|

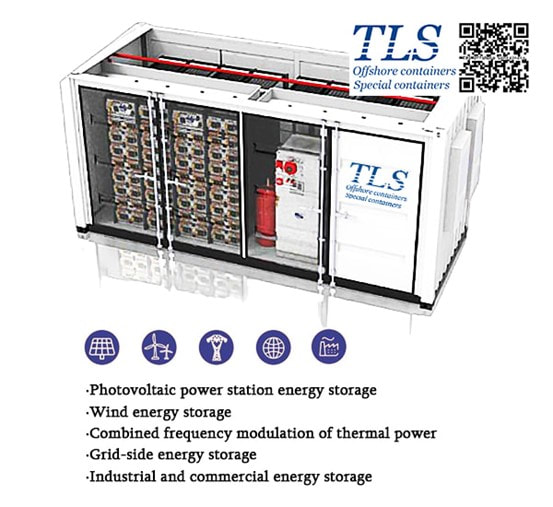

The battery pack refers to a collection of batteries, along with a battery management system, connectors, and installation parts enclosed within a standardized battery box structure. Its primary functions include the ventilation and dissipation of heat from the battery, insulation and waterproofing, and protection against physical damage. With the emergence of new energy technologies, the TLS battery energy storage container has been developed to meet the demands of the market. Our containerized solutions are engineered to comply with the most rigorous specifications and can withstand harsh environmental conditions. For further details about our battery energy storage system container, please do not hesitate to contact us. We are enthusiastic about sharing the possibilities of this technology for your specific applications. You may also refer to the Energy Storage System (ESS) Containers brochure for additional information. In recent years, battery energy storage systems (BESS) have become increasingly popular, as they can provide backup power during outages, reduce peak demand on the electrical grid, and store energy generated from renewable sources like solar and wind. BESS typically use containerized solutions to house the battery packs and associated equipment. A containerized BESS has several advantages over other types of BESS. Firstly, it allows for faster installation and easier transportation, as the container can be pre-assembled and transported to the installation site. Secondly, it provides a standardized, enclosed environment that protects the batteries and equipment from environmental hazards, such as extreme temperatures, humidity, and physical damage. Thirdly, containerized BESS can be easily scaled up or down to meet changing energy demands, as additional containers can be added or removed as needed. TLS has developed a containerized BESS solution that is designed to meet the most demanding specifications and operate in harsh environmental conditions. Our solution includes a modular design that can be customized to meet the specific needs of our customers. The container is engineered to provide excellent ventilation and heat dissipation, which is essential for maintaining the longevity and safety of the battery pack. The container is also equipped with a BMS that monitors and controls the charging and discharging of the batteries, ensuring their safety and longevity. If you are interested in learning more about our containerized BESS solution, please do not hesitate to contact us. We would be happy to discuss how our solution can meet your energy storage needs and help you achieve your sustainability goals. Written by Oliver TLS Company Overview and Featured Products: pressurised containers, BESS containers, TR shelters2/14/2023

TLS is a global leader in the design and manufacture of specialized containers for a range of industries. The company's mission is to provide high-quality, innovative solutions that meet the needs of clients around the world. With a focus on safety, efficiency, and sustainability, TLS has become a trusted supplier of pressurized containers, TR shelters, and BESS containers. Pressurized containers are a key product for TLS, providing a safe and secure environment for equipment and personnel in hazardous environments. These containers are designed to withstand high pressures, ensuring that their contents remain intact in a range of conditions. TLS pressurized containers are commonly used in the oil and gas industry, chemical processing plants, and other industries where hazardous materials are present. TR shelters are another important product from TLS, providing a temporary refuge for personnel in the event of an emergency. These shelters are designed to withstand the impact of blast events, providing a protective environment for personnel to wait until it is safe to evacuate the area. TLS TR shelters are available in a range of sizes to meet the needs of clients in various industries, from offshore oil rigs to chemical processing plants. BESS (Battery Energy Storage System) containers are a newer addition to the TLS product lineup, offering a sustainable energy storage solution for clients in a range of industries. These containers are designed to store large amounts of energy in batteries, which can be used to power a range of equipment and applications. BESS containers are becoming increasingly popular in renewable energy industries, such as wind and solar power, where they provide a reliable and efficient way to store energy. All TLS products are designed with safety and efficiency in mind, using the latest technologies and materials to ensure high-quality and reliable solutions. The company works closely with clients to understand their needs and customize products to meet their specific requirements. With a focus on sustainability, TLS products are also designed to minimize their environmental impact, using energy-efficient technologies and materials wherever possible. In addition to its product lineup, TLS also provides a range of services to support its clients, including installation, maintenance, and repair. The company's global network of service centers ensures that clients can access support and assistance wherever they are in the world. Overall, TLS is a trusted supplier of specialized containers, providing high-quality, innovative solutions to clients in a range of industries. With a focus on safety, efficiency, and sustainability, the company is well-positioned to meet the evolving needs of clients around the world. The Future of Energy: The Rise of Mobile Energy Storage Systems in the Renewable Energy Revolution2/8/2023

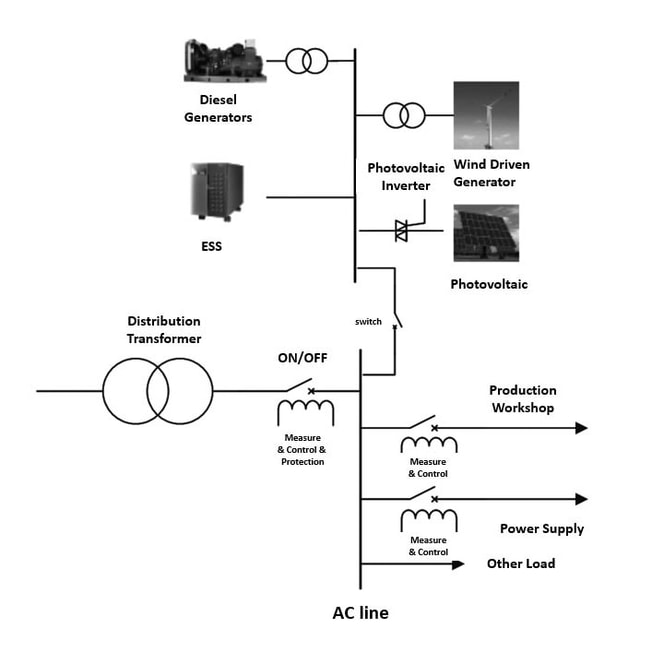

In the context of the deep global energy transformation, it has become a general trend for renewable energy to replace traditional fossil energy. However, due to the natural instability of wind and photovoltaic power generation, it is necessary to support energy storage to achieve full installation of conventional fossil energy replace. In addition to energy storage, BESS also has various functions such as energy conversion, scheduling, supply, and guarantee, and has a wide range of application scenarios in the process of green development of the oil and gas industry. Distributed and mobile wind-solar storage integrated technologies can supply energy for on-site exploration, oil and gas field monitoring, drilling, fracturing, down-hole tools and other equipment, alternative fuel and gas power generation, and carbon reduction; Long-term heat storage, electricity storage, and hydrogen storage technologies will play a role in peak regulation and scheduling in the future comprehensive energy system, providing strong support for stable and safe energy supply. With the continuous promotion and application of electrochemical energy storage in power systems, a containerized mobile energy storage system is coming into view. Such mobile energy storage systems, with their compact structure, short engineering construction period and rapid response to customer needs, hold the promise of becoming the mainstream group mode of electrochemical energy storage in the future. In the future, with the continued breakthroughs in battery technology, the energy density of mobile energy storage systems will be further improved, and the cost will be greatly reduced,and it is expected to become an important carrier for promoting the revolution of energy production and it is a technology and industry with great development prospects in the energy Internet. TLS energy storage solutions can be customized according to customer needs:

Product brochures: Energy Storage System (ESS) Containers brochure If you are interested in mobile energy storage, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Written by Mandy The global Battery Energy Storage System (BESS) market is expected to grow significantly in the coming years due to the increasing demand for renewable energy storage solutions. The growth of the renewable energy sector, the need for grid stability and reliability, and supportive government policies are driving the growth of the BESS market. The Asia-Pacific region is expected to see significant growth in the BESS market, driven by the rapid growth of renewable energy in countries such as China and India. As for TLS, as a BESS manufacturer, they have several advantages that give them a strong position in the market. They have expertise and knowledge in BESS technology, which allows them to offer high-quality and reliable products to their customers. Their strong customer support and service ensures that customers receive the support they need during the installation and operation of their BESS systems. Additionally, TLS offers competitive pricing and cost-effectiveness, making their BESS products an attractive option for customers looking for affordable energy storage solutions. Finally, TLS offers a wide range of BESS products to meet different needs and requirements, ensuring that their customers have access to the right solution for their specific requirements. Overall, the BESS market is expected to continue to grow in the future, and with its strong advantages, TLS is well positioned to take advantage of this growth. A Microgrid is an independent power system that can operate without being connected to the main grid. It usually consists of one or more generators, batteries and other energy storage devices that can meet the electricity needs of the local area. Microgrids are commonly used by local governments, schools, hospitals, rural and other remote areas, and to provide emergency power support in the event of a major power grid failure or disaster. Energy storage containers can be used as storage systems to help balance power supply and demand in microgrids and ensure the stability and reliability of power. The container energy storage system is connected to the busbar of the microgrid. Depending on the characteristics of the peaks and troughs, the microgrid charges the batteries in the troughs, stores the excess energy of the microgrid, and feeds the energy back to the grid during the peak. This helps reduce over-reliance on generators and improve the efficiency and economics of microgrids. Depending on the control of the microgrid system, wind and photovoltaic power generation systems can be connected to the bus; when connected to the busbar, energy such as wind power and photovoltaics can be stored, truly realizing "load regulation, matching new energy access, making up for line losses, and power compensation.”, improve power quality", and can also realize the function of isolated grid operation. The energy storage battery cluster is in standby state after charging and can be fed back to the grid under the uniform control of the background. Containerized energy storage systems play an important role in microgrids, and their compact and modular design, combined with their versatility and reliability, make them ideal solutions for microgrid applications. Written by Mandy The electricity sector is undergoing a transformation as it moves towards a more digital and intelligent system. This transformation is driven by advances in technology, growing demand for clean energy, and a desire to improve efficiency and reliability in the electricity grid. One of the key technologies enabling this transformation is the integration of digitization and intelligence into the electricity sector. By digitizing and automating various processes, the electricity sector is able to operate more efficiently and with greater reliability. For example, smart grid technology allows utilities to monitor and control the flow of electricity in real-time, enabling them to respond quickly to changes in demand and generation. Battery energy storage systems (BESS) are a key technology in the transition towards a more sustainable and efficient energy system. These systems allow excess energy generated from renewable sources to be stored and used when needed, rather than being lost as waste. This not only helps to reduce greenhouse gas emissions and promote the use of clean energy, but also helps to stabilize the grid by balancing supply and demand. Battery energy storage systems are becoming increasingly popular due to declining costs and advancements in technology. As battery prices continue to fall, more and more businesses and households are installing these systems to store excess energy generated from rooftop solar panels, for example. In addition, battery energy storage systems are becoming more flexible and efficient, making them a more viable solution for a wider range of applications. In the electricity sector, battery energy storage systems play a crucial role in the trend towards digitization and intelligence. By storing energy and releasing it when needed, these systems help to ensure that there is always a reliable and consistent supply of power. This is especially important in areas with high levels of renewable energy generation, as fluctuations in wind and solar generation can cause instability in the grid. Battery energy storage systems can also help to integrate renewable energy into the grid by smoothing out fluctuations in generation. This makes it easier for utilities to incorporate renewable energy into their energy mix, as the grid can more easily handle fluctuations in generation. In addition, battery energy storage systems can help to defer or avoid the need for expensive grid upgrades, as they can be used to store excess energy during periods of high generation and release it when needed. In addition to their role in balancing supply and demand, battery energy storage systems are also becoming increasingly intelligent. Many systems are now equipped with sophisticated monitoring and control systems that can optimize performance and ensure efficient operation. For example, some systems can be programmed to release energy when demand is high and prices are high, or to store energy when demand is low and prices are low. The trend towards digitization and intelligence in the electricity sector is expected to continue in the coming years, and battery energy storage systems will play a key role in this trend. As renewable energy continues to become more widespread and battery technology continues to improve, it is likely that these systems will become even more widespread and play an even more important role in the transition towards a more sustainable energy future. In conclusion, battery energy storage systems are a critical technology in the trend towards digitization and intelligence in the electricity sector. By allowing excess energy to be stored and used when needed, these systems help to ensure a reliable and consistent supply of power, integrate renewable energy into the grid, and improve the efficiency and stability of the electricity system. TLS Offshore Containers offers cutting-edge BESS solutions, designed and manufactured to meet the specific needs of their clients. Their BESS products are highly reliable, efficient, and sustainable, and they provide a vital solution in the transition towards a cleaner energy future. With a commitment to innovation and customer satisfaction, TLS Offshore Containers is at the forefront of the digitization and intelligence transformation in the electricity industry. Renewable energy is the future, which makes it even more challenging to provide electricity whenever and wherever it is needed. Compared with traditional energy storage, battery energy storage systems (BESS) are based on a modular design, which is very suitable for backup reserve power. It has the advantages of modular design for multimodal transportation, easy installation, flexibility, safety and reliability. Suitable for use in remote areas or areas lacking electricity. The bess make it possible to store the energy produced by photovoltaics, wind turbines, or CHP. Due to its high cycle lifetime, the energy storage system containers are also used for peak-shaving, thereby reducing the electricity bill. Containerized energy storage solutions provided by TLS can be configured to match the power and capacity requirements required by customer applications, meet the most demanding specifications, and be able to handle a wide range of adverse conditions. If you have any inquiries on BESS containers, please download the check list and send it together with your inquiry. Don’t hesitate to contact us for more information about the battery energy storage system container, We are eager to explain the possibilities for your applications. Please download Energy Storage System (ESS) Containers brochure for reference.

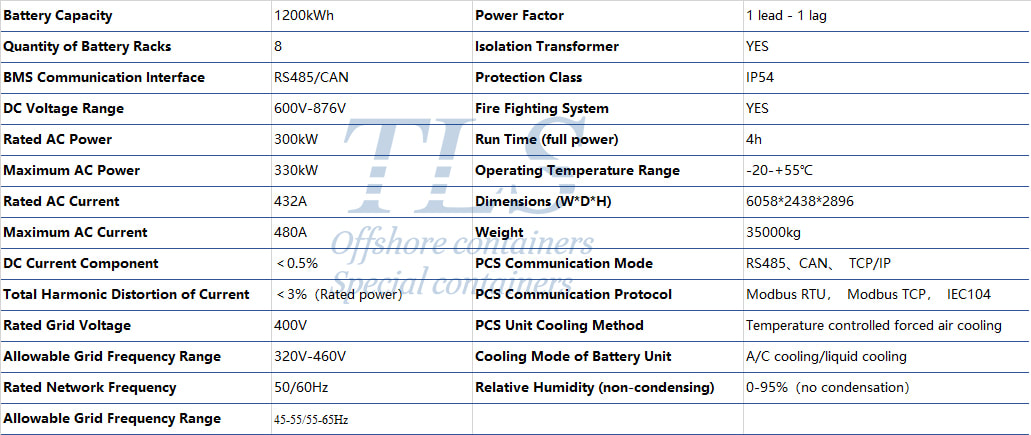

TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Taking the 1MW/1MWh battery energy storage system as an example, the system is generally composed of energy storage battery system, monitoring system, battery management unit, special fire protection system, special air conditioning system, power conversion system (PCS) and isolation transformer, and finally integrated in a container. The battery system is mainly composed of battery cells in series and parallel: first, a dozen groups of battery cells are connected in series and parallel to form a battery pack, then the battery boxes are connected in series to form a battery string to increase the system voltage, and finally the batteries are connected in series and parallel to increase the system capacity, and are integrated in inside the battery container. The monitoring system mainly enables the functions of external communication, network data monitoring and data acquisition, analysis and processing to be realized, ensuring accurate data monitoring, high voltage and current sampling accuracy, data synchronization rate and fast execution speed of remote control commands; the battery management unit has high precision The single-cell voltage detection and current detection functions ensure the voltage balance of the battery modules and avoid circulating currents between the battery modules, which will affect the system operation efficiency. In order to ensure the safety of the system, the container is equipped with a special fire protection and air conditioning system. The fire protection system senses the fire through smoke sensors, temperature sensors, humidity sensors, emergency lights and other safety equipment, and automatically extinguishes the fire; the special air conditioning system is based on the external ambient temperature. The cooling and heating system of the air conditioner is controlled through the thermal management strategy to ensure that the temperature in the container is in a suitable range and prolong the service life of the battery. The Power Conversion System(PCS) is an energy conversion unit that converts battery direct current to three-phase AC and can operate in grid-connected and off-grid modes. In grid-connected mode, the converter interacts with the power grid according to the power instruction from the upper dispatching. In off-grid mode, energy storage converters can provide voltage and frequency support for plant loads, and provide black start power for some renewable energy sources. The outlet of the energy storage converter is connected with the isolation transformer, so that the electrical insulation of the primary side and the secondary side is completely isolated, to ensure the safety of the container system to the greatest extent. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 The ability to store and transfer the electricity generated by solar panels and wind turbines is the key to get energy for users when they need it—during outages, when the sun is not shining, or the wind is not turning the turbines blades. Battery energy storage system (BESS) container helps balance electricity generation and demand—creating a more flexible and reliable grid. Battery Energy Storage Systems (BESS) are one way to store energy so system operators can use their energy to soft transition from renewable power to grid power for uninterrupted supply. Ultimately, battery storage can save money, improve continuity and resilience, integrate generation sources, and reduce environmental impacts. If you have any inquiries on BESS containers, please download the check list and send it together with your inquiry. Don’t hesitate to contact us for more information about the battery energy storage system container, We are eager to explain the possibilities for your applications. Please download Energy Storage System (ESS) Containers brochure for reference. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|