|

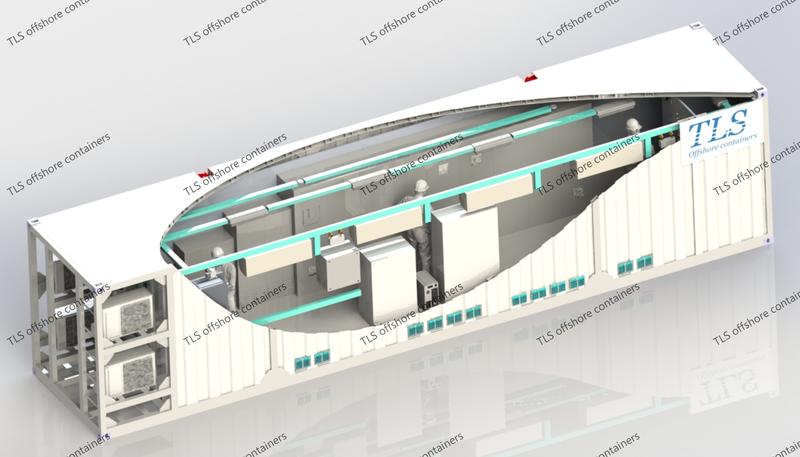

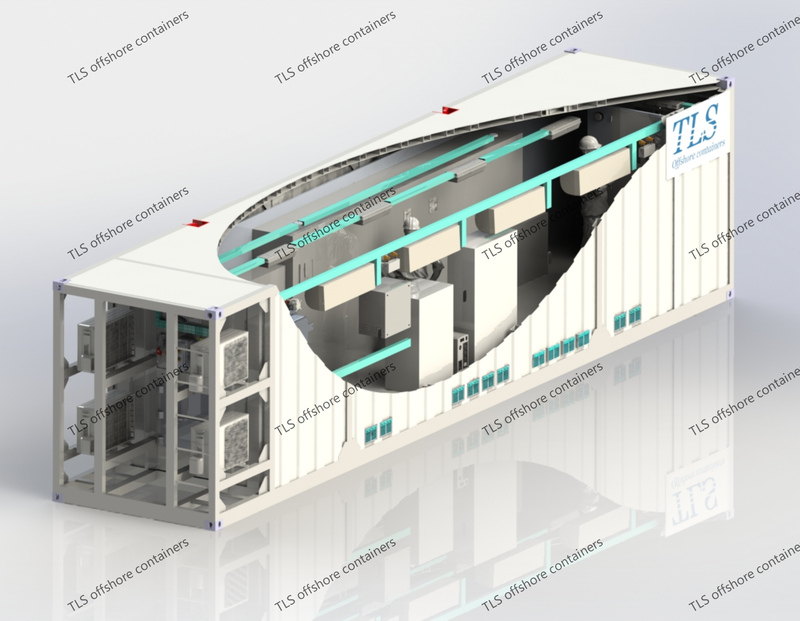

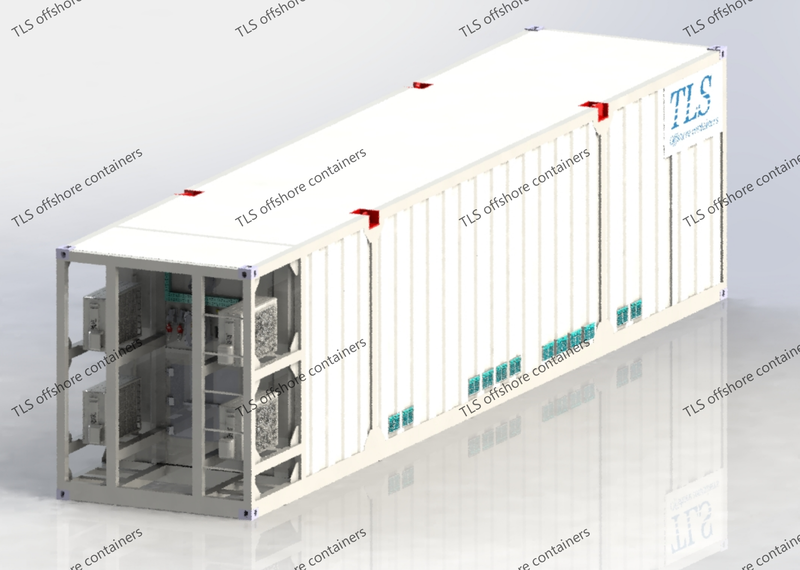

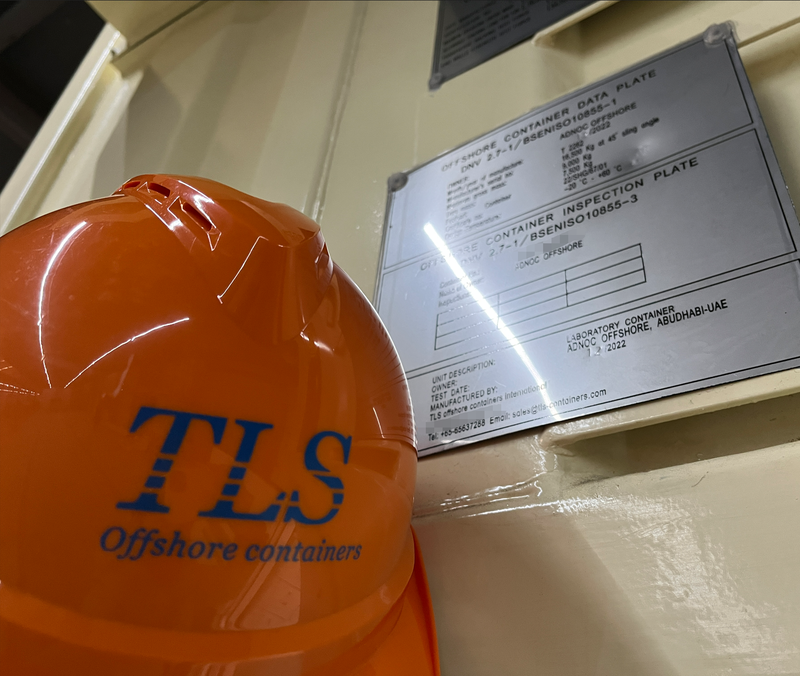

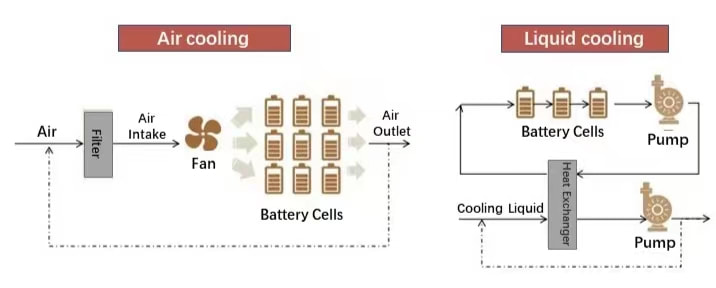

Introducing the MCC Shelter, the ultimate solution for hazardous zones! This innovative product by TLS provides a safe and secure environment for electrical equipment in hazardous environments, where flammable or hazardous gases may be present. Placing electrical equipment in the MCC Shelter protects it from the dangers of gas explosions and fire, ensuring that it continues to operate safely and effectively. The shelter is designed and tested to meet the highest safety standards, making it the ideal choice for hazardous zones, including Zone 1 and Zone 2. In addition to its exceptional safety features, the MCC Shelter is also designed for ease of use and versatility. Its compact design and customizable features allow it to be tailored to your specific needs, ensuring optimal performance and functionality. So if you're looking for a reliable, durable, and safe solution for your electrical equipment in hazardous environments, look no further than the MCC Shelter by TLS. Get yours today and enjoy the peace of mind that comes with knowing your equipment is protected and operating at its best! Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter More information about offshore pressurised container/cabin Don’t hesitate to contact us for more information about the offshore pressurised container. Our skilled engineers are eager to explain the possibilities for your applications. The electricity sector is undergoing a transformation as it moves towards a more digital and intelligent system. This transformation is driven by advances in technology, growing demand for clean energy, and a desire to improve efficiency and reliability in the electricity grid. One of the key technologies enabling this transformation is the integration of digitization and intelligence into the electricity sector. By digitizing and automating various processes, the electricity sector is able to operate more efficiently and with greater reliability. For example, smart grid technology allows utilities to monitor and control the flow of electricity in real-time, enabling them to respond quickly to changes in demand and generation. Battery energy storage systems (BESS) are a key technology in the transition towards a more sustainable and efficient energy system. These systems allow excess energy generated from renewable sources to be stored and used when needed, rather than being lost as waste. This not only helps to reduce greenhouse gas emissions and promote the use of clean energy, but also helps to stabilize the grid by balancing supply and demand. Battery energy storage systems are becoming increasingly popular due to declining costs and advancements in technology. As battery prices continue to fall, more and more businesses and households are installing these systems to store excess energy generated from rooftop solar panels, for example. In addition, battery energy storage systems are becoming more flexible and efficient, making them a more viable solution for a wider range of applications. In the electricity sector, battery energy storage systems play a crucial role in the trend towards digitization and intelligence. By storing energy and releasing it when needed, these systems help to ensure that there is always a reliable and consistent supply of power. This is especially important in areas with high levels of renewable energy generation, as fluctuations in wind and solar generation can cause instability in the grid. Battery energy storage systems can also help to integrate renewable energy into the grid by smoothing out fluctuations in generation. This makes it easier for utilities to incorporate renewable energy into their energy mix, as the grid can more easily handle fluctuations in generation. In addition, battery energy storage systems can help to defer or avoid the need for expensive grid upgrades, as they can be used to store excess energy during periods of high generation and release it when needed. In addition to their role in balancing supply and demand, battery energy storage systems are also becoming increasingly intelligent. Many systems are now equipped with sophisticated monitoring and control systems that can optimize performance and ensure efficient operation. For example, some systems can be programmed to release energy when demand is high and prices are high, or to store energy when demand is low and prices are low. The trend towards digitization and intelligence in the electricity sector is expected to continue in the coming years, and battery energy storage systems will play a key role in this trend. As renewable energy continues to become more widespread and battery technology continues to improve, it is likely that these systems will become even more widespread and play an even more important role in the transition towards a more sustainable energy future. In conclusion, battery energy storage systems are a critical technology in the trend towards digitization and intelligence in the electricity sector. By allowing excess energy to be stored and used when needed, these systems help to ensure a reliable and consistent supply of power, integrate renewable energy into the grid, and improve the efficiency and stability of the electricity system. TLS Offshore Containers offers cutting-edge BESS solutions, designed and manufactured to meet the specific needs of their clients. Their BESS products are highly reliable, efficient, and sustainable, and they provide a vital solution in the transition towards a cleaner energy future. With a commitment to innovation and customer satisfaction, TLS Offshore Containers is at the forefront of the digitization and intelligence transformation in the electricity industry. The energy storage system plays an increasingly important role in solving new energy consumption, enhancing the stability of the power grid, and improving the utilization efficiency of the power distribution system. arouse people's general attention.Its application scale is growing rapidly, and the safety of energy storage power stations has also attracted widespread attention. There are three lines of defense for energy storage safety. The first is the material safety of the energy storage battery itself. The second is the fire protection design of the system, efficient thermal management, temperature control, early warning and intervention of thermal runaway, through BMS system linkage to cut off the power when thermal runaway occurs. The third is fire safety, effectively blocking the spread of energy storage battery fires, quickly cooling down and efficiently extinguishing fires, and preventing re-ignition. The energy storage fire protection system is mainly composed of a detection part and a fire extinguishing part, which can realize the automatic detection, alarm and fire extinguishing protection functions of the protection zone or battery storage container. There are three common energy storage container fire protection systems on the market. One is the design idea of total submersion, which uses a gas fire extinguishing system to extinguish the fire; the second uses a gas fire extinguishing system + sprinkler; the third uses a Pack level fire extinguishing solution, and the solution is a fire extinguishing solution designed for each battery pack. Total submersion System composition: fire extinguishing device, detection system, fire extinguishing agent delivery pipeline 1.Fire extinguishing device: Usually, the energy storage container fire fighting system will choose the heptafluoropropane fire extinguishing system. Experiments have shown that if the lithium battery catches fire in a closed environment, heptafluoropropane can quickly extinguish the fire and will not re-ignite in a closed environment; ultra-fine dry powder can also quickly extinguish the fire and will not resume Combustion; carbon dioxide can quickly extinguish the fire, but it will re-ignition; 2.Detection system:For lithium battery energy storage containers, we usually design a variety of detectors, such as temperature, smoke, combustible gas, carbon monoxide, hydrogen and other detectors, to sense the fire, and activate the fire extinguishing device through a prefabricated algorithm. 3.Fire extinguishing agent delivery pipeline: When the energy storage container fire protection system uses pipe network type heptafluoropropane, special gas pipelines will be used. Usually, the electrical area and the energy storage area will be separated. The electrical area adopts a suspended fire extinguishing device, and the energy storage area adopts a pipe network for formula heptafluoropropane. Arranging multiple nozzles through the pipe network to the protected area can ensure the uniform spraying of the fire extinguishing agent. Gas fire extinguishing system + sprinkler Energy storage container fire system design gas fire extinguishing system, while installing sprinkler system, is considered to be the most comprehensive and economical solution in the case of scientific design.The initial fire can be suppressed in time, buying valuable time for the next personnel to deal with it. If the fire is very large, the sprinkler will also be triggered. If the water resources are relatively sufficient, the fire can be completely suppressed normally.If the water resources are insufficient, it can also buy more valuable time for personnel to deal with.When the energy storage container is installed in a remote outdoor area and there is no water resource, there should be an emergency plan on site, such as how to quickly remove the battery on fire, and how to quickly remove the battery on fire. These basic plans and corresponding equipment such as a forklift is a must. Pack level fire extinguishing solution It detects and protects each battery pack through composite detectors, pipeline solenoid valves, fire extinguishing device spot spraying and other technologies.The core value point is that electrical fires can be effectively monitored and suppressed at the initial stage.The cost of Pack-level fire extinguishing is relatively high. In energy storage scenarios with a relatively high risk factor, a targeted fire extinguishing scheme is designed. The construction of the energy storage container fire protection system pays more attention to details. For example, the pressure relief port and emergency start and stop must have sealing measures. If the sealing is not good, there is a risk of short circuit;For example, sound and light and deflated lights must be protected against rain to reduce the risk of electrical short circuits. Written by Mandy The ultra-wide offshore lab container for Petrobras is a specialized piece of equipment designed for use in the oil and gas industry. It is specifically designed to be used in offshore environments, such as on oil rigs or platforms, where space is limited and the conditions are harsh. The container is ultra-wide to provide more space for laboratory equipment and personnel, and is built to withstand the extreme conditions of the offshore environment, such as high winds, saltwater corrosion, and extreme temperatures. The container is equipped with various features to ensure the safe and efficient operation of the laboratory equipment it contains. These may include ventilation systems to maintain proper air flow and temperature, as well as lighting and power systems to ensure that the equipment can be safely operated at all times. It may also be equipped with fire suppression systems, emergency shut-off valves, and other safety features to help prevent accidents and protect personnel in case of an emergency. The container is also designed to be easily transportable and can be easily moved from one location to another, making it ideal for use on multiple offshore platforms. It can also be customized to meet the specific needs of the facility in which it is installed, such as the use of special materials and coatings to protect the container from corrosive environments. Overall, the ultra-wide offshore lab container for Petrobras is a critical piece of equipment for conducting laboratory work in offshore environments. It not only helps to ensure the safety of the equipment and personnel, but also helps to improve the efficiency of laboratory operations and reduce maintenance costs. A pressurized MCC (motor control center) shelter is a type of equipment used to house and protect electrical equipment, specifically motor control centers, in environments where there may be a risk of explosion or other hazards that could damage the equipment. These shelters are typically made of metal or other durable materials and are designed to withstand high pressures and temperatures. They are often used in oil and gas facilities, mines, and other industrial settings. Inside the pressurized MCC shelter, the air pressure is regulated and maintained at a level higher than the surrounding atmosphere, which helps to prevent the ingress of explosive gases or dust. This helps to ensure the safety of the electrical equipment and personnel working near the shelter. A pressurized MCC shelter typically includes a variety of features to ensure the safe and efficient operation of the electrical equipment it contains. These may include ventilation systems to maintain proper air flow and temperature, as well as lighting and power systems to ensure that the equipment can be safely operated at all times. The shelter may also be equipped with fire suppression systems, emergency shut-off valves, and other safety features to help prevent accidents and protect personnel in case of an emergency. Pressurized MCC shelters also feature a pressurization system which maintains a positive pressure inside the shelter and prevents the ingress of flammable gases and dust. The pressurization system typically includes air filters and a blower to ensure that the air inside the shelter is clean and free from contaminants. The pressurized MCC shelter is designed to be durable and long-lasting, and can be customized to meet the specific needs of the facility in which it is installed. This may include the use of special materials and coatings to protect the shelter from corrosive environments, as well as the inclusion of additional features such as security systems to protect the equipment and personnel inside. Overall, pressurized MCC shelter is a critical piece of equipment for protecting electrical equipment in hazardous environments. It not only helps to ensure the safety of the equipment and personnel, but also helps to prolong the life of the equipment and reduce maintenance costs. Offshore lab containers are specialized containers that are designed and built to meet the unique needs of laboratories operating in offshore environments. These containers typically include features such as climate control, electrical and plumbing systems, and safety equipment to ensure that laboratory personnel can work comfortably and safely. Offshore lab containers can be used for a variety of purposes, such as testing and analysis, research and development, and sample preparation. They can be equipped with various types of laboratory equipment, including analytical instruments, microscopes, and centrifuges, to support a wide range of scientific and technical activities. Offshore lab containers are typically constructed from durable, corrosion-resistant materials and are designed to withstand harsh offshore conditions such as high winds, saltwater, and extreme temperatures. They are also typically equipped with safety features such as fire suppression systems and emergency lighting to ensure the safety of laboratory personnel. Because of their durability, flexibility, and safety features, offshore lab containers are becoming increasingly popular among offshore operators in the oil and gas, renewable energy, and mining industries. They can be deployed on a temporary or permanent basis, and can be easily transported and installed on offshore platforms, ships, and other floating structures. Overall, Offshore lab containers are a cost-effective and efficient solution for companies looking to conduct laboratory work in offshore environments and they are designed to provide a safe, secure and comfortable working environment for the lab personnel. ADNOC, or Abu Dhabi National Oil Company, is a state-owned oil company based in Abu Dhabi, United Arab Emirates. It is the largest oil and gas company in the UAE and one of the largest in the world, with a production capacity of over 3 million barrels of oil and 10.5 billion cubic feet of natural gas per day. ADNOC is a key player in the global oil and gas industry and is actively involved in exploration, production, refining, marketing, and distribution of oil and gas products. We have previously had the pleasure of providing offshore functional containers to ADNOC and are proud to say that our products have been accepted and utilized by the company. The temperature control system is an important link to ensure the normal operation of lithium battery energy storage. At present, air cooling and liquid cooling technologies are the mainstream temperature control solutions in the energy storage industry. The selection of energy storage temperature control technology should comprehensively consider safety, economy, and battery pack design, the environment, and other factors, not simply considering the cooling performance. Refrigeration power requirements:

Please download Energy Storage System (ESS) Containers brochure for reference. Written by Mandy Temperature control as a thermal management executor to ensure the safety of energy storage systems1/18/2023

Thermal management is a crucial aspect of ensuring the safe operation of energy storage systems, specifically in terms of improving the safety performance of batteries and maintaining stability during operation. There are two main angles to consider when improving the safe operation of energy storage systems:

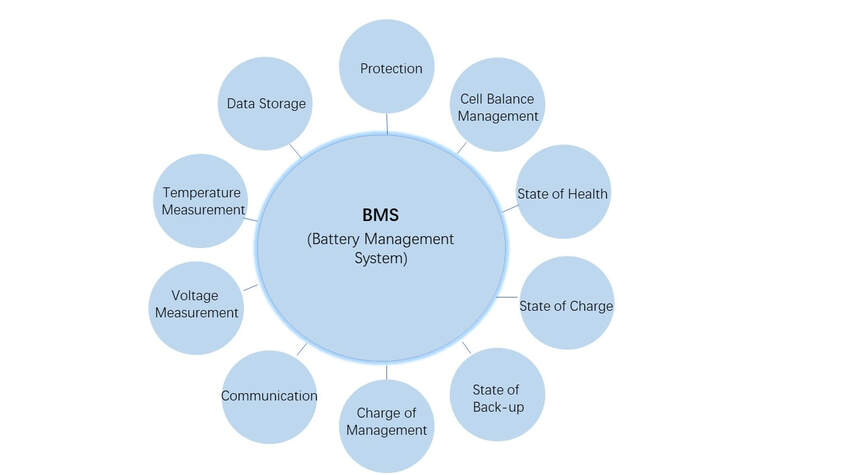

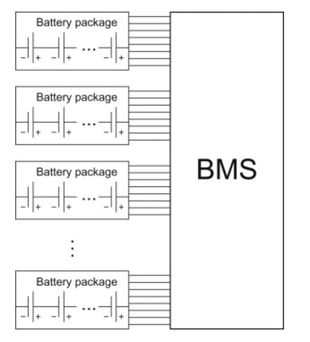

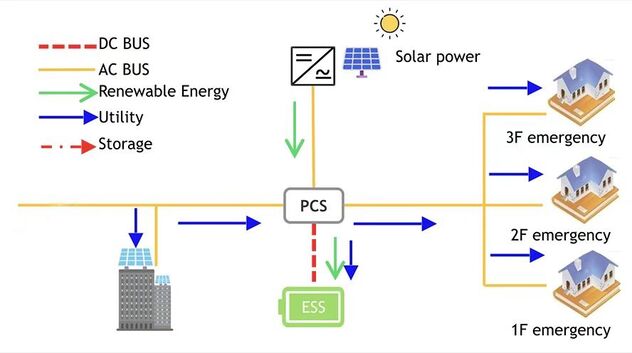

In summary, thermal management is essential for the safe operation of energy storage systems and can be achieved by improving the safety performance of batteries, and maintaining stability during operation by implementing BMS and temperature control equipment. This ensures that energy storage systems are operating within a safe range, avoiding thermal runaway and providing efficient performance. Written by Mandy The BMS (Battery Management System) is an essential component of an ESS (Energy Storage System). It is responsible for monitoring and controlling the state of the battery pack, ensuring that the batteries are operating within safe parameters and maintaining their performance over time. The BMS monitors key parameters such as battery voltage, current, temperature, and state of charge (SOC). It also has safety features such as over-voltage, over-current, and over-temperature protection to prevent damage to the battery pack. The BMS also controls the charging and discharging of the battery pack. This includes managing the charging rate to optimize battery life and performance, and balancing the cells within the battery pack to ensure that they are all operating at the same voltage level. Overall, the BMS plays a critical role in the overall performance and safety of an ESS. It allows the ESS to operate at peak efficiency, prolonging the life of the battery pack and ensuring that the system is always safe to operate. PCS (Power Conversion System) is the core part of an energy storage system, which is responsible for converting currents. It is a bidirectional reversible AC/DC converter that can convert the electric energy output from the grid or new energy generation through the energy storage inverter into DC power, which charges the battery. The energy released by the battery can then be converted back into AC power through the energy storage inverter and fed back to the grid or used to supply power to the load. Energy storage converters have two working modes: grid-connected and off-grid. In grid-connected mode, the PCS bidirectionally converts the energy between the battery pack and the grid. It has features such as anti-islanding, automatic tracking of grid voltage phase and frequency, and low voltage ride-through. According to the requirements of grid dispatching or local control, the PCS charges the battery pack with AC power from the grid and can also discharge the energy storage battery. During peak grid load periods, the PCS inverts the DC power of the energy storage battery into AC power and feeds it back to the public grid; it also feeds or absorbs active power to the grid, providing reactive power compensation when necessary. In off-grid mode, PCS is able to disconnect from the main grid and meet the set requirements, providing local partial loads with AC that meets the power quality requirements of the grid electrical energy. It can also smoothly switch between grid-connected and off-grid modes. Written by Mandy |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|