Understanding A60 Fire Rating Standard and A60 Fireproof Materials for Offshore Containers8/31/2023

In order to fully enable offshore containers to fulfill various functions such as transporting perishable goods, providing living quarters, and accommodating workspaces, it becomes essential to undertake modifications that adhere to the container's thermal insulation and fire protection prerequisites. Typically, the containers offered by TLS are designed to meet the A60 standard, ensuring compliance with stringent safety regulations. Key Specifications for A60 Classification Society Standard:

Characteristics of A60 Fireproof Materials: The chosen fireproof material should exhibit both rigidity and the ability to withstand fire for a minimum of 1 hour, all while preserving its structural integrity to thwart the passage of smoke and flames. Rock wool and ceramic fiber wool stand out as two distinct alternatives for insulation materials in A60 fire protection applications. However, it is imperative that both materials receive official endorsement from the pertinent classification society to ensure adherence to safety standards and regulations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #A60 fire rating #A60 fireproof material #Offshore containers #Thermal insulation #Fire protection #Classification society standards #Steel thickness #Anti-flexion reinforcement #Non-combustible materials #Average temperature rise Written by OliverContainer weld inspections are crucial to ensure structural integrity and safety. Among the non-destructive testing methods available, Magnetic Particle Inspection (MPI) stands out. This technique utilizes magnetic powders to reveal defects and discontinuities in ferromagnetic materials without causing any damage. The process of MPI involves magnetizing the ferromagnetic workpiece, which leads to localized distortions in the magnetic field lines when discontinuities are present. This results in a leakage magnetic field that attracts magnetic powders applied to the surface. When appropriately illuminated, these powders form visible indications, allowing for the identification of location, size, shape, and severity of any defects. For effective flaw detection, TLS employs black magnetic paste during MPI. This specific approach boasts high sensitivity in detecting even the smallest surface imperfections. The procedure comprises the following steps:

All our Quality Assurance personnel undergo rigorous certification examinations. At TLS, we uphold an unwavering commitment to product quality, delivering only after thorough confirmation that our offerings align with stringent quality inspection standards. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Container weld inspections #Non-destructive testing #Magnetic Particle Inspection #MPI technique #Ferromagnetic materials #Defect detection #Discontinuity identification #Structural integrity #Safety standards #Surface imperfections Written by OliverIn the dynamic realm of global trade, shipping containers have risen to prominence as a primary means of transporting goods across borders. However, as consumer demands for personalized products surge, the spotlight has shifted to customized containers. This article aims to delve into the delicate equilibrium between customized containers and standardized sizes, and how companies can address customer preferences while upholding efficient shipping practices and cost-effectiveness.

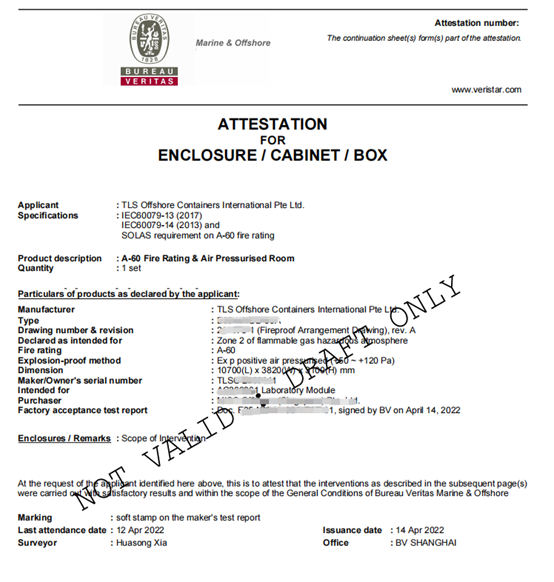

The surge in demand for customized containers underscores the evolving landscape of consumer expectations. As markets diversify, an increasing number of clients seek containers that reflect the unique essence of their products, encapsulating brand identity and distinctiveness. Consequently, this paradigm shift introduces bespoke requirements for dimensions, configurations, materials, and other aspects of container design. However, it's worth noting that the pursuit of tailor-made sizes can introduce a spectrum of challenges, particularly when it comes to the logistics of cargo transportation. Amid this backdrop, the established standard sizes of containers—such as the ubiquitous 20-foot (20ft) and 40-foot (40ft) variants—offer an array of benefits. These standardized dimensions seamlessly integrate into the global logistics framework, spanning from seafaring vessels and bustling ports to the intricacies of transport and warehousing. This harmonious alignment equates to heightened operational efficiency, cost savings, and a reduction in operational intricacies. Yet, the call for customized containers reverberates. Achieving equilibrium between catering to bespoke demands and safeguarding transport efficiency necessitates deliberate consideration. One strategy that has gained traction involves augmenting non-standard containers with steel frameworks, transforming them into standard dimensions. This proactive approach ensures that non-standard containers are conformed into standard sizes ahead of the transportation phase. By doing so, transportation costs are curtailed, and the complexity of operations is diminished. Additionally, these interlinking frameworks confer augmented cargo protection and stability, a paramount consideration to ensure goods remain intact throughout transit. As enterprises navigate decisions in this domain, an array of factors must be pondered. The metamorphosis of non-standard containers into standard sizes could entail supplementary expenses encompassing design and fabrication, alongside adherence to exacting technical and engineering criteria. Therefore, the delicate balance between personalized requirements and transport efficiency mandates a comprehensive evaluation of factors like expenditure, cargo attributes, and logistical requisites. Harmonizing the pursuit of individualized demands with optimal transport practices is no small feat. However, through a panoramic assessment of an array of considerations, it's possible to satiate customer yearnings for uniqueness while ensuring that the transportation of goods embodies efficiency, predictability, and security. Embracing the evolving trend of customized containers, TLS Offshore Containers stands as a testament to this transformative ethos. By tailoring their offerings to match client needs, they embody the spirit of innovation while diligently striving to optimize costs. In a world where personalization reigns, the voyage towards equilibrium between customization and efficiency becomes a voyage laden with possibility and promise. Introduction In today's rapidly advancing industrial landscape, where technology and innovation are at the forefront, various industries such as oil and gas, chemicals, pharmaceuticals, and mining rely heavily on machinery and equipment to streamline their operations. However, these industries often operate in hazardous environments where the presence of flammable gases, vapors, and dust can pose significant safety risks. This is where the IEC 60079-13 certificate comes into play, ensuring the safe operation of equipment in explosive atmospheres. What is the IEC 60079-13 Certificate? The IEC 60079-13 certificate is a critical standard within the International Electrotechnical Commission (IEC) 60079 series, which sets the guidelines for equipment used in explosive atmospheres, also known as hazardous locations. IEC 60079-13 specifically deals with the installation and maintenance of electrical equipment in explosive gas atmospheres. This certificate ensures that electrical equipment, including motors, control panels, sensors, and other devices, is designed and maintained to prevent the ignition of potentially explosive atmospheres due to electrical sparks or other sources of energy. Why is the IEC 60079-13 Certificate Important?

Obtaining and Maintaining the Certificate To obtain the IEC 60079-13 certificate, manufacturers and operators must follow a series of steps:

Conclusion The IEC 60079-13 certificate is an indispensable tool for ensuring safety in industries that operate in hazardous environments. By adhering to the guidelines set out in this standard, businesses can mitigate the risks associated with explosive atmospheres, safeguard their personnel and assets, and contribute to a safer industrial landscape. With the increasing emphasis on safety regulations worldwide, obtaining and maintaining the IEC 60079-13 certificate is not just a legal requirement but a crucial step toward responsible and reliable industrial operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #IEC 60079-13 #Hazardous environments #Explosive atmospheres #Electrical equipment certification #Safety standards #Hazardous locations #Flammable gases #Compliance regulations #Industrial safety #Legal requirements Written by OliverOffshore industries, including oil and gas, renewable energy, and maritime operations, demand specialized solutions to ensure the safety and well-being of workers in harsh and challenging environments. One such solution that has gained significant attention is offshore accommodation containers equipped with ex-proof (explosion-proof) and A60 fire ratings. These cutting-edge containers provide a crucial combination of safety, durability, and comfort for personnel working in remote offshore locations. Understanding Ex-Proof and A60 Fire Ratings Before delving into the benefits of offshore accommodation containers with ex-proof and A60 fire ratings, it's important to understand what these terms mean:

Benefits of Offshore Accommodation Containers with Ex-Proof and A60 Fire Ratings

Conclusion Offshore industries face unique challenges that demand innovative solutions. Offshore accommodation containers with ex-proof and A60 fire ratings represent a significant advancement in ensuring the safety, comfort, and efficiency of personnel working in hazardous offshore environments. By combining explosion-proof technology with robust fire resistance, these containers provide a comprehensive solution that meets regulatory standards while safeguarding the lives of workers. As technology continues to evolve, we can expect further refinements in offshore accommodation designs, contributing to even safer and more productive offshore operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. #Offshore accommodation containers #Ex-proof accommodation #A60 fire rating #Offshore safety solutions #Explosion-proof technology #Hazardous environment accommodation #Offshore personnel safety #Maritime industry accommodations #Oil and gas accommodations #Renewable energy offshore housing Written by OliverIntroduction: Perishable goods, including fresh produce, dairy, meat, and seafood, are essential in our daily lives. The storage and transportation of these goods are critical for maintaining quality. TLS's refrigeration sea containers offer an innovative approach to storing perishables, creating a controlled environment that ensures optimal conditions. In this article, we delve into the factors influencing the storage duration of perishable cargo within refrigerated sea containers, recommended storage times for different goods, and strategies for optimizing storage duration. Factors Influencing Storage Duration: Several factors impact the quality and shelf life of perishable goods stored in refrigerated sea containers. These factors encompass temperature control, humidity management, and effective air circulation. Temperature Control: Precise temperature control is key to preserving perishables. Different goods require specific temperature ranges to retain freshness. For instance, fruits and vegetables typically need temperatures between 32°F and 55°F (0°C to 13°C), while dairy and seafood may demand slightly lower temperatures. Maintaining a consistent temperature is vital, as fluctuations can hasten spoilage. Humidity Management: Humidity levels play a pivotal role in preserving perishables. Some goods are sensitive to high humidity (e.g., leafy greens), while inadequate humidity can lead to dehydration (e.g., meat). Maintaining recommended humidity levels ensures product freshness and texture. Air Circulation and Ventilation: Proper air circulation within refrigeration sea containers is crucial. Adequate airflow prevents temperature irregularities and ensures even cooling. Additionally, ventilation regulates gas concentrations, preventing the buildup of harmful gases and removing ethylene gas, which accelerates spoilage. Recommended Storage Periods for Different Goods: Fresh Fruits and Vegetables:

Dairy Products:

Meat, Poultry, and Seafood:

Factors Beyond Container Conditions: Other factors impacting storage life include:

Conclusion: TLS's refrigeration sea containers offer a solution for preserving perishable goods' quality and safety. By understanding influencing factors, maintaining temperature and humidity control, ensuring proper air circulation, and following best practices, shelf life can be extended. Monitoring, quality control, and inspection ensure consumers receive top-quality goods, minimizing waste and maximizing profit in the perishable goods industry. Any more information regarding Offshore Reefer container, ISO reefer container, please download TLS offshore reefer containers brochure for your reference TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 #Perishable goods storage #Refrigeration sea containers #Storage duration of perishables #Controlled environment storage #Temperature-controlled storage #Humidity management for perishables #Air circulation in storage containers #Fresh produce preservation #Dairy product storage guidelines #Meat and seafood shelf life Written by OliverIn recent years, shipping container accommodations have gained popularity for their versatility and adaptability in various settings. From construction sites to temporary housing during emergencies, these repurposed containers have proven to be more than just metal boxes. In this blog, we will delve into some common questions about shipping container accommodations and shed light on their uses in different scenarios.

Construction Sites: Used as worker dormitories, dining areas, and temporary restroom facilities. Business Establishments: Converted into classrooms, dorms, and cafeterias in factories and other facilities. Emergency Shelters: Offer temporary housing during crises, such as epidemic isolation. Public Events: Transformed into exhibition halls to host expos and activities. Shipping container accommodations have evolved into much more than mere metal boxes. With effective insulation solutions for hot climates, flexible foundation options, customizable doors and windows, and a wide range of applications, these containers have proven their worth in various scenarios. Their adaptability, combined with smart design choices, makes shipping container accommodations an innovative and sustainable solution for modern living and working needs. Whether it's for construction, temporary housing, emergency relief, or public events, these containers offer a versatile canvas for creative solutions. Introduction: In the pursuit of sustainable energy solutions, energy storage systems (ESS) are pivotal for grid stability and efficient energy utilization. Batteries have emerged as a preferred energy storage technology due to their versatility and scalability. To unlock the full potential of battery-based ESS, Battery Management Systems (BMS) play a vital role. This article delves into the significance of BMS in energy storage, their functions, and their role in optimizing battery performance, safety, and lifespan. Importance of Energy Storage Systems: Energy storage bridges the gap between renewable sources and consistent energy supply. Energy storage systems facilitate optimal energy use by storing excess energy during low demand and releasing it during peak times. This enhances grid stability and reduces reliance on traditional power sources, fostering sustainability. The Role of Battery Management Systems (BMS): Battery Management Systems are intelligent controllers that monitor, regulate, and protect battery packs within ESS. They optimize battery performance, prevent overcharging, and manage thermal conditions, significantly impacting efficiency and longevity. Key Functions of Battery Management Systems:

Design Considerations for Battery Management Systems:

Advanced Battery Management Systems: The Future of ESS: As battery tech evolves, BMS incorporating AI, machine learning, and predictive analytics promise enhanced performance optimization and grid integration. These intelligent systems adapt to energy demands in real-time, ensuring efficiency and cost-effectiveness. Conclusion: Battery Management Systems are vital for modern energy storage systems, ensuring efficient battery use and safety. By optimizing performance and lifespan, BMS facilitate the transition to renewable energy. As technology progresses, advanced BMS will drive the adoption of sustainable energy storage solutions. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. #Energy storage systems #Battery Management Systems #Battery-based ESS #Battery performance optimization #Renewable energy solutions #Grid stability solutions #Battery health management #Battery efficiency enhancement #Energy storage technology #Sustainable energy solutions Written by OliverIntroduction: Producing top-notch offshore containers requires a meticulous production process that ensures durability, safety, and compliance with industry standards. In this article, we'll delve into the step-by-step procedure and key requirements for manufacturing high-quality TLS offshore containers. From structural fabrication to final acceptance, each phase plays a crucial role in delivering containers that excel in the challenging marine environment. 1. Frame Fabrication and Welding: Ensuring Structural Integrity Creating a solid foundation is paramount. Our expert class-certified welders execute all primary structural welds with precision, using full penetration welding techniques. A durable paint package is applied to protect containers from harsh marine conditions. Rigorous third-party inspections guarantee the containers' quality before they proceed to the next stage. 2. Floor Installation: Stability and Quality Building upon the foundation, we meticulously install the floor. Starting with calcium silicate plates on the lower deck, we overlay fixed steel mesh and upper deck dressings. This layered approach ensures stability and resilience. The final deck dressings are meticulously placed, and the flatness of the floor is thoroughly examined and approved by qualified inspectors. 3. Insulation Material Placement: Energy Efficiency and Fire Safety Prioritizing energy efficiency and fire safety, our process involves strategic nail placement for subsequent rock wool insulation. Attention to detail is crucial during the installation of rock wool to ensure proper coverage, sufficient overlap, and secure joints with fireproof tape. 4. Pipe and Cable Tray Setup: Utility Integration with Precision Our containers are designed for optimal functionality. Before installing water pipes, air pipes, and cable trays, insulation is meticulously placed. To maintain straightness and stability, supporting booms are strategically reserved on the container's top plate for secure pipe attachment. 5. Interior Wall Panel Integration: Aesthetics and Structure Balancing aesthetics and structure, our containers receive interior wall panels that provide both visual appeal and structural support. Fixing slots are pre-installed to ensure a seamless fit for the inner panels. Our team guarantees a smooth, flat surface for the panels and ceilings, featuring immaculate and straight splicing gaps. 6. Furniture and Appliance Integration: Seamlessly Functional Creating a comfortable environment, we install furniture and appliances according to the preliminary design drawings. To ensure proper functionality and safety, our installations adhere to regulations, and all power connections undergo meticulous inspection by qualified quality inspectors. 7. Rigorous Testing and Acceptance: Meeting Client Expectations Prior to shipping, our containers undergo a comprehensive testing and acceptance phase. We offer a range of acceptance methods, including on-site inspections, video assessments, and graphic evaluations. Only containers that successfully meet acceptance criteria are approved for shipping. Conclusion: Manufacturing high-quality offshore containers demands a comprehensive approach that encompasses structural integrity, insulation, utilities integration, and meticulous quality control. Our process guarantees durability, safety, and compliance with industry standards. Whether through expert welds, precision installations, or rigorous inspections, our containers are built to thrive in the demanding marine environment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Offshore containers #High-quality production process #Insulation material #Structural integrity #Full penetration welding #Marine environment #Third-party inspection #Container floor installation #Calcium silicate plates #Steel mesh overlay Written by OliverIn the realm of scientific research and experimentation, Laboratory environments play a pivotal role in driving innovation and discovery across various fields. Within these controlled spaces, researchers employ cutting-edge technologies and techniques to conduct experiments, analyze data, and advance our understanding of the natural world. One such innovation that has gained significant traction in recent years is the Negative Pressure Laboratory container. This article delves into the concept of negative pressure Lab containers, their benefits, and the diverse applications they facilitate. Understanding Negative Pressure Lab Containers Negative Pressure Lab containers, also known as negative pressure isolation containers, represent a novel approach to creating controlled and secure Laboratory environments. Unlike traditional Laboratories, which maintain positive air pressure to prevent contaminants from entering the space, Negative Pressure Laboratory containers operate on the principle of negative pressure. This means that the air pressure within the container is lower than that of the surrounding environment. This setup ensures that any potential airborne contaminants, such as hazardous fumes, pathogens, or particles, are drawn into the container rather than escaping into the outside environment. Benefits of Negative Pressure Lab Containers

Applications of Negative Pressure Lab Containers

In conclusion, negative pressure Lab containers represent a remarkable advancement in Laboratory safety and experimentation. Their ability to confine hazardous materials and prevent contamination opens new avenues for research across various scientific domains. From biocontainment research to chemical analysis and beyond, these containers offer a versatile and secure solution that enhances both scientific progress and the well-being of researchers. As technology continues to evolve, negative pressure Lab containers are poised to play an increasingly crucial role in shaping the future of scientific exploration. TLS Offshore Containers offers professional design and manufacturing services for customized Lab containers to suit specific locations and requirements. We welcome any inquiries and are ready to assist you in creating your ideal Laboratory environment. Please contact us for any inquiries or to discuss your unique needs. Please download Laboratory container brochure for reference. #Negative pressure LAB container #Negative pressure isolation container #Laboratory containment solutions #Secure laboratory environment #Hazardous material containment #Controlled laboratory setup #Biocontainment research #Contaminant isolation technology #Lab safety innovation #Negative pressure applications Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|