|

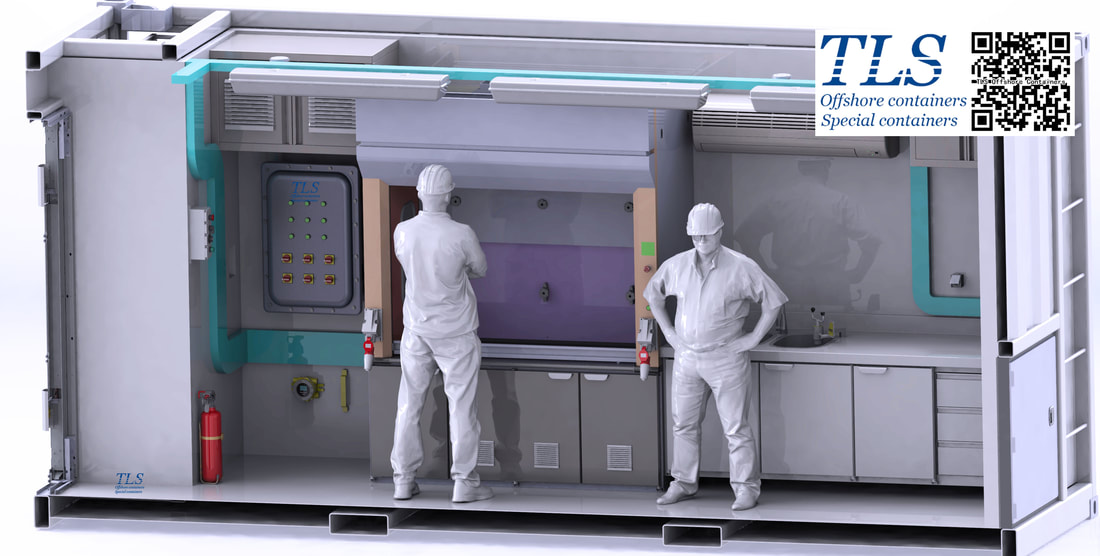

Introduction In the world of offshore research and exploration, safety and precision are paramount. Enter TLS's negative pressure offshore lab containers – innovative solutions designed to create controlled environments for scientific work on oil rigs, vessels, and other offshore platforms. In this blog post, we'll delve into the benefits, features, and applications of these cutting-edge containers. The Importance of Negative Pressure in Offshore Labs Negative pressure environments are crucial for:

TLS's Negative Pressure Lab Containers: Setting the Standard TLS is a pioneer in offshore container technology, and their negative pressure lab containers stand out for several reasons:

Applications of TLS Negative Pressure Offshore Lab Containers These versatile containers are ideal for a wide range of offshore applications, including:

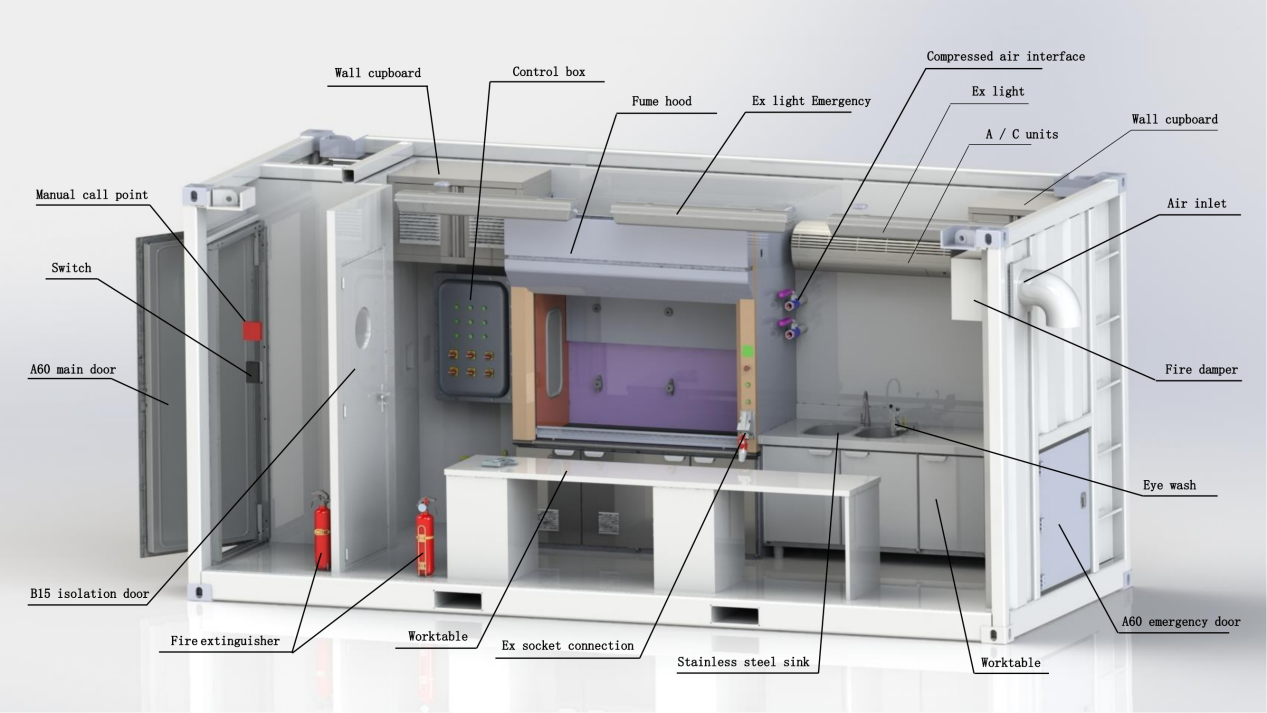

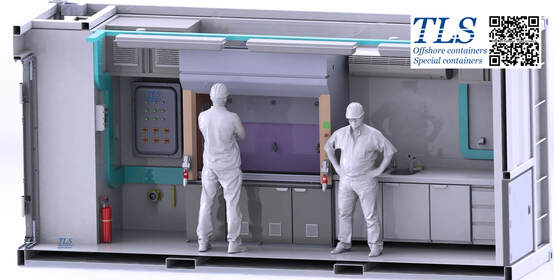

The Future of Offshore Research As offshore activities continue to expand, the demand for safe and reliable lab spaces will only grow. TLS is at the forefront of this movement, developing innovative solutions that empower scientists and researchers to push the boundaries of knowledge in challenging environments. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Keywords: #Negative pressure lab container #Offshore lab container #TLS lab container #Offshore research container #Oil rig lab container #Vessel lab container #Scientific container #Containment container #HEPA filtration container #Customizable lab container Written by OliverIn the realm of laboratory research, maintaining safety and preventing substance leaks are paramount concerns. Negative pressure laboratory containers offer an innovative solution by creating a controlled environment that prevents hazardous materials from escaping into the surrounding area. However, the safety of the external environment becomes crucial for the proper functioning of negative pressure laboratory containers. Any potential presence of hazardous substances or contaminants in the external environment can impact the operation of these containers and compromise experimental integrity. Ensuring Safety of the External Environment: When selecting the environment for implementing negative pressure laboratory containers, ensuring the safety of the external surroundings is of utmost importance. This process involves carefully selecting suitable locations, conducting assessments of the surrounding environment's safety, and implementing necessary protective measures to prevent the ingress of external pollutants. Training for Personnel: Personnel involved in the operation of negative pressure laboratory containers should receive comprehensive training to understand proper usage and maintenance protocols. This ensures their competence in operating and maintaining the containers, leading to the containers' effective functioning, optimal safety, and reliability. TLS Container Configuration: TLS offers negative pressure containers equipped with two fans - a small fan for normal operation and a large fan for emergency situations. When either fan is activated, it creates a negative pressure environment inside the container. In normal mode, when only the small fan in the ventilation cabinet is operating, the internal pressure ranges from -30 to 40 Pa, ensuring regular ventilation within the container. In case of low-level alarms triggered by combustible gases or H2S, the external fan automatically activates, resulting in an internal pressure of approximately -130 Pa, signifying an emergency state. The system automatically shuts off the external fan when the gas concentration falls below the set threshold. However, if the gas concentration does not decrease, a high-level alarm for combustible gases or H2S is triggered. After a 10-second alarm period, the container's power supply is disconnected as a safety precaution. The safety of the external environment is a crucial aspect when implementing negative pressure laboratory containers. By ensuring the external surroundings are secure, the containers can effectively prevent substance leaks and safeguard experimental outcomes. Adequate training for personnel and adherence to safety protocols further enhance the containers' functionality and protect the well-being of both personnel and the environment. For any inquiries or further information regarding negative pressure containers, please feel free to contact us. In the ever-evolving world of offshore oil and gas exploration, Floating Production Storage and Offloading units (FPSO) have emerged as a popular and flexible solution. These vessels allow companies to extract hydrocarbons from deep-sea fields, store them onboard, and transfer them to tankers for transportation to onshore facilities. However, the unique challenges of operating in a confined and hazardous environment have driven the need for advanced safety measures. One such innovation is the implementation of Negative Pressure Laboratories onboard FPSOs. In this article, we explore the significance of Negative Pressure Laboratory and how they contribute to the overall safety and efficiency of FPSO operations.

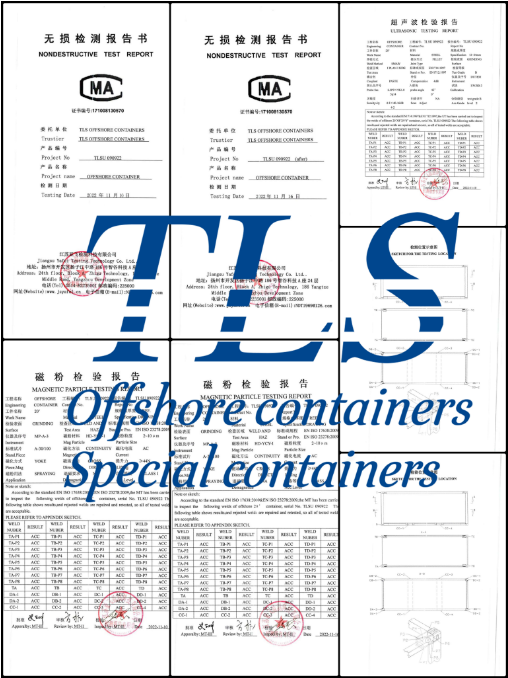

Conclusion As FPSOs continue to play a vital role in offshore oil and gas production, the importance of maintaining the highest safety standards cannot be overstated. Negative Pressure Laboratories represent a significant step forward in ensuring the well-being of onboard personnel, the protection of the marine environment, and the efficient operation of these complex vessels. By containing potentially hazardous materials and gases within a controlled environment, Negative Pressure Laboratory exemplify the industry's commitment to safety and innovation in the pursuit of sustainable energy resources. As technology advances and safety protocols evolve, Negative Pressure Laboratory are poised to become an indispensable component of FPSO operations in the future. TLS Offshore Containers offers professional design and manufacturing services for customized lab containers to suit specific locations and requirements. We welcome any inquiries and are ready to assist you in creating your ideal laboratory environment. Please contact us for any inquiries or to discuss your unique needs. #Negative Pressure Laboratories #FPSOs (Floating Production Storage and Offloading units) #Offshore oil and gas exploration #Safety measures #Hazardous materials #Explosive containment #Flammable substances #Toxic gas handling #Environmental protection #Marine ecosystem Written by OliverPressurized containers are specialized enclosures designed to maintain a safe and controlled environment for personnel and equipment. TLS, a company registed in Singapore with factories in China, specializes in the design and manufacturing of pressurized containers for a wide range of applications, including lab containers, mud logging cabins, MWD (Measurement While Drilling) systems, MCC (Motor Control Center) shelters, and other types of equipment used in the oil and gas industry. One of the key components in TLS's pressurized containers is the CPFG (Combined Pressure, Fire, and Gas) system. This system is critical for ensuring the safety of personnel and equipment by providing protection against pressure-related hazards, such as overpressure or vacuum conditions, as well as fire and gas hazards, such as combustible or toxic gases that could be released in the event of a leak. The CPFG system is designed to automatically release excess pressure, suppress fires, and detect gas leaks to minimize the risk of accidents and ensure a safe working environment. TLS's pressurized containers are widely used in the oil and gas industry, and are in high demand by companies such as ADNOC, Petrobras, and Halliburton, etc. These containers are designed to meet the strict safety and performance standards required by the industry, and are often customized to meet the specific needs of each customer. The containers are typically equipped with a range of specialized equipment and systems, including ex-proof air conditioners, fire dampers rated at A60, and other safety features. In addition to their use in the oil and gas industry, pressurized containers from TLS are also used in a wide range of other applications, including scientific research, military operations, and emergency response situations. These containers are designed to provide a safe and reliable environment for personnel and equipment, even in the most challenging conditions. Overall, pressurized containers from TLS are an essential component in many industries, and the inclusion of a CPFG system is critical for ensuring the safety of personnel and equipment. With their high quality and customizable designs, these containers are in high demand by companies around the world. In a laboratory, it is essential to maintain a controlled environment to ensure accurate results and prevent the contamination of samples. One of the ways to achieve this is by using a container with negative pressure. Negative pressure, also known as a vacuum, is a process that reduces the air pressure inside a container to a level that is lower than the outside atmospheric pressure. Negative pressure is created using a mechanical device, such as a vacuum pump, that removes the air molecules from the container. The vacuum pump creates a vacuum by reducing the pressure inside the container below the pressure outside the container. This creates a pressure differential, which forces air from outside the container to flow into the container, and not the other way around. Negative pressure is often used in laboratory containers to prevent the release of hazardous materials or biological agents. This process is called containment. A container with negative pressure can prevent the release of harmful substances by ensuring that the air pressure inside the container is lower than the pressure outside. This prevents the air from flowing out of the container and carrying the hazardous material with it. In addition to containment, negative pressure is also used in laboratory containers to prevent contamination. Contamination can occur when particles, such as dust or microorganisms, enter the workspace and settle on surfaces or samples. Negative pressure can prevent contamination by pulling in clean air from outside the container and filtering it before it enters the workspace. This creates a clean environment that is free from contaminants. Negative pressure can also be used in laboratory containers to control the temperature and humidity of the workspace. The vacuum pump can remove moisture from the air, which can prevent the growth of microorganisms. This can be particularly important in a laboratory where humidity can impact the outcome of experiments. In conclusion, negative pressure is a critical component of laboratory containers. It is used to contain hazardous materials, prevent contamination, and control the temperature and humidity of the workspace. A laboratory container with negative pressure can create a controlled environment that is essential for accurate results and the safety of laboratory personnel. Understanding how negative pressure works is an essential part of laboratory safety and experimentation. Written by OliverOffshore research has become an important part of modern science, providing valuable insights into the ocean environment and its impact on the planet. However, conducting research in remote and challenging offshore locations can be difficult due to a lack of proper infrastructure. That's where offshore laboratory containers come in as a solution. An offshore laboratory container is a modular and transportable unit designed specifically for use in offshore environments. These containers are manufactured by companies like TLS Offshore Containers and are used by scientists, engineers, and researchers to conduct experiments, gather data, and analyze samples in remote locations. One of the key benefits of using an offshore laboratory container is its mobility. Unlike traditional laboratory structures, these containers can be easily moved from one location to another, making them ideal for use in areas where access is limited or conditions change frequently. Additionally, because they are designed to be used in harsh offshore environments, they are built to withstand extreme weather conditions, such as strong winds, heavy rain, and high waves. Another advantage of offshore laboratory containers is their versatility. They can be customized to meet the specific needs of each research project, making them suitable for a wide range of applications, including oceanographic research, environmental monitoring, and geotechnical studies. In terms of safety and efficiency, offshore laboratory containers are equipped with two overwhelming fans, which form negative pressure inside the container. This helps to withdraw flammable or toxic gases that may occur during experiments, ensuring the safety of the researchers and preventing the release of hazardous substances into the environment. The negative pressure inside the container also helps to maintain a clean and controlled environment for experiments. In addition to the overwhelming fans, offshore laboratory containers are also equipped with state-of-the-art technology, including specialized scientific instruments, communication systems, and power generation units. This allows researchers to work in the field with ease and efficiency, and to collect and analyze data in real-time. In conclusion, offshore laboratory containers are a safe and efficient solution for conducting research in remote and challenging environments. With their mobility, versatility, and advanced safety features, they provide a reliable and secure platform for scientists, engineers, and researchers to work and gather valuable data. If you are looking for a solution for your offshore research needs, consider an offshore laboratory container from TLS Offshore Containers. About offshore negative pressure lab container certified by DNV2.7-1 The basic principle of the negative pressure system is to keep the pressure of the environment inside the container lower than that outside, so that the toxic gas or flammable gas in the container will not be directly discharged from the it, and the negative pressure system captures dangerous and infectious particles in the air, and it is removed with a blower and a set of filters. The negative pressurized container provide by TLS typically has 2 fans, a small fan for normal mode and a large fan for emergency mode. When either fan is turned on, a negative pressure environment is formed inside. When only the small fan in the fume hood is turned on, the internal pressure is around -30~40Pa, and normal ventilation mode in the container; When the flammable gas/H2S low level alarm is triggered, the outdoor Ex-fan will automatically turn on, the internal pressure is around -130Pa and the container enter the emergency mood and it will automatically turn off when the gas concentration is lower than the set value. If the gas concentration does not decrease, the high-level alarm of flammable gas/H2S would sound, after the alarm lasts for 10 seconds, the power supply of the container will be cut off. Negative pressure is a safe sealing solution which is widely used in lab containers, Mud Labs, etc. Please download laboratory container brochure for reference. The regular production cycle of 20ft offshore negative pressure containers is around 3 months after order is confirmed. Those lab containers are specially designed and manufactured for Abu Dhabi National Oil Company (ADNOC).

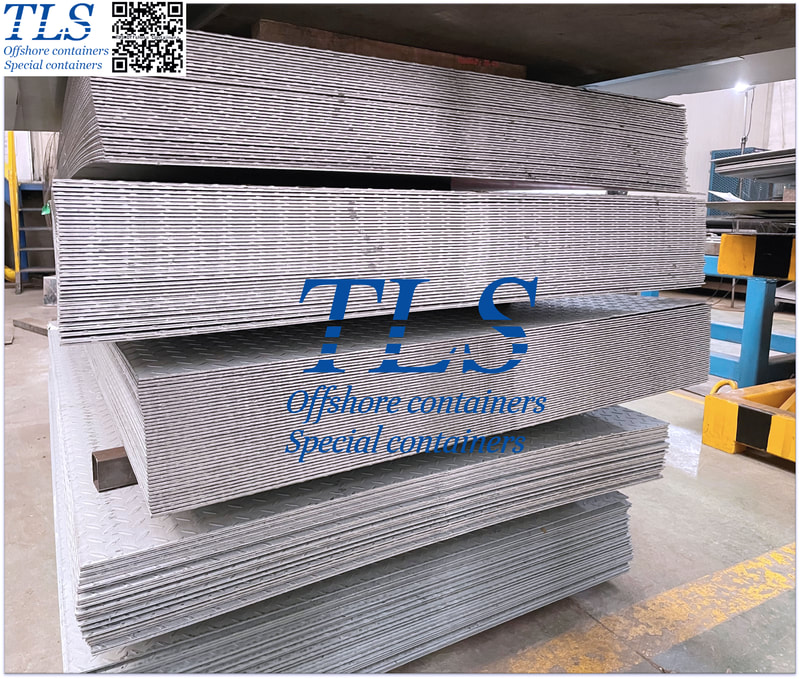

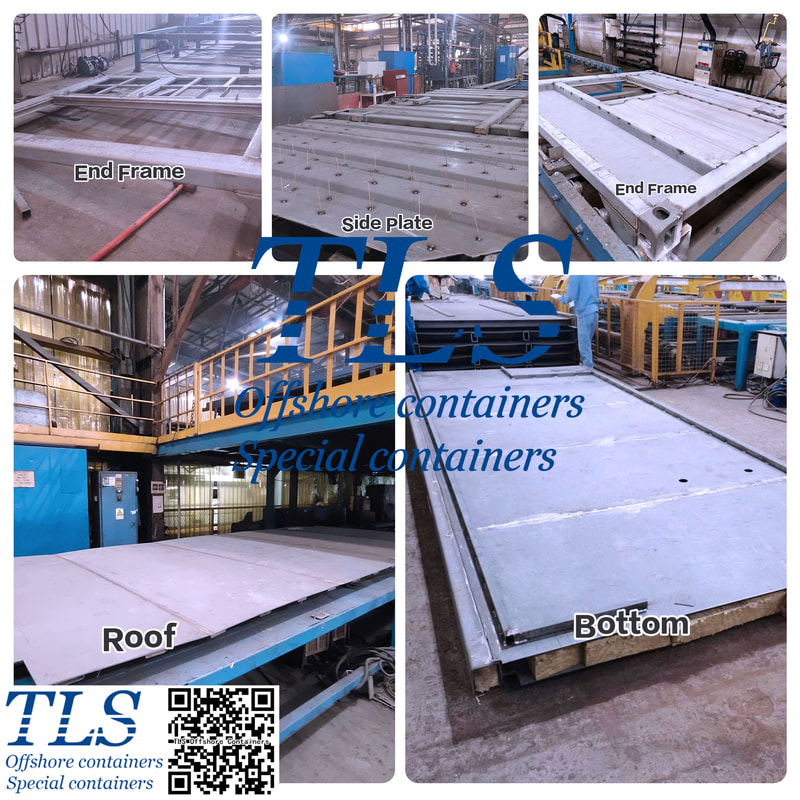

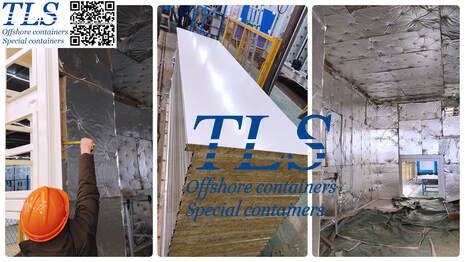

Container shell Production 1.Plate and Section Steel Pretreatment 2.Stamping 3.Welding Prefab 4.Bottom, End Frame, Top Side Production 5.Main Assemble 6. NDT for the welds (Certificate issued by a third-party inspection agency) 7. Painting (Ivory, C3 paint system, suitable for harsh offshore environment) 8. Structure Adjustment(Although the production drawings have been confirmed before the official production, we also fully support the changes proposed by the customer during the production process to avoid delivery delays and higher additional costs.) Container Interior Decoration 1.A60 Rock-wool Laying and Aluminum Film Tape Pasting 2. Stainless Steel Pipe Embedded for Waterway 3. Laying of Auxiliary Materials at The Bottom of The Container 4. PVC trunking/metal tie plate fixing, Cable laying, Hardware installations 5. Floor leather /Equipment and furniture/Door/ Air conditioner cover installation and circuit debugging 6. FAT (Final Analysis Test) including appearance inspection,insulation resistance test,function check The basic principle of the negative pressure system is to keep the pressure of the environment inside the container lower than that outside, so that the toxic gas or flammable gas in the container will not be directly discharged from the it, and the negative pressure system captures dangerous and infectious particles in the air, and it is removed with a blower and a set of filters.

The negative pressurized container provide by TLS typically has 2 fans, a small fan for normal mode and a large fan for emergency mode. When either fan is turned on, a negative pressure environment is formed inside. When only the small fan in the fume hood is turned on, the internal pressure is around -30~40Pa, and normal ventilation mode in the container; When the flammable gas/H2S low level alarm is triggered, the outdoor Ex-fan will automatically turn on, the internal pressure is around -130Pa and the container enter the emergency mood and it will automatically turn off when the gas concentration is lower than the set value. If the gas concentration does not decrease, the high-level alarm of flammable gas/H2S would sound, after the alarm lasts for 10 seconds, the power supply of the container will be cut off. Negative pressure is a safe sealing solution which is widely used in lab containers, Mud Labs, etc. Negative air pressure is a safe containment solution in which more air is taken in than is expelled.

Negative air pressure in the environment does not mean that the actual pressure is negative because, according to science, absolute pressure can never be less than zero. Negative air pressure means that the pressure within an environment is less than the pressure of its surroundings. As air flows from high pressure to low pressure, this difference in pressure level acts as a vacuum effect and causes air to flow in from the outside. The negative air system produces a vacuum effect or a direction of air flow into the space by creating and maintaining the air pressure differential. In doing so, it restricts the spread of contaminants such as dust and mould and pollutants such as bacteria and viruses from the controlled space to the outside. This system traps dangerous and infectious particles in the air and removes them by means of a blower and a group of filters. In summary, when the external environment is safe, but toxic and harmful gases are generated inside, negative pressure is preferred • Modular Petroleum Laboratory • Laboratory container / cabin • Blast Resistant Container, Blast proof Container • Mud Lab What is negative pressure? When the exhaust air volume in the space is greater than the air intake volume, the space is in a negative pressure state, the air outside flows into the interior and is discharged through the exhaust outlet for centralized treatment. When to choose negative pressure? When the external environment is safe, but toxic and harmful gases are generated inside, negative pressure is preferred.

NEGATIVELY PRESSURISED CONTAINERS PROVIDED BY TLS

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|