|

Refrigerated containers, also known as refrigerated shipping containers, freezer containers, 20-foot refrigerated containers, or specialized refrigerated containers, are special containers designed for the transportation and storage of frozen and perishable goods during maritime shipping. They play a crucial role in transporting and preserving vegetables, fruits, meats, and other perishable items, ensuring that the goods remain fresh at specific low temperatures. The greatest advantage of refrigerated containers used in maritime shipping lies in their excellent insulation and high mechanical strength. Polyurethane foam is commonly used in the industry to ensure effective insulation. When the density of polyurethane foam is 40 kg/m3, it provides the lowest thermal conductivity. In practical production, the density is slightly higher than 40 kg/m3 to ensure strength, minimize voids, and account for factors such as leakage during foaming. The wall thickness of maritime refrigerated containers generally ranges from 50 to 120 mm, while for specialized applications, it can be reduced to 30 mm. Choosing the right refrigerated container is of paramount importance, especially for transporting perishable goods and temperature-sensitive medications. To ensure successful delivery of frozen products, the following factors are crucial: uninterrupted cold chain transportation, appropriate cooling technology, and selecting the correct insulation materials, dimensions, and container designs. Different products have varying temperature requirements, making it essential to understand the temperature requirements for each product along the transportation route when selecting a maritime refrigerated container. For example, blood needs to be stored between 2-6°C, vaccines must be maintained between -70°C and -5°C, and frozen foods need to be kept at -18°C. Refrigerated containers play a vital role in global trade, meeting the transportation needs of various frozen goods while ensuring product quality and safety. Through scientific and rational design and usage, refrigerated containers provide convenience and assurance, promoting the development of the food and pharmaceutical industries. In conclusion, refrigerated containers are indispensable tools for transporting frozen and perishable goods via maritime shipping. With their exceptional insulation properties and mechanical strength, they effectively maintain the freshness and quality of goods during ocean transportation. Understanding the temperature requirements of different products and selecting appropriate refrigerated containers are key to ensuring the safe transportation of goods. The widespread use of refrigerated containers drives the development of global trade, providing convenience and reliability to people's lives. 20ft and 40ft are usually the most common specifications for shipping, 2 units 10ft containers are usually combined into 20ft when they are transported. TLS is an international company that can customize onshore | offshore special containers for you. Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 DNV2.7-1 offshore refrigerated container with curtains and Man-trap alarm, offshore reefer container8/12/2022

WHAT STANDARD OFFSHORE REFRIGERATED CONTAINER CAN TLS PROVIDE, IS THAT YOU ARE LOOKING FOR?8/5/2022

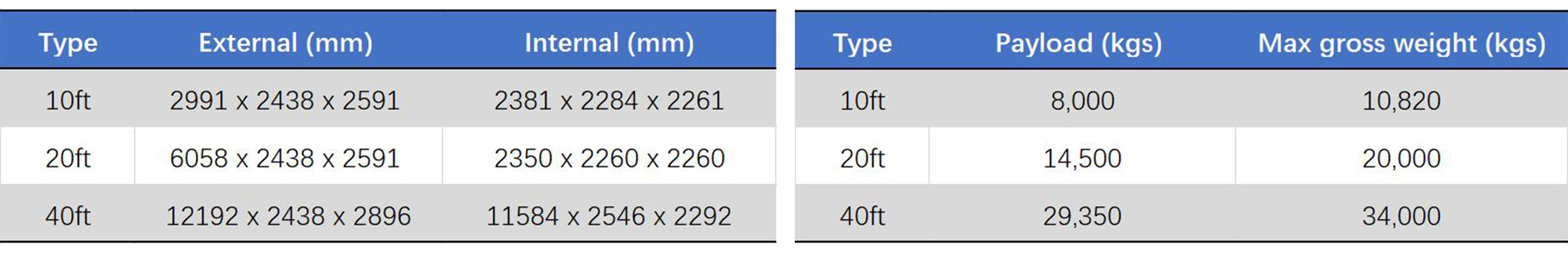

Offshore refrigerated containers provided by TLS are equipped with DAIKIN, CARRIER or THERMO KING refrigeration units to maintain the internal temperature between -20°C to +25°C. 10ft, 20ft, 40ft or customised size reefer container for option.

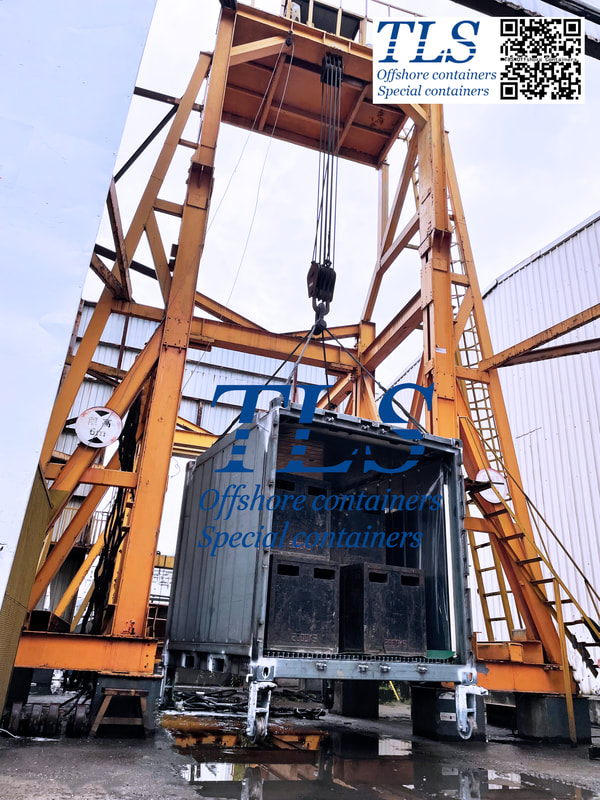

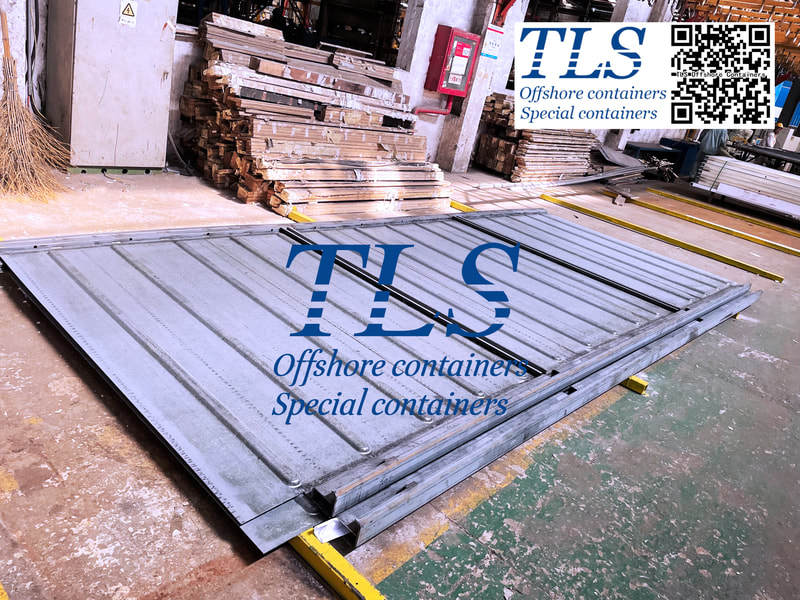

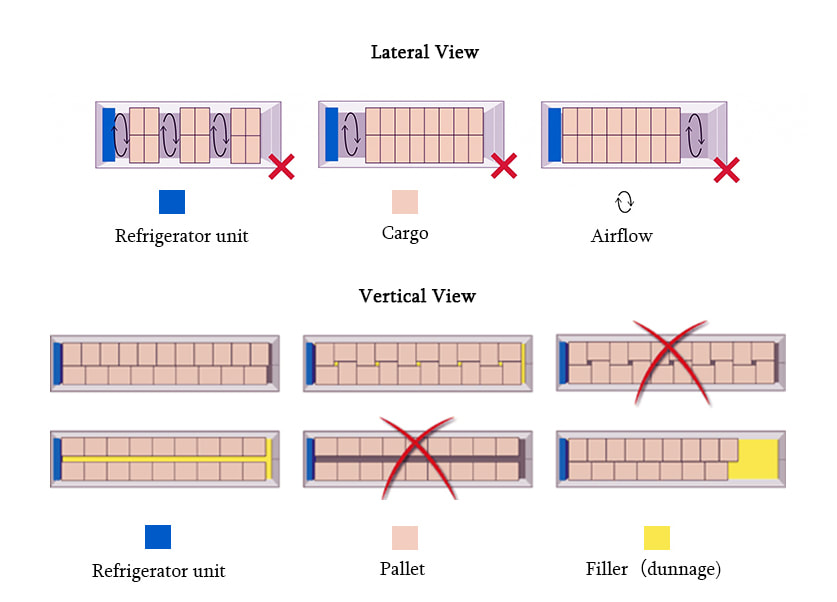

TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #DNV 2.7-1 #BV #LR #offshore reefer container #ISO #EN12079 #door curtains #shelving #lasing ring #Man-trap alarm #TLS Offshore Refrigerated Containers are reusable "portable units" designed to transport goods/food etc. on FPSOs or vessels. DNV 2.7-1 is considered the standard certification for marine reefer containers, and DNV 2.7-1 marine transport containers are certified containers for the oil and gas industry. DNV, BV, LR ABS classification societies can also certify DNV2.7-1 reefers according to DNV2.7-1 international standards. The size of offshore reefer is diversified, and it also solves the needs of all customers for reefer size according to the size of FOSO, which is the best choice for all FPSOs and Vessel. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #DNV 2.7-1 #BV #LR #offshore reefer container #FPSO #TLS Certified by BV/LR, DNV 2.7-1 standard 10ft, 20ft reefer containers are being manufactured. The 10ft/20ft reefer containers are our standard container type, but if you have any personalized needs, we can also customize and modify them accordingly. During the production process, our quality inspectors will track each production step, specific links, the third-party organizations such as BV/LR will also participate in the tracking quality inspection. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Key words: #DNV 2.7 #BV #LR #offshore reefer container #Assembly Welding Processing #TLS How does the refrigerated container work? The purpose of the reefer container is not to cool the product, but to maintain the temperature of the product. So instead of adding cool air, the refrigeration process removes heat from the air inside the container. The reefer container distributes cold air from the floor through the T-deck. Precautions for the use of reefer containers

A refrigerated |reefer Container is a closed container with refrigeration equipment and low thermal conductivity materials on the inner wall which is used to transport or preserve fresh fish, fresh meat, frozen food, fruits, vegetables, films, medicines and other required goods. Refrigerated containers are also divided into refrigerated containers and insulated containers.

Livestock and poultry meat Include cattle, sheep, pigs, chickens, ducks, geese, etc. Usually, meat reaches a dormant state below -18°C, and if it is below -23°C, the refrigeration period can be doubled. Frozen fish and aquatic products The storage time of fish and seafood is closely related to temperature. Under normal conditions, the freezing period increases by a factor of 3 for every 10°C decrease in temperature. Low-fat fish has a shorter freezing period, while muscle red fish has a shorter freezing period. Chocolate products Shippers often ask to check that the humidity is set to 65%. Depending on the variety of chocolate, the temperature is usually between 8°C and 18°C. Temperature control products Goods that require temperature stability during transportation, such as films, medicines, food, etc. To avoid clumping and deterioration, the temperature was set between -2°C and 30°C. Dangerous goods and harmful goods Reefer containers maintain high standards and maintain quality for the transport of dangerous or sensitive cargo. This type of refrigerated container is distinguished by a particular color and logo. Mixed refrigerated goods Generally, it should be avoided to mix all kinds of fresh fruits and vegetables in the reefer container. Due to the volume, variety, cost and other reasons, pay attention to the temperature during transportation, Fruits and vegetables are mixed in containers. The closer the refrigeration temperature is, the better. Key words: #reefer #refrigerated #TLS offshore containers #Portable reefer container #Insulation containers #container cold storage Reefer containers|refrigerated containers are used to transport or store goods that require temperature control. Fruit, vegetables, dairy products, meat and other products are typical goods transported or stored in such containers. At first glance, reefer containers look similar to traditional shipping containers, but they have many different features.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|