|

Are you seeking unparalleled safety solutions for hazardous offshore environments? TLS presents a groundbreaking innovation: the Offshore Ex-Proof Positive Pressure Container. Engineered to thrive in Zone 1/2 areas, and compatible with ATEX/IECEx certified electrical equipment, these containers redefine safety standards in offshore operations. Join us as we explore the myriad advantages of TLS's cutting-edge containers and their transformative impact on offshore safety. Understanding Offshore Ex-Proof Positive Pressure Containers TLS's Offshore Ex-Proof Positive Pressure Containers are purpose-built for the rigors of offshore oil and gas exploration and production. Designed to mitigate the risks associated with hazardous environments, these containers offer a comprehensive solution for ensuring the safety of personnel and assets. Advantages of TLS Offshore Ex-Proof Positive Pressure Containers

Conclusion TLS's Offshore Ex-Proof Positive Pressure Containers represent the pinnacle of safety, reliability, and performance in hazardous offshore environments. With their Zone 1/2 compatibility, ATEX/IECEx certified electrical equipment compatibility, unparalleled safety features, durability, customization options, efficiency gains, and regulatory compliance, TLS's containers offer a comprehensive solution for offshore operations. Invest in TLS's Offshore Ex-Proof Positive Pressure Containers today and experience the peace of mind that comes with knowing your personnel and assets are protected in even the most challenging offshore conditions. Contact TLS to learn more about how their innovative containers can elevate your offshore operations to new heights of safety and efficiency. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Offshore #Ex-Proof #Positive Pressure Container #Hazardous Area #Zone 1 #Zone 2 #ATEX #IECEx #Safety #Reliability Written by OliverIntroduction: In the challenging environment of offshore operations, protecting precision equipment is paramount. The use of positive-pressure explosion-proof containers in ZONE 2 areas has emerged as a crucial safety measure. These containers are designed to ensure the safety of personnel and the integrity of sensitive equipment in potentially hazardous locations. In this article, we delve into the significance of positive-pressure explosion-proof containers and how they contribute to safeguarding precision equipment in offshore ZONE 2 environments. Understanding ZONE 2: In the context of hazardous areas in the oil and gas industry, ZONE 2 refers to locations where flammable gases or vapors are present, but not in sufficient quantities to be classified as ZONE 0 or ZONE 1. Despite the lower risk, these areas still demand strict safety measures to prevent accidents and protect critical assets. Positive-Pressure Explosion-Proof Containers: Positive-pressure explosion-proof containers are engineered to create a controlled environment that prevents the intrusion of hazardous gases or vapors. These containers maintain a higher internal pressure than the surrounding atmosphere, effectively containing any potential explosion within the unit. This proactive approach significantly reduces the risk of ignition and minimizes the impact on nearby equipment and personnel. Key Benefits:

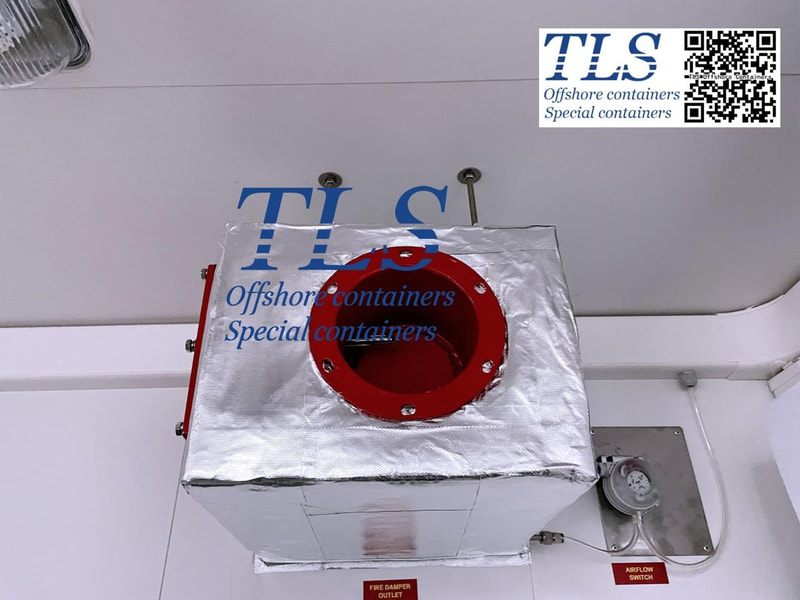

Conclusion: In conclusion, the use of positive-pressure explosion-proof containers in offshore ZONE 2 environments plays a pivotal role in safeguarding precision equipment. These containers not only enhance safety by containing potential explosions but also create a controlled environment that preserves the integrity and functionality of critical devices. As the offshore industry continues to evolve, investing in such safety measures becomes imperative to ensure the well-being of personnel and the longevity of precision equipment. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #Offshore ZONE 2 safety #Precision equipment protection #Hazardous area safety measures #Oil and gas industry safety #Controlled environment solutions #Explosion-proof container benefits #ZONE 2 compliance #Offshore equipment safeguarding #Precision equipment longevity #Explosion mitigation solutions #Offshore equipment maintenance #Precision equipment integrity Written by OliverIntroduction: Safety at sea is a paramount concern, and one of the critical challenges faced by vessels is the risk of onboard fires. In this comprehensive guide, we explore the importance of fire dampers in pressurized shipping containers, detailing why they are crucial and providing practical insights on their effective usage. Why Fire Dampers Matter for Pressurized Shipping Containers? Pressurized shipping containers are designed to maintain a controlled atmosphere, but this feature also heightens the risk of rapid fire spread. Fire dampers play a vital role in mitigating this risk, acting as a barrier against the accelerated spread of fire and smoke. Understanding their importance is key to safeguarding both the crew and cargo. How Fire Dampers Operate in Pressurized Shipping Containers? Fire dampers function by regulating airflow within the ventilation system of a pressurized container. In the event of a fire, these dampers automatically close, preventing the passage of smoke and flames through the ventilation system. This containment provides crucial time for the crew to respond effectively, minimizing the impact of the fire. Best Practices for Fire Damper Usage: To ensure the effectiveness of fire dampers, certain best practices should be followed:

Conclusion: In conclusion, fire dampers are indispensable safety components in pressurized shipping containers. By understanding their importance, functionality, and best practices for usage, this guide aims to contribute to enhanced safety measures at sea. Professional installation, regular testing, and crew training are essential for a safer and more efficient maritime operation. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter #Fire Dampers #Pressurized Shipping Containers #Maritime Safety #Ship Fire Prevention #Vessel Fire Control #Ventilation System Safety #Cargo Protection at Sea #Emergency Response Protocols #Maritime Regulations #Safety Equipment for Ships Written by OliverIntroduction In hazardous environments, safety is of paramount importance. Industries such as oil and gas, petrochemicals, and pharmaceuticals often operate in areas classified as ZONE 1 or ZONE 2, where the presence of flammable substances poses a risk. In these settings, the use of containers that are positively pressurized, following the guidelines outlined in the IEC60079-13 standard, becomes crucial. This article explores the reasons behind the necessity of positive pressurization for containers used in ZONE 1/ZONE 2 and highlights the benefits of implementing this safety measure. Understanding ZONE 1/ZONE 2 Classification Before delving into the significance of positive pressurization, it is essential to understand the classification of hazardous areas. ZONE 1 refers to an environment where flammable gases, vapors, or liquids are likely to be present in sufficient quantities to cause an explosion. ZONE 2, on the other hand, indicates an area where such substances are less likely to be present, but may still occur under abnormal conditions. The Role of Positive Pressurization Positive pressurization is a technique used to prevent the ingress of hazardous substances into a protected area. When applied to containers in ZONE 1/ZONE 2, it ensures that the pressure inside the container is maintained at a level higher than the surrounding atmosphere. This positive pressure acts as a barrier, preventing the entry of potentially explosive or flammable gases, vapors, or dust. Benefits of Positive Pressurization

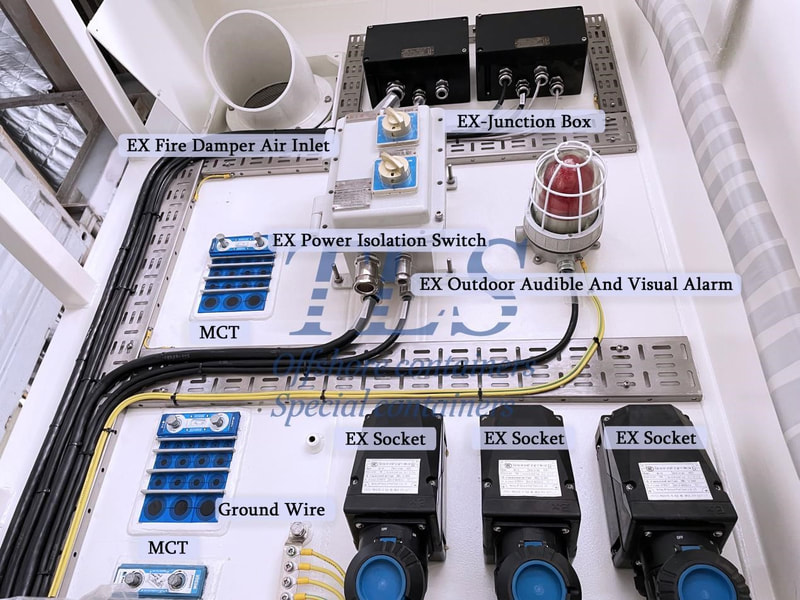

Conclusion Positive pressurization plays a vital role in maintaining a safe working environment in ZONE 1/ZONE 2 hazardous areas. By implementing this technique in containers, organizations effectively protect their personnel, equipment, and surroundings from the risks associated with flammable substances. The adherence to the IEC60079-13 standard ensures that these safety measures are in line with internationally recognized guidelines. Ultimately, the use of positively pressurized containers enhances safety, prevents the ingress of hazardous substances, and contributes to the overall well-being of industries operating in hazardous environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding Intelligent pressurized containers from TLS , please download Offshore pressurised mud logging cabin brochure and MCC | Switchgear | VFD | VSD pressurised shelter for reference. #Positive pressurization #ZONE 1/ZONE 2 containers #Hazardous environments #IEC60079-13 standard #Flammable substances #Safety measures #Hazardous areas #Explosions and fires #Contaminant exclusion #Equipment integrity Written by OliverIn hazardous environments such as offshore and land-based petroleum exploration, safety and reliability are paramount concerns. The A60 Positive Pressure Explosion-Proof Laboratory Container by TLS offers a reliable and customizable solution designed to meet the unique needs of these challenging environments. Designed for Hazardous Environments: The A60 Positive Pressure Explosion-Proof Laboratory Container is specifically designed to withstand extreme conditions, making it suitable for use in dangerous areas. With its sturdy construction and adherence to industry standards such as IEC60079-13, DNV2.7-1, and SOLAS 2009, this container provides a high level of safety and reliability. Versatility and Environmental Protection: Operating efficiently within a temperature range of -25°C to +50°C, this container offers versatility in various environments. Its excellent sealing properties provide protection against rain and sand, ensuring the safety and integrity of the equipment housed inside. Integrated Safety Systems: The A60 Positive Pressure Explosion-Proof Laboratory Container features a comprehensive array of integrated safety systems. These include the CPFG control cabinet, positive pressure air system, explosion-proof centrifugal fans, safety power supply system, fire alarm system, lighting system, alarm system, explosion-proof air conditioning, air valve control system, and explosion-proof isolation switchgear. These systems work together to create a safe working environment, providing peace of mind for operators. Customization for Specific Needs: TLS understands that each customer's requirements may vary. As a result, they offer customized solutions tailored to individual needs. With their expertise and attention to detail, TLS ensures that the container meets the specific demands of the customer's operations and safety standards. From design to construction, every aspect is closely monitored to guarantee a high-quality, personalized solution. Key words:#ZONE1 #ZONE2 #A60 #DNV2.7-1 #CPFG #TLS #LAB CONTAINER #pressurised #ATEX #IECEx #offshore CARBIN #workshop container In today's modern society, the comfort and well-being of employees in the workplace have become increasingly important. With advancements in technology and innovation, new solutions for office spaces have emerged. Among them, positive pressure office containers have gained popularity.

Construction Sites: They provide temporary office spaces for construction teams, enabling efficient coordination and management with a comfortable working environment and superior air quality. Exhibitions and Event Venues: These containers serve as temporary display and office spaces, catering to exhibitions, events, conferences, and trade shows. They can be quickly deployed, offering exhibitors and organizers a comfortable, clean, and safe workspace. Temporary Projects and On-Site Offices: They are ideal for temporary projects and on-site work requirements. The mobility and flexibility of positive pressure office containers allow for easy relocation, providing isolated and secure office spaces for industries such as mining, energy, and surveying. Disaster Recovery and Emergency Response: Positive pressure office containers play a vital role in post-disaster recovery and emergency response efforts. They can be rapidly deployed to disaster-stricken areas, serving as safe, comfortable workspaces for government agencies, rescue organizations, and volunteers. Creative Workspaces: Positive pressure office containers offer innovative design possibilities for creative workspaces. By incorporating personalized decoration and design elements, these containers create unique and comfortable environments suitable for creative industries, design studios, and artist studios. Positive pressure office containers offer flexibility, mobility, and multifunctionality, making them suitable for various settings and needs. They provide comfortable, clean, and secure office spaces in different work scenarios, resulting in improved efficiency and employee satisfaction. Whether it is for temporary projects, construction sites, exhibitions, emergency response, or creative workspaces, positive pressure office containers represent an innovative solution for modern workplaces, prioritizing employee well-being and productivity. Introduction: Working in hazardous areas presents a unique set of challenges that require specialized equipment to ensure the safety of personnel and the surrounding environment. Positive Pressure Containers have emerged as an innovative solution to address these challenges effectively. This article explores how Positive Pressure Containers offer a safe and cost-effective means of operation in hazardous areas, reducing risks and enhancing efficiency.

Conclusion: Positive Pressure Containers offer a comprehensive solution for safe and cost-effective operations in hazardous areas. By establishing a controlled atmosphere, Positive Pressure Containers mitigate the risks associated with explosive environments, protecting workers and equipment from potential harm. Additionally, these containers contribute to increased efficiency by minimizing downtime, reducing repair costs, and enhancing overall productivity. As industries continue to prioritize worker safety and operational excellence, the adoption of Positive Pressure Containers represents a valuable investment in ensuring safe and efficient operations in hazardous environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding Intelligent pressurized containers from TLS , please download Offshore pressurised mud logging cabin brochure and MCC | Switchgear | VFD | VSD pressurised shelter for reference. Written by OliverA video takes you through the automatic mode operation of the 16ft positive pressure container5/30/2023

#Positive Pressure Container #DNV2.7-1 #IEC60079-13 #Automated Operation

Offshore oil and gas platforms are among the most hazardous work environments in the world, and the equipment used in these environments must meet strict safety standards. One of the key challenges in offshore oil and gas production is ensuring safe containment, transportation and storage in a flammable and explosive environment. This is where positive pressure containers come into play. Positive pressure containers are designed to maintain a positive pressure inside the container at all times, preventing flammable or explosive gases from entering the container and creating a potentially dangerous environment. These containers are typically made from high-grade materials that are resistant to corrosion, extreme temperatures, and other environmental factors. TLS Offshore Containers is a leading manufacturer of positive pressure containers for use in offshore oil and gas production. Our containers are designed and manufactured to meet the highest safety standards and are widely used by some of the world's largest oil and gas companies. So, why do flammable and explosive hazardous areas, especially offshore oil and gas platforms, need positive pressure containers designed and manufactured by TLS Offshore Containers? The answer lies in the unique challenges posed by these environments. Offshore oil and gas platforms are exposed to a wide range of environmental factors, including saltwater, wind, and extreme temperatures. This can create significant challenges when it comes to storing and transporting hazardous materials. Positive pressure containers are designed to withstand these environmental factors and maintain a safe environment for workers. In addition to environmental factors, offshore oil and gas platforms are also exposed to a wide range of potential hazards, including fires, explosions, and leaks. Positive pressure containers are designed to minimize these risks by preventing flammable or explosive gases from entering the container and creating a potentially dangerous environment. TLS Offshore Containers has been designing and manufacturing high-quality containers for use in offshore oil and gas production for many years. Our containers are designed to meet the highest safety standards and are rigorously tested to ensure they can withstand the unique challenges posed by offshore environments. In conclusion, positive pressure containers designed and manufactured by TLS Offshore Containers are essential for ensuring the safety of workers in flammable and explosive hazardous areas, especially offshore oil and gas platforms. These containers are designed to withstand a wide range of environmental factors and potential hazards, and are crucial for maintaining a safe work environment in one of the world's most dangerous industries. Wherever you are in the world TLS can help you, please contact us. #Flammable and explosive hazardous areas #Positive pressure containers #Offshore oil and gas platforms #Environmental factors #Corrosion resistance #Extreme temperatures Written by Oliver#positive pressure, #blast-proof container, #hazardous area, #ventilation system, #ducts, # flammable gas, enclosure, alarm system,

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|