|

Visual inspection and non-destructive testing are commonly used to inspect container welds. Magnetic particle inspection is one of the types of non-destructive testing. Magnetic particle inspection is a method of observing defects using magnetic powders as a display medium. After the ferromagnetic material workpiece is magnetized, as the existence of discontinuity, the magnetic field lines on the surface and near the surface of the workpiece are locally distorted to generate a leakage magnetic field, which adsorbs the magnetic powder applied on the surface of the workpiece and forms a visible magnetic field under suitable illumination,and the location, size, shape, and severity of the discontinuities are shown. TLS normally uses black magnetic paste for flaw detection. This method has high sensitivity to detect small defects on the surface of the workpiece. The steps are:

Any requirements about specialized shipping containers, please feel free to contact us. CPFG Systems offers a range of systems, together with Remote I/O manufacturers, suitable for hazardous and safe areas, either as a combination of both, or as zone of operation specific systems.

Containers are no longer a traditional transport tool that can only be used to carry goods. More and more container types are known to us. In order to meet the needs of different container types, the correct selection of doors has also become an important step in the design process. Before choosing, please answer the following questions: What does this container need to be used for? Do large-sized items need to be placed in the container? Are containers used as offices or homes? Do we need to go inside the container frequently? 5 Basic Types of Container Doors for Your Reference 1. Cargo door "Original" doors for shipping containers. Usually installed at the end of the container. These heavy duty doors are weatherproof and very secure. They open outward, and the secure cam and locking system are robustly designed to deter theft and reduce the risk of damage from inclement weather and other environmental threats. Applicable environment:Large objects need to be easily placed in the container Features: Affordable, no modification or installation required. 2. Personnel door Use in case of storing smaller items or as a laboratory, office, house etc. They are usually installed on the end face of the container and have good sealing performance. According to the different use environments, there are doors that meet the level of B30 and A60. Applicable environment: It is frequently used for easy entry and exit of people, (movable office building, portable office station, laboratory shipping container) Features: Easy to use, various styles and standards to choose from 3. Roll-Up Doors Sometimes referred to as overhead doors, they are welded to the container walls, are usually rolled up from the bottom, can be locked, are easy to maneuver and are relatively lightweight. Applicable environment: Used to store large objects or equipment Features: Save space, easy to operate 4. Glass door Sliding glass doors are the same height and width as double-width personnel doors, but they are made of durable glass with a vinyl frame. These doors come with safety locks to protect the interior, although they shouldn't be considered as secure or durable as the alternative doors mentioned above, since they are transparent. Applicable environment: Office, storefront |shop or living space. Features: Create better lighting for the interior in accordance with the environment, and the design is more fashionable 5. Combination door For containers with larger space or special needs, it is usually also considered to design multiple channels The design of any container building should be tailored to the specific needs of each project.

Feel free to contact us ,we customize special containers as you need. What is the A60 fire rating standard? What kind of A60 fireproof material will be put into use?9/29/2022

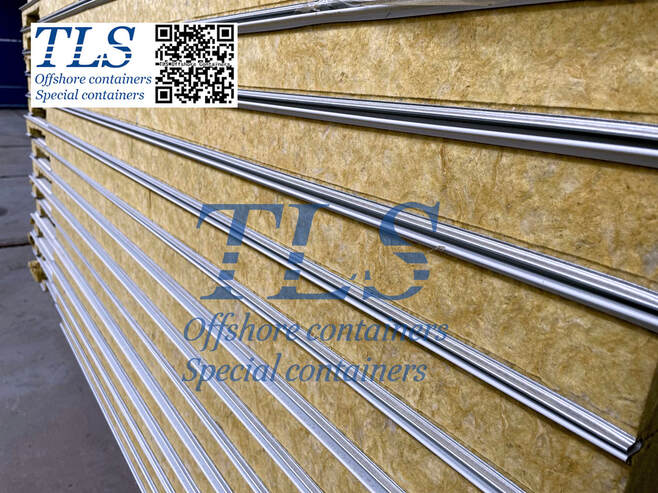

For the functions of sea containers, such as transporting refrigerated, living or working, etc., it is necessary to carry out modifications to meet the requirements of thermal insulation and fire protection of the container. Normally, the sea land containers provided by TLS can comply with the A60 standard.

Classification society standard A60 level specific requirements:

What type of refractory material is A60 fireproof? The material is required to have a certain rigidity and fire resistance for more than 1 hour, during which time the integrity is maintained to prevent the passage of smoke and flame. Rock wool and ceramic fiber wool are two different materials, both of which can be used as insulation materials for A60 fire protection but must be approved by the relevant classification society. As early as the 1950s, the motor center was widely used by the automotive industry to control manufacturing, and many industrial motor companies used motor control center to install directly and other equipment at the location center. Although many motor control centers(MCCs) are located directly on the factory floor, there are additional benefits to having the motor control center located in the shell of a shipping container.

Unlike ordinary dry cargo containers, which are primarily used for land transportation, offshore containers are specialized containers used on offshore oil rigs; Therefore, there is a well-established set of European standards for their design and manufacture, including DNV 2.7-1 and EN 12079.

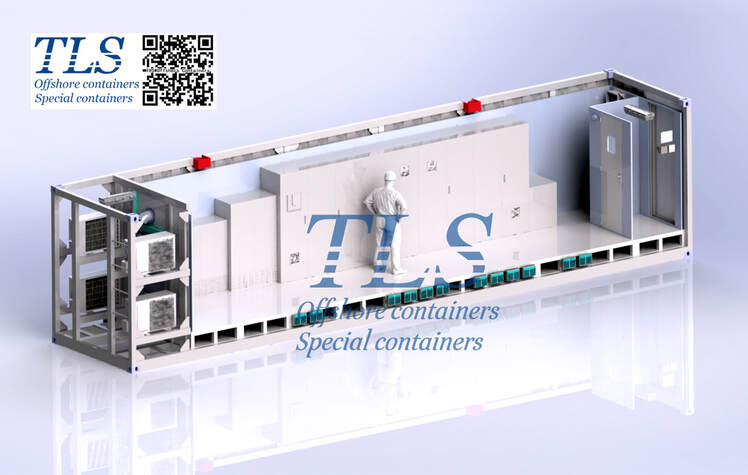

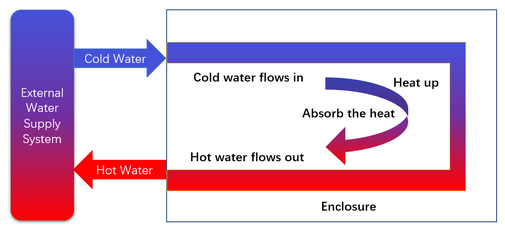

Marine containers are mainly used on marine drilling platforms, where the operating environment is demanding and frequent hoisting is required, which places high requirements on container hoisting equipment. All four corners of the top of the container have a top corner piece structure. The top corner piece structure consists of a standard container top corner piece, a lifting lug, and a reinforcing piece. The uplifted ears are located on the inner side of the top horn, adjacent to it, and are arranged and fixed to it. The four-point or two-point lifting of a container can be performed by means of a hoist, and therefore there is a higher strength requirement on the hoist itself as well as on the top of the box in which the hoist is mounted. The lifted lug material must have low-temperature shock resistance properties. The reinforcing piece consists of a bottom plate for the lifting lug, and a coaming plate arranged on three sides of the bottom plate of the lifting lug. The setting of the coaming plate not only strengthens the lifting ear area but also protects the lifting ear. When lifted, a special sling is used, the shackles are passed through the eye holes and locked firmly, then the sling is lifted through the main ring of the sling. Energy storage containers are portable energy storage devices that are often used for power backup. Thermal dissipation in energy storage batteries is a key factor in determining their performance, safety and lifetime. In order to maintain the temperature in the container at the normal operating temperature of the battery, the main heat dissipation structures of current energy storage container can be classified into two categories: air cooling and liquid cooling.

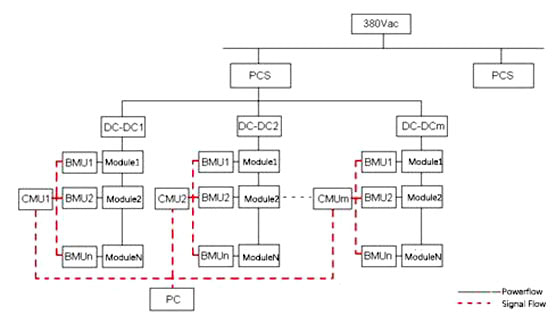

Large-scale power storage technology is the key technology for smart grid, new energy generation and grid connection, power load shifting and valley filling. Lithium-ion batteries have been widely used in many fields due to their high energy density, low self-discharge rate, smooth discharge voltage, long cycle life and other advantages, and the application of lithium batteries in large-scale power storage systems will become an inevitable trend in technology development. In order to ensure the efficient and safe application of lithium-ion solar battery storage (Battery Energy Storage System, BESS), all components of the system must be integrated and optimized, and managed and controlled in a reasonable and effective manner.

The battery management technology and system integration technology of energy storage systems can be developed to improve the safety, reliability and service life of the battery system and promote the popularization and application of large-scale power storage. The key technologies include: (1) advanced battery management technology ; (2) temperature monitoring and management technology; (3) state of health (SOH) monitoring technology; (4) system integration technology. The portable living container is a "plug and play" module, which can be moved anytime, anywhere, recycled, and environmentally friendly. Compared with traditional buildings, the construction time is significantly shortened. Features of accommodation container

The design and construction of this specially customized portable shipping container home(10700mm*3820mm*3100mm) with explosion-proof function meet the IEC60079-13 2010 specification, DNV2.7-1 and SOLAS 2009, A60 fire rating. TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|