy storage #Industrial energy storage #Microgrid energy storage #Battery system safety #Energy efficiency #Renewable energy integration #Demand charge reduction #Peak shaving Written by OliverTLS freezer containers are revolutionizing temperature-sensitive material preservation. In today's world, maintaining precise and ultra-low temperatures is essential across various sectors, including biomedical research, pharmaceuticals, genetics, and the food industry. In this condensed article, we will explore the mechanics of super freezer containers, their distinctive features, and their profound impact on multiple industries. Section 1: The Working Principle of Super Freezer Containers Super freezer containers excel at reaching and maintaining ultra-low temperatures, often dipping below -80°C (-112°F). They are crucial for preserving sensitive materials like biological samples, vaccines, genetic specimens, and gourmet ingredients. These containers employ advanced temperature control mechanisms and high-efficiency insulation to achieve ultra-low temperatures. Their powerful refrigeration systems, consisting of compressors, evaporators, and condensers, work swiftly to cool the interior. This combination of refrigeration technology and insulation prevents heat exchange with the external environment. Section 2: The Role of Insulation in Maintaining Ultra-Low Temperatures Super freezer containers require top-tier insulation to minimize heat transfer between the interior and the external surroundings. This insulation ensures stability in ultra-low temperatures, even when external conditions fluctuate. Conventional household refrigerators, designed to maintain around -18°C (0°F), have less insulation since they do not require extreme temperatures like super freezer containers. The latter's insulation is engineered to keep temperatures below -80°C (-112°F) without excessive energy consumption. Section 3: The Cooling System Super freezer containers employ state-of-the-art refrigeration systems for efficient cooling. Compressors, evaporators, and condensers work together to achieve rapid temperature reduction. The compressor plays a vital role by compressing refrigerant gas, releasing heat, and converting it into a high-pressure, high-temperature gas. This gas then condenses into a liquid, further releasing heat and maintaining the desired low temperature. Section 4: Distinctive Features of Super Freezer Containers The key difference between super freezer containers and regular freezers lies in the range of temperatures they can reach and maintain. Regular household refrigerators maintain temperatures around -18°C (0°F), sufficient for everyday frozen items. Super freezer containers, in contrast, can reach temperatures as low as -80°C (-112°F) or even lower. This capability is essential for preserving highly sensitive materials. Section 5: Professional Applications and Precise Temperature Control Super freezer containers find critical applications in various industries:

These containers offer precise temperature control through advanced control panels. Integrated monitoring systems track internal temperatures and provide real-time alerts to ensure the integrity of sensitive materials. Section 6: Energy Efficiency and Sustainability Despite their extreme cooling capabilities, super freezer containers prioritize energy efficiency. Advanced compressor technology optimizes energy consumption, and premium insulation minimizes heat transfer, reducing the need for constant cooling. Many manufacturers also embrace sustainable practices, using eco-friendly refrigerants and energy-efficient designs. Conclusion In summary, super freezer containers are at the forefront of refrigeration technology. Their ability to reach and maintain ultra-low temperatures, coupled with advanced insulation, refrigeration systems, precise controls, and specialized applications, sets them apart. They play a pivotal role in preserving sensitive materials across various industries, contributing to scientific progress, and upholding quality standards in the food industry. These super freezer containers empower professionals and researchers with precision cooling solutions that are here to stay. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference #Super freezer containers #Ultra-low temperature storage #Precision cooling #Refrigeration technology #Temperature-sensitive materials #Advanced insulation #Refrigeration systems #Temperature control mechanisms #Biomedical research preservation #Pharmaceutical storage Written by OliverHigh-Quality Offshore Negative Pressure Laboratory Containers: Safeguarding Innovation and Safety10/9/2023

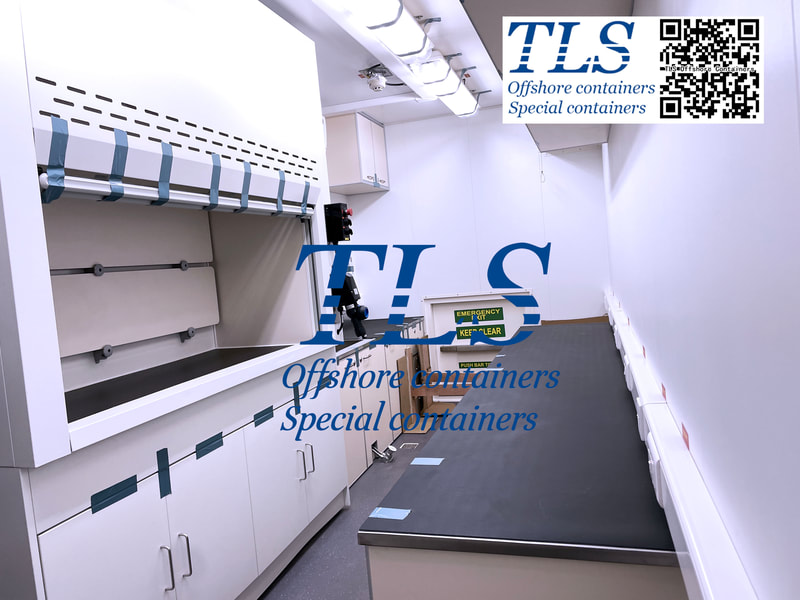

Introduction Offshore negative pressure laboratory containers are a cornerstone of safety and innovation in various industries, including pharmaceuticals, healthcare, and research. These specialized containers are engineered to prevent the escape of hazardous substances, ensuring the well-being of workers and the environment. In this article, we delve into the world of high-quality offshore negative pressure laboratory containers, exploring their significance, characteristics, and the crucial factors to consider when choosing or manufacturing them. The Importance of High-Quality Offshore Negative Pressure Laboratory Containers High-quality offshore negative pressure laboratory containers serve several vital purposes, making them indispensable in numerous industries:

Characteristics of High-Quality Offshore Negative Pressure Laboratory Containers To ensure the highest level of safety and performance, high-quality offshore negative pressure laboratory containers exhibit specific characteristics:

Choosing the Right Offshore Negative Pressure Laboratory Container When selecting or manufacturing these containers, consider the following factors:

Conclusion High-quality offshore negative pressure laboratory containers are essential for safeguarding workers and the environment while fostering innovation in various industries. By understanding their significance, characteristics, and the factors to consider when choosing or manufacturing them, you can make informed decisions to protect your personnel and advance your industry. These containers are not just physical barriers; they are a testament to the commitment to safety and progress in today's rapidly evolving world. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. #Offshore Negative Pressure Laboratory Containers #High-Quality Laboratory Containers #Safety in Laboratory Containers #Innovation in Container Design #Hazardous Material Containment #Biological Research Containers #Pharmaceutical Manufacturing Containers #Offshore Oil and Gas Containers #Corrosion-Resistant Materials #Stainless Steel Containers Written by OliverIn various fields, specialized containers play a crucial role, ensuring structural stability and safety during transportation and use, from pressure vessels to experimental equipment and Modular Control Centers (MCC) shelters. The lifting and dropping test of specialized containers has become a pivotal step in ensuring their safe application across diverse domains. In this article, we will delve into the significance of the specialized container lifting and dropping test and its critical roles in different sectors.

In many industries, the use of specialized containers must comply with strict industry standards and regulations. Conducting lifting and dropping tests is a necessary step to meet these standards and regulations. Qualified specialized containers can obtain the necessary certifications, ensuring legal and secure usage. In summary, the lifting and dropping test for specialized containers is not just a routine procedure; it is a crucial means of ensuring safe application across various sectors. Through this specialized testing, specialized containers can be safely transported and used under various extreme conditions, providing reliable assurance for industries, ensuring both personnel and property safety. At TLS Offshore Containers, we are committed to providing excellent container products and outstanding services to our clients. We understand that when it comes to specialized containers, quality is your utmost concern. Therefore, we meticulously control every step to ensure our products meet the highest standards, fulfilling your expectations and requirements. For any container-related needs, please contact us. In the unforgiving realms of offshore environments, safety is non-negotiable. But what exactly makes TLS Offshore Containers stand out as the ultimate safeguard in Zone 1 and Zone 2 areas?

At TLS Offshore Containers, we comprehend the critical importance of safety in high-risk environments. Our containers are more than secure enclosures; they are peace of mind, engineered to safeguard lives and assets. With A60 insulation, explosion-proof electronics, CPFG systems, MCP, ESD, and thoughtful design considerations, TLS offers more than just safety; we provide unwavering confidence even in the face of adversity. In the realm of offshore operations, the question isn't just about safety; it's about the TLS advantage. Discover why TLS Offshore Containers is the future of offshore safety. Your safety, our priority. #CPFG #TLS Offshore Containers #ZONE 1/ZONE 2 #gas detectors |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|