|

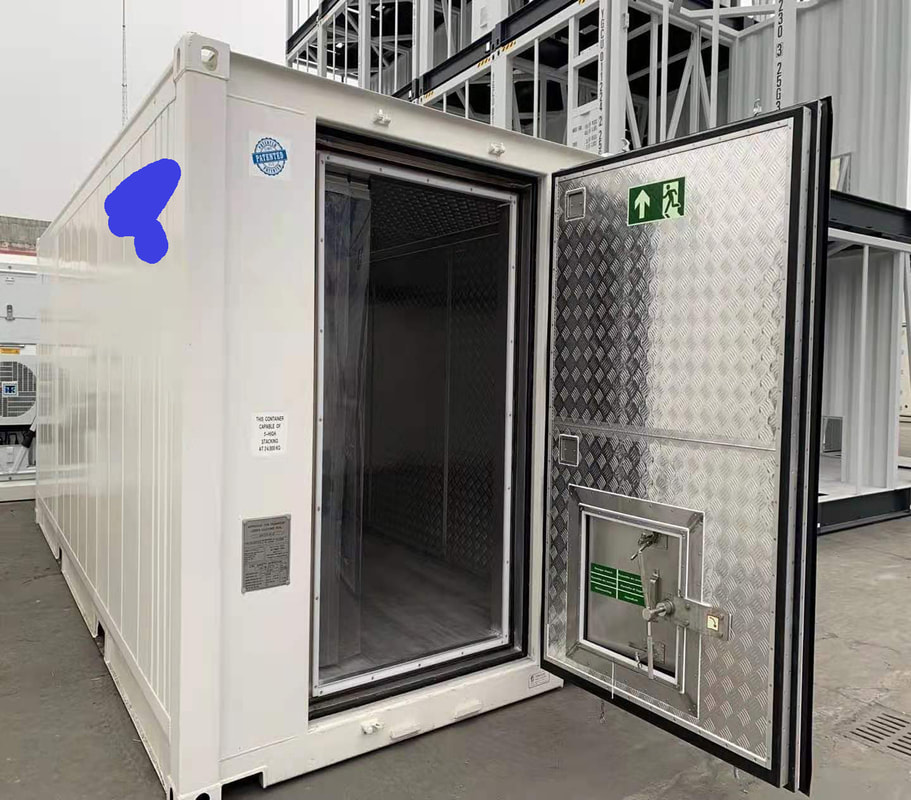

PRESSURISED LABORATORY CABIN, PRESSURISED WORKSHOP CONTAINER, MUD LOGGING UNIT, MUD LOGGING CABIN, PRESSURISED MODULES, OFFSHORE PRESSURISED MODULES DNV 2.7-1, A60 Fire Rated and Zone I / zone II Flexible and customised dimension and layout, 10ft/12ft/15ft/16ft/20ft/26ft/40ft etc Lead time: 3-4 months. which includes: Engineering : Structural drawings, Architectural drawings and Documentation package c/w as built drawings and Certifications (CSC certificate, DNV2.7-1/EN12079 certificate, A60/Zone 1/Zone 2 certificate of conformity). Fabrication : Structural materials to DNV 2.7-1 and A60 fire rated specification, Welding procedures, Welding inspections and Secondary steel provisions. Assembly : 1 x A60 Main door, 1 x A60 Escape hatch, A60 Thermal Insulation, 1 x B15 Airlock Door w/ viewing glass, self- fabricated internal panel for wall, ceiling and airlock compartment. Testing and Inspection: MPI and load testing in accordance with DNV 2.7-1, A60 insulation certification by DNV and Factory Acceptance Test (FAT) , Pressurised, Fire and Gas System, Electrical Work : Lighting and small power Distribution Board(DB) c/w circuit breakers, Cabling within Laboratory unit for lighting and power points, Conduit wiring for lightings, Trunking wiring for 220V, 8 x Double gang 230V 13A switch socket (Non-Ex), 3 x IP rated 2x36W fluorescent lighting, 1 x Non Ex rated light switch, MCT frames c/w MCT inserts, Earth bosses, 1 x Exe PJB at recessed area. Safety Equipment : Purge, Pressurized, Fire and Gas Control Panel, 2 x CH4 Detector, 1 x H2S Detector, 1 x Smoke Detector, 1 x Heat Detector, Pressure Switches and gauge, 1 x Ex Loss of Pressure Alarm, A60 Shutdown dampers, 1 x Emergency Lightings, 1 x Emergency Shut-down Button, 1 x Ex-proof Pressurisation Blower set & 1 x DNV 2.7-1 compliance lifting sling set. Air Conditioning System: 1 set 14,000BTU Split System c/w indoor evaporator set, indoor compressor set, indoor aircon circuitry box, outdoor copper condenser coil in stainless steel housing & Ex condenser motor. (20ft cabin) Air Conditioning System: 2 set 14,000BTU Split System c/w indoor evaporator set, indoor compressor set, indoor aircon circuitry box, outdoor copper condenser coil in stainless steel housing & Ex condenser motor. (40ft cabin) Furnishing : N.A. Painting Work : Preparation : Blasting to S.A. 2.5, Painting System : Three (3) coat System of 1st coat (65micron) with zinc rich epoxy primer, 2nd coat (75micron) with red lead epoxy primer, final coat (50micron) with Polyurethane coat. Please download Pressurised cabin product brochure for reference. Please don't hesitate to contact us at [email protected] for any inquiries. 40 foot Containerized Filling/fueling station with safe fill level of approx. 67,000 litres. STANDARD FITTINGS: 80 nb Camlock male tanker hose filler with dust cap connect, Tanker full point supplied with 80nb full bore, fire safe flanged ball valve and wafer style non return valve, container corner castings, statutory access manway, permanent ladder and platform, water evacuation pipe, interstitial space fluid dipstick, containment compartment with pressure vent, marine grade polyurethane paint

TLS provides standard or customized helicopter fuel tanks (helifuel tank) to safely transport and store aviation fuel. Our design is well integrated into the design of helicopter fuel distribution systems. The helifuel tank is equipped with a vapor recovery system, which is in compliance with DNV 2.7-1 / EN 12079, IMDG/ADR/RID, ASME VIII-1, PED 97/23/EC (CE marking) and CAP 437 (UK ) And CAAP 92-4 (Australia). Features:

Please don't hesitate to contact us at [email protected] for more information.

A MUD logging unit is installed on the rig when geologic information must be retrieved on a timely basis. If the formations drilled are not well known or if a specific geologic horizon is targeted, mineralogical data from cuttings brought to the surface with the mud might be essential. MUD logging units can discover and evaluate oil & gas reservoirs rapidly, provide complete drilling parameters and monitor toxic gases, thus ensuring drilling safety, enhancing drilling efficiency and reducing operation cost. As mud logging units are normally located in the hazardous zone 1 or zone 2, where fire or explosion hazards may exist, and the all the measurement equipment installed inside the mud logging units are not explosion proof, therefore the mud logging units should be positively pressurized by blowing fresh air without flammable gases, which creates a safe working environment not only for electric equipment inside, but also for mud loggers and working personnel. Our explosion proof and intelligent pressurized containers are designed to meet the requirement of clients, suitable for onshore or offshore drilling, A0 or A60 fire rated. Intelligent pressurized containers are equipped with CPFG (combined pressurization, fire and gas control panels), gas detectors, pressurization fan, fire dampers, etc, which is suitable to be used as mud logging cabin. TLS provides intelligent pressurized containers to global clients for many years. The pressurized container dimension and specifications can be customized according to client’s requirement. Main Features: 1.Positive Pressure & Explosion-Proof Container

2.Wireless data acquisition system

3. SGC-3K Multicomponent Chromatograph

4.SL-IR-II CO2 Analyzer

5.SL-SAS Safety Alarm System

6.CVD Constant Volume Degasser

7.SS - 3 mud logging Software System

Please don’t hesitate to contact us at [email protected] if you have the requirement. Fight against COVID-19, Deep freeze container solutions for transport, storage and distribution COVID-19 vaccines.

Vaccine manufacturers, transportation and storage providers face major challenges in the fight against the coronavirus, because according to the current state of science, many of these vaccines only work at temperatures as low as -80°C / -112°F Maintain its effectiveness. TLS developed ultra-cold freezer containers with temperatures as low as -80°C / -112°F. This deep freeze container solution can freeze vaccines directly at the manufacturer's factory. For this reason, the cold storage system is located near the production, and the refrigerated container is set outside the production building. Immediately after production, the vaccine is deep-frozen in the refrigerator. This cold storage solution can be installed anywhere that can be used for deep-cooled vaccines. Since the freezing container is based on active deep freezing technology, it does not require dry ice for cooling, which also makes it suitable for safe international air transportation. Please contact [email protected] if you need urgently.

Every funtional container is customised according to client's specific requirement. TLS is driven by the passion for being a global leading supplier of containerised solutions, TLS does the best to deliver the most premium quality product and service to our clients cost competitively and efficiently. TLS has a container manufacturing base with 150,000 square meters located in China, which allows TLS to provide the most cost-effective and the complete containerised solutions to worldwide clients. TLS provides ranges of containerised solutions including intelligent pressurised cabins, temporary refuge shelters, BESS containers, water treatment plant containers, etc.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|