|

A offshore laboratory contain has potential sources of release such as hydrocarbon liquid and gas samples, and vapors from heated hydrocarbon liquids. Some equipment is not designed for hazardous area which it could present an ignition source. The laboratory container is designed by using external extracting system for the toxic fumes (Ex certified) from the fume cupboard. Other electrical equipment inside the lab container is also certified by Ex approvals, including split-type air conditioner, lighting, sockets, distribution boards, etc. Negative pressure is maintained by using exhaust blower and speically designed air-lock system. The temporary refuge shelter (TR) or toxic gas refuge (TGR) is designed for drilling platform, offshore barge, oil & gas, petroleum, and chemical industries. The temporary refuge shelter is designed to protect personnel against H2S gases and other hazardous gases that can appear in case of an uncontrolled release. The design of the TR is that everybody can rush into the shelter immediately without any time-consuming air-locking process. During the stay of the people inside the TR they can breathe normally from the atmosphere in the room. The shelter is protected by over pressurization during stand-by as well as during emergency. More information about temporary refuge (TR) shelter | toxic gas refuge (TGR) | safe haven cabin Don’t hesitate to contact us [email protected] for more information about the temporary refuge shelter and toxic gas refuge. We are eager to explain the possibilities for your applications. Please download TLS containerised solutions of temporary refuge shelter product brochure for reference. Our client announced that they successfully started their offshore project in China, TLS is proud of being involved to support them to make their projects successful. Technical specifications

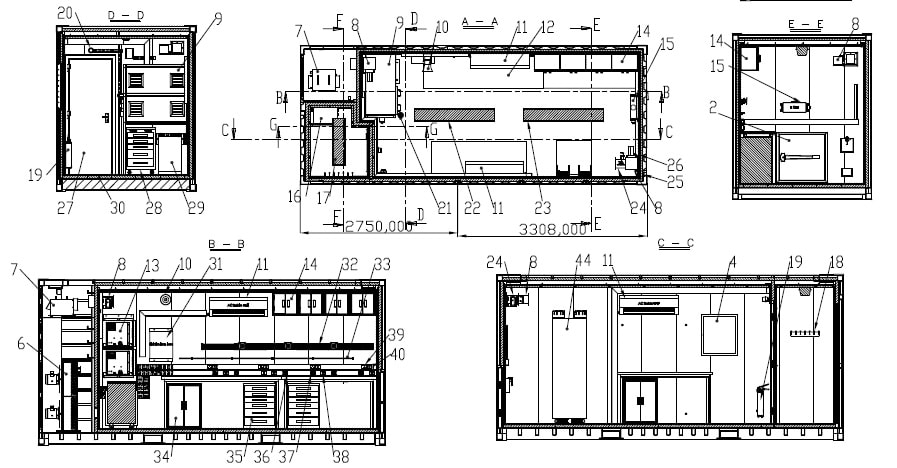

Mud Logging unit, mud logging cabin Since its commercial introduction in 1939, the mud logging unit has become a hub for monitoring formation responses to the drilling process. Initially, the mud logger's mandate was to record the depth and describe the lithology of formations encountered by the drill bit then determine whether those formations contained hydrocarbons. However, the scope of mud logging has expanded as additional sensors brought more data into the logging unit—such as gas chromatographs, weight-on-bit and mud pit level indicators. Basic mud logging services now typically track drilling rates, lithology, visual hydrocarbon indicators, total combustible gas in mud and individual hydrocarbon compounds in the gas along with numerous drilling parameters. The mud logger monitors and evaluates a broad range of surface indicators to compile a concise record of subsurface geology, hydrocarbons encountered and significant drilling events. These days, the term surface logging is sometimes used to encompass a range of enhanced mud logging services that incorporate advanced sensor and computing technology to provide monitoring for wellbore stability and early kick detection. The practice of mud logging relies heavily on the mud circulation system. High-pressure mud pumps draw mud, or drilling fluid, from surface tanks and direct it downhole through the drillpipe. The mud exits the drill string through nozzles in the bit. As a bit drills through the subsurface, the rock it grinds—along with water, oil or gas in the formation—is carried back up the hole by the drilling fluid. Upon reaching the surface, the fluid exits through a flowline above the blowout preventer and is deposited over a vibrating mesh screen at the shale shaker, which separates formation cuttings from the liquid mud. The liquid portion of the drilling fluid falls through the screens to the mud pits, ready to be pumped back into the well; the rock cuttings on the shaker screen provide the basis for determining downhole lithology. Main specifications:

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

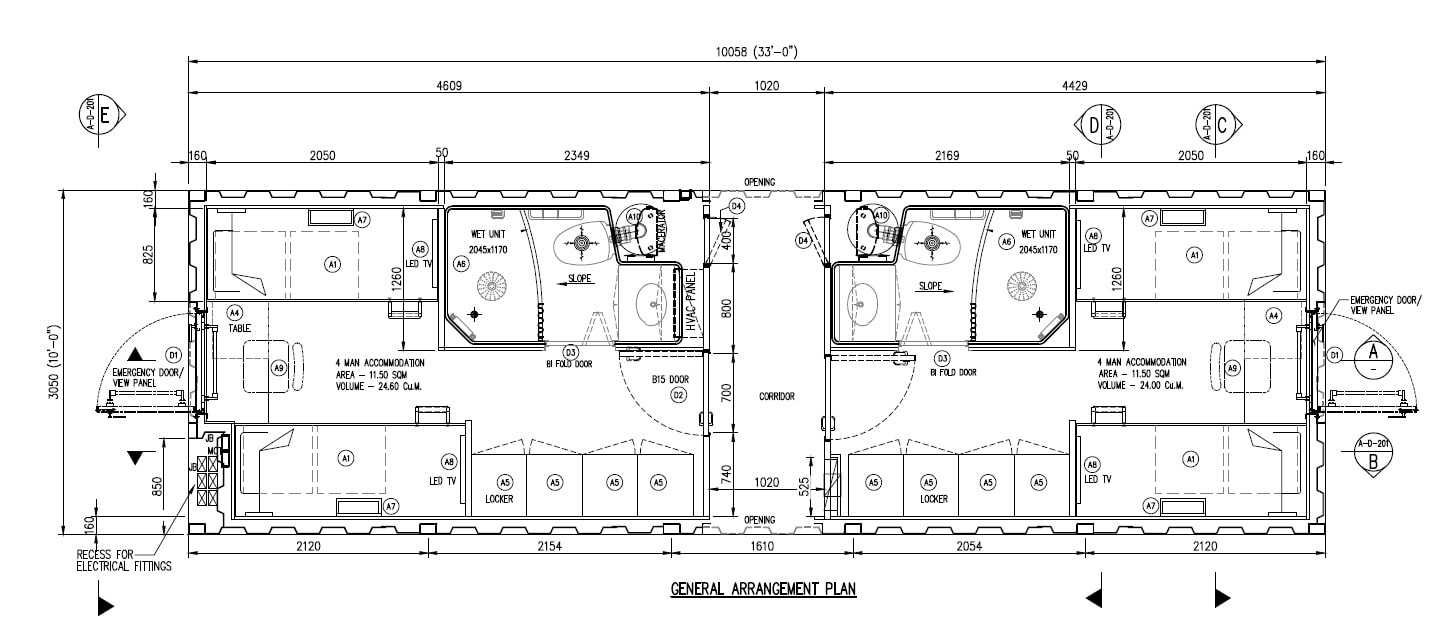

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|