|

Offshore containers play a vital role in the global shipping and offshore industries. These rugged and specialized containers are designed to withstand the harshest environments, ensuring the safe transport and storage of valuable goods and equipment. Whether you're in the oil and gas, renewable energy, or maritime industry, producing high-quality offshore containers is crucial. In this guide, we'll explore the key steps and considerations to produce offshore containers that meet industry standards and exceed customer expectations while adhering to stringent safety regulations. Understanding Offshore Containers Before delving into the production process, it's essential to understand what offshore containers are and why they're essential. Offshore containers are purpose-built containers designed for use in offshore and marine environments. They are used for transporting, storing, and securing equipment, tools, and goods on offshore platforms, vessels, and during transport between locations. These containers come in various sizes and configurations, such as open-top, closed-top, half-height, and specialized versions like offshore baskets and skips. To produce high-quality offshore containers, manufacturers must adhere to industry standards and regulations that ensure safety and durability in challenging conditions. Key Steps in Producing High-Quality Offshore Containers 1. Design and Engineering The foundation of any high-quality offshore container is its design and engineering. This phase involves creating a detailed blueprint that considers the container's purpose, the environment it will be used in, and the materials required for construction. Essential aspects to consider during the design and engineering phase include:

2. Fabrication and Manufacturing Once the design is finalized, the manufacturing process begins. This involves cutting, shaping, welding, and assembling the container components according to the approved design. Key considerations during manufacturing include:

3. Testing and Certification Before an offshore container can be used in the field, it must undergo rigorous testing and certification processes. This includes:

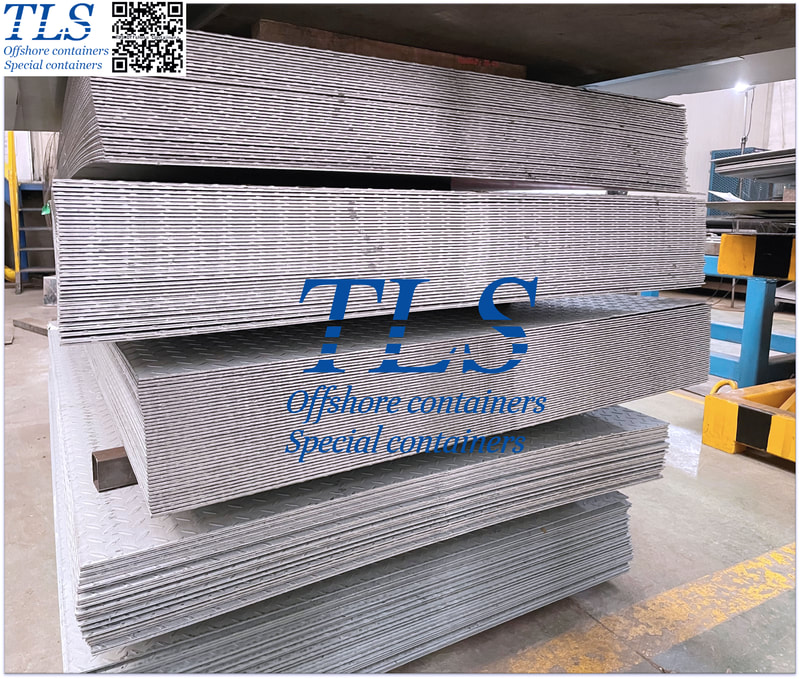

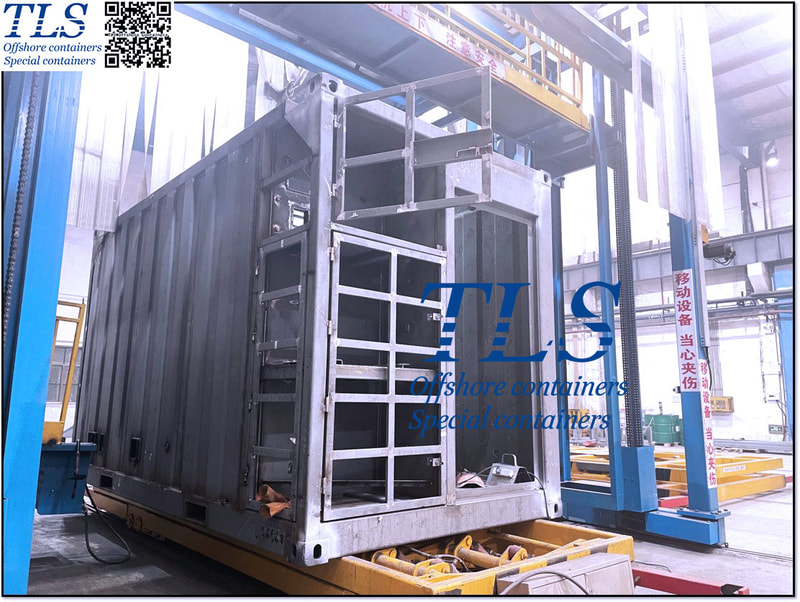

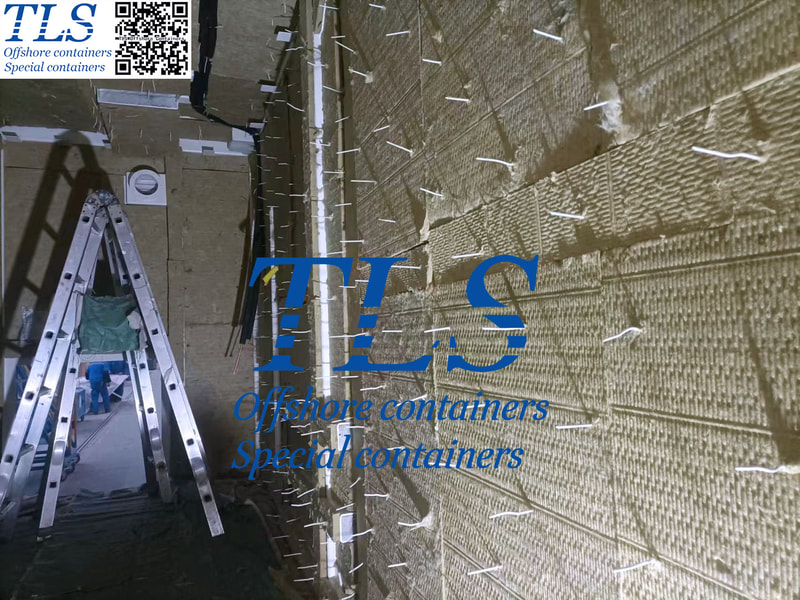

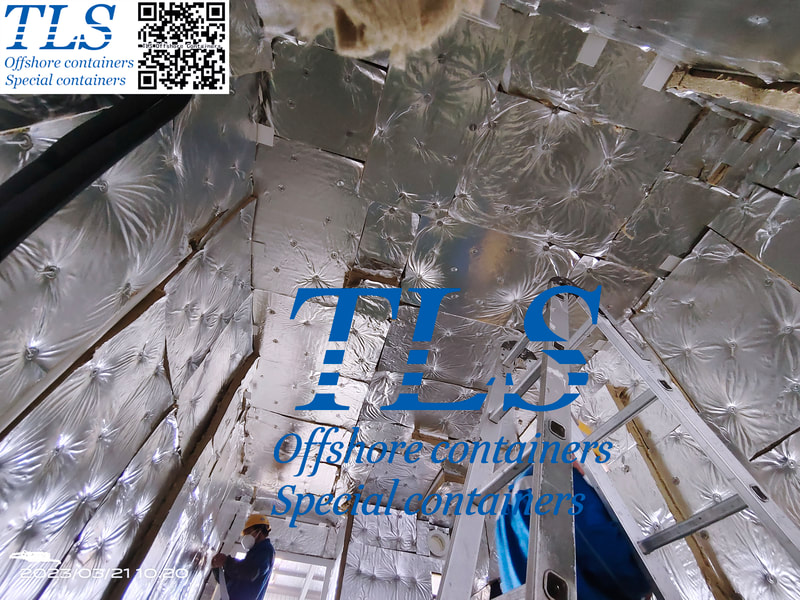

4. Maintenance and Inspection Producing a high-quality offshore container is just the beginning. To ensure its continued reliability and safety, regular maintenance and inspection are essential. Maintenance tasks include repainting, repairing damage, and replacing worn components. Routine inspections, typically conducted annually, help identify and address issues before they become safety concerns. Conclusion Producing high-quality offshore containers is a complex process that demands attention to detail, expertise in design and engineering, strict adherence to safety standards, and a commitment to quality control. These containers are vital to the offshore industry, ensuring the safe transport and storage of valuable equipment and goods in challenging environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Offshore containers #Offshore container production #Offshore container manufacturing #Offshore container design #Offshore container engineering #High-quality containers #Offshore container materials #Structural integrity #Corrosion resistance #Safety standards Written by OliverIntroduction: Producing top-notch offshore containers requires a meticulous production process that ensures durability, safety, and compliance with industry standards. In this article, we'll delve into the step-by-step procedure and key requirements for manufacturing high-quality TLS offshore containers. From structural fabrication to final acceptance, each phase plays a crucial role in delivering containers that excel in the challenging marine environment. 1. Frame Fabrication and Welding: Ensuring Structural Integrity Creating a solid foundation is paramount. Our expert class-certified welders execute all primary structural welds with precision, using full penetration welding techniques. A durable paint package is applied to protect containers from harsh marine conditions. Rigorous third-party inspections guarantee the containers' quality before they proceed to the next stage. 2. Floor Installation: Stability and Quality Building upon the foundation, we meticulously install the floor. Starting with calcium silicate plates on the lower deck, we overlay fixed steel mesh and upper deck dressings. This layered approach ensures stability and resilience. The final deck dressings are meticulously placed, and the flatness of the floor is thoroughly examined and approved by qualified inspectors. 3. Insulation Material Placement: Energy Efficiency and Fire Safety Prioritizing energy efficiency and fire safety, our process involves strategic nail placement for subsequent rock wool insulation. Attention to detail is crucial during the installation of rock wool to ensure proper coverage, sufficient overlap, and secure joints with fireproof tape. 4. Pipe and Cable Tray Setup: Utility Integration with Precision Our containers are designed for optimal functionality. Before installing water pipes, air pipes, and cable trays, insulation is meticulously placed. To maintain straightness and stability, supporting booms are strategically reserved on the container's top plate for secure pipe attachment. 5. Interior Wall Panel Integration: Aesthetics and Structure Balancing aesthetics and structure, our containers receive interior wall panels that provide both visual appeal and structural support. Fixing slots are pre-installed to ensure a seamless fit for the inner panels. Our team guarantees a smooth, flat surface for the panels and ceilings, featuring immaculate and straight splicing gaps. 6. Furniture and Appliance Integration: Seamlessly Functional Creating a comfortable environment, we install furniture and appliances according to the preliminary design drawings. To ensure proper functionality and safety, our installations adhere to regulations, and all power connections undergo meticulous inspection by qualified quality inspectors. 7. Rigorous Testing and Acceptance: Meeting Client Expectations Prior to shipping, our containers undergo a comprehensive testing and acceptance phase. We offer a range of acceptance methods, including on-site inspections, video assessments, and graphic evaluations. Only containers that successfully meet acceptance criteria are approved for shipping. Conclusion: Manufacturing high-quality offshore containers demands a comprehensive approach that encompasses structural integrity, insulation, utilities integration, and meticulous quality control. Our process guarantees durability, safety, and compliance with industry standards. Whether through expert welds, precision installations, or rigorous inspections, our containers are built to thrive in the demanding marine environment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Offshore containers #High-quality production process #Insulation material #Structural integrity #Full penetration welding #Marine environment #Third-party inspection #Container floor installation #Calcium silicate plates #Steel mesh overlay Written by Oliver About offshore positive pressure container used in Zone1/Zone2 Positive pressurized containers can provide a safe environment for equipment and people in hazardous areas. The principle of a positive pressure blast-proof container is to achieve the technical requirements of blast-proofing through enclosure. A positive pressure ventilation system is the key. It delivers fresh air from a safe area to the container through ducts that pure the air inside the container and maintain a slightly higher air pressure inside the container than outside. In this condition, no harmful and flammable gas can enter the enclosure.If the blast control system detects the presence of hazardous gases in the enclosure or fails to maintain positive pressure, the alarm system will sound an alarm and issue a warning. If the control conditions inside the container are still not required within the specified time, the non-explosive device will automatically cut off. Thus, the common equipment in the container fulfils the purpose of blast protection.  About the air lock room of the positive pressure container The positive pressure container provided by TLS arrange two doors between the safe zone inside the container and the hazardous zone outside the container, and the isolation space formed between the two doors is the air-lock compartment. The purpose of setting the air-lock compartment is to control the airflow when people or materials enter and exit. The two doors of the air-lock compartment are usually interlocked, with one door open and the other closed. When entering the offshore container, the operator enters the air-lock compartment through the enclosed outer door and then opens the inner door after closing the enclosed outer door. In this way, no harmful gases from the outside can enter the main compartment, and the pressure of the air in the main compartment does not fall too fast.  About CPFG(combined pressurization fire&gas system) of positive pressure container CPFG is a complete suite of intelligent booster control systems, typically used in positive pressure containers, with gas detectors, smoke detectors, heat detectors, fire alarms, pressure switches, flow switches, booster fans, emergency stop & alarm mute switches, and other explosion protection equipment. The CPFG is also connected to a power distribution board, which will be connected by non-explosive devices inside the container, such as sockets, fume hoods, computers, water heaters, etc. When the power is turned on, the CPFG turns on the booster fan to purge the inside of the container to positive pressure. This prevents dangerous gases entering from outside. When the environment inside is safe, the DB (distribution board) will start up and the internal non-explosive electrical equipment can be used normally. The DB cannot be started if the environment inside the container is not secure. During operation, if dangerous gases are detected in the container or the positive pressure cannot be maintained, the alarm system will sound an alarm and issue a warning. If the control conditions in the container are not met within the specified time, the non-explosive device is automatically turned off. Therefore, the general equipment in the container is suitable for blast protection purposes. More information please download the brochure for reference. Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Container Shell Production 1.Plate and Section Steel Pretreatment 2.Stamping 3.Welding Prefab 4.Bottom, End Frame, Top and Side Structure Fabrication 5.Main Assemble 6.Lifting Test,Dropping Test, NDT for The Welding 7.Sanding and Painting (C5-H coating system--outside 260μm, inside 120μm) 8.Offline and Watertight Test Container Interior Decoration 1.Floor Material Laying 2.AC Copper Pipe Pre-embedded 3.The First Rock Wool Laying 4.The Second Rock Wool Laying 5.Aluminum Film Tape Paste 7.Hardware installation 8.Circuit debugging/cross inspection Subsequent production process is waiting for update. The process of container shell: Step 1: Plate and section steel pretreatment Step 2: Stamping Step 3: Welded prefabrication Step 4: Bottom structure, End structure, Top and side structure fabrication Step 5: Final assembly Step 6: Lifting and drop test Step 7: Flaw detection inspection Step 8: Sanding Step 9: Painting TLS offshore containers specialize in providing customized solutions and comply with strict offshore standards in our production process If you want to know more details, please feel free to contact us. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Written by OliverThe production process and requirements for TLS offshore container are as below:

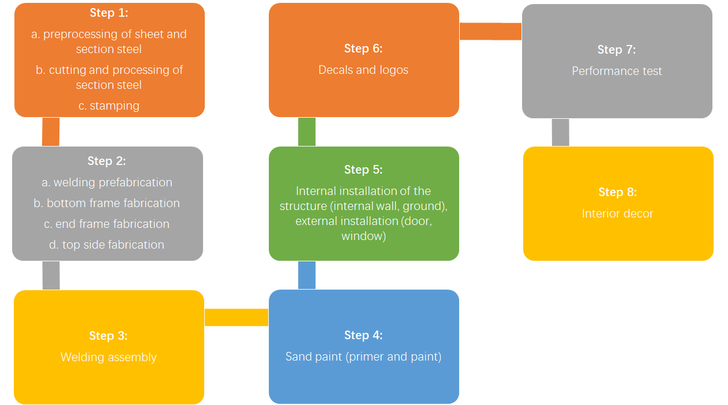

1. Produce the container frame and weld the container. All primary structural welds are required to be welded by a class-certified welder, and full penetration welding is required. For containers that have passed the third-party inspection, they are sprayed according to the paint process, and the paint package is suitable for the marine environment 2. Install the floor. First, calcium silicate plates were laid on the lower deck, then fixed steel mesh was installed on the surface, then the upper deck dressings were laid on the steel mesh, and finally the deck dressings were laid on the floor. After construction is complete, the flatness of the floor is measured and accepted by professional quality inspectors. 3. Lay down insulation material. Fix the nails in advance at the locations where the rock wool insulation needs to be laid in the container. When attaching the nails, reserve space to make sure that the nails are firmly attached according to the standard. Laying of rock wool ensures that the length of the overlapping surface is sufficient, and the joints are covered with fireproof tape. 4. Install water pipes, air pipes, and cable trays. Pre-lay insulation. Reserve the supporting boom needed to install the pipe on the top plate of the container to ensure that the pipe is straight and firmly secured. 5. Install interior trim wall panels. Install the fixing slot of the fixing plate first, and then install the inner panel in the fixing slot. Before installation, ensure that the surface of the wall panel and the ceiling is smooth and flat, and ensure that the splicing gap is neat and straight. 6. Install the furniture and appliances. The furniture in the container must be installed and secured according to the requirements and locations in the preliminary design drawings. The power connection of the relevant equipment shall be constructed in accordance with the regulations and must be inspected by qualified quality inspectors during this period. 7. Testing & Acceptance TLS accepts client's on-site inspection, video inspection, graphic inspection, and other methods for acceptance. We will only ship the containers after they pass the acceptance. Offshore shipping containers are widely used for the transportation and hoisting of goods or equipment between offshore facilities and ships in harsh environments with high temperature, high humidity, and high salt spray. Therefore, there are extremely high requirements for the anti-corrosion of the surface of the offshore container. The coating process steps of TLS are as follows: 1. Preprocessing Remove the oxide scale, rust, grease, dirt, and other attachments on the surface of the exposed steel structure to ensure the anti-corrosion performance of the coating; zinc-rich primers are applied automatically on the assembly line after the steel is shot-blasted. It temporarily protects the surface of freshly shot steel, preventing it from rusting in the gaps made during the container's manufacture. 2. Shot-blasted the whole container Before painting, the surface of the weld and the heat sensitive area of the weld should be shot-blasted. The surface of the steel structure should be free of burrs, bumps, dust, dirt, no painting, sharp edges, and all rough-cut edges should be ground to a radius of at least 2mm; 3. Pre-coating Pre-coating is applied to areas that are not easy to coat, including, but not limited to, the edges of steel plates, welds, corners, bolt holes, beam edges, and other areas that are difficult to paint. 4. Spray Each coat should be applied evenly over the entire surface, and defects such as missing paint, sags, and drips must be avoided. And each coating should contain no pinholes, blisters, and leaks. 5. Drying: Speed up the curing process. TLS uses environmentally friendly water-soluble paints, and the coating operators have relevant technical certifications. TLS containers are not prone to corrosion, paint failure, fading and discoloration which can make the container work better for its use value. THE PROCESS OF CONTAINER MANUFACTURING Step 1: a. preprocessing of sheet and section steel b. cutting and processing of section steel c. stamping Step 2: a. welding prefabricationb. bottom frame fabrication c. end frame fabricationd. top side fabrication Step 3: Welding assembly Step 4: Sand paint (primer and paint) Step 5: Internal installation of the structure (internal wall, ground), external installation (door, window) Step 6: Decals and logos Step 7: Performance test Step 8: Interior decor The customized ultra-wide laboratory container is being assembled, we will follow up every process in real time, and we will take every detail seriously. Rest assured, products tailored to your needs are sure to satisfy you. |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|