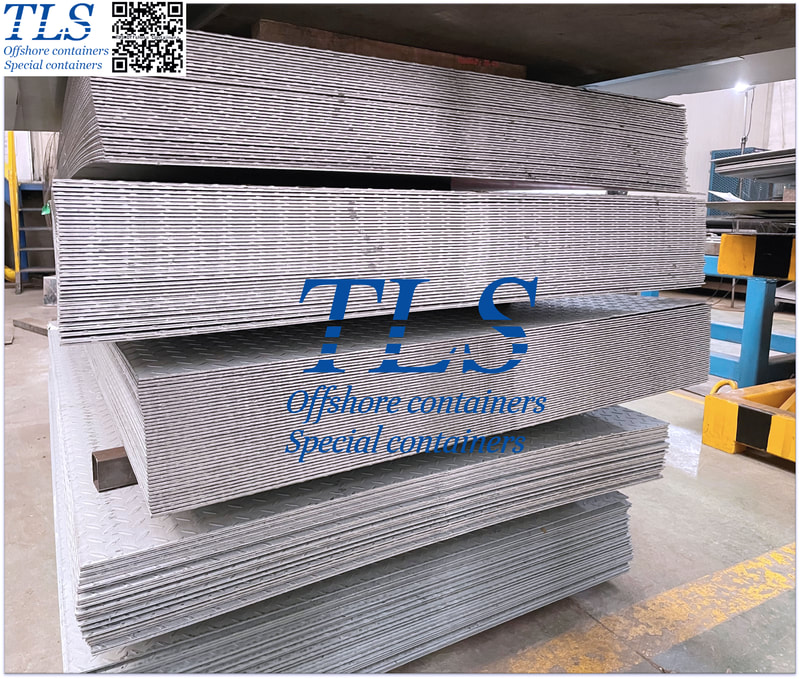

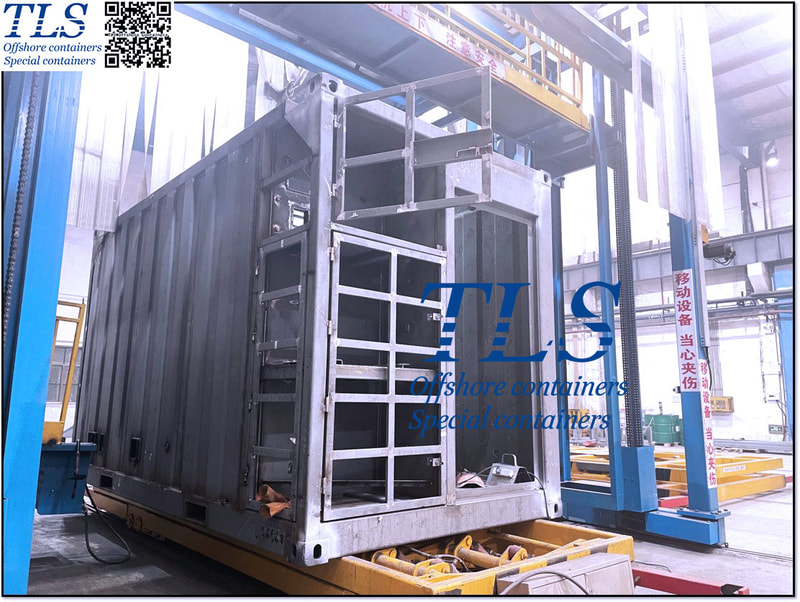

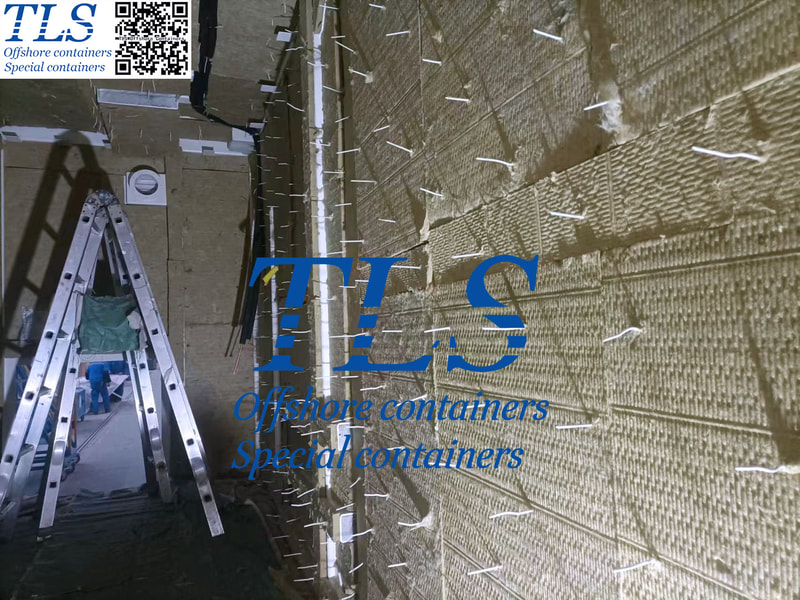

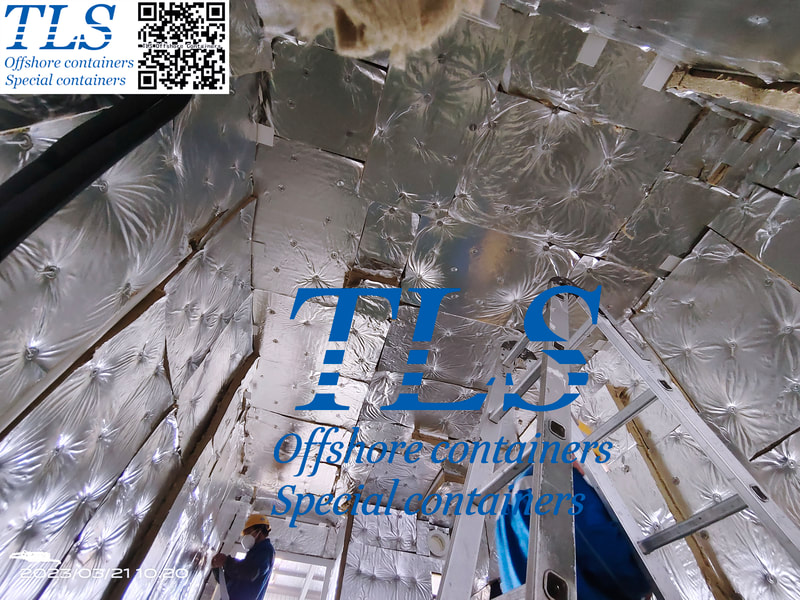

About offshore positive pressure container used in Zone1/Zone2 Positive pressurized containers can provide a safe environment for equipment and people in hazardous areas. The principle of a positive pressure blast-proof container is to achieve the technical requirements of blast-proofing through enclosure. A positive pressure ventilation system is the key. It delivers fresh air from a safe area to the container through ducts that pure the air inside the container and maintain a slightly higher air pressure inside the container than outside. In this condition, no harmful and flammable gas can enter the enclosure.If the blast control system detects the presence of hazardous gases in the enclosure or fails to maintain positive pressure, the alarm system will sound an alarm and issue a warning. If the control conditions inside the container are still not required within the specified time, the non-explosive device will automatically cut off. Thus, the common equipment in the container fulfils the purpose of blast protection.  About the air lock room of the positive pressure container The positive pressure container provided by TLS arrange two doors between the safe zone inside the container and the hazardous zone outside the container, and the isolation space formed between the two doors is the air-lock compartment. The purpose of setting the air-lock compartment is to control the airflow when people or materials enter and exit. The two doors of the air-lock compartment are usually interlocked, with one door open and the other closed. When entering the offshore container, the operator enters the air-lock compartment through the enclosed outer door and then opens the inner door after closing the enclosed outer door. In this way, no harmful gases from the outside can enter the main compartment, and the pressure of the air in the main compartment does not fall too fast.  About CPFG(combined pressurization fire&gas system) of positive pressure container CPFG is a complete suite of intelligent booster control systems, typically used in positive pressure containers, with gas detectors, smoke detectors, heat detectors, fire alarms, pressure switches, flow switches, booster fans, emergency stop & alarm mute switches, and other explosion protection equipment. The CPFG is also connected to a power distribution board, which will be connected by non-explosive devices inside the container, such as sockets, fume hoods, computers, water heaters, etc. When the power is turned on, the CPFG turns on the booster fan to purge the inside of the container to positive pressure. This prevents dangerous gases entering from outside. When the environment inside is safe, the DB (distribution board) will start up and the internal non-explosive electrical equipment can be used normally. The DB cannot be started if the environment inside the container is not secure. During operation, if dangerous gases are detected in the container or the positive pressure cannot be maintained, the alarm system will sound an alarm and issue a warning. If the control conditions in the container are not met within the specified time, the non-explosive device is automatically turned off. Therefore, the general equipment in the container is suitable for blast protection purposes. More information please download the brochure for reference. Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Container Shell Production 1.Plate and Section Steel Pretreatment 2.Stamping 3.Welding Prefab 4.Bottom, End Frame, Top and Side Structure Fabrication 5.Main Assemble 6.Lifting Test,Dropping Test, NDT for The Welding 7.Sanding and Painting (C5-H coating system--outside 260μm, inside 120μm) 8.Offline and Watertight Test Container Interior Decoration 1.Floor Material Laying 2.AC Copper Pipe Pre-embedded 3.The First Rock Wool Laying 4.The Second Rock Wool Laying 5.Aluminum Film Tape Paste 7.Hardware installation 8.Circuit debugging/cross inspection Subsequent production process is waiting for update. Comments are closed.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|