|

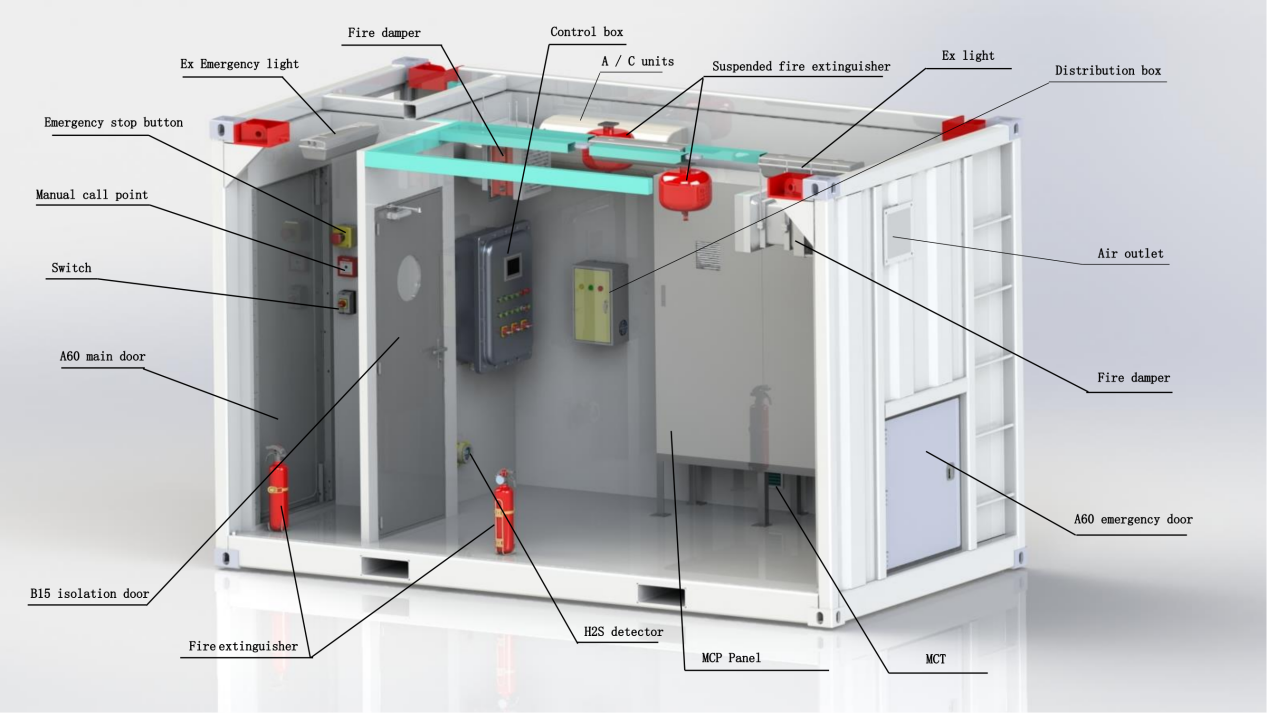

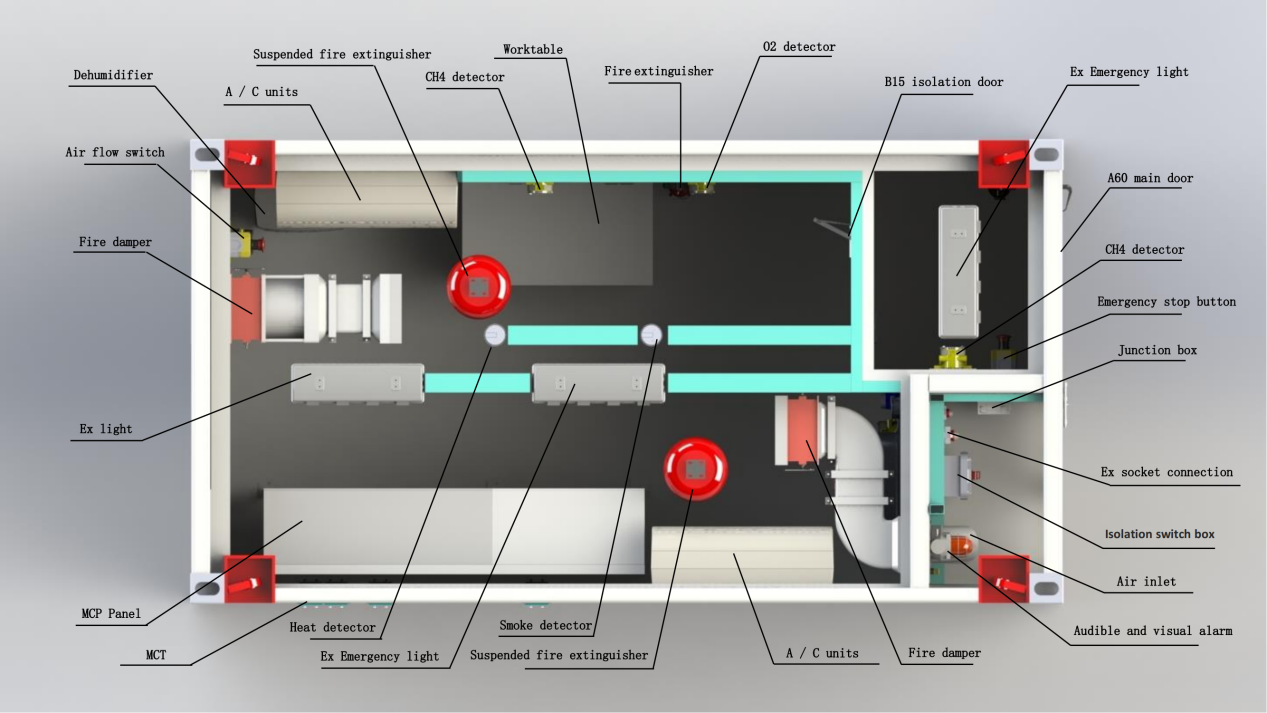

Introduction: In industries where hazardous environments are common, ensuring the safety of equipment and personnel is of utmost importance. To achieve this, One of the key features of TLS intelligent pressurized containers is the incorporation of state-of-the-art safety monitoring systems. These include integrated fire and gas detection, pressurization and emergency shutdown systems, making them suitable for use in Zone 1/Zone 2 hazardous areas. All pressurized containers from TLS are designed, manufactured and certified to the latest DNV 2.7-1, EN 12079 offshore container standards, ATEX, IEC 60079-13 and/or SOLAS standards. This ensures that the containers meet the highest industry standards and are built to withstand the harsh conditions of offshore operations.This ensures that personnel and equipment are protected at all times, even in the most challenging environments.In this article, we will explore three prominent certifications: ATEx, IECEx, and CNEx. Understanding these certifications is vital for businesses operating in potentially explosive atmospheres, as they help ensure compliance and mitigate risks.

Benefits of Certifications: Obtaining ATEx, IECEx, or CNEx certifications offer several benefits for businesses operating in explosive atmospheres:

Conclusion: When operating in hazardous environments, businesses must prioritize the safety of personnel and equipment. ATEx, IECEx, and CNEx certifications provide clear guidelines and standards for ensuring compliance and mitigating risks associated with explosive atmospheres. By obtaining these certifications, companies can enhance safety, achieve legal compliance, access global markets, and benefit from standardized processes. Investing in certified equipment is an investment in the safety and success of your operations in hazardous environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #ATEx #IECEx #CNEx #Certification #Explosive atmospheres #Hazardous environments #ATEX Directive #International Electrotechnical Commission #Compliance #Safety Written by OliverIn today's modern society, the comfort and well-being of employees in the workplace have become increasingly important. With advancements in technology and innovation, new solutions for office spaces have emerged. Among them, positive pressure office containers have gained popularity.

Construction Sites: They provide temporary office spaces for construction teams, enabling efficient coordination and management with a comfortable working environment and superior air quality. Exhibitions and Event Venues: These containers serve as temporary display and office spaces, catering to exhibitions, events, conferences, and trade shows. They can be quickly deployed, offering exhibitors and organizers a comfortable, clean, and safe workspace. Temporary Projects and On-Site Offices: They are ideal for temporary projects and on-site work requirements. The mobility and flexibility of positive pressure office containers allow for easy relocation, providing isolated and secure office spaces for industries such as mining, energy, and surveying. Disaster Recovery and Emergency Response: Positive pressure office containers play a vital role in post-disaster recovery and emergency response efforts. They can be rapidly deployed to disaster-stricken areas, serving as safe, comfortable workspaces for government agencies, rescue organizations, and volunteers. Creative Workspaces: Positive pressure office containers offer innovative design possibilities for creative workspaces. By incorporating personalized decoration and design elements, these containers create unique and comfortable environments suitable for creative industries, design studios, and artist studios. Positive pressure office containers offer flexibility, mobility, and multifunctionality, making them suitable for various settings and needs. They provide comfortable, clean, and secure office spaces in different work scenarios, resulting in improved efficiency and employee satisfaction. Whether it is for temporary projects, construction sites, exhibitions, emergency response, or creative workspaces, positive pressure office containers represent an innovative solution for modern workplaces, prioritizing employee well-being and productivity. Intelligent Pressure Containers: Advancing Safety and Efficiency in Hazardous Environments6/26/2023

Introduction: Intelligent pressure containers, developed by TLS, are innovative solutions designed to create secure environments using positive pressure differentials. With broad applications across industries, these containers offer valuable benefits in hazardous settings like the oil and gas industry and chemical processing plants. In this article, we will explore how intelligent pressure containers are employed in the oil and gas sector, focusing on their role in MWD/LWD cabins, MCC shelters, and MUD logging cabins. Additionally, we will discuss the integration of intelligent features within these containers, ensuring the safety and efficiency of critical equipment. Section 1: MWD/LWD Cabin MWD/LWD cabins play a pivotal role in collecting data and measurements during drilling operations. By housing advanced tools and instruments, these cabins enable the monitoring of temperature, pressure, and formation properties. Intelligent pressure containers provide a controlled and secure environment for sensitive sensors and electronics, contributing to well safety and operational efficiency. Section 2: MCC Shelter MCC shelters are essential for housing electrical equipment used in controlling and monitoring drilling operations. Intelligent pressure containers offer an ideal solution for storing and transporting MCC equipment, providing a clean, dry, and safe environment for delicate electronics. These containers can be pressurized to prevent dust and other contaminants from entering, safeguarding equipment against shock and vibration during transportation. Section 3: MUD Logging Cabin MUD logging cabins serve as portable laboratories, facilitating accurate evaluation of formation samples. These cabins are equipped with essential functions and equipment for surface loggers, enabling them to obtain precise results efficiently. Intelligent pressure containers can be seamlessly integrated into mud logging cabins, creating controlled environments that ensure optimal conditions for sample analysis. Section 4: Integration of Intelligence in Containers Intelligent pressure containers incorporate various technologies to enhance their functionality. Sensors, electronic controls, and communication systems enable continuous monitoring and adjustment of internal pressure levels. They also regulate temperature and humidity, creating optimal conditions for equipment within the containers. Wireless communication technologies allow for real-time data transmission, facilitating monitoring and analysis. Conclusion: Intelligent pressure containers are revolutionizing safety and efficiency in hazardous environments, particularly within the oil and gas industry. By providing secure and efficient environments for critical equipment such as MWD/LWD and MCC, these containers prioritize worker safety and enhance operational effectiveness. The integration of intelligent technologies further augments their capabilities, enabling real-time monitoring and control. Choose TLS for reliable intelligent pressure containers that meet the stringent demands of the oil and gas sector, ensuring safety and productivity in challenging environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding Intelligent pressurized containers from TLS , please download Offshore pressurised mud logging cabin brochure and MCC | Switchgear | VFD | VSD pressurised shelter for reference. #Intelligent pressure containers #Hazardous environments #Oil and gas industry #Positive pressure differentials #Safety and efficiency #MWD/LWD cabins #MCC shelters #MUD logging cabins #Integration of intelligence #Equipment protection Written by OliverIn today's dynamic industrial landscape, where hazardous environments are commonplace, the need for safe and efficient workspaces is paramount. Companies operating in offshore oil and gas exploration, chemical processing, and other high-risk industries understand the significance of ensuring employee safety while maintaining productivity. This is where offshore pressurized containers, serving as offices in hazardous areas, emerge as indispensable assets. In this article, we explore the importance of these specialized containers and how they contribute to the overall well-being of workers in perilous work environments. Enhancing Safety:

Boosting Efficiency:

Conclusion: The importance of offshore pressurized containers as offices in hazardous areas cannot be overstated. With their emphasis on safety, compliance with regulations, and the ability to enhance operational efficiency, these specialized containers prove to be indispensable assets for companies operating in high-risk industries. By prioritizing the well-being of employees and providing them with secure and efficient workspaces, businesses can effectively mitigate risks, maximize productivity, and contribute to the overall success of their operations. In an era where safety and productivity go hand in hand, offshore pressurized containers serve as a tangible testament to the commitment of companies towards ensuring a secure and thriving workplace environment in hazardous areas. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding Intelligent pressurized containers from TLS , please download Offshore pressurised mud logging cabin brochure and MCC | Switchgear | VFD | VSD pressurised shelter for reference. #Offshore pressurized containers #Hazardous area offices #Safety #Efficiency #Industrial workplaces #Offshore oil and gas #Chemical processing #High-risk industries #Employee well-being #Containment Written by OliverThe oil and gas industry operates in challenging environments that involve various hazardous materials and potentially explosive atmospheres. Understanding hazardous locations within this industry is crucial for ensuring the safety of personnel, preventing accidents, and mitigating potential damages. In this article, we will delve into the definition of hazardous locations specifically within the oil and gas industry, their classification, and the key considerations necessary for maintaining a safe working environment. Defining Hazardous Locations in the Oil and Gas Industry: Hazardous locations in the oil and gas industry refer to areas where the presence of flammable gases, vapors, combustible dust, or ignitable fibers poses a significant risk of fire or explosion. These locations include oil refineries, drilling rigs, production platforms, pipeline facilities, storage tanks, and other related installations. Due to the nature of the operations involved, strict safety measures and specialized equipment are necessary to prevent accidents and protect personnel. Classification of Hazardous Locations:

Understanding the classification system applicable to the oil and gas industry is crucial for implementing appropriate safety measures and selecting suitable equipment. Why Understanding Hazardous Locations is Important? Ensuring worker safety in the oil and gas industry, particularly on offshore rigs, is of utmost importance. The unique challenges posed by weather, water, and isolation make it crucial to address risks associated with abatement, rescue, and extraction. Offshore classification societies establish strict rules and regulations that govern offshore vessels and operations. Throughout the lifecycle of operations, from installation and commissioning to ongoing activities and decommissioning, continuous risk analysis is essential. This analysis involves assessing potential hazards and classifying the atmosphere to effectively mitigate the risks of fire and explosion. By following this process, the hierarchy of control can be implemented to enhance safety measures for equipment, processes, and personnel. In the oil and gas industry, many chemicals used in mining operations or released during extraction processes are flammable. This factor further increases the importance of risk analysis and hazard classification. Through these assessments, specific recommendations can be made regarding the appropriate class of doors, walls, or buildings needed to effectively contain fires in the event of an accident. By proactively identifying and addressing potential risks through thorough risk analysis and hazard classification, the oil and gas industry can significantly reduce the possibility of accidents, prioritize worker safety, and minimize the impact of potential incidents.equipment are necessary to prevent accidents and protect personnel. Why TLS' explosion-proof containers work in hazardous areas? Intelligent pressurized containers from TLS Offshore Containers are the ultimate solution for safe and efficient offshore energy storage. These containers are designed and constructed to meet the specific needs and requirements of the customer, with built-in HVAC and power control systems to create a safe environment for personnel and equipment. The key features of TLS intelligent pressurized containers is the incorporation of state-of-the-art safety monitoring systems. These include integrated fire and gas detection, pressurization and emergency shutdown systems, making them suitable for use in Zone 1/Zone 2 hazardous areas. This ensures that personnel and equipment are protected at all times, even in the most challenging environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Hazardous locations #Oil and gas industry #Explosive atmospheres #Safety measures #Classification system #Hazardous substances Written by Oliver#positive pressure, #blast-proof container, #hazardous area, #ventilation system, #ducts, # flammable gas, enclosure, alarm system,

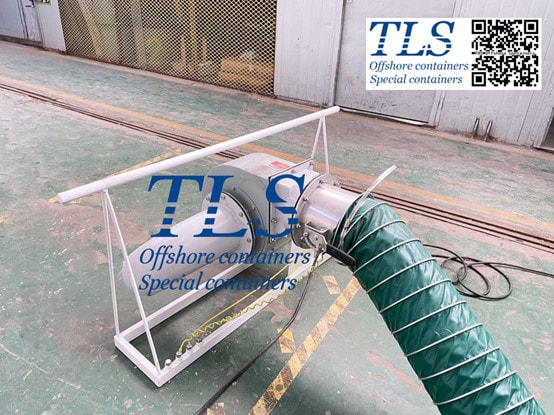

Positive pressure and negative pressure test containers are common equipment in laboratory work, designed to maintain a relatively stable pressure environment to meet the needs of experiments. To achieve this goal, these test containers usually need to be equipped with some auxiliary facilities, among which centrifugal fans are a very important part. A centrifugal fan is a commonly used type of fan that works by sucking in air and blowing it out into the target area through rotating blades. In positive pressure containers, the role of the centrifugal fan is to blow fresh air into the container to maintain a positive pressure state. This helps prevent harmful substances from entering the test container from the external environment, thus ensuring the purity and stability of the experimental environment. In contrast, in negative pressure containers, the role of the centrifugal fan is to exhaust the air inside the container to the external environment to maintain a negative pressure state. This helps prevent harmful substances from leaking from the test container into the external environment, ensuring the safety of operators and the reliability of the experiment. To maintain the pressure stability inside the positive pressure and negative pressure containers, they usually need to be equipped with some auxiliary facilities such as pressure controllers, flow meters, pressure switches, etc. These facilities can monitor pressure changes inside the container and adjust the speed and air flow of the centrifugal fan to maintain a positive or negative pressure state. In addition, positive pressure and negative pressure containers also need to be equipped with safety facilities such as sealed doors and explosion-proof devices to ensure the safety and stability of the experimental environment. In summary, centrifugal fans play a very important role in positive pressure and negative pressure containers, which can maintain a stable air pressure inside the containers, providing a reliable environment for experiments. Besides, positive pressure and negative pressure containers need to be equipped with other auxiliary facilities to ensure the safety and stability of the experimental environment. #centrifugal fan, #positive pressure, #negative pressure, #test chamber, #laboratory equipment, #pressure controllers, #explosion-proof devices. The Importance of Air-Lock Compartments in Positive Pressure Containers in the Oil and Gas Industry4/7/2023

Positive pressure containers are a critical component in various industries, including the oil and gas industry, where maintaining a sterile environment and preventing contamination is essential for safe and efficient operations. These containers utilize a specialized mechanism known as an air-lock compartment to ensure that the air inside remains under positive pressure. An air-lock compartment is a small chamber located between the outside environment and the positive pressure container. This chamber features two airtight doors that prevent air from passing through when they are closed. The first door faces the external environment, while the second door faces the positive pressure container. The air-lock compartment's purpose is to enable people and objects to enter and exit the positive pressure container without compromising the sterile environment inside. The process of entering the air-lock compartment begins by closing the first door. The chamber is then pressurized to match the positive pressure inside the container, preventing any air from the outside environment from entering the container. Once the air-lock compartment is pressurized, the second door facing the container can be opened, allowing a person or object to enter. Upon entry, the second door is closed, and the air-lock compartment is depressurized, removing any contaminants that may have entered the chamber. In addition to providing a safe and sterile entry and exit point for people and objects, the air-lock compartment also serves as a means of removing objects and waste from the positive pressure container without contaminating the outside environment. When an object or waste is removed from the container, it is placed inside the air-lock compartment, and the second door is closed. The compartment is then pressurized, and the first door is opened, allowing the object or waste to be removed from the air-lock compartment and into the external environment. In the oil and gas industry, positive pressure containers with air-lock compartments are essential for safe and efficient operations. They are used to maintain a sterile environment when drilling or performing other operations that require strict contamination control measures. Additionally, these containers are used to store hazardous materials and waste safely, reducing the risk of environmental contamination. In conclusion, air-lock compartments are a critical component of positive pressure containers, enabling safe and sterile entry and exit points for people and objects while maintaining a contamination-free environment. In the oil and gas industry, these containers play a crucial role in ensuring safe and efficient operations, minimizing the risk of environmental contamination and protecting workers from hazardous materials. Written by OliverIntelligent pressurized containers are indeed an effective way to provide a safe environment for equipment and people in hazardous areas. By maintaining a positive pressure inside the container, the risk of harmful gas or explosive substances entering the enclosure is greatly reduced, and the equipment and people inside the container are protected from potential explosions. The positive pressure ventilation system is the key to ensuring the safety of the container. By delivering fresh air from a safe area through ducts, the system purges the air inside the container and maintains a slightly higher air pressure inside the container than outside. This pressure difference prevents hazardous gases or other harmful substances from entering the container. In the event that the blast control system detects the presence of hazardous gases in the enclosure or fails to maintain positive pressure, the alarm system will sound an alarm and issue a warning. This warning gives the people inside the container time to take appropriate measures to ensure their safety. If the control conditions inside the container are still not met within the specified time, the non-explosive device will automatically cut off, providing an additional layer of protection. All pressurized containers from TLS are designed, manufactured and certified to the latest DNV 2.7-1, EN 12079 offshore container standards, ATEX, IEC 60079-13 and/or SOLAS standards.This ensures that the containers meet the highest industry standards . More information about offshore pressurised container/cabin Don’t hesitate to contact us for more information about the offshore pressurised container. Our skilled engineers are eager to explain the possibilities for your applications. Written by Mandy TLS Offshore Containers is proud to offer positively pressurized containers as a featured product in our range of functional containers. These containers are designed to create a safe and clean working environment for engineers or equipment operating in hazardous zones offshore. By maintaining a higher air pressure inside the container than the surrounding environment, positively pressurized containers prevent potential contaminants, such as dust, dirt, and hazardous gases, from entering the container. This helps to reduce the risk of explosions, fires, and other safety hazards, making them an important tool for ensuring worker safety. Positively pressurized containers are equipped with air-conditioning systems that regulate temperature and humidity levels, creating a comfortable and productive working environment for workers. They are also designed to be durable and reliable, even in harsh offshore environments. TLS Offshore Containers can customize positively pressurized containers to meet the specific needs of the project or application. These containers can be equipped with additional features, such as lighting, electrical outlets, and communication systems, to create a fully functional working environment for engineers or equipment. At TLS Offshore Containers, we take our responsibility to ensure the safety of workers and the environment seriously. Our positively pressurized containers are manufactured to meet the highest quality standards and safety regulations, ensuring that our clients receive a safe and reliable product. Overall, positively pressurized containers are an essential product for offshore projects. With the use of these containers, workers can operate with peace of mind, knowing that they are protected from potential safety hazards. TLS Offshore Containers is committed to providing these products to clients around the world, enabling them to carry out their projects safely and efficiently. TLS Offshore Containers' positively pressurized containers are versatile and can be used for a range of offshore applications, including as mud logging cabins, MWD (Measurement While Drilling) units, MCC (Motor Control Center) shelters, and lab containers. For mud logging, positively pressurized containers provide a safe and clean environment for technicians to analyze drilling mud samples, detect hydrocarbon gases, and monitor drilling parameters. In MWD applications, these containers protect sensitive electronic equipment from the harsh offshore environment and ensure that the data collected is accurate and reliable. MCC shelters protect motor control centers from environmental damage and provide a safe working environment for electricians. Lab containers are used for a variety of laboratory purposes, from chemical analysis to environmental monitoring. No matter the application, TLS Offshore Containers' positively pressurized containers are designed to maintain a safe and clean working environment for offshore engineers and equipment. By providing a higher air pressure inside the container, potential contaminants are kept out, and the air conditioning system regulates temperature and humidity levels, creating a comfortable and productive work environment. TLS Offshore Containers can customize positively pressurized containers to meet the specific needs of the project or application. These containers can be equipped with additional features, such as lighting, electrical outlets, and communication systems, to create a fully functional working environment for engineers or equipment. TLS Offshore Containers' positively pressurized containers meet the highest quality standards and safety regulations, ensuring that our clients receive a safe and reliable product. Contact us today to learn more about our range of functional containers and how we can help you to create a safe and productive working environment offshore. |

Archives

April 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|