|

In industries that deal with hazardous substances, safety and compliance are paramount. When working in Zone 1 & 2 areas, where the risk of explosive atmospheres is present, the choice of equipment becomes critical. This is where specialized laboratory containers, like those manufactured by TLS, offer a vital solution. Understanding Zone 1 & 2 Hazardous Areas Zone 1 & 2 areas are classified based on the frequency and duration of the presence of flammable gases, vapors, or dust.

Why Specialized Laboratory Containers are Essential In these hazardous environments, standard laboratory containers are not suitable. The risk of ignition from electrical components or sparks is too high. Specialized containers address these risks by incorporating:

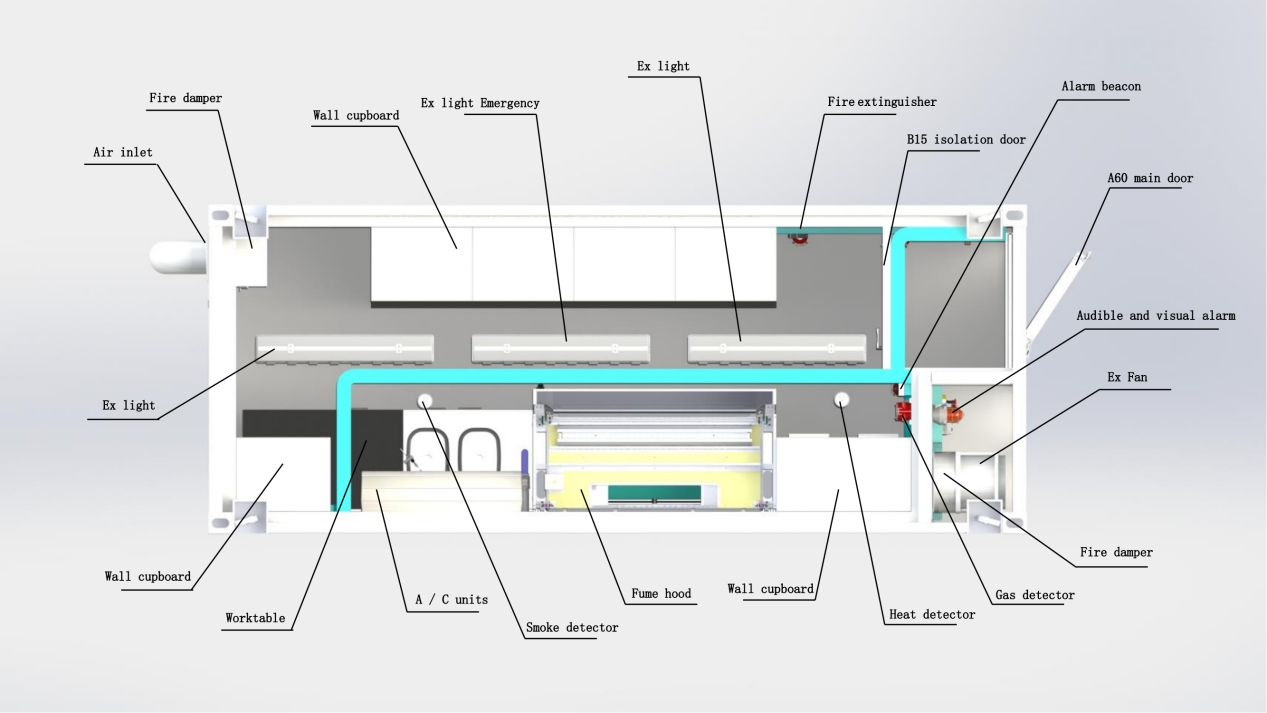

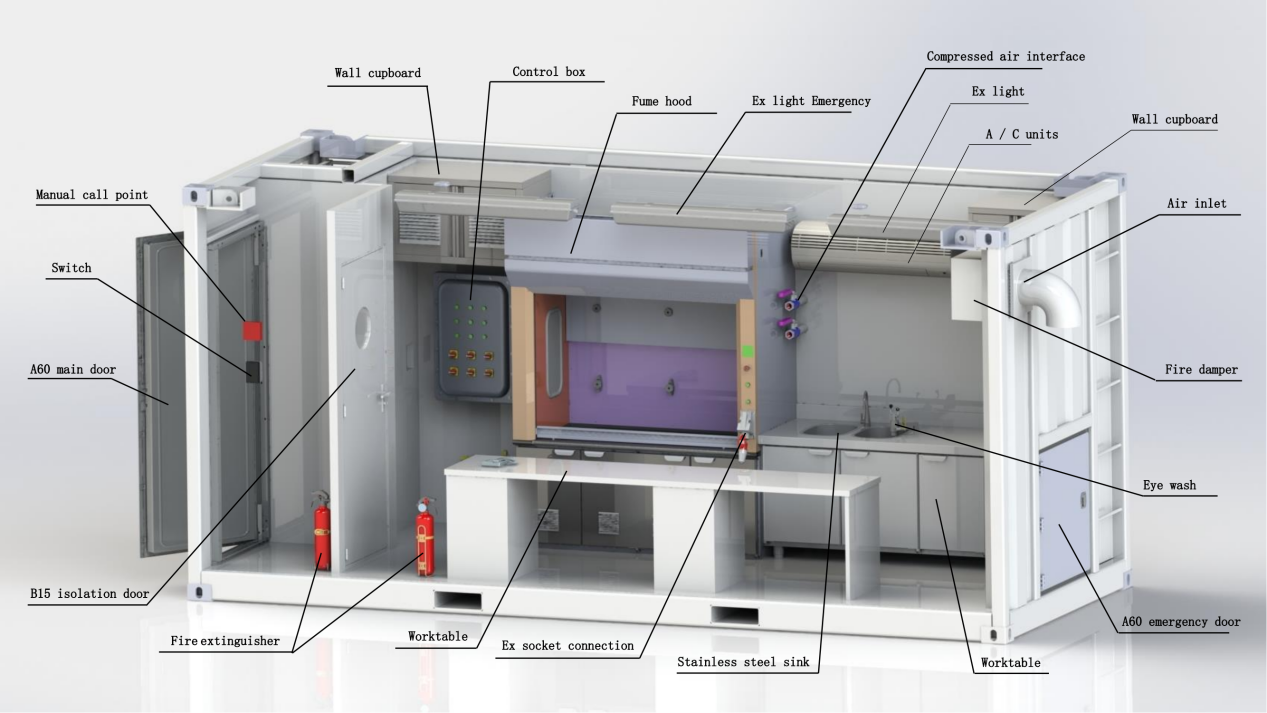

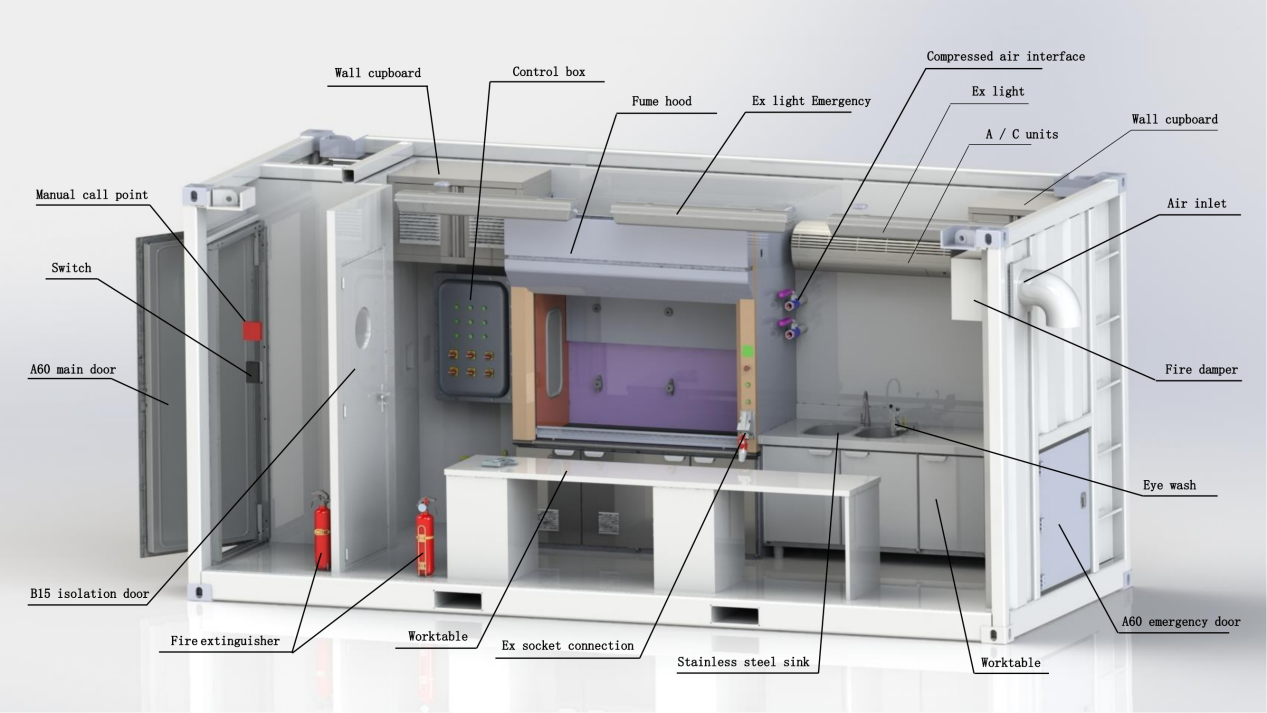

TLS Laboratory Containers: Engineered for Safety and Performance TLS is a leader in the design and manufacture of hazardous area equipment. Their laboratory containers are engineered to meet the stringent safety requirements of Zone 1 & 2 environments. Key Features of TLS Laboratory Containers:

Benefits of Choosing TLS Laboratory Containers:

Who Can Benefit from TLS Laboratory Containers?

Investing in Safety Protecting your personnel and assets is not just a responsibility; it's an investment in the future of your operations. With TLS laboratory containers, you're not just buying equipment; you're investing in a safer, more productive work environment. Let TLS be your partner in navigating the complexities of working in hazardous areas. Contact us today to discuss your laboratory container needs. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #laboratory containers Zone 1 & 2 #hazardous area laboratory containers #explosion-proof laboratory containers #TLS laboratory containers #Zone 1 laboratory #Zone 2 laboratory #laboratory containers for hazardous areas #safety laboratory containers #ATEX laboratory containers #IECEx laboratory containers #modular laboratory containers Written by OliverIn the fast-evolving world of offshore operations, having a reliable, safe, and efficient laboratory setup is crucial. TLS, a leader in manufacturing specialized containers, offers 20ft offshore lab containers designed specifically for safe area use. These containers are engineered to provide a controlled environment for scientific research, testing, and analysis, ensuring maximum productivity and safety. In this blog post, we will explore the features, benefits, and applications of these innovative lab containers. Why Choose a 20ft Offshore Lab Container?

Key Features of TLS 20ft Offshore Lab Containers

Benefits of Using 20ft Offshore Lab Containers

Applications of 20ft Offshore Lab Containers

Conclusion TLS's 20ft offshore lab containers are a game-changer for safe area operations. Their robust construction, customizable features, and advanced safety systems make them an ideal choice for a wide range of offshore applications. By investing in these lab containers, companies can enhance their operational efficiency, ensure safety, and achieve cost savings, all while maintaining the highest standards of research and analysis. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #20ft offshore lab container #TLS lab containers #safe area lab container #mobile offshore lab #portable lab container #customized offshore lab #20ft container lab #climate-controlled lab container #durable lab containers #fire-resistant lab container Written by OliverIn the realm of scientific research and experimentation, ensuring the safety of both researchers and the surrounding environment is paramount. This is particularly true when dealing with hazardous materials or volatile substances that could pose risks if not properly contained. That's where TLS Negative Pressure Lab Containers step in, offering a solution that not only maintains a secure environment within the container but also emphasizes the importance of selecting a safe location for operation. Understanding Negative Pressure Environments Negative pressure environments play a crucial role in laboratory settings, especially when handling substances that could potentially contaminate the surrounding air or pose health hazards. These environments work by maintaining a pressure inside the container that is lower than the pressure outside, effectively preventing the escape of hazardous materials into the laboratory or workspace. Importance of Negative Pressure Lab Containers TLS Negative Pressure Lab Containers are designed with precision to uphold this critical function. By creating a controlled environment within the container, they provide researchers with the confidence to work with hazardous materials safely. Whether dealing with infectious agents, volatile chemicals, or other dangerous substances, having a reliable containment system is indispensable. Safeguarding Researchers and the Environment Beyond just containing hazardous materials, TLS Negative Pressure Lab Containers prioritize the safety of researchers and the environment. One key aspect is the need for these containers to be located in a safe area, away from populated or sensitive zones. Placing them in designated laboratory spaces with proper ventilation and containment measures further minimizes risks. Advantages of TLS Negative Pressure Lab Containers

Conclusion In the ever-evolving landscape of scientific research, safety should always be at the forefront. TLS Negative Pressure Lab Containers provide a robust solution for maintaining secure environments while handling hazardous materials. By emphasizing the importance of negative pressure and selecting appropriate locations for operation, researchers can mitigate risks and ensure both their safety and the integrity of the surrounding environment. With TLS, safety and innovation go hand in hand, shaping a future where scientific exploration thrives in a secure and controlled manner. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Negative pressure lab containers #TLS lab containers #Laboratory safety #Hazardous material containment #Controlled environment containers #Laboratory ventilation #Safe location for operation #Biological containment #Chemical containment Written by OliverIn the dynamic realm of offshore operations, safety and efficiency are paramount concerns. As industries push the boundaries of exploration and research, the need for reliable infrastructure, including laboratory facilities, becomes increasingly crucial. Enter TLS, a pioneer in offshore container solutions, offering cutting-edge technology to meet diverse industry needs. Among TLS's innovations is the offshore lab container, fortified with advanced ventilation systems, particularly the fume hood, ensuring a safe and productive working environment even in the most challenging offshore conditions. Understanding Offshore Lab Containers Offshore lab containers are bespoke units designed to provide on-site laboratory capabilities in remote offshore locations. These containers serve a diverse range of industries, including oil and gas exploration, environmental research, and marine biology, among others. Their compact yet comprehensive design allows for the execution of critical tests, experiments, and analyses without the need for extensive onshore facilities. The Crucial Role of Ventilation Systems Within the confined space of offshore lab containers, effective ventilation is imperative. Proper ventilation not only ensures the comfort of personnel but, more importantly, mitigates the risks associated with hazardous fumes, chemicals, and contaminants commonly found in laboratory settings. TLS understands this necessity and has engineered a ventilation system tailored to the specific challenges of offshore environments. Introducing the Fume Hood At the heart of TLS's ventilation system is the fume hood—a sophisticated apparatus designed to contain and remove harmful airborne substances generated during laboratory procedures. The fume hood operates on the principle of negative pressure, wherein air is drawn into the unit, capturing contaminants, and then safely vented outside the container. Key Features and Benefits

Conclusion In the fast-paced world of offshore industries, safety and efficiency are non-negotiable. TLS's offshore lab containers, featuring state-of-the-art ventilation systems centered around the innovative fume hood, represent the pinnacle of engineering excellence and dedication to excellence. By prioritizing the well-being of personnel and the integrity of operations, TLS continues to redefine standards and inspire confidence in offshore endeavors worldwide. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Offshore lab containers #Ventilation systems #Fume hood #Offshore safety #Environmental safety #Offshore operations #Industrial ventilation #Offshore exploration #Laboratory containers #Ventilation technology #Airflow optimization Written by OliverIntroduction: In the realm of scientific research, innovation knows no bounds. However, conducting experiments and research projects often requires specialized infrastructure, which can be both expensive and logistically challenging to set up. This is where TLS Offshore Lab Containers step in to revolutionize the landscape. In this article, we delve into the transformative potential of these containers, exploring their features, benefits, and the impact they can have on various fields of study. Unraveling Offshore Lab Containers: TLS Offshore Containers International specializes in designing and manufacturing lab containers and more, meticulously crafted to customer specifications. These containers are engineered to adhere to industry-leading standards, including DNV 2.7-1, NORSOK, ATEX/IECEx, as well as SOLAS/IMO regulatory requirements. With a focus on functionality and compliance, TLS containers ensure optimal performance and safety in any environment. Features That Redefine Possibilities:

Benefits Galore:

Impact Across Disciplines: The versatility of Offshore Lab Containers makes them indispensable across various fields of scientific inquiry:

Conclusion: In an era where scientific breakthroughs are essential for addressing global challenges, Offshore Lab Containers by TLS emerge as a game-changer. By combining innovation, durability, and flexibility, these containers empower researchers to push the boundaries of knowledge, transcending geographical limitations and unlocking new avenues of discovery. Embrace the future of scientific exploration with TLS's Offshore Lab Containers. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #ATEX/IECEx #SOLAS/IMO regulations #Customization #Compliance #Climate control #Efficiency #Rapid deployment #Scientific research #Innovation #Insulation #Offshore containers #Laboratory containers #DNV 2.7-1 Written by OliverIn the ever-evolving landscape of scientific research and experimentation, the demand for innovative solutions that ensure safety, efficiency, and mobility has never been higher. Enter the 20' offshore negative pressure lab container – a cutting-edge solution that is revolutionizing laboratory research across diverse fields. In this blog post, we'll explore the functionalities, benefits, and applications of these remarkable containers. Understanding Offshore Negative Pressure Lab Containers Offshore negative pressure lab containers are specialized units designed to provide a controlled environment for laboratory experiments, analysis, and research activities. What sets them apart is their ability to maintain negative pressure within the container, ensuring that hazardous materials and contaminants are effectively contained and prevented from escaping into the surrounding environment. Features and Specifications These containers typically come in a compact 20-foot size, making them highly versatile and suitable for various applications. They are equipped with state-of-the-art ventilation and filtration systems that create and maintain negative pressure, thereby minimizing the risk of exposure to harmful substances. Key features of offshore negative pressure lab containers include:

Applications Across Industries The versatility and functionality of 20' offshore negative pressure lab containers make them invaluable across a wide range of industries and research fields:

Conclusion In conclusion, 20' offshore negative pressure lab containers represent a significant advancement in laboratory safety and mobility, offering researchers a versatile and secure environment for conducting a wide range of experiments and analyses. With their advanced features, durability, and compliance with industry standards, these containers are poised to transform the way research is conducted across various disciplines. As the demand for portable and efficient laboratory solutions continues to grow, offshore negative pressure lab containers emerge as indispensable tools in the pursuit of scientific innovation and discovery. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Offshore negative pressure lab container #Laboratory research #20-foot container #Scientific experimentation #Hazardous materials #Ventilation system #Filtration technology #Modular design #Environmental monitoring Written by OliverIntroduction: In the fast-evolving landscape of laboratory safety, innovation is key to ensuring the well-being of researchers and maintaining the integrity of experiments. One such groundbreaking solution is the Negative Pressure Laboratory Containers by TLS Offshore Containers. In this blog post, we'll delve into the significance of negative pressure environments, the features of TLS Offshore Containers' cutting-edge solutions, and how they are transforming laboratory safety. Why Negative Pressure Matters: Negative pressure environments are crucial in laboratories where the containment of hazardous substances is of paramount importance. These environments help prevent the escape of harmful contaminants, ensuring the safety of researchers and the surrounding environment. Negative pressure laboratory containers create a controlled atmosphere where air flows into the container but doesn't escape, effectively containing any potential dangers within. TLS Offshore Containers' Innovative Solution: TLS Offshore Containers, a leading name in the industry, has engineered state-of-the-art negative pressure laboratory containers that set new standards for safety and efficiency. Here are some key features that make our containers stand out:

Benefits for Laboratories:

Conclusion: In the ever-evolving landscape of laboratory safety, TLS Offshore Containers emerges as a trailblazer with its negative pressure laboratory containers. By prioritizing safety, customization, and user-friendly design, TLS is revolutionizing the way laboratories approach containment and experimentation. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Negative Pressure Laboratory Containers #Laboratory Safety Solutions #Hazardous Substance Containment #Advanced Filtration Systems #HEPA and Carbon Filtration #Customizable Laboratory Containers #Biohazard Containment #Pharmaceutical Research Safety #Cutting-edge Laboratory Technology #Regulatory Compliance in Laboratories Written by OliverUnveiling Excellence: The Superiority of TLS Offshore Containers' Negative Pressure Lab Containers1/19/2024

Introduction: In the ever-evolving landscape of laboratory technology, the demand for cutting-edge solutions is more prominent than ever. When it comes to ensuring the safety and precision of lab processes, TLS Offshore Containers stands out as a beacon of innovation. In this blog post, we delve into the unparalleled quality of TLS Offshore Containers' Negative Pressure Lab Containers and how we set a new standard in the industry.

Conclusion: In the realm of laboratory equipment, TLS stands out as a pioneer in the design and manufacturing of Negative Pressure Lab Containers. Our commitment to advanced technology, precision engineering, durability, safety compliance, customization options, cost-effectiveness, and environmental responsibility makes us the go-to choice for laboratories aiming for excellence. With TLS Offshore Containers, labs can elevate their standards, ensuring a future-proof and reliable environment for scientific endeavors. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key Words: #Precision Engineering #Durability #Robust Construction #Safety Standards #Customization Options #Cost-Effective Solutions #Environmental Responsibility #Scientific Innovation #Controlled Environment #Hazardous Substance Containment #Green Practices #Laboratory Technology Written by OliverIn the ever-evolving landscape of global industry, the need for cutting-edge solutions and innovative technologies is paramount. Enter TLS Offshore Containers, a company at the forefront of providing specialized containers tailored to meet the unique demands of various industries. Recently, TLS made waves by sending a 20-foot Lab Container to Dubai, marking a significant milestone in offshore logistics. TLS Offshore Containers has long been recognized for our commitment to delivering state-of-the-art solutions for industries such as oil and gas, renewable energy, and research. Our expertise in designing and manufacturing specialized containers has enabled us to cater to the diverse and complex needs of our clients. The 20-foot Lab Container, equipped with advanced technology and safety features, represents a leap forward in offshore research and development capabilities. This container is not just a conventional shipping unit; it is a mobile laboratory, designed to facilitate scientific experiments and data collection in the challenging offshore environments that are characteristic of the industry. TLS Offshore Containers International designs and produces lab containers, crane containers, workshop containers, rigging loft containers, ROV control containers, and more, all built to customer specifications and compliant with standards such as DNV 2.7-1, NORSOK, and ATEX/IECEx, including SOLAS/IMO regulatory requirements. Our functional containers are fully insulated, capable of operating in any climate, and feature air conditioning with filtered air extraction and return, creating a comfortable working environment while reducing operating costs. Our containers can be fully operational within hours of arriving on site. TLS Offshore Containers International also provides a range of additional services to meet customer requirements. These include customised design and production of functional containers, testing and certification, and on-site installation and commissioning. Our team of experienced engineers and technicians are available to provide advice and support on all aspects of container design, production and installation. We can also provide technical advice on the selection of appropriate materials and components, and on the use of the latest technologies to ensure that the containers are designed and produced to the highest standards. Our commitment to customer service and quality ensures that all containers are delivered on time and to the customer's exact specifications. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #TLS Offshore Containers #20-foot Lab Container #Offshore logistics #Innovation #Global industry #Specialized containers #Research and development #Cutting-edge technology #Offshore environments #Security measures #Industrial collaboration Written by OliverWhy Are Explosion-Proof Fans Essential for Safety in Negative Pressure Laboratory Containers?12/15/2023

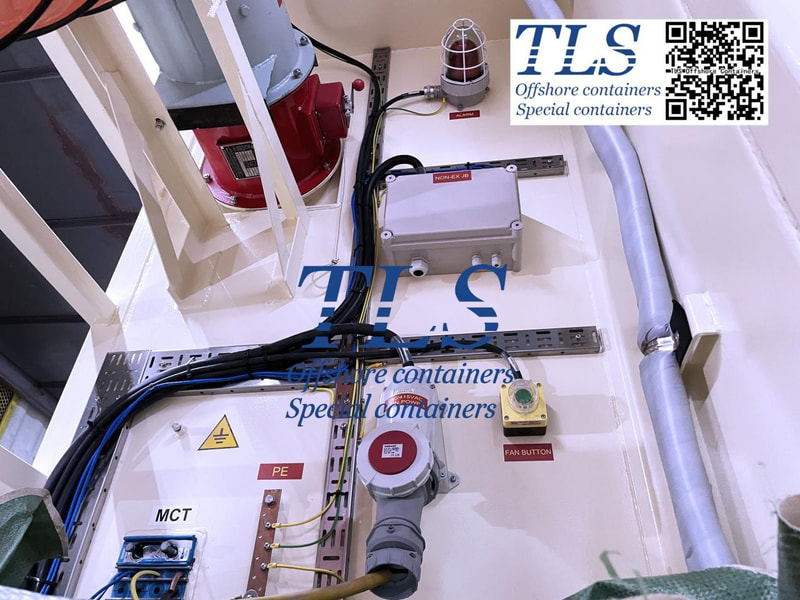

Introduction: In the realm of laboratory safety, maintaining controlled environments is paramount. One critical aspect of this control is the prevention of explosions, especially within negative pressure laboratory containers. Explosion-proof fans play a crucial role in ensuring the safety and integrity of these environments. In this article, we will delve into the significance of negative pressure laboratory container explosion-proof fans and their role in safeguarding both personnel and valuable research. Understanding Negative Pressure Laboratories: Negative pressure laboratories are designed to prevent the escape of hazardous substances into the surrounding environment. These specialized environments are employed in various industries, including pharmaceuticals, chemical research, and biocontainment facilities. Negative pressure ensures that any potential contaminants within the laboratory remain contained, minimizing the risk of exposure to personnel and external environments. The Risk of Explosions in Laboratories: Laboratories dealing with volatile substances face the inherent risk of explosions. Gases, chemicals, and other materials used in experiments can create a combustible atmosphere if not handled with precision. The consequences of an explosion in a laboratory can range from equipment damage to severe injuries or even fatalities. Thus, implementing safety measures to mitigate explosion risks is of paramount importance. The Role of Explosion-Proof Fans: Negative pressure laboratory container explosion-proof fans are engineered to minimize the risk of explosions within confined spaces. These fans are designed to operate in hazardous environments where flammable gases or vapors may be present. Their construction includes features such as spark-resistant materials, reinforced casings, and specialized motor enclosures, ensuring that they do not become sources of ignition. Key Features of Explosion-Proof Fans:

Benefits of Negative Pressure Laboratory Container Explosion-Proof Fans:

Conclusion: In conclusion, negative pressure laboratory container explosion-proof fans play a pivotal role in maintaining the safety and integrity of laboratory environments. By investing in these specialized fans, industries can significantly reduce the risk of explosions, protecting both personnel and valuable research. As technology continues to advance, the development of more sophisticated and efficient explosion-proof fans will further enhance the safety measures in laboratories, allowing for continued progress in scientific exploration while minimizing the associated risks. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. #Negative pressure laboratory #Explosion-proof fan #Laboratory safety #Controlled environment #Hazardous substances #Combustible atmosphere #Spark-resistant materials #Reinforced casings #Specialized motor enclosures #Personnel safety Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|