|

Introduction: In the realm of deep-sea exploration, safety and innovation are paramount. TLS Offshore Containers, a pioneering company renowned for its commitment to excellence, has introduced a groundbreaking solution to revolutionize underwater exploration: the ROV Pressurized Cabin. In this SEO blog post, we delve into the significance of this innovative technology and its transformative impact on underwater expeditions. Unveiling the ROV Pressurized Cabin: TLS Offshore Containers' ROV Pressurized Cabin is a marvel of engineering, designed to redefine the possibilities of deep-sea exploration. This cutting-edge cabin offers a secure environment for human operators, enabling direct occupancy in the depths of the ocean. Equipped with advanced safety features and state-of-the-art technology, it ensures unparalleled protection and comfort for operators during underwater missions. Safety at the Forefront: Safety is the cornerstone of TLS Offshore Containers' design philosophy, and the ROV Pressurized Cabin exemplifies this commitment. Constructed with robust materials and equipped with stringent safety protocols, it shields occupants from the extreme pressures and environmental hazards of the deep sea. TLS prioritizes the well-being of operators, providing peace of mind in the most challenging underwater conditions. Empowering Exploration: The ROV Pressurized Cabin transcends the limitations of traditional remote-operated vehicles (ROV) by facilitating direct human interaction with the underwater environment. This human presence enhances the scope and quality of exploration, allowing operators to conduct intricate tasks and make real-time observations with unprecedented clarity and precision. TLS empowers exploration teams to push boundaries and unlock new discoveries beneath the waves. Adaptability and Versatility: TLS Offshore Containers' commitment to innovation extends to the adaptability and versatility of the ROV Pressurized Cabin. Whether navigating complex underwater terrain, conducting scientific research, or inspecting offshore infrastructure, this versatile technology rises to the challenge. Its modular design enables seamless customization to suit the unique requirements of diverse exploration projects, ensuring maximum efficiency and effectiveness. Sustainable Exploration: TLS Offshore Containers recognizes the importance of responsible environmental stewardship in deep-sea exploration. The ROV Pressurized Cabin facilitates non-invasive observation and data collection, minimizing disturbance to fragile underwater ecosystems. By promoting sustainable exploration practices, TLS contributes to the preservation and conservation of marine environments for future generations. Conclusion: The ROV Pressurized Cabin by TLS Offshore Containers represents a paradigm shift in underwater exploration technology. With its unwavering focus on safety, empowerment, adaptability, and sustainability, it heralds a new era of discovery beneath the ocean's surface. As exploration teams embark on voyages of exploration and scientific inquiry, TLS's innovative cabin serves as a beacon of progress and possibility, driving forward the frontiers of human knowledge and understanding in the depths of the sea. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #ROV Pressurized Cabin #TLS Offshore Containers #Deep-sea exploration #Underwater technology #Safety features #Exploration capabilities #Innovation #Versatility #Adaptability #Environmental conservation #Sustainable exploration #Modular design #Underwater observation Written by OliverIn the dynamic realm of offshore energy exploration, efficiency and safety are paramount. Enter TLS Offshore Containers, a pioneering force in offshore energy storage solutions. Among our cutting-edge offerings stands the Offshore Pressurized Mud Logging Cabin, a game-changer in offshore operations. Understanding the Need Offshore drilling activities, particularly mud logging, demand a controlled environment where personnel can work efficiently amidst hazardous conditions. Traditional setups often fall short in providing the necessary safety measures and operational efficiency. TLS recognized this gap and engineered a solution that sets new standards in offshore mud logging. The TLS Difference TLS Offshore Pressurized Mud Logging Cabins are not just containers; they're meticulously crafted hubs of innovation. Let's delve into what sets them apart:

Applications and Beyond The versatility of TLS Offshore Pressurized Mud Logging Cabins extends beyond mud logging. These cabins find applications in various offshore scenarios, including MWD/LWD operations, ROV control, accommodation quarters, and more. Wherever there's a need for a secure and controlled environment in hazardous zones, TLS cabins deliver. Conclusion In the competitive landscape of offshore energy exploration, TLS Offshore Pressurized Mud Logging Cabins stand tall as beacons of innovation and reliability. With their unwavering commitment to safety, efficiency, and compliance, TLS continues to redefine industry standards and empower offshore operators worldwide. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Offshore energy exploration #Mud logging operations #TLS Offshore Containers #Pressurized Mud Logging Cabins #Safety #Efficiency #Hazardous area certifications #Integration #Mobility #Productivity #Customized solutions Written by OliverThe Pivotal Role of MUD Logging Cabins in Offshore Drilling: Innovations by TLS Offshore Containers4/19/2024

In the highly specialized field of offshore drilling, precise data collection and analysis are crucial for optimizing the extraction process and ensuring operational safety. Among the various technologies used on drilling sites, MUD logging cabins stand out for their critical role in continuous drilling surveillance. TLS Offshore Containers, a leader in engineered offshore container solutions, offers state-of-the-art MUD logging cabins designed to meet the complex demands of the oil and gas industry. Understanding MUD Logging Cabins MUD logging cabins, also known as logging units, are essential in capturing detailed geological data as drilling progresses. These cabins monitor drilling activity by analyzing the drilling mud returned from the borehole. The analysis provides valuable information on the geological formation, including the presence of hydrocarbons, drilling mechanics, and well safety. Features of TLS Offshore Containers' MUD Logging Cabins

Why Choose TLS Offshore Containers for MUD Logging? 1. Enhanced Operational Efficiency: TLS's intelligent pressurized cabins are engineered to optimize space and functionality, allowing for more efficient monitoring and analysis of geological data, which is vital for timely decision-making in drilling operations. 2. Unmatched Safety Standards: With built-in advanced safety monitoring systems and compliance with international safety standards, TLS ensures that the MUD logging cabins provide a safe working environment under all offshore conditions. 3. Seamless Integration and Mobility: Understanding the need for swift and hassle-free deployment, TLS designs its cabins for easy connectivity and rapid mobilization, which is critical for operations that move frequently between drilling sites. 4. Tailored Solutions: TLS’s commitment to customization allows for each MUD logging cabin to be specifically tailored to meet the exact requirements of each client, ensuring that all operational needs are met with precision. Conclusion In the competitive and high-stakes environment of offshore drilling, MUD logging cabins are more than just shelters—they are advanced, mobile data centers. TLS Offshore Containers is at the forefront of delivering these specialized solutions, designed to enhance operational efficiencies, ensure safety, and ultimately, drive the success of drilling operations. As the demand for more sophisticated and safer offshore operations grows, TLS’s MUD logging cabins are well-positioned to meet and exceed these industry needs. For offshore operations looking to leverage the best in safety and technology, TLS Offshore Containers represents a premier choice in equipping your site with the most advanced MUD logging cabins on the market. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #MUD logging cabin #Offshore drilling equipment #Oil and gas drilling technology #Hazardous area containers #Pressurized cabins for drilling #MUD logging technology #Geology analysis in drilling #Drilling data analysis #Zone 1 Zone 2 safety cabins #Atex certificate Written by OliverEnhancing Safety in Oil and Gas Operations: Positive Pressure Ex-Proof Containers for MWD/LWD Cabins12/7/2023

Introduction: In the ever-evolving landscape of oil and gas exploration, safety remains a top priority. The integration of advanced technologies like Measurement While Drilling (MWD) and Logging While Drilling (LWD) has revolutionized the industry, but it also poses unique challenges, particularly in terms of ensuring the safety of personnel and equipment. One crucial aspect of this safety equation is the application of positive pressure Ex-Proof containers for MWD/LWD cabins. Understanding MWD/LWD Cabins: MWD and LWD are indispensable technologies in modern drilling operations. MWD systems provide real-time data on drilling parameters, while LWD tools offer invaluable insights into subsurface formations. These technologies are typically housed in dedicated cabins on drilling rigs, serving as the nerve center for data acquisition and analysis. Challenges in Hazardous Environments: Oil and gas drilling often takes place in challenging and hazardous environments. These conditions demand robust safety measures to protect personnel and equipment from potential risks associated with explosive atmospheres. Ex-Proof (explosion-proof) equipment is designed to prevent the ignition of flammable gases or vapors, providing a critical layer of protection in such environments. The Role of Positive Pressure Ex-Proof Containers: Positive pressure Ex-Proof containers play a pivotal role in enhancing the safety of MWD/LWD cabins. These containers are specifically engineered to maintain a pressure level higher than the surrounding atmosphere. By doing so, they effectively prevent the ingress of hazardous gases or vapors into the cabin, mitigating the risk of explosions. Key Benefits of Positive Pressure Ex-Proof Containers for MWD/LWD Cabins:

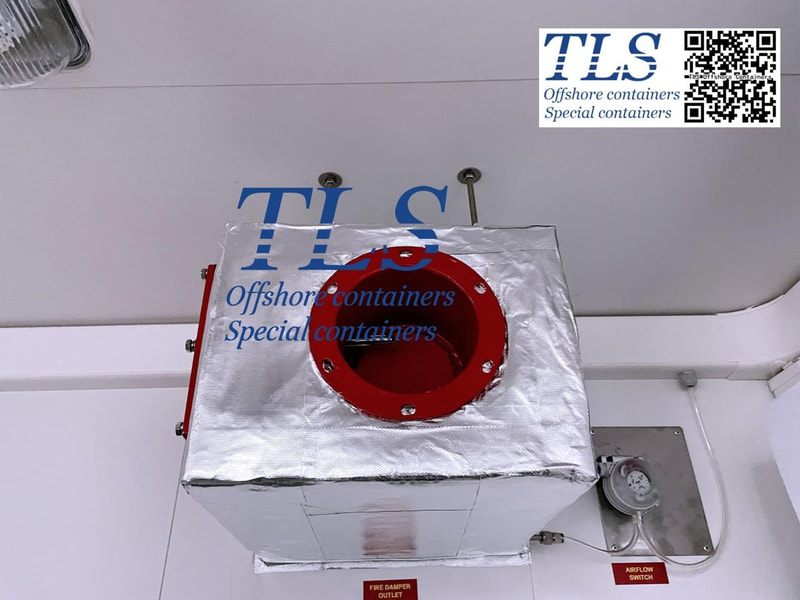

Conclusion: As the oil and gas industry continues to advance, embracing cutting-edge safety technologies is imperative. Positive pressure Ex-Proof containers for MWD/LWD cabins represent a crucial step towards creating a safer work environment in hazardous drilling operations. Intelligent pressurized containers from TLS Offshore Containers are the ultimate solution for safe and efficient offshore energy storage. These containers are designed and constructed to meet the specific needs and requirements of the customer, with built-in HVAC and power control systems to create a safe environment for personnel and equipment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #MWD cabins #LWD cabins #Positive pressure #Ex-Proof containers #Oil and gas safety #Hazardous environments #Explosion prevention #Personnel safety #Equipment protection #Regulatory compliance Written by OliverIntroduction: Safety at sea is a paramount concern, and one of the critical challenges faced by vessels is the risk of onboard fires. In this comprehensive guide, we explore the importance of fire dampers in pressurized shipping containers, detailing why they are crucial and providing practical insights on their effective usage. Why Fire Dampers Matter for Pressurized Shipping Containers? Pressurized shipping containers are designed to maintain a controlled atmosphere, but this feature also heightens the risk of rapid fire spread. Fire dampers play a vital role in mitigating this risk, acting as a barrier against the accelerated spread of fire and smoke. Understanding their importance is key to safeguarding both the crew and cargo. How Fire Dampers Operate in Pressurized Shipping Containers? Fire dampers function by regulating airflow within the ventilation system of a pressurized container. In the event of a fire, these dampers automatically close, preventing the passage of smoke and flames through the ventilation system. This containment provides crucial time for the crew to respond effectively, minimizing the impact of the fire. Best Practices for Fire Damper Usage: To ensure the effectiveness of fire dampers, certain best practices should be followed:

Conclusion: In conclusion, fire dampers are indispensable safety components in pressurized shipping containers. By understanding their importance, functionality, and best practices for usage, this guide aims to contribute to enhanced safety measures at sea. Professional installation, regular testing, and crew training are essential for a safer and more efficient maritime operation. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #Fire Dampers #Pressurized Shipping Containers #Maritime Safety #Ship Fire Prevention #Vessel Fire Control #Ventilation System Safety #Cargo Protection at Sea #Emergency Response Protocols #Maritime Regulations #Safety Equipment for Ships Written by OliverIn the exploration and production of oil and gas, logging and measurement operations play a crucial role in obtaining vital subsurface well data. Mud logging cabins serve as specialized equipment designed for the installation and transportation of logging instrument systems. TLS Offshore Containers offers cutting-edge, customized logging cabin solutions to the offshore industry. Importance and Functionality of Mud Logging Cabins Mud logging cabins are specifically designed to accommodate logging instrument systems, which are essential for measuring parameters such as rock properties, fluid characteristics, and pressures within underground wellbores. These measurements help assess well productivity and reserves. Constructed from sturdy welded steel containers, logging cabins provide durability and reliability. They are designed to house various logging instruments and equipment, including logging tools, sensors, control systems, and data recording devices. The cabins prioritize safety, protection, and convenience to ensure the effective operation of logging instruments in diverse work environments. Design and Features of Offshore power unit Mud logging cabins are aesthetically furnished and organized to accommodate the installation and operation of logging instruments. They incorporate racks, fixtures, and cable corridors to securely mount equipment and ensure the orderly arrangement of cables. Lighting, ventilation, air conditioning, and fire suppression systems are often integrated to create a comfortable and safe working environment within the cabin. Mud logging cabins possess excellent lifting and transportation capabilities, enabling easy installation and relocation using cranes or lifting equipment. Their structural design minimizes deformation during lifting and transportation, safeguarding the integrity and safety of internal equipment. Fire Protection and Safety Measures Due to the presence of high-voltage electrical equipment and flammable substances within logging instruments, fire protection is of utmost importance. Logging cabins are constructed with high-level fire protection measures, including the use of fire-resistant materials for internal decorations and the installation of fire doors, windows, and emergency exits. Mud logging cabins serve as specialized equipment designed for the installation and transportation of logging instrument systems, ensuring secure and efficient logging and measurement operations. TLS Offshore Containers offers premium logging cabin solutions that prioritize durability, safety, and fire protection. These cabins play a vital role in the exploration and production of oil and gas, providing essential subsurface well data for decision-making and optimizing production processes. Introduction: When it comes to offshore or depth drilling, ensuring safety and efficiency is crucial. Technological advancements have revolutionized the oil and gas industry, providing secure accommodations for drill operators and enabling more efficient directional drilling techniques. In this article, we will explore MWD and LWD processes, their distinctions, and the significance of zoned accommodation cabins in optimizing drilling operations. Learn how to effectively source these cabins for a successful drilling venture. What is MWD (Measurement While Drilling)? MWD, or measurement while drilling, is a well logging technique designed to overcome challenges when drilling at extreme angles. It involves incorporating measurement tools into the drill string to provide real-time information for optimized drill steering. MWD measures physical properties such as temperature, pressure, and wellbore trajectory. It accurately determines borehole inclination and azimuth, transmitting the data to the surface for immediate operator monitoring. What is LWD (Logging While Drilling)? LWD, or logging while drilling, is a methodology that records, stores, and transmits information during drilling operations. It acquires valuable formation evaluation data, including pore pressure estimates and mud weight, enabling operators to gain deeper insights into the reservoir's nature and make informed drilling decisions. LWD encompasses various techniques like electromagnetic drilling, nuclear logging, acoustic logging, and nuclear magnetic resonance logging. It facilitates geosteering, geomechanical analysis, petrophysical analysis, reservoir fluid analysis, and reservoir mapping. Differences Between MWD and LWD: While MWD falls under the umbrella of LWD, there are notable differences between these techniques.

Conclusion: In summary, MWD and LWD are crucial processes for optimizing offshore drilling operations. MWD offers real-time data transmission, primarily focusing on directional information, while LWD provides more comprehensive formation evaluation data. By understanding the differences between these techniques, companies can enhance drilling efficiency and safety. Additionally, sourcing zoned accommodation cabins plays a vital role in ensuring a successful drilling venture. Consider these factors to streamline your drilling operations and drive overall success. Please download our product brochure for your reference: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Don’t hesitate to contact us for more information about the offshore pressurised container. #Offshore drilling #Depth drilling #Drill operators #LWD (Logging While Drilling) #MWD (Measurement While Drilling) #Drilling operations Written by OliverMud logging cabins are an essential part of the oil and gas exploration process. These cabins are mobile units that are usually stationed at the drilling site and are responsible for collecting and analyzing geological data during the drilling process. Mud logging is an important process that helps determine the viability of a well and the potential for oil and gas production. Mud logging cabins are typically located near the drilling rig and are designed to provide a comfortable and safe environment for the mud loggers to work in. These cabins are usually equipped with the latest technology and equipment to ensure that accurate data is collected during the drilling process. They are usually made of durable materials such as steel or aluminum to withstand the harsh conditions of the drilling site. One of the most critical aspects of a mud logging cabin is the communication and data transfer capabilities. Mud loggers need to be able to communicate with the drilling team and relay data in real-time. This ensures that the drilling team can make informed decisions based on the data collected by the mud loggers. Mud logging cabins are equipped with advanced communication equipment such as satellite phones, radios, and computers to ensure that the data is collected and relayed efficiently. Mud loggers are responsible for collecting data on the formation being drilled, the drill cuttings, and the drilling mud. The drilling mud is analyzed for various parameters such as density, viscosity, and pH levels. The mud loggers also collect drill cuttings that are analyzed for their mineral content and texture. This information helps geologists and drilling engineers determine the potential for oil and gas production. In addition to collecting data, mud logging cabins also provide shelter and safety for the mud loggers. These cabins are usually equipped with HVAC systems to provide heating and cooling, depending on the weather conditions. They also have safety features such as fire extinguishers and emergency exits in case of an emergency. Mud logging cabins play a critical role in the oil and gas exploration process. They are an essential component of the drilling operation, providing real-time data and analysis to the drilling team. Without mud logging cabins, it would be challenging to collect accurate data and make informed decisions about the potential for oil and gas production. Mud logging cabins are a testament to the ingenuity and innovation of the oil and gas industry, providing a safe and efficient way to explore for new resources. Please download our product brochure for your reference: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Don’t hesitate to contact us for more information about the offshore pressurised container. Written by OliverPressurized containers are a feature product of TLS, these containers are designed to use a positive pressure differential to keep the environment inside the shell safe. It has important applications in many industries, especially in hazardous environments, such as oil and gas industry, chemical processing plants, etc.

Intelligent pressure vessels help ensure the safe and efficient operation of equipment such as MWD/LWD and MCC, providing a reliable and safe environment for these critical components and workers. Written by Mandy Safety and Efficiency for Offshore Operations with TLS Intelligent Pressurized Containers"2/18/2023

TLS Offshore Containers offers intelligent pressurized containers that are designed and constructed to meet the specific needs and requirements of the customer. The containers are designed to provide a safe environment for personnel and equipment, with built-in HVAC and power control systems. One of the key features of TLS intelligent pressurized containers is the incorporation of state-of-the-art safety monitoring systems. These include integrated fire and gas detection, pressurization and emergency shutdown systems, making them suitable for use in Zone 1/Zone 2 hazardous areas. This ensures that personnel and equipment are protected at all times, even in the most challenging environments. TLS intelligent pressurized containers are also designed for easy connection and rapid mobilization. The company is able to integrate data communication networks, fire suppression systems, air conditioning systems, and other systems to ensure that the container is ready for use as soon as it reaches its destination. The containers are designed, manufactured, and certified to the latest DNV 2.7-1, EN 12079 offshore container standards, ATEX, IEC 60079-13, and/or SOLAS standards, ensuring that they meet the highest industry standards and are built to withstand the harsh conditions of offshore operations. The design of the pressurized containers is based on a combination of engineering principles and customer requirements. The containers are typically designed using 3D modeling software, allowing the customer to visualize the design and make any necessary modifications. The containers are then manufactured using high-quality materials and state-of-the-art welding techniques to ensure maximum durability and longevity. Some of the main features of TLS intelligent pressurized containers include A60 or A0 passive fire protection, hazardous area ratings for Zone 1/Zone 2, and DNV 2.7-1/EN12079 structural design codes. The containers are also equipped with an intelligent combined pressurization fire and gas panel (CPFG), automatic fire dampers, and ex-proof pressurization fans. Other safety features include fire and smoke detectors, flammable gas detectors, and H2S detectors. In addition to safety features, TLS intelligent pressurized containers are also designed for easy installation and mobilization. The containers are equipped with air conditioning systems that are ATEX compliant or ex-proof, and they feature emergency lighting and automatic fire extinguishing systems. The containers are fully load/drop tested and are certified by the Container Safety Convention (CSC). TLS offshore pressurized containers are trusted by esteemed clients such as ADNOC, ENSP, Sonatrach, Halliburton, SNF, Perenco, and many others who demand the highest level of safety and efficiency for their offshore operations. With advanced safety features, easy installation and mobilization, and industry-standard certifications, TLS intelligent pressurized containers provide peace of mind and ensure the safety of personnel and equipment. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|