|

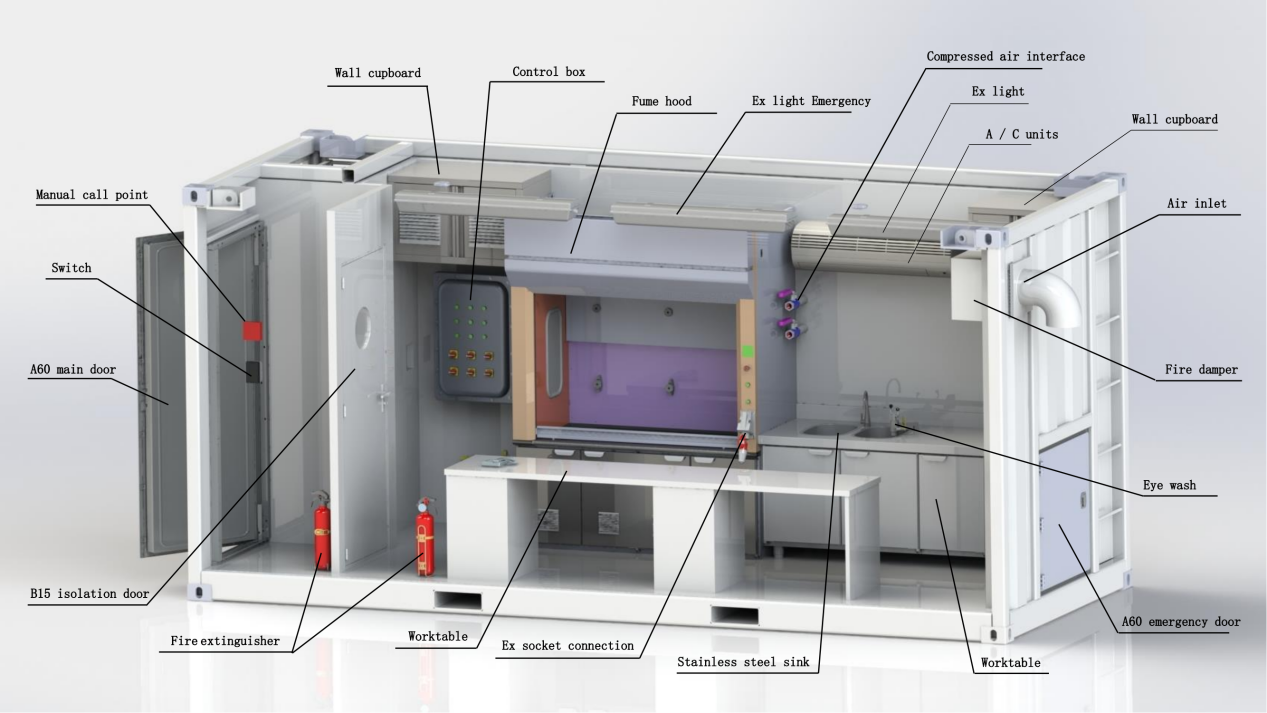

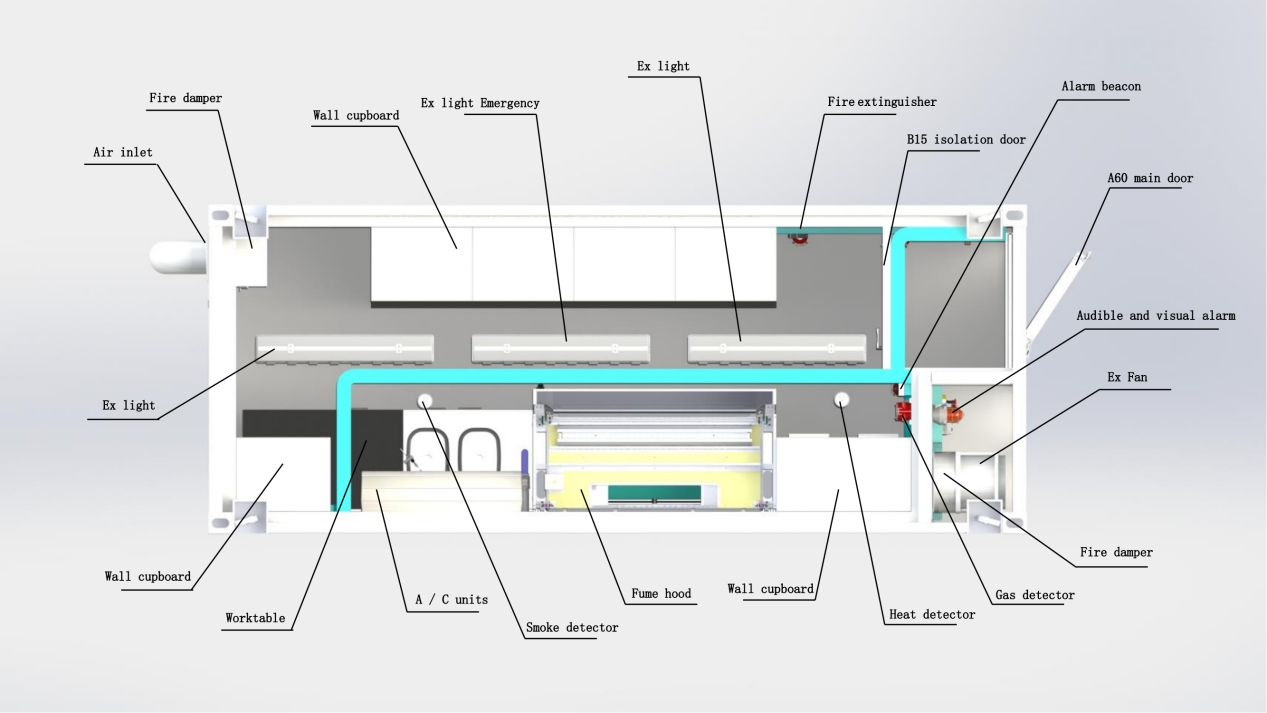

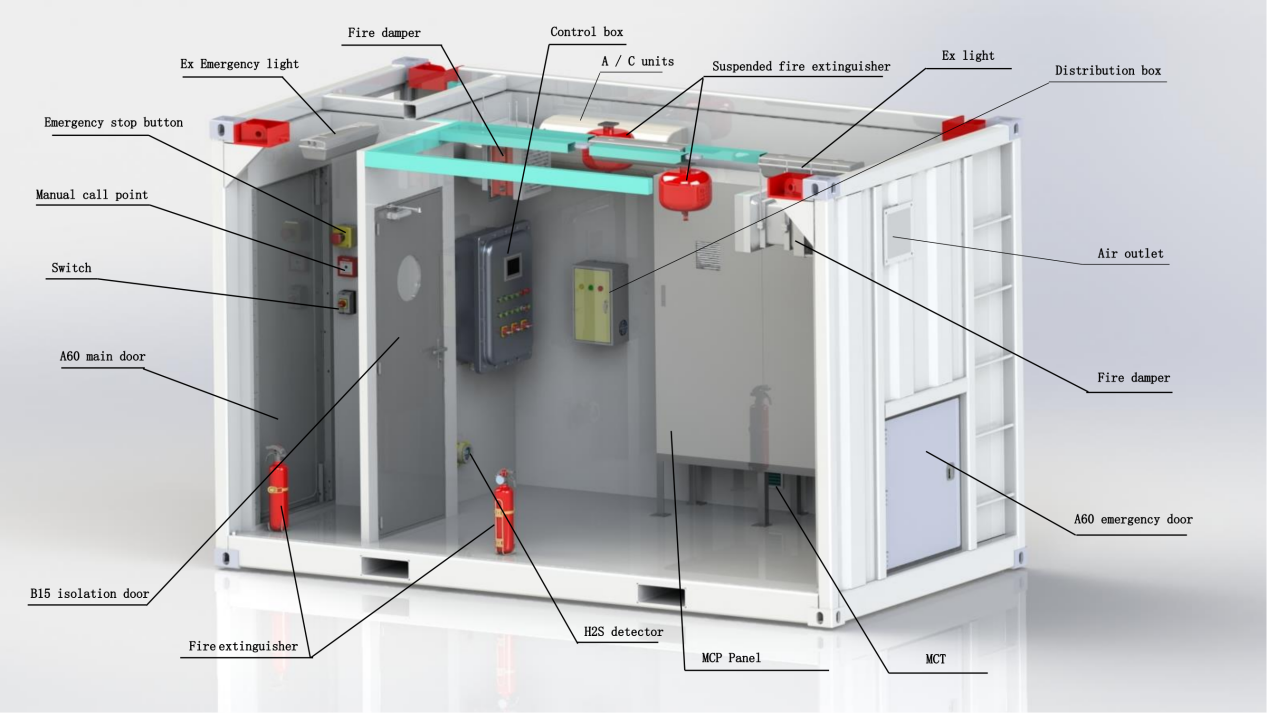

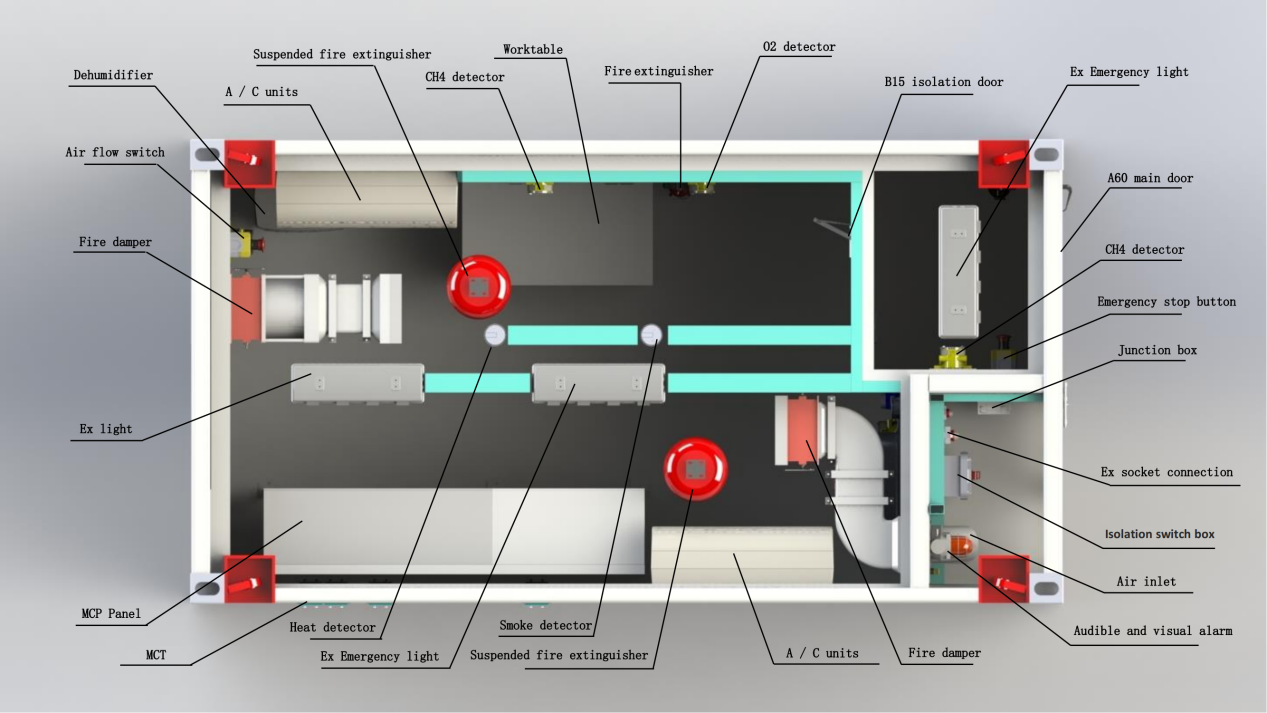

Introduction The offshore energy industry operates in some of the harshest environments on Earth, where safety, reliability, and efficiency are paramount. TLS Offshore Containers, a leading provider of specialized container solutions, is at the forefront of innovation with their intelligent pressurized containers, transforming how critical operations are conducted offshore. What are Intelligent Pressurized Containers? Intelligent pressurized containers are custom-engineered units designed to house essential equipment and processes in offshore settings. They are built to withstand extreme weather conditions, high pressures, and hazardous environments. What sets them apart is the integration of advanced technology for monitoring, control, and safety. TLS Offshore Containers: A Leader in Innovation TLS Offshore Containers has established a reputation for excellence by delivering tailored solutions that meet the unique demands of the offshore industry. Their intelligent pressurized containers offer a wide range of benefits:

Applications of Intelligent Pressurized Containers

Why Choose TLS Offshore Containers?

Conclusion TLS Offshore Containers is revolutionizing the offshore energy industry with their intelligent pressurized containers. By combining safety, efficiency, and customization, they are enabling companies to operate more effectively and securely in challenging offshore environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #TLS Offshore Containers #offshore pressurized containers #intelligent pressurized containers #offshore control rooms #hazardous area enclosures #DNV 2.7-1 containers #mud logging cabin #ROV cabin #intelligent pressurized container applications #safety features of TLS pressurized containers #how to customize TLS offshore containers #offshore containers Singapore Written by OliverWhen it comes to industrial safety, especially in offshore environments, understanding and managing hazardous areas is crucial. These areas are typically classified into zones based on the frequency and duration of the presence of explosive atmospheres. In this blog, we'll explore the definitions and distinctions between Zone 0, Zone 1, and Zone 2 hazardous areas, and highlight the advantages of using pressure containers made by TLS Offshore Containers in such environments. What are Hazardous Areas? Hazardous areas are locations where flammable gases, vapors, or dust are present in the air in sufficient quantities to produce explosive or ignitable mixtures. Proper identification and classification of these areas are vital for implementing appropriate safety measures and ensuring compliance with regulations.

Advantages of TLS Offshore Containers in Hazardous Areas When working in hazardous areas, particularly offshore, the equipment used must meet stringent safety standards to prevent accidents and ensure operational efficiency. TLS Offshore Containers specializes in manufacturing pressure containers designed specifically for such environments. Here are the key advantages of using TLS pressure containers in Zone 0, Zone 1, and Zone 2 hazardous areas:

Conclusion Identifying and managing Zone 0, Zone 1, and Zone 2 hazardous areas is essential for maintaining safety in industrial operations, especially in offshore environments. Using high-quality, compliant equipment like TLS Offshore Containers can significantly enhance safety and reliability in these environments. With their robust design, adherence to international standards, and dedicated support, TLS Offshore Containers are an excellent choice for any operation dealing with hazardous areas. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Explosive atmosphere classification #Industrial safety zones #TLS Offshore Containers #Pressure containers for hazardous areas #ATEX #IECEx #Offshore safety equipment #Hazardous area management #Customizable pressure containers #Offshore hazardous zones Written by OliverIntroduction In the demanding environments of the offshore industry, safety and reliability are paramount. TLS Offshore Containers International, a leader in designing and manufacturing high-quality offshore containers, ensures these needs are met, particularly in ZONE 2 areas. This blog delves into the specifics of how TLS offshore pressurized containers operate efficiently and safely in ZONE 2 hazardous locations. What are ZONE 2 Areas? ZONE 2 areas are classified as hazardous locations where explosive gases are not likely to occur in normal operation, and if they do occur, it will be for a short period. These areas require equipment that is robust, safe, and compliant with stringent safety standards. The Role of TLS Offshore Pressurized Containers TLS Offshore Containers International specializes in providing containers designed to withstand the rigors of ZONE 2 environments. Here's how our containers ensure safety and functionality:

Conclusion Operating in ZONE 2 areas requires equipment that not only meets but exceeds safety standards. TLS Offshore Containers International's pressurized containers are engineered to provide maximum safety, reliability, and functionality in these demanding environments. By choosing TLS, you're investing in quality and peace of mind, knowing that your operations are supported by the best in the industry. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #TLS Offshore Containers #ZONE 2 hazardous areas #Offshore pressurized containers #ATEX certified containers #IECEx certified containers #DNV 2.7-1 containers #Offshore safety equipment #Hazardous location containers #Pressurization systems for containers #Customizable offshore containers #Explosion-proof containers #Offshore container solutions Written by OliverNavigating the hazardous landscapes within the oil and gas industry is paramount to safeguarding lives and assets amidst potentially explosive environments. In this exploration, we'll delve into the intricacies of hazardous locations specific to this industry, understand their classification, and highlight the critical considerations imperative for maintaining a secure operational milieu. Understanding Hazardous Locations in the Oil and Gas Industry: Within the oil and gas sector, hazardous locations denote areas where the presence of flammable gases, vapors, combustible dust, or ignitable fibers poses a significant risk of fire or explosion. These zones encompass a spectrum of sites, including oil refineries, drilling rigs, production platforms, pipeline facilities, and storage tanks. Given the inherent dangers, stringent safety protocols and specialized equipment are indispensable for accident prevention and personnel protection. Classification of Hazardous Locations: Hazardous locations in the oil and gas industry are categorized into:

The Significance of Understanding Hazardous Locations: Ensuring worker safety within the oil and gas industry, particularly in offshore settings, is paramount. The formidable challenges posed by adverse weather, marine conditions, and geographical isolation necessitate a robust approach to risk management, rescue operations, and emergency preparedness. Offshore classification societies impose stringent regulations governing vessel operations to uphold safety standards. Throughout the operational lifecycle, from installation and commissioning to ongoing activities and decommissioning, continual risk assessment is imperative. This entails evaluating potential hazards, classifying the atmosphere, and deploying a hierarchy of controls to fortify safety measures for equipment, processes, and personnel. Given the prevalence of flammable chemicals used in extraction and processing operations, meticulous risk analysis and hazard classification are indispensable. These assessments inform recommendations regarding the requisite structural integrity of doors, walls, and buildings to contain fires effectively in the event of an incident. Proactive identification and mitigation of potential risks through comprehensive risk analysis, hazard classification, and the deployment of cutting-edge safety equipment are instrumental in averting accidents, prioritizing worker safety, and mitigating the impact of unforeseen incidents. Why TLS' Explosion-Proof Containers Excel in Hazardous Environments: TLS Offshore Containers offer intelligent pressurized containers designed to meet the unique demands of offshore energy storage. These containers feature integrated HVAC and power control systems, creating a secure environment for both personnel and equipment. A standout feature of TLS' intelligent pressurized containers is their incorporation of state-of-the-art safety monitoring systems. These systems encompass integrated fire and gas detection, pressurization, and emergency shutdown mechanisms, rendering them suitable for use in Zone 1 and Zone 2 hazardous areas. This ensures unwavering protection for personnel and equipment, even in the most challenging operational environments. In conclusion, a thorough understanding of hazardous locations, coupled with proactive risk management and the utilization of advanced safety solutions like TLS' explosion-proof containers, is paramount for safeguarding lives and assets in the oil and gas industry's dynamic and hazardous operational landscapes. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Hazardous locations #Oil and gas industry #Safety measures #Risk management #Zone classification #Offshore operations #Hazardous substances #Explosion-proof containers #Safety equipment #Regulatory compliance Written by OliverIntroducing: Welcome to the forefront of offshore energy storage innovation, where TLS Offshore Containers leads the charge as your premier partner for intelligent pressurized containers. Engineered to meet the exacting demands of offshore operations, our state-of-the-art solutions redefine safety and efficiency standards. Central to our offering are our intelligent pressurized containers, meticulously crafted to address the unique requirements of each client. These cutting-edge containers boast sophisticated HVAC and power control systems, ensuring a secure and optimal environment for both personnel and equipment alike. With TLS, customization isn't just a feature – it's a commitment to delivering operational excellence in offshore energy storage. For offshore oil and gas ventures seeking dependable and efficient energy storage solutions, look no further than TLS intelligent pressurized containers. Our unwavering focus on advanced safety features, seamless integration capabilities, and adherence to industry-leading certifications guarantees the assurance and peace of mind you deserve. Discover the transformative power of TLS – where safety and efficiency seamlessly converge. Two different kinds of The Offshore Intelligent Pressurized Container Type 1: Negative Pressure Container Principle: Negative pressure containers operate on the principle of creating a pressure difference between the interior and exterior environments. This difference causes air to flow from outside the container to inside, effectively preventing the escape of hazardous gases. By maintaining a lower pressure inside the container compared to its surroundings, any leaks or releases of hazardous gases are drawn into the container rather than being expelled into the environment. Characteristics:

Type 2: Positive Pressure Container Principle: Positive pressure containers work on the principle of maintaining a higher internal pressure compared to the surrounding environment. This higher pressure within the container prevents the ingress of hazardous gases from the outside. By ensuring that the internal pressure is consistently higher, any potential leaks or openings will result in the outward flow of air, rather than the inward flow of hazardous gases. Characteristics:

Conclusion: When selecting the appropriate TLS Offshore Intelligent Pressurized Container for your offshore energy storage needs, thorough evaluation and consideration of various factors are paramount. Understanding the operational requirements, environmental conditions, hazard zones, safety features, compliance with regulations, customization options, and budget constraints are essential steps in making an informed decision. Whether opting for a Negative Pressure Container or a Positive Pressure Container, TLS offers cutting-edge solutions engineered to prioritize safety, efficiency, and regulatory compliance in offshore operations. With TLS, you can confidently navigate the complexities of offshore energy storage, knowing that you have a reliable partner dedicated to delivering operational excellence and peace of mind. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Key words: #Intelligent pressurized containers #Negative Pressure Container #Positive Pressure Container #Offshore oil and gas #Hazardous zones #Customization #Explosion-proof electrical installations #Environmental conditions #DNV2.7-1 #Operational excellence Written by OliverIn the dynamic realm of offshore energy exploration, safety and efficiency stand as paramount concerns. Among the many innovations driving this industry forward, A60 Intelligent Pressurized Containers emerge as a game-changer. Designed to withstand the harshest offshore conditions while ensuring unparalleled safety and efficiency, these containers are revolutionizing offshore operations. Let's delve deeper into what makes A60 Intelligent Pressurized Containers the go-to solution for offshore energy storage needs. Understanding A60 Intelligent Pressurized Containers A60 Intelligent Pressurized Containers, crafted by TLS Offshore Containers, represent the pinnacle of offshore storage solutions. Built with meticulous attention to detail and engineered for excellence, these containers offer a secure and conducive environment for both personnel and equipment. Unmatched Safety Standards Safety is non-negotiable in the offshore environment, where even the slightest oversight can have catastrophic consequences. A60 Intelligent Pressurized Containers lead the industry with their advanced safety monitoring systems. Equipped with integrated fire and gas detection, along with pressurization and emergency shutdown capabilities, these containers are certified for use in hazardous areas (Zone 1/Zone 2). TLS's commitment to safety ensures the protection of personnel and equipment under all circumstances. Seamlessly Integrated and Mobile Swift deployment is essential in offshore operations, and A60 Intelligent Pressurized Containers are designed for effortless connection and quick mobilization. These containers incorporate comprehensive data communication networks, fire suppression systems, and air conditioning, ensuring they are operation-ready upon arrival. Adherence to stringent DNV 2.7-1, EN 12079, ATEX, IEC 60079-13, and SOLAS standards further underscores TLS's dedication to quality and safety. Customized for Excellence No two offshore operations are alike, and A60 Intelligent Pressurized Containers are tailored to the unique needs of each client. TLS's commitment to customization ensures that every container is a step towards operational excellence in offshore energy storage. Whether it's for MUD logging units, motor control centers, hazardous zones, or MWD/LWD cabins, these containers offer unmatched flexibility and adaptability. Why Choose A60 Intelligent Pressurized Containers? For offshore oil and gas operations seeking reliable and efficient energy storage solutions, A60 Intelligent Pressurized Containers are the answer. TLS's focus on advanced safety features, seamless integration capabilities, and compliance with industry-leading certifications provides assurance and peace of mind. With A60 Intelligent Pressurized Containers, offshore operations can navigate challenges with confidence, knowing they have a solution that stands up to the rigors of the offshore environment. Conclusion In the ever-evolving landscape of offshore energy exploration, safety, efficiency, and adaptability are paramount. A60 Intelligent Pressurized Containers represent the pinnacle of innovation, offering unmatched safety standards, seamless integration, and customization tailored to the unique needs of each operation. As offshore operations continue to push boundaries, A60 Intelligent Pressurized Containers serve as a beacon of reliability, ensuring that safety and efficiency remain at the forefront of every endeavor. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #A60 container #Intelligent pressurized container #Offshore safety solutions #Offshore container certification #Hazardous area container #ATEX container #DNV 2.7-1 certification #EN 12079 standards Written by OliverIn the dynamic realm of offshore industries, safety and efficiency stand as paramount pillars for operational success. Remote Operated Vehicles (ROVs) play a pivotal role in underwater inspections, maintenance, and repair activities, often in hazardous environments. To ensure optimal performance and safety, the integration of ROV Ex-Proof Control Cabins/Containers emerges as a crucial consideration. Understanding ROV Ex-Proof Control Cabins/Containers ROV Ex-Proof Control Cabins/Containers serve as specialized control centers designed to house the command and control systems for remotely operated vehicles in hazardous areas. These areas may include offshore drilling platforms, oil rigs, chemical processing plants, and other potentially explosive atmospheres where traditional electronic equipment could pose significant risks. Ensuring Safety Compliance Safety regulations in hazardous environments are stringent and non-negotiable. ROV Ex-Proof Control Cabins/Containers adhere to stringent safety standards, ensuring compliance with regulatory requirements such as ATEX, IECEx, and other relevant directives. These standards mandate the design, construction, and operation of equipment intended for use in explosive atmospheres, mitigating the risks of ignition and explosion. Key Features and Benefits

Enhancing Operational Efficiency By integrating ROV Ex-Proof Control Cabins/Containers into offshore operations, companies can achieve significant enhancements in operational efficiency and risk mitigation. These benefits include:

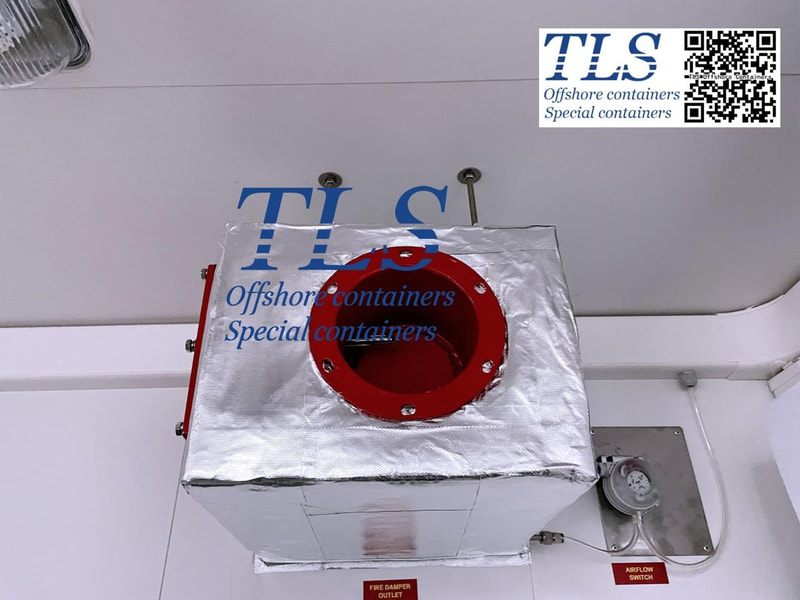

Conclusion ROV Ex-Proof Control Cabins/Containers represent a paradigm shift in the domain of offshore operations, combining cutting-edge technology with uncompromising safety standards to unlock new levels of efficiency and reliability. By investing in these specialized enclosures, companies can navigate the complexities of hazardous environments with confidence, driving sustainable growth and operational excellence in the offshore industry. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #ROV (Remote Operated Vehicle) #Ex-Proof (Explosion-Proof) #Control Cabin/Container #Hazardous Environments #Safety Standards #ATEX/IECEx #Explosive Atmospheres #Regulatory Compliance #Operational Efficiency #Remote Monitoring #Modular Design Written by OliverPositive pressurized containers play a pivotal role in ensuring the safety of equipment and personnel in environments where explosive or flammable materials are present. This article delves into the essential principles behind these containers and their significance in achieving explosion-proof requirements. The positive pressure explosion-proof container operates by utilizing the container shell to meet technical standards for explosion-proofing. This allows the installation of regular non-explosion-proof machinery and electrical equipment within the container while ensuring safety. A critical component of the positive pressurized container is the positive pressure ventilation system. This system is instrumental in achieving explosion-proof conditions within the container. Here's how it works:

TLS offshore pressurized containers adhere to the latest standards and regulations, guaranteeing design, manufacturing, and testing in compliance with industry requirements. Explore the cutting-edge features of our containers to ensure a secure and explosion-proof environment for your operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Positive pressurized containers #Explosion-proof containers #Pressurized container ventilation #Explosion-proof blast system #Centrifugal fan for explosion-proof #Hazardous gas monitoring #Positive pressure box #Explosion-proof control system #Technical requirements for explosion-proof Written by OliverShould I choose a positive pressure container or a negative pressure container for the safety area?12/6/2023

In workplaces where hazardous materials and hazardous environments are handled, selecting appropriate protective equipment is an important part of ensuring worker safety. Positive pressure containers and negative pressure containers are two types of containers widely used in these environments. They have unique applications in the division of dangerous areas and safe areas and the protective effect. DANGER ZONE AND SAFE ZONE DIVISION Positive pressure containers are suitable for hazardous areas: The principle of a positive pressure container is to fill the container with air from a safe area through a hose connected to a positive pressure source to maintain a positive pressure state in the container. It is suitable for hazardous areas that need to prevent external harmful substances from entering, such as handling chemicals, biological experiments, medical isolation and other environments. Negative pressure containers are suitable for safe areas: The negative pressure container draws out the air in the container through the hose to ensure the negative pressure state in the container and prevent toxic gases or dust from leaking into the surrounding environment. It is suitable for scenarios where the spread of harmful substances needs to be controlled in a safe area, such as chemical processing, dust control, etc. PROTECTIVE EFFECT Positive pressure container: prevent external contamination from entering: The positive pressure container effectively isolates operators in the dangerous area from the influence of dangerous substances in the external environment by maintaining a positive pressure state inside the container. Through the principle of positive pressure, external pollutants are prevented from entering the work space, providing an efficient external barrier. Negative pressure container: prevent leakage of internal pollutants: The negative pressure container draws out the air inside the container to ensure that the air pressure inside the container is lower than the external environment, effectively preventing internal toxic and harmful substances from leaking to the surroundings. Through the negative pressure principle, hazardous materials can be quickly confined in the container even in an emergency, protecting the external environment and the safety of operators. When choosing between a positive pressure container and a negative pressure container, the key is to understand the nature of the work environment and the characteristics of hazardous materials. Positive pressure containers are suitable for scenarios where external pollution needs to be blocked in dangerous areas, while negative pressure containers are suitable for scenarios where the spread of internal pollutants needs to be controlled in safe areas. No matter which protective equipment is chosen, relevant safety standards and regulations need to be followed to ensure the suitability, performance and reliability of the equipment to ensure a safe and controllable working environment. Maximizing Offshore Safety: The Ultimate Guide to Combined Pressurization Fire and Gas Panels11/29/2023

In the fast-paced world of offshore safety, the Combined Pressurization Fire and Gas (CPFG) panel emerges as a game-changer. Intelligent pressurized containers from TLS Offshore Containers are the ultimate solution for safe and efficient offshore energy storage. These containers are designed and constructed to meet the specific needs and requirements of the customer, with CPFG control systems to create a safe environment for personnel and equipment. This article delves into the intricacies of CPFG systems, shedding light on their crucial role in mitigating risks and enhancing safety measures in hazardous environments. What is a CPFG Panel? A Combined Pressurization Fire and Gas (CPFG) panel is an advanced safety solution engineered to tackle fire and gas risks seamlessly. By integrating fire detection and gas detection functions, this system offers a streamlined approach to offshore safety, ensuring a swift response to potential threats. Applications of CPFG Panels in Offshore Modules

Safety Features that Set CPFG Apart

Benefits of CPFG Systems

Conclusion Embracing the advanced capabilities of Combined Pressurization Fire and Gas panels is not just a safety measure; it's a strategic move towards a secure, efficient, and compliant offshore operation. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #CPFG panels #Offshore safety #Hazardous areas #Offshore modules #Safety systems #Zone segmentation #Intelligent alarms #Safety shutdown systems #Real-time monitoring #Environmental protection #Regulatory compliance Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|