|

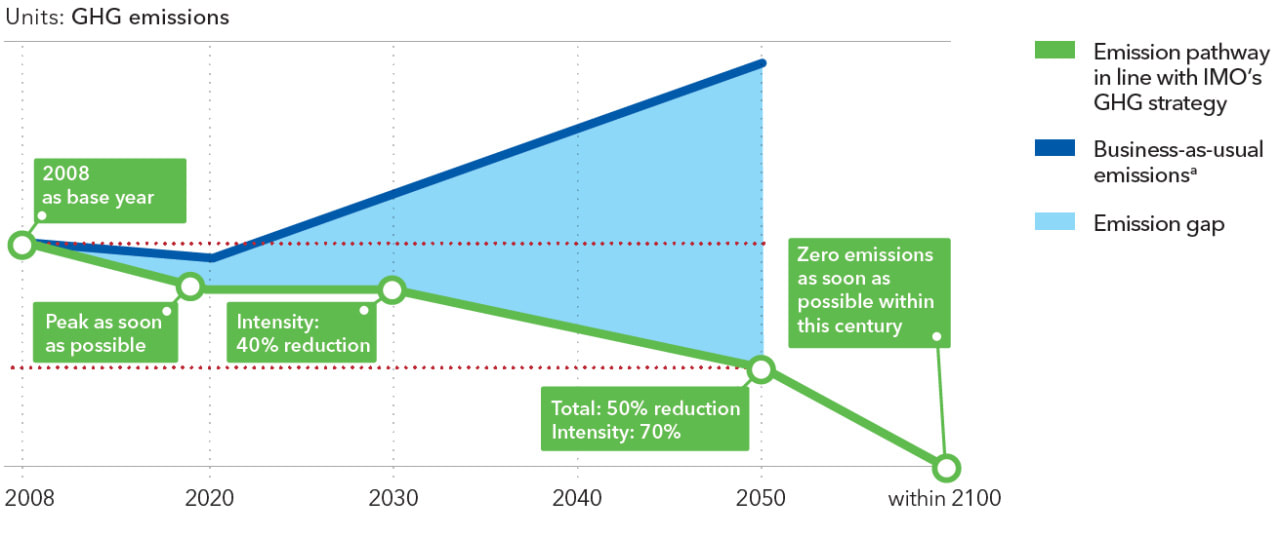

IMO (international maritime organization) has adopted mandatory measures to reduce emissions of greenhouse gases from international shipping, under IMO's pollution prevention treaty (MARPOL) - the Energy Efficiency Design Index (EEDI) mandatory for new ships, and the Ship Energy Efficiency Management Plan (SEEMP). MEPC 74 (May 2019) adopted on Invitation to Member States to encourage voluntary cooperation between the port and shipping sectors to contribute to reducing GHG emissions from ships. This could include regulatory, technical, operational and economic actions, such as the provision of: Onshore Power Supply (preferably from renewable sources); safe and efficient bunkering of alternative low-carbon and zero-carbon fuels; incentives promoting sustainable low-carbon and zero-carbon shipping; and support for the optimization of port calls including facilitation of just-in-time arrival of ships. The Global Industry Alliance to support low carbon shipping (GIA), operating under the auspices of IMO’s GloMEEP project, has recognized the key role of ports in the decarbonization of shipping. In particular, just-in-time (JIT) operation of ships has a potential to reduce emissions. The GIA has been gathering experience from ports that have successfully (or unsuccessfully) implemented JIT; has been analysing barriers; and has been studying concrete measures for removal of these barriers to large-scale uptake of JIT. Is zero-carbon shipping going to become a reality? In the initial IMO strategy, there is a clear ambition to pursue efforts towards phasing out GHG emissions from international shipping entirely, by the end of this century. This has to become a reality. As United Nations Secretary-General Antonio Guterres has said, “We need to put the brake on deadly greenhouse gas emissions and drive climate action…. The world is counting on all of us to rise to the challenge before it’s too late”. Research and development will be crucial, as the targets agreed in the IMO initial strategy will not be met using fossil fuels. There is a need to make zero-carbon ships more attractive and to direct investments towards innovative sustainable technologies and alternative fuels. What is a maritime BESS containerized solution?

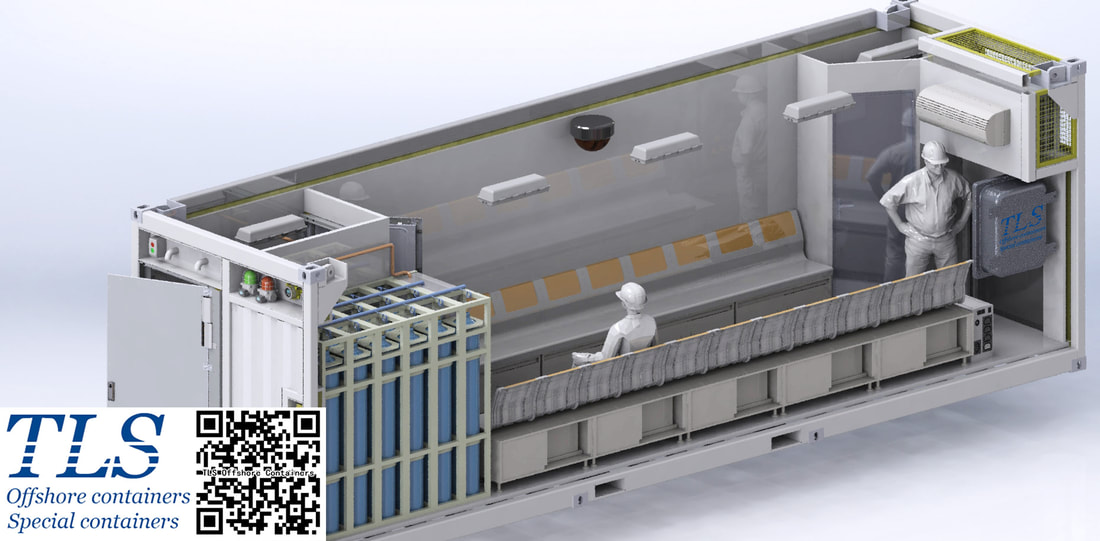

Containerized energy storage solution is a complete, self-contained battery solution for a large-scale marine energy storage. The batteries and all control, interface, and auxiliary equipment are delivered in a single standard shipping container for simple installation on board any vessel. The standard maritime BESS container delivery includes

How does maritime BESS container work? The maritime BESS stores energy when demand is low, and delivers it back when demand increases, enhancing the performance of the vessel’s power plant. The flow of energy is controlled by dynamic Energy Storage Control System. It enables several new modes of power plant operation which improve responsiveness, reliability, safety, and fuel consumption. What are the benefits of maritime BESS container?

what are the building standards for maritime BESS containers? DNV 2.7-1/-2/-3 Offshore containers DNVGL-CP-0553 Following items may be described in the certificate (if applicable): — container (description) — EES specifics (type and size of batteries, module data, information about chemistry, cells parameters, cooling method) — BMS (components data with software versions) — EES converter (rated parameters (input/output) and cooling method) — transformer (rated power and cooling method) — fire safety system(s) (fire rating/insulation) 1. During the test, a uniformly distributed load equivalent to the difference between the rated mass and the tare weight of the container should be placed in the container and fully bolted.

2. The ground on which the offshore container falls should be a flat concrete floor or other hard surface. The ground may be covered with planks, which shall not exceed 50 mm in thickness. 3. Lift the marine container tilted so that the angle between the side beam and the end beam connected to the lowest angle on the bottom of the container and the ground is not less than 5°. On the bottom surface of the container, the height difference between the lowest corner point and the highest corner point should not be greater than 400 mm. 4. During testing, the corner with the worst stiffness should be selected as the lowest impacted corner. 5. The lowest corner point of the offshore container should be more than 50 mm away from the ground. The initial impact velocity of the offshore container touching the ground shall not be less than 1m/s. 6. After testing, the offshore container shall not show significant permanent deformation or damage. Small repairable open welds and deformations are allowed. TLS will not proceed to the next production step until the marine container has passed the vertical impact test The production process and requirements for TLS offshore container are as below:

1. Produce the container frame and weld the container. All primary structural welds are required to be welded by a class-certified welder, and full penetration welding is required. For containers that have passed the third-party inspection, they are sprayed according to the paint process, and the paint package is suitable for the marine environment 2. Install the floor. First, calcium silicate plates were laid on the lower deck, then fixed steel mesh was installed on the surface, then the upper deck dressings were laid on the steel mesh, and finally the deck dressings were laid on the floor. After construction is complete, the flatness of the floor is measured and accepted by professional quality inspectors. 3. Lay down insulation material. Fix the nails in advance at the locations where the rock wool insulation needs to be laid in the container. When attaching the nails, reserve space to make sure that the nails are firmly attached according to the standard. Laying of rock wool ensures that the length of the overlapping surface is sufficient, and the joints are covered with fireproof tape. 4. Install water pipes, air pipes, and cable trays. Pre-lay insulation. Reserve the supporting boom needed to install the pipe on the top plate of the container to ensure that the pipe is straight and firmly secured. 5. Install interior trim wall panels. Install the fixing slot of the fixing plate first, and then install the inner panel in the fixing slot. Before installation, ensure that the surface of the wall panel and the ceiling is smooth and flat, and ensure that the splicing gap is neat and straight. 6. Install the furniture and appliances. The furniture in the container must be installed and secured according to the requirements and locations in the preliminary design drawings. The power connection of the relevant equipment shall be constructed in accordance with the regulations and must be inspected by qualified quality inspectors during this period. 7. Testing & Acceptance TLS accepts client's on-site inspection, video inspection, graphic inspection, and other methods for acceptance. We will only ship the containers after they pass the acceptance. The basic principle of the negative pressure system is to keep the pressure of the environment inside the container lower than that outside, so that the toxic gas or flammable gas in the container will not be directly discharged from the it, and the negative pressure system captures dangerous and infectious particles in the air, and it is removed with a blower and a set of filters.

The negative pressurized container provide by TLS typically has 2 fans, a small fan for normal mode and a large fan for emergency mode. When either fan is turned on, a negative pressure environment is formed inside. When only the small fan in the fume hood is turned on, the internal pressure is around -30~40Pa, and normal ventilation mode in the container; When the flammable gas/H2S low level alarm is triggered, the outdoor Ex-fan will automatically turn on, the internal pressure is around -130Pa and the container enter the emergency mood and it will automatically turn off when the gas concentration is lower than the set value. If the gas concentration does not decrease, the high-level alarm of flammable gas/H2S would sound, after the alarm lasts for 10 seconds, the power supply of the container will be cut off. Negative pressure is a safe sealing solution which is widely used in lab containers, Mud Labs, etc. Why would you want TLS offshore workshop container instead of a garage or shed? There are a number of advantages that make it a better choice.

FOUR-POINT LIFTING

TWO-POINT LIFTING (DIAGONAL LIFTING TEST)

R - maximum allowable total mass of offshore container and loaded cargo (without spreader) T - Empty mass of offshore container including attachments (without spreader) The TLS containers will not promote the next production step until the lifting test is passed. With the gradual deepening of the development and utilization of oil and gas resources by human beings, oil and gas exploration and development have shifted from the shallow continental shelf to the deep sea, drilling engineering operations must also be carried out in the ocean away from the continental shelf.

In the event of a fire, explosion, leakage or other critical situation on the platform, the personnel on board can escape to the temporary refuge shelter, guarantee the life safety of the personnel in the temporary shelter within a certain period, and organize the person discuss the escape strategy, and gain time to be rescued. Features of temporary refuge shelter provided by TLS:

BMS (Battery Management System) is one of the core subsystems of battery energy storage systems. It is a system that uses energy storage as a carrier to manage the storage of electric energy and the supply of electric energy over a certain period. The electric energy managed by BMS has functions such as smooth transition of electric energy, peak shaving and valley filling, frequency regulation and voltage regulation. It is also a device that monitors the status of energy storage batteries, intelligently manages, and maintains each battery unit, prevents over-charging and over-discharging of batteries, prolongs battery life and monitors battery status.

Its principal works are:

People working at sea live for weeks or months in confined spaces away from their families. During this time, they are exposed to difficult living and working conditions in a harsh working environment. However, thanks to advanced technologies, we can create a safe and comfortable living and working environment for our workers. TLS is able to offer offshore accommodation modules that can provide safe and comfortable living space for 1, 2, 3, 4 or 8 workers.

Safety on the marine should never be compromised. Therefore, when choosing marine accommodation container, you need to be sure that your supplier can provide you with the best solution to keep your employees safe. At TLS, we take safety very seriously. In fact, all our accommodation and other modules are built to the highest standard to meet your requirements. At the same time, you need to consider comfort. Our A60 Container house include a higher level of comfort to meet the stringent safety requirements on the high seas. The furniture in the modules can be customized to ensure the comfort of your employees in harsh working conditions. TLS A60 residential storage containers are manufactured and designed according to ABS guidelines. Please download TLS accommodation modular brochure, TLS ABS approved offshore accommodation module brochure for reference. Why is sewage treatment necessary? Sewage is divided into domestic and industrial wastewater, which pollutes water resources so seriously that it has begun to affect people's normal lives. A variety of industrial wastewater and domestic wastewater discharged in large quantities, has polluted many water resources, making our lives available clean resources of water is increasingly lacking.

The harm caused by sewage is still expanding. The only way to better mitigate this vicious cycle of sewage pollution is to make more rational use of limited resources through industrial wastewater treatment. The treatment of wastewater discharged from our industrial production with sewage treatment equipment can make the completion of the purification of sewage to get the opportunity to use again, and also play a good role in protecting the environment, because some chemical plants excluded from the sewage has a lot of corrosive substances in it, if not industrial sewage treatment is discharged, it will cause great harm and pollution to the living environment, so that the conduct of Industrial sewage treatment work becomes very necessary. TLS intelligent containerized wastewater treatment system or sewage treatment plant (STP) is a modular system where all wastewater treatment equipment is completely preinstalled in ISO standard or offshore standard containers. Our containerized sewage treatment plant (STP) is made for easy setup and relocation. This solution is ideal for remote locations such as mining camps and oil rig sites. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|