|

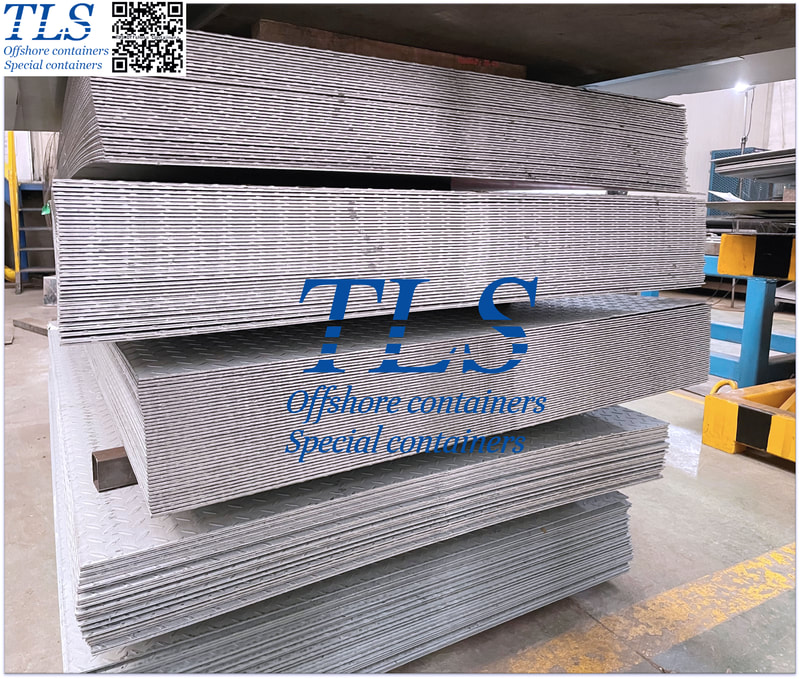

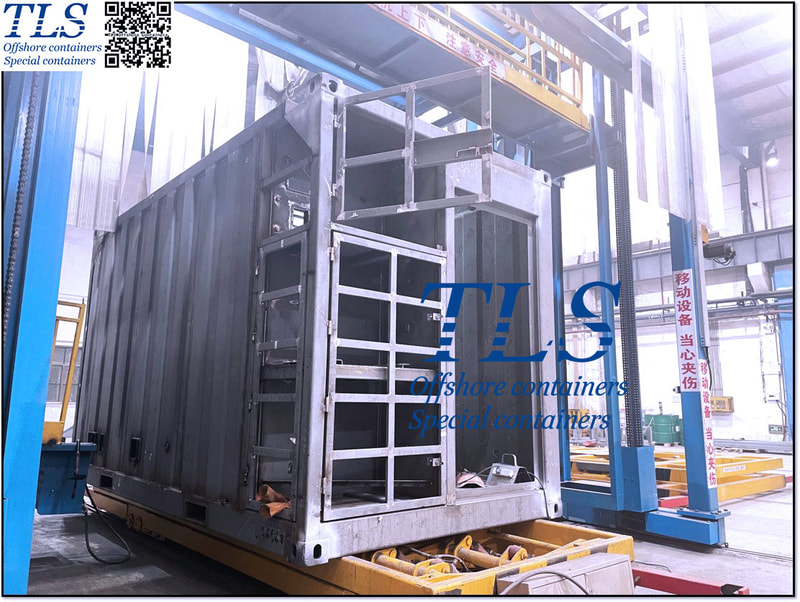

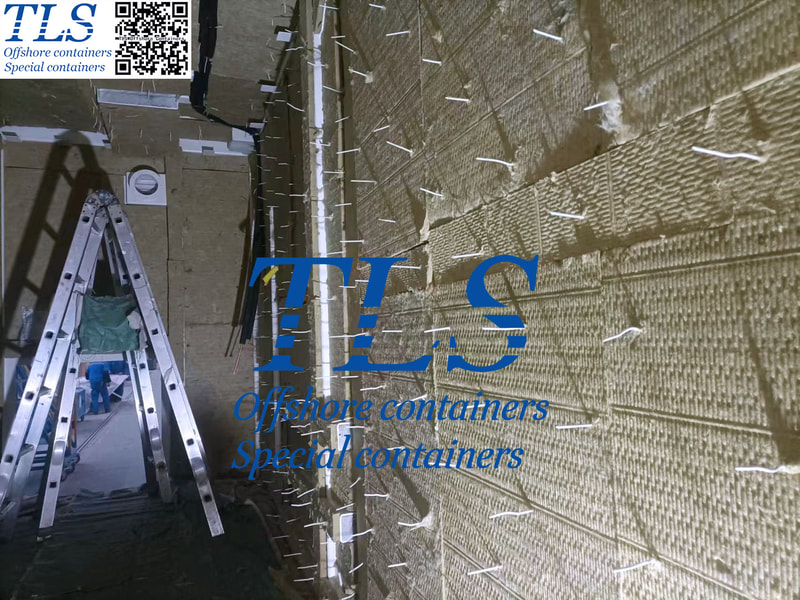

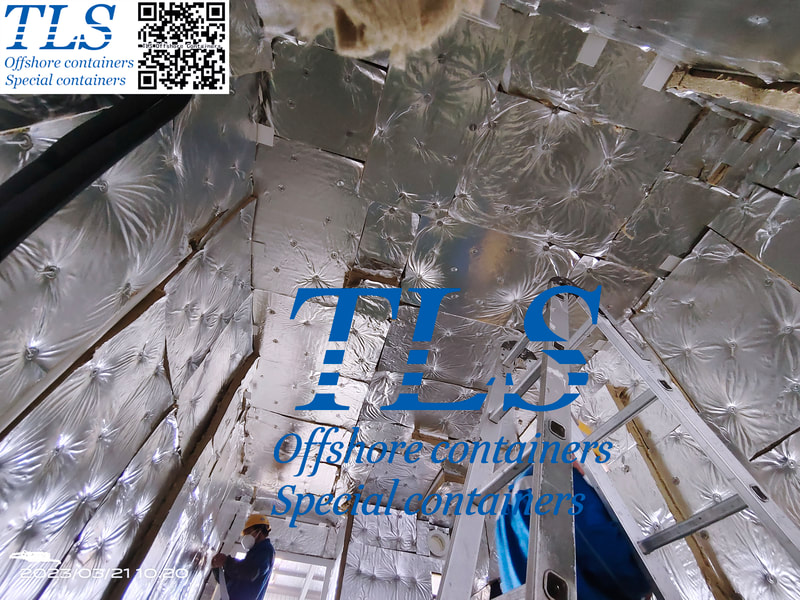

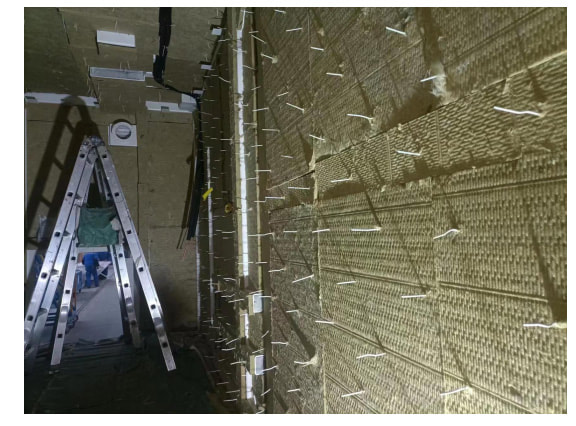

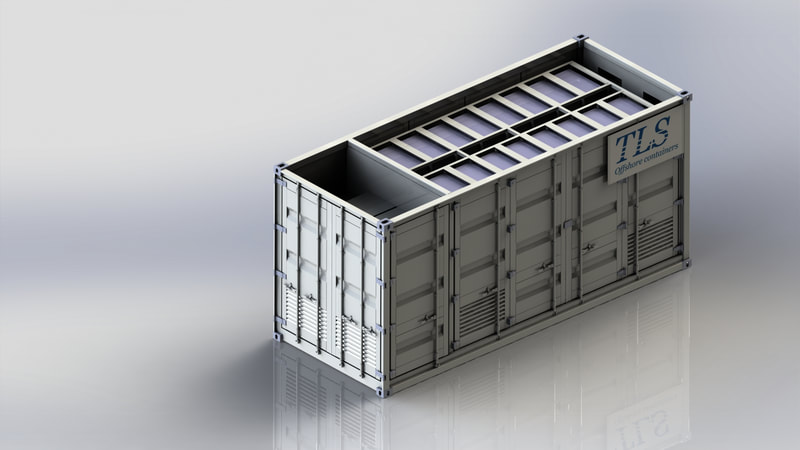

An offshore accommodation module is an accommodation facility that utilizes shipping containers as a basic structure. These accommodation modules are often used in places far from cities and infrastructure, such as remote oil rigs, mining camps, offshore wind farms, and more. Offshore container accommodation modules usually consist of multiple containers that have been specially designed and modified to meet the needs of the accommodation. For example, toilets, showers, kitchens, bedrooms and other facilities can be installed inside the container, as well as infrastructure such as heating, ventilation and air conditioning. At the same time, special facilities such as windproof, waterproof, and explosion-proof can also be installed on the outside of the container to meet the needs of use in harsh environments. The offshore container accommodation module has the following advantages: Flexibility: Offshore container accommodation modules can be flexibly combined and disassembled, and can be customized according to different needs, so as to meet various housing needs. This flexibility makes offshore container accommodation modules ideal for remote workforce housing and temporary housing. Durability: The shell of the offshore container accommodation module is usually made of high-strength steel, which has high durability and wind and shock resistance. This structure can ensure that the accommodation modules can still operate safely in harsh environments, thereby ensuring the safety of workers. Fast Construction: Offshore container accommodation modules can be built faster than traditional construction methods because of their relatively short manufacturing and shipping times. This rapid build can help businesses accommodate workers more quickly, increasing work efficiency and productivity. Mobility: Since the offshore container accommodation modules can be easily disassembled and combined, they can be easily moved to different workplaces. This mobility can allow enterprises to more flexibly adjust and optimize their resource allocation, thereby achieving higher efficiency and productivity. Cost-effective: Offshore container accommodation modules are usually more economical than traditional construction methods. This is because they are relatively inexpensive to manufacture and ship, as are their maintenance and management costs. This cost-effectiveness makes offshore container accommodation modules ideal for remote workforce housing and temporary housing. Environmentally friendly and sustainable: Offshore container accommodation modules are usually transformed and assembled with recycled containers, which avoids the large amount of material and energy consumption required by traditional buildings and reduces the impact on the environment. At the same time, the offshore container accommodation module can achieve energy saving and environmental protection, such as the use of solar panels, ground source heat pumps and other technologies to reduce energy consumption. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. Written by Mandy The global push towards renewable energy has highlighted the need for reliable and efficient energy storage solutions. As the world continues to move away from fossil fuels, the demand for advanced energy storage systems has grown exponentially. One such solution is the Battery Energy Storage System (BESS) container, which addresses the unique challenges posed by renewable energy sources. TLS Offshore Containers International, a leading manufacturer of BESS containers, is well-positioned to play a significant role in the evolving energy market with their innovative products. The Significance of Battery Energy Storage Systems Renewable energy sources such as solar, wind, and hydroelectric power have become increasingly popular as the world seeks to reduce its carbon footprint. However, these sources often face challenges related to intermittency and unpredictability. The need for efficient energy storage solutions has become paramount to ensure a stable and reliable power supply. Battery Energy Storage Systems (BESS) offer a means of storing excess energy generated during periods of high production, releasing it when needed, and thereby helping to maintain grid stability. By providing a buffer between supply and demand, BESS plays a crucial role in managing the integration of renewable energy sources into the grid. The Rise of BESS Containers BESS containers offer a flexible, scalable, and cost-effective solution to the challenges posed by renewable energy storage. By housing advanced battery systems within a secure and climate-controlled environment, these containers ensure the safety and longevity of the energy storage infrastructure. Some of the advantages of BESS containers include: Modularity: BESS containers can be easily transported, installed, and expanded to meet the growing needs of a particular site or project. This modularity allows for rapid deployment in various settings, including remote areas, urban environments, and existing power generation facilities. Compatibility: BESS containers can be designed to accommodate a range of battery technologies, including lithium-ion, flow batteries, and other emerging technologies. This adaptability ensures that BESS containers can be tailored to the specific requirements of a project or the evolving landscape of renewable energy. Customization: BESS container manufacturers, such as TLS Offshore Containers International, offer a wide range of customization options to suit the unique needs of each project. These may include fire suppression systems, temperature and humidity control, and other safety features. TLS Offshore Containers International: A Market Leader in BESS Container Manufacturing As a leading manufacturer of BESS containers, TLS Offshore Containers International is at the forefront of this rapidly expanding market. With years of experience in the offshore container industry, the company has leveraged its expertise to develop state-of-the-art BESS containers that meet the highest safety and quality standards. Some of the key features of TLS Offshore Containers International's BESS containers include: Robust structural engineering: TLS Offshore Containers International's containers are designed to withstand harsh environmental conditions, including extreme temperatures, high winds, and seismic events. Advanced safety features: To protect the valuable battery systems housed within, TLS Offshore Containers International's BESS containers incorporate fire suppression systems, gas and smoke detection, and emergency ventilation systems. Compliance with industry standards: TLS Offshore Containers International's BESS containers are designed to meet or exceed industry standards, including DNV GL, ISO, and other applicable certifications. Market Prospects for BESS Containers The market for BESS containers is poised for significant growth in the coming years, driven by the increasing adoption of renewable energy and the need for efficient energy storage solutions. Key industries that stand to benefit from the deployment of BESS containers include: Utilities: As the share of renewable energy in the power generation mix continues to grow, utilities will need to invest in BESS containers to maintain grid stability and manage fluctuations in supply and demand. This will help ensure a reliable power supply for consumers while supporting the integration of renewable energy sources. Commercial and industrial facilities: BESS containers can be used by commercial and industrial facilities to reduce their reliance on grid-supplied electricity, lower energy costs, and improve resiliency. By storing excess energy generated by on-site renewable energy systems, these facilities can achieve greater energy independence and reduce their environmental impact. Remote communities and microgrids: In areas with limited access to the main grid or in regions with unreliable power supplies, BESS containers can play a crucial role in providing a stable and consistent source of electricity. By integrating BESS containers with renewable energy sources, these communities can achieve greater energy security and reduce their reliance on expensive and polluting diesel generators. Electric vehicle (EV) charging infrastructure: As the adoption of electric vehicles accelerates, the demand for fast-charging infrastructure will grow. BESS containers can be used to store energy generated by renewable sources, providing a green and efficient solution for powering EV charging stations. Grid services and ancillary markets: BESS containers can be utilized to provide various grid services, such as frequency regulation, voltage support, and demand response. These services help maintain grid stability and reliability, enabling the further integration of renewable energy sources. Governments worldwide are also investing heavily in renewable energy projects and supporting policies that encourage the deployment of energy storage solutions. These initiatives are likely to further boost the demand for BESS containers in the coming years. BESS containers represent a promising solution to the energy storage challenges faced by the renewable energy sector. As a leading manufacturer of these containers, TLS Offshore Containers International is well-positioned to capitalize on the growing market demand. Their commitment to quality, safety, and innovation ensures that their BESS containers will play a pivotal role in the global transition to a cleaner, more sustainable energy future. As the market for BESS containers continues to expand, TLS Offshore Containers International's expertise and cutting-edge products will remain essential for addressing the needs of a rapidly evolving renewable energy landscape.  About offshore positive pressure container used in Zone1/Zone2 Positive pressurized containers can provide a safe environment for equipment and people in hazardous areas. The principle of a positive pressure blast-proof container is to achieve the technical requirements of blast-proofing through enclosure. A positive pressure ventilation system is the key. It delivers fresh air from a safe area to the container through ducts that pure the air inside the container and maintain a slightly higher air pressure inside the container than outside. In this condition, no harmful and flammable gas can enter the enclosure.If the blast control system detects the presence of hazardous gases in the enclosure or fails to maintain positive pressure, the alarm system will sound an alarm and issue a warning. If the control conditions inside the container are still not required within the specified time, the non-explosive device will automatically cut off. Thus, the common equipment in the container fulfils the purpose of blast protection.  About the air lock room of the positive pressure container The positive pressure container provided by TLS arrange two doors between the safe zone inside the container and the hazardous zone outside the container, and the isolation space formed between the two doors is the air-lock compartment. The purpose of setting the air-lock compartment is to control the airflow when people or materials enter and exit. The two doors of the air-lock compartment are usually interlocked, with one door open and the other closed. When entering the offshore container, the operator enters the air-lock compartment through the enclosed outer door and then opens the inner door after closing the enclosed outer door. In this way, no harmful gases from the outside can enter the main compartment, and the pressure of the air in the main compartment does not fall too fast.  About CPFG(combined pressurization fire&gas system) of positive pressure container CPFG is a complete suite of intelligent booster control systems, typically used in positive pressure containers, with gas detectors, smoke detectors, heat detectors, fire alarms, pressure switches, flow switches, booster fans, emergency stop & alarm mute switches, and other explosion protection equipment. The CPFG is also connected to a power distribution board, which will be connected by non-explosive devices inside the container, such as sockets, fume hoods, computers, water heaters, etc. When the power is turned on, the CPFG turns on the booster fan to purge the inside of the container to positive pressure. This prevents dangerous gases entering from outside. When the environment inside is safe, the DB (distribution board) will start up and the internal non-explosive electrical equipment can be used normally. The DB cannot be started if the environment inside the container is not secure. During operation, if dangerous gases are detected in the container or the positive pressure cannot be maintained, the alarm system will sound an alarm and issue a warning. If the control conditions in the container are not met within the specified time, the non-explosive device is automatically turned off. Therefore, the general equipment in the container is suitable for blast protection purposes. More information please download the brochure for reference. Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Container Shell Production 1.Plate and Section Steel Pretreatment 2.Stamping 3.Welding Prefab 4.Bottom, End Frame, Top and Side Structure Fabrication 5.Main Assemble 6.Lifting Test,Dropping Test, NDT for The Welding 7.Sanding and Painting (C5-H coating system--outside 260μm, inside 120μm) 8.Offline and Watertight Test Container Interior Decoration 1.Floor Material Laying 2.AC Copper Pipe Pre-embedded 3.The First Rock Wool Laying 4.The Second Rock Wool Laying 5.Aluminum Film Tape Paste 7.Hardware installation 8.Circuit debugging/cross inspection Subsequent production process is waiting for update. A60 rock wool is is an excellent choice for the insulation of tls offshore functional containers3/28/2023

A60 Rock Wool is a high-performance insulation material made from mineral fibers derived from basalt rocks. The term "A60" refers to its fire resistance rating, meaning that it can withstand fire for up to 60 minutes before its structural integrity is compromised. Rock wool is known for its excellent thermal, acoustic, and fire-resistant properties. A60 Rock Wool is indeed an excellent choice for insulation in offshore functional containers due to its unique combination of properties. Offshore containers are exposed to harsh environmental conditions, including high humidity, saltwater, and extreme temperature fluctuations. In these environments, insulation materials must provide reliable performance and meet strict safety standards. A60 Rock Wool fits these requirements well.Here's why A60 Rock Wool is suitable for offshore functional containers:

Energy consumption has become a pressing concern for businesses and consumers today, and energy storage containers from TLS have emerged as a sustainable solution to reduce energy costs, improve energy efficiency, and provide backup power during outages. Energy storage containers from TLS are self-contained units that store electricity in batteries or other forms of energy storage. They come in various sizes and can be customized to meet specific energy needs. These containers can be charged using renewable energy sources such as solar or wind power, providing power for homes, businesses, and communities. One of the main benefits of energy storage containers for businesses is that they can help reduce energy costs. They allow businesses to store energy during off-peak hours when electricity is cheaper and then use it during peak hours when electricity is more expensive, resulting in significant cost savings. Energy storage containers can also help businesses become more energy-efficient by storing energy when electricity demand is low, avoiding the use of fossil fuels to generate electricity during peak demand periods, and reducing greenhouse gas emissions. For businesses that rely on uninterrupted power, energy storage containers can provide backup power during outages. Storing energy in batteries ensures that businesses have a reliable backup power source that can keep their operations running during power outages. Consumers can also benefit from energy storage containers. By storing energy during off-peak hours when electricity is cheaper and using it during peak hours when electricity is more expensive, energy storage containers can help consumers reduce their energy bills significantly. Additionally, energy storage containers can provide backup power for homes during outages, which is essential for households with medical equipment or other critical needs. Energy storage containers from TLS also have significant environmental benefits. By storing energy from renewable sources such as solar and wind power, they can help reduce greenhouse gas emissions and contribute to a more sustainable future. The future of energy storage containers looks promising, as the demand for renewable energy sources continues to grow. Energy storage containers are expected to become more efficient and cost-effective, making them more accessible to businesses and consumers. They are also expected to play a more significant role in the development of smart grids, improving the stability and reliability of intelligent grids. In summary, energy storage containers offer numerous benefits for businesses and consumers looking for sustainable solutions, including energy independence, cost savings, reduced carbon footprint, backup power, and flexibility. As renewable energy sources become more prevalent, energy storage containers will play a crucial role in helping businesses and homeowners become more self-sufficient and sustainable. Investing in energy storage containers can help achieve a more sustainable future. Written by OliverContainerIZED energy storage system: an important technical support for future energy transformation3/27/2023

With the rapid development of renewable energy, containerized energy storage system, as a convenient and efficient form of energy storage, has gradually attracted the attention of the market. Its main advantages include: High flexibility: The containerized energy storage system can be moved and reconfigured to adapt to different application scenarios and grid requirements. Compared with traditional forms of energy storage, such as reservoirs and pumped storage power plants, containerized energy storage systems have higher flexibility and operability, and can better adapt to changes and needs of the power system. Efficiency: The containerized energy storage system has high charging and discharging efficiency, can complete a large amount of energy storage and release in a short period of time, and has the ability of quick response. This enables the containerized energy storage system to cope with fluctuations and peaks in power demand, improving the stability and reliability of the power system. Economy: Compared with traditional forms of energy storage, the cost of containerized energy storage systems is lower, especially in terms of large-scale production and operation. At the same time, because the containerized energy storage system can better adapt to the changes and demands of the power system, it can improve the efficiency and reliability of the power system, thereby reducing the operating costs and risks of the power system. High safety: The containerized energy storage system adopts high-quality battery technology and advanced safety measures, which has high safety and stability. In addition, since it is usually installed in a closed container, it can better prevent the influence and damage of the external environment. Good environmental protection: container energy storage systems usually use renewable energy and high-efficiency energy-saving technologies, which are environmentally friendly and sustainable, and can make positive contributions to energy transformation and carbon emission reduction. The containerized energy storage system is of great significance in the market layout. It can provide stable and reliable energy storage support for the power system, provide important technical support for the popularization and development of renewable energy, and make positive contributions to energy transformation and carbon emission reduction. In the future market competition, the container energy storage system will become a field that attracts much attention, and it is expected to achieve the goal of sustainable development in the energy field. Written by Mandy 1.Design Offshore containers are built to suit specific equipment and are often designed to withstand high dynamic loading. 2. Ability to withstand adverse weather conditions Offshore reefer containers are more exposed to open seas and are often left on ship decks or on loading platforms in adverse weather conditions. Therefore, they require a minimum design temperature of -20°C. This also means that the material they are made of must be strong enough to withstand this temperature. On the other hand, ISO sea containers (also called shipping containers) are made of corrosion-resistant steel. 3. Microprocessor control DNV 2.7-1 offshore reefer containers have microprocessor control of the fresh air exchange rate, a feature that traditional ISO containers do not have. This means that the air exchange rate can be modified according to the goods being transported and other requirements. 4. Ventilation on demand This is a unique feature offered by DNV's offshore refrigerated containers, which makes them a clear winner compared to traditional ISO containers. Ventilation on demand offers maximum protection for perishable goods/cargo. The system works by providing full, automated ventilation in response to changes in respiratory gas levels. In conclusion, DNV offshore refrigerated containers are built to withstand the harsh environments and conditions prevalent in the shipping industry, making them the best choice for the oil and gas industry. TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Written by OliverDNV 2.7-1 Certified Offshore Containers: Robust Solutions for the Global Offshore Industry3/25/2023

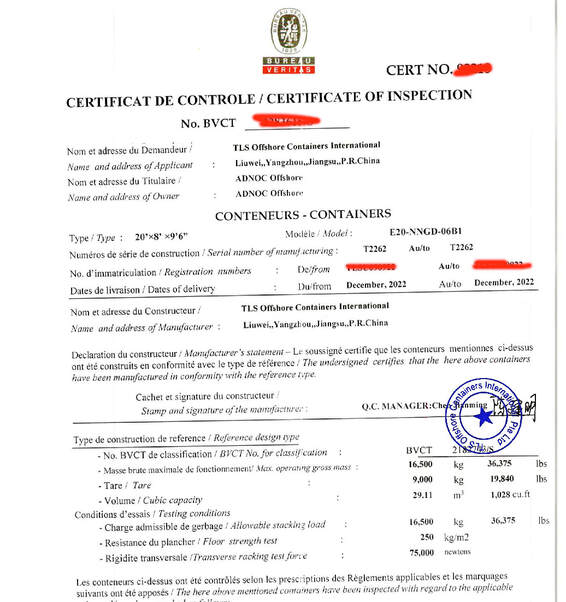

The DNV 2.7-1 certificate is a globally recognized standard for the design, manufacture, and certification of offshore containers, developed by Det Norske Veritas Germanischer Lloyd (DNV GL), a leading international classification society. This standard ensures the safety, reliability, and quality of offshore containers used in various applications, including the transportation and storage of equipment and materials, as well as providing workspaces and living quarters for personnel in the offshore oil, gas, and renewable energy industries. TLS Offshore Containers International is a reputable manufacturer of DNV 2.7-1 certified offshore functional containers. With a commitment to safety, quality, and customer satisfaction, they offer a wide range of container solutions to clients worldwide. Some of their key offerings include:

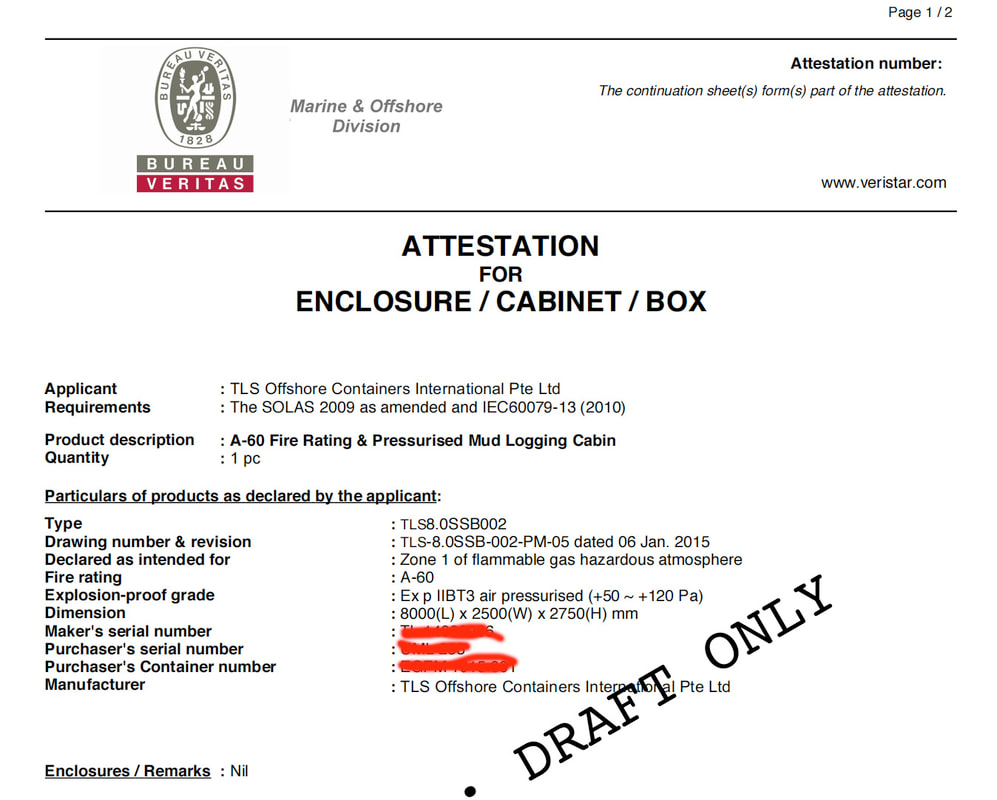

By providing a comprehensive range of DNV 2.7-1 certified offshore functional containers, TLS Offshore Containers International is well-positioned to serve the needs of clients in various industries worldwide. Their commitment to safety, quality, and innovation ensures that their products not only meet but exceed the stringent requirements of the global offshore market. The IEC 60079-13 design standard, developed by the International Electrotechnical Commission (IEC), plays a critical role in ensuring the safety and reliability of electrical equipment used in explosive atmospheres. This standard focuses on equipment using pressurized (Type "p") enclosures to protect against explosive gas atmospheres or combustible dusts. TLS Offshore Containers International, a professional company specializing in the manufacture of pressurized containers, adheres to the IEC 60079-13 standard, demonstrating its commitment to safety, quality, and industry best practices. IEC 60079-13 Design Standard The IEC 60079-13 standard is part of the broader IEC 60079 series of standards that address electrical equipment for explosive atmospheres. It provides guidelines and requirements for the design, construction, and testing of electrical equipment using pressurized enclosures. Key aspects of the standard include:

TLS Offshore Containers International: Expertise in Pressurized Containers TLS Offshore Containers International is a leading global provider of specialized containers, primarily focused on the offshore oil and gas, renewable energy, and maritime industries. With a comprehensive range of products and services, the company has built a strong reputation for its expertise in the design, manufacture, and supply of pressurized containers. Expertise in Pressurized Containers:

In conclusion, TLS Offshore Containers International's expertise in pressurized containers can be attributed to their strong commitment to design and engineering, manufacturing quality, customization, inspection and certification, after-sales support, and their extensive experience in the industry. By maintaining a customer-centric approach and consistently delivering high-quality products and services, the company has positioned itself as a leader in the offshore container market. This has allowed TLS Offshore Containers International to serve a diverse range of clients across various industries, including offshore oil and gas, renewable energy, and maritime sectors, providing them with the robust and reliable pressurized containers they need to operate safely and efficiently in challenging environments. DNV 2.7-2 is a standard developed by DNV (Det Norske Veritas), a leading global provider of risk management, assurance, and advisory services. The DNV 2.7-2 standard specifically addresses the design, fabrication, and testing of portable offshore units, with an emphasis on the safety of Temporary Equipment installed on these units. These units are primarily used in the oil and gas industry for offshore installations such as drilling rigs, production platforms, and support vessels. The DNV 2.7-2 standard aims to ensure that the temporary equipment used on offshore installations is safe, reliable, and able to withstand the harsh environmental conditions often encountered in offshore operations. It covers various aspects of design, construction, and testing of these portable offshore units, including:

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|