|

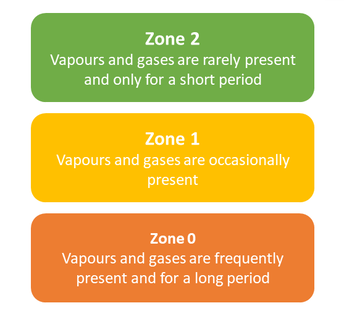

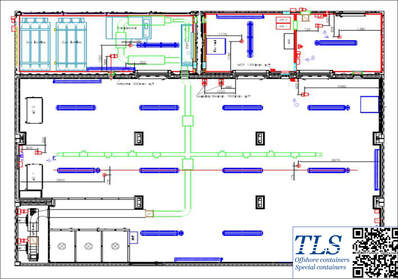

Our range of Ex d combined pressurisation fire & gas (CPFG) systems are PLC based. When used in conjunction with other products, such as gas detectors, smoke detectors, pressure switches, flow switches and pressurization fans, etc, a complete intelligent pressurisation control system can be constructed, which monitors the conditions of pressurised cabins in hazardous areas. In electrical and safety engineering, hazardous locations (HazLoc, pronounced haz·lōk) are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations could provide an ignition source, due to electrical arcing, or high temperature. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations. please find more information from wiki link and download hazardous areas difinition reference. The electric facilities installed in hazardous areas should be explosion proof certified. please refer to related information from the link in our website. The energy storage system (ESS) containers are based on a modular design. They can be configured to match the required power and capacity requirements of client’s application. The energy storage systems are based on standard sea freight containers starting from kW/kWh (single container) up to MW/MWh (combining multiple containers). The containerised energy storage system allows fast installation, safe operation and controlled environmental conditions. The battery energy storage system (BESS) containers are designed for neighbourhoods, public buildings, medium to large businesses and utility scale storage systems, weak- or off-grid, e-mobility or as backup systems. The energy storage system containers make it possible to store the energy produced by photovoltaics, wind turbines, or CHP. Due to its high cycle lifetime, The energy storage system containers are also used for peak-shaving, thereby reducing the electricity bill. Our containerised battery energy storage system (BESS) is the perfect solution for large-scale energy storage projects. The energy storage containers can be used in the integration of various storage technologies and for different purposes. All our containerised solutions are designed to meet the most demanding specifications and can to cope with all kinds of adverse conditions. In the case of storage in batteries the container are mechanically adapted to integrate the air conditioning equipment that allows energy storage according to the project. These solutions provide greater flexibility and robustness to renewable power production systems. TLS has also integrated stations for energy storage projects with: super-capacitors, lithium ion batteries, hydrogen storage and hybrid technologies. The extensive experience accumulated by TLS, and our passion for tackling modern technological challenges, makes it possible to undertake any energy storage project. As the wave quality stations that improve the quality of the electric energy supplied by the generation source or the stations intended for the electric power injection when the main supply is interrupted, allowing to synchronise several emergency and power equipment at the same time, both in DC and AC. Temporary shelter (TR) shelters (sometimes called toxic gas shelters (TGR), safe harbor pods, H2S temporary shelters, TR pressurizing units) are most important for ensuring the safety of personnel. Flammable and explosive chemicals are commonly used, stored, handled and transported in large quantities in facilities such as chemical processing plants or floating production, storage and offloading (FPSO), or in floating ships, offshore platforms or industrial manufacturers. These potentially dangerous situations should happen. Depending on the toxicity or intensity of the chemical, the release or explosion of the chemical may seriously affect persons. Explosive or closed loss of gas can lead to disorientation, incapacitation or death. The temporary refuge has the double functions as dayroom during normal operation and as temporary shelter functions in emergency situations. The TR is used as normal control room, office space or even canteen when operated in normal situation. In the event of an emergency such as an explosion or chemical release, a temporary shelter is a safe option in the situation that evacuation is not possible and is an important component of emergency management. When preventive control fails, the installation of temporary shelters, such as safe havens, in-place shelters and toxic gas shelters, is a mitigation measure that reduces loss of life and damage to property and equipment. Ultimately, these temporary shelters help improve survival. In response, TLS temporary refuge shelter (toxic gas refuge shelter, or Safe haven cabin) provides a safe "access" area for toxic chemical releases, fires, explosions or other dangerous emergencies, ranging from hundreds to hundreds of people. The Temporary refuge shelter is a place or sanctuary where persons are adequately protected while remaining in the installation in a major disaster such as chemical release, explosion, etc, it can protect people from associated risks, and people from there to communicating, monitoring and controlling equipment necessary to ensure their physical safety, and to safely and completely evacuate from there if necessary. The temporary refuge shelter switches HVAC from fresh air mode to full recirculation mode to prevent potentially toxic gases from entering and the external gas detector activates the fire valve to close. TR will also provide a minimum breathing air concentration from the compressed air cylinder for at least 1 hour or longer. The location of the temporary shelter ensures the safety of personnel for a period to the convening of the call until the incident has been investigated and controlled or equipment has been successfully evacuated. The temporary refuge shelter has adequate medical and welfare facilities as well as emergency communications.TR enclosures are designed for external installation and are equipped with air supply piping to the interior of the TR muster area. The TR shield control panel is designed to be installed internally within the TR area. When TR shelter went into operation, it was designed as a fail-safe system, meaning that if the shelter suffered damage or an air seal leak, clean air would leak out of the shelter instead of being inhaled by contaminated air. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|