What are the functions of the additional equipment of the TLS offshore container refrigeration unit?10/31/2022

Instructions for additional equipment related to refrigeration units such as CA, MA and humidity controllers.

TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly:

E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Negative air pressure is a safe containment solution in which more air is taken in than is expelled.

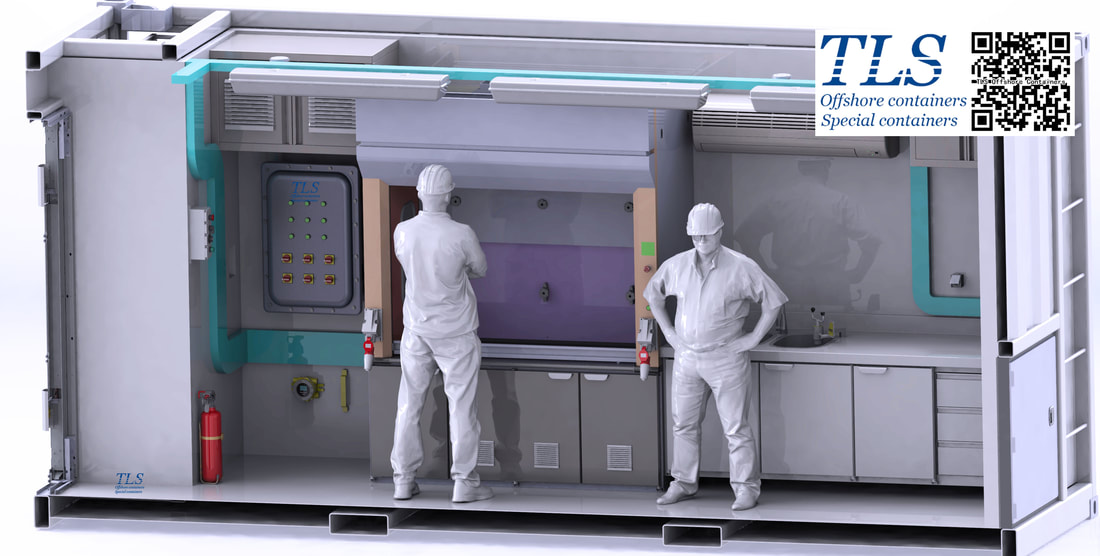

Negative air pressure in the environment does not mean that the actual pressure is negative because, according to science, absolute pressure can never be less than zero. Negative air pressure means that the pressure within an environment is less than the pressure of its surroundings. As air flows from high pressure to low pressure, this difference in pressure level acts as a vacuum effect and causes air to flow in from the outside. The negative air system produces a vacuum effect or a direction of air flow into the space by creating and maintaining the air pressure differential. In doing so, it restricts the spread of contaminants such as dust and mould and pollutants such as bacteria and viruses from the controlled space to the outside. This system traps dangerous and infectious particles in the air and removes them by means of a blower and a group of filters. In summary, when the external environment is safe, but toxic and harmful gases are generated inside, negative pressure is preferred • Modular Petroleum Laboratory • Laboratory container / cabin • Blast Resistant Container, Blast proof Container • Mud Lab Offshore containers should be inspected regularly every year. Regular inspections should be performed on the inside and outside of the container when it is empty. TLS has prepared tips for you to check including:

1.Keeps the temperature cold

The refrigeration unit distributes cold air through the floor of a refrigerated container The floor of the container has slots, also known as T-shaped covers. This T-shaped cover allows a constant supply of cold air around the shipment. If you are considering using a refrigerated container, you should be aware that it cannot reduce the temperature of your goods. A refrigerated container only maintains the desired temperature. Therefore, you will have to pre-cool your cargo to the temperature you want the reefer to maintain. 2.The genset provides electricity Genset is short for generating set. It provides electricity to the refrigeration unit to operate. A refrigerator is usually connected to a power source on ships. But in the case of extremely sensitive cargoes that could spoil outside a temperature range, gensets provide a back-up power source. It is best to use a refrigerator equipped with a genset to ensure the safety of the cargo. 3.Ventilation keeps cargo cool The purpose of a refrigerated container is to keep the cargo cool. Fruit and vegetables release heat, water, and CO₂. If these gases are not removed, they can damage the cargo leading to uncontrolled ripening, ageing, and altered taste. For this reason, refrigerators are kept ventilated with fresh air. To facilitate the loading and unloading of the cargo, the bottom of TLS offshore containers is usually designed with fork pockets, which are required as follows:

1. If provided, the fork pockets shall be arranged in the bottom structure with the top closed to penetrate the bottom and prevent the offshore container from overturning from the fork tine. 2. The net opening size of the fork pocket of the offshore container shall not be less than 200mm×90mm. 3. Considering the length, height, width, and rated weight of the offshore container, the position of the fork pocket should ensure the stability of the container when it is transported by the forklift. The fork pockets should be as far apart as possible, generally not less than 900 mm from the center, but not more than 2,050 mm. 4. The bottom plate of the fork pockets can be closed completely, but openings are recommended for maintenance and to reduce the risk of loose items being left in the fork pockets, thereby preventing items from falling during the lifting process. Where openings are provided, the size and position of the opening should be set to avoid jamming or being damaged by the tines The opening at the bottom of the fork pockets are not allowed at the bottom side rails, and the distance between the opening and the bottom side rails should not be less than 200mm. 5. The weakening of vertical shear strength of bottom side rails by fork pockets opening should be taken into account when calculating the bottom side rails strength. In general, a reinforcement plate should be attached to the top of the bottom side rail. The reinforcement plate should be in the same plane as the bottom side rails web. The reinforcement plate should be extended by at least 100mm at both ends. At this point, the weld between the reinforcement plate and the bottom side rail should be completely melted through. Energy storage is the process of storing energy through a medium or device and releasing it when it is needed. When we talk about energy storage, we are mainly referring to the storage of electrical energy. In fact, energy storage itself is not an emerging technology, but from an industrial point of view it is in its infancy and development stage. Energy storage technology is a key node for future energy systems to be flexible, inclusive, and balanced.

TLS containerized energy storage system (BESS) is the perfect solution for large-scale energy storage projects. The energy storage containers can be used in the integration of various storage technologies and for different purposes. Movable container modules are becoming more and more popular in both offshore and onshore work areas. Because of its mobility, security, customizability, durability and cost-effectiveness, it can better meet people's needs.

Take the workshop container as an example.

This type of container workshop is windproof, waterproof and fireproof, has good sealing, can be easily transferred, and is easy to install. As a tool workshop| storage container workshop, it is cost-effective and provides more convenience for work and life. Any related needs, please feel free to contact us. During oil exploration and production, large quantities of well waste fluids and drill cuttings are generated. This drilling waste is disposed of in storage ponds at the well site and can cause serious pollution to the groundwater, surface water and surrounding environment due to leakage, spillage, and flooding. Drilling waste is a long-standing environmental problem in the oilfield, so we have a solution for it.

Offshore cutting skips & waste skips provided by TLS Offshore Containers International are designed, manufactured and tested in accordance with requirements of the following latest editions standards and regulations

ROV stands for Remotely Operated Vehicle; ROVs are unoccupied, highly mobile underwater machines that can be used to explore the depths of the ocean while being operated by a person on the surface.

Remotely operated vehicles (ROVs) allow us to explore the ocean without actually being in it. These underwater machines are usually controlled by a person on a surface vessel, using a joystick in a similar way to play a video game. A set of cables or tethers connects the ROV to the ship, sending electrical signals back and forth between the operator and the vehicle. ROVs have made exploration of several deep-sea gas and oil reserves much easier because many oil reserves are difficult for divers to find. Precisely because of the uses and characteristics of ROVs, the TLS ROV cabin is designed to provide personnel with the facility to operate the ROV in a safe, comfortable, and climate-controlled environment. The TLS ROV cabins are equipped to a high standard and specification. We can design the equipment requirements internally to your specifications to achieve the most space efficient layout. Units can be modified or customized to meet customer requirements. The TLS ROV cabins have the following standard specifications:

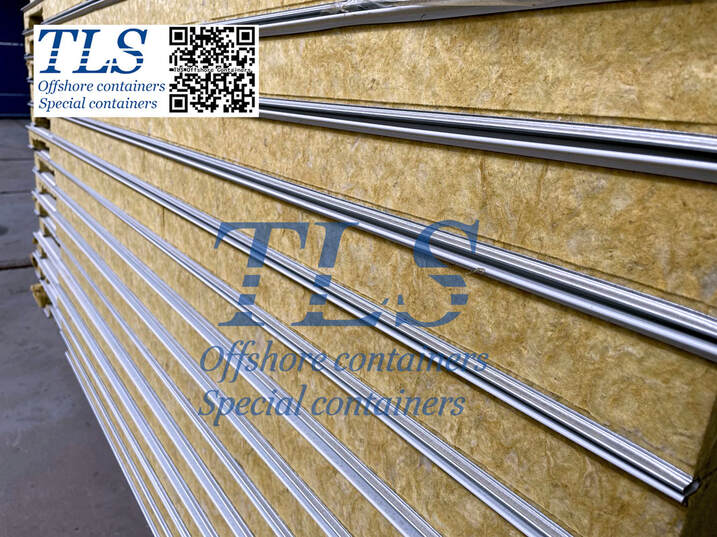

1.How to deal with the insulation problem of accommodation containers in high temperature climate?

The most popular insulation material for container homes is rock wool. Rock wool products are made of high-quality basalt and dolomite as the main raw materials. After melting at a high temperature above 1450°C, the fiber is formed by high-speed centrifugation using the world's advanced four-axis centrifuge. Pendulum method, plus three-dimensional cotton laying method, curing and cutting to form a thermal insulation layer. So don't worry about insulation. 2. Does the container house need a foundation? The shipping container house can choose a natural base. When the bearing capacity of the foundation soil of the ground floor house is less than 60kPa or the bearing capacity of the multi-storey house structure is less than 100kPa, and the foundation soil is soft soil or the foundation is poor, the foundation treatment should be carried out. implement. 3. How to install the doors and windows of the prefab container homes? Doors and windows can be installed according to personal preference, glass doors and wooden doors can be customized. Windows can also be customized as round windows, shutters, floor-to-ceiling windows, etc. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|