Unveiling the Trend of Modular Solutions: Revolutionizing Industries with Containerization12/15/2023

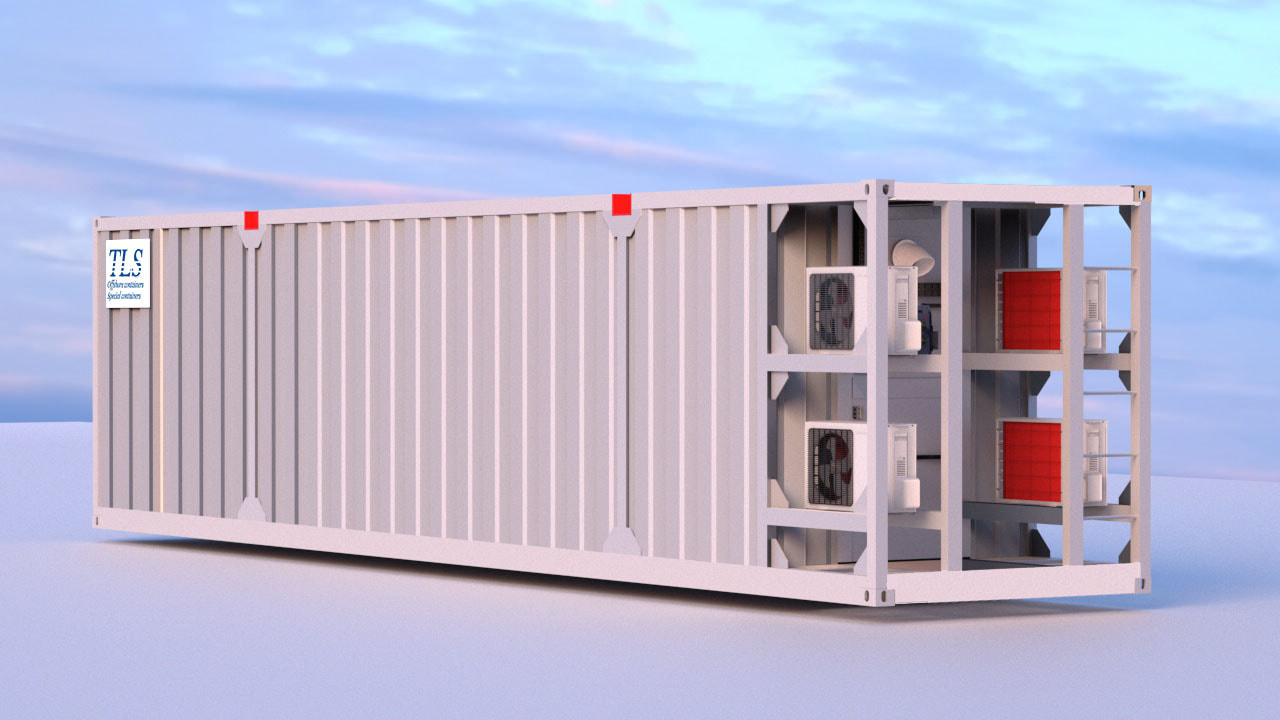

In the last few decades, traditional containers have been the backbone of goods transportation, providing an efficient and reliable solution for global trade. However, as technology advances and societal needs evolve, the usage of containers is undergoing a revolutionary change. Modern businesses are increasingly opting for containerized modular solutions, a design that brings new possibilities and opportunities across various industries. Traditional Containers: The Sturdy Pillar of Goods Transportation Traditional containers, constructed from robust steel, have long been renowned for their standardization, reliability, and efficiency in the realm of cargo transportation. While excelling in maritime, rail, and road transport, the traditional container design did not fully address the needs of other industries. Containerized Solutions: The Multifaceted Future The demand for flexibility, mobility, and sustainability in modern society is propelling the rise of containerized solutions. This innovative modular design goes beyond the limits of traditional containers, offering diverse choices and opportunities for different sectors. Diverse Application Scenarios

Advantages of Containerized Solutions

Key words: #Dry Containers #Flat Rack Containers #Open Top Container #Tunnel Container #Side Opening Container #Tank #Half Height Containers #Cutting Skip #Reefer Container #Refrigerated Container #Positive Pressure Container #Negative Pressure Container #Energy Storage System (#ESS) #Lab Container|Workshop Container #Accommodation Container #Temporary shelter #Temporary #refuge shelter ( #TR) #Sewage Treatment Container Introduction: When it comes to offshore containers, the lifting lugs play a critical role in ensuring safe and efficient lifting operations. Meeting strict requirements is crucial for their design and functionality. In this article, we will explore the key requirements for offshore container lifting lugs, keeping in mind the challenging offshore environment and the need for optimal performance. Section 1: Design Considerations for Lifting Lugs

Section 2: Alignment and Stability

Section 3: Optimal Lifting Lug Configuration

Section 4: Compatibility with Shackles

Section 5: Structural Integrity and Material Considerations

Section 6: Welding and Connection Methods

Conclusion: Complying with the strict requirements for offshore container lifting lugs is vital for safe and efficient lifting operations in challenging offshore environments. By understanding and implementing these essential guidelines, you can ensure the reliability, stability, and structural integrity of lifting lugs, promoting successful and secure lifting operations for offshore containers. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #Offshore containers #Lifting lugs #Design requirements #Harsh environment #Safety #Efficiency #Entanglement prevention Written by OliverIntroduction: Are you interested in understanding the production process of top-notch offshore containers? In this article, we will guide you through the essential steps and requirements for creating high-quality TLS offshore containers. From welding and structural integrity to insulation, interior paneling, and final testing, we'll cover it all. Let's dive in! Section 1: Welding and Structural Integrity To ensure robust structural integrity, all primary welds of the container frame must be performed by a certified welder. These experts employ full penetration welding techniques, guaranteeing the container's strength. Additionally, third-party inspections are conducted to verify the weld quality. Once approved, the container is painted using marine-grade coatings suitable for harsh offshore environments. Section 2: Floor Installation for Durability The floor installation process is critical for creating a durable offshore container. It begins with the laying of calcium silicate plates on the lower deck, followed by the installation of fixed steel mesh. Then, the upper deck dressings and floor dressings are carefully placed, guaranteeing a smooth surface. Quality inspectors assess and approve the floor's flatness to meet professional standards. Section 3: Insulation for Optimal Performance Efficient insulation is crucial to maintaining a comfortable and safe environment within the offshore container. During the production process, insulation material, such as rock wool, is meticulously laid in designated areas. Adequate overlap length and fireproof tape ensure proper insulation coverage and enhanced fire resistance. Section 4: Pipe, Air, and Cable Tray Installation Proper installation of water pipes, air pipes, and cable trays is essential to ensure the functionality of the offshore container. Insulation is pre-laid, and supporting booms are positioned on the top plate to secure and align the pipes accurately. This meticulous process guarantees a reliable and efficient system for water, air, and electrical needs. Section 5: Interior Paneling for a Polished Look Installing interior trim wall panels adds both aesthetics and functionality to the offshore container. First, the fixing slots are prepared, followed by the careful installation of the inner panels. Prior to installation, surfaces are thoroughly inspected to ensure smoothness and flatness, while neat and straight splicing gaps create a polished appearance. Section 6: Furniture and Appliance Installation Properly installed and secured furniture and appliances contribute to a comfortable offshore living or working space. In accordance with preliminary design drawings, furniture is positioned accordingly. Qualified professionals handle the construction of power connections, adhering to regulations and undergoing inspections to guarantee safe and reliable operations. Section 7: Testing and Acceptance TLS places great importance on the quality of their offshore containers. Various acceptance methods, including on-site inspections, video inspections, and graphic inspections, are offered to clients. Containers are shipped only after passing these rigorous acceptance procedures, ensuring the highest standards of quality. Conclusion: By adhering to stringent production processes and requirements, TLS manufactures high-quality offshore containers. From skilled welding and structural integrity to precise floor installation, insulation, pipe and cable tray installation, interior paneling, furniture and appliance setup, and thorough testing and acceptance, every step is carefully executed to deliver reliable and durable offshore containers. Trust TLS for your offshore container needs. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #High-quality offshore containers #Production process #Requirements #Welding #Structural integrity #Marine environment #Floor installation #Insulation Written by OliverDNV 2.7-1 Certified Offshore Containers: Ensuring Safety and Efficiency in the Oil and Gas Industry5/4/2023

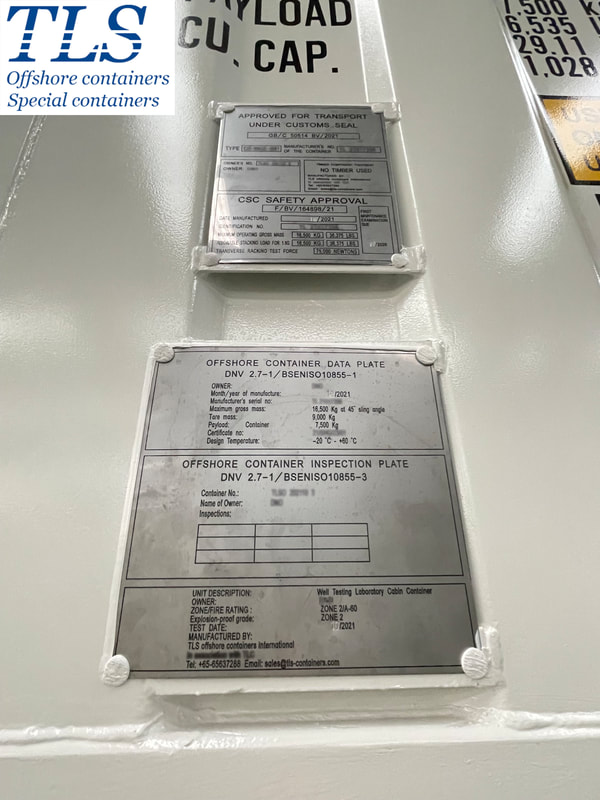

The oil and gas industry is one of the most challenging and demanding industries in the world. Operating in harsh offshore environments, the industry requires equipment and infrastructure that can withstand extreme conditions while ensuring the safety of personnel and the environment. This is where DNV 2.7-1 certified offshore containers come into play. DNV 2.7-1 is a globally recognized standard for offshore containers, developed by the international certification body Det Norske Veritas (DNV). The standard specifies the requirements for design, manufacture, testing, inspection, and certification of offshore containers for use in the oil and gas industry. DNV 2.7-1 certified offshore containers are designed to meet the highest standards of safety, quality, and efficiency. These containers are built to withstand harsh weather conditions, heavy loads, and rough handling during transport and lifting. They are also designed to protect personnel and equipment from hazards such as fire, explosion, and impact. One of the key benefits of DNV 2.7-1 certified offshore containers is their versatility. These containers can be used for a wide range of applications in the oil and gas industry, including storage, transportation, and accommodation. They can be customized to meet specific requirements, such as the need for temperature control, hazardous material storage, or equipment protection. DNV 2.7-1 certified offshore containers are subject to rigorous testing and inspection procedures to ensure compliance with the standard. This includes testing for structural strength, water-tightness, fire resistance, and lifting capacity. Only containers that meet these requirements and are certified by an accredited certification body are allowed to be used in the offshore industry. Using DNV 2.7-1 certified offshore containers can help companies to reduce risk, improve safety, and increase efficiency in their operations. By using certified containers, companies can ensure that their equipment and personnel are protected from hazards and that their operations comply with industry standards and regulations. In conclusion, DNV 2.7-1 certified offshore containers play a critical role in ensuring the safety and efficiency of operations in the oil and gas industry. These containers are designed and tested to meet the highest standards of quality and safety, and their versatility makes them ideal for a wide range of applications. By using certified containers, companies can minimize risk and improve the overall performance of their operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #DNV 2.7-1 #offshore containers #oil and gas industry #risk reduction #structural strength #water-tightness #fire resistance Written by OliverExplosion-proof offshore containers are an essential part of offshore oil and gas operations. These containers are designed to withstand harsh environmental conditions and prevent explosions from occurring, thereby ensuring the safety of personnel and equipment. One important feature of these containers is the fire suppression system, which is critical in preventing fires from spreading and causing extensive damage. Fire suppression systems in explosion-proof offshore containers are designed to quickly detect and extinguish fires. These systems typically consist of a network of fire detection sensors, which are strategically placed throughout the container. When a fire is detected, the system will trigger an alarm and release the fire suppression agent. The most commonly used fire suppression agents in explosion-proof offshore containers are foam and dry chemical. Foam fire suppression systems are effective at extinguishing fires by smothering the flames and cooling the surface of the material. Dry chemical fire suppression systems, on the other hand, work by interrupting the chemical reaction of the fire, thereby preventing it from spreading. When designing fire suppression systems for explosion-proof offshore containers, there are several factors to consider.

In conclusion, fire suppression systems are an essential part of explosion-proof offshore containers. These systems are designed to quickly detect and extinguish fires, thereby ensuring the safety of personnel and equipment. When designing these systems, it is important to consider factors such as fire detection, release systems, and environmental conditions to ensure their effectiveness. By incorporating these features, explosion-proof offshore containers can provide a safe and reliable environment for offshore oil and gas operations. Written by OliverOffshore container shell insulation is an essential aspect of maintaining the integrity and safety of offshore operations. These containers are used to store and transport materials and equipment to and from offshore oil and gas rigs, wind farms, and other maritime facilities. In this article, we will explore the importance of offshore container shell insulation and how it can benefit offshore operators. What is offshore container shell insulation? Offshore container shell insulation refers to the process of insulating the outer shell of a container used in offshore operations. This insulation serves to protect the container and its contents from extreme temperature variations, humidity, and other environmental factors that can cause damage. The insulation material used for offshore containers is typically high-density polyurethane foam, which provides excellent insulation and protection against the elements. This material is lightweight, durable, and has excellent insulation properties, making it ideal for offshore container applications. Why is offshore container shell insulation important? Offshore container shell insulation is essential for several reasons. First and foremost, it helps protect the contents of the container from extreme temperature variations. Offshore operations often take place in harsh environments where temperatures can fluctuate drastically, and without proper insulation, the contents of the container can be damaged or destroyed. In addition to temperature protection, offshore container shell insulation also helps to protect against humidity and moisture. Offshore environments are often humid, and this can lead to corrosion and other forms of damage to the container and its contents. Insulation helps to prevent moisture from entering the container and damaging its contents. Furthermore, offshore container shell insulation also helps to reduce energy consumption. When containers are not properly insulated, they require more energy to maintain the desired temperature inside. This increased energy consumption can lead to higher costs and a greater environmental impact. By insulating offshore containers, energy consumption can be reduced, resulting in cost savings and a lower carbon footprint. Benefits of offshore container shell insulation The benefits of offshore container shell insulation are numerous. Here are some of the most significant advantages:

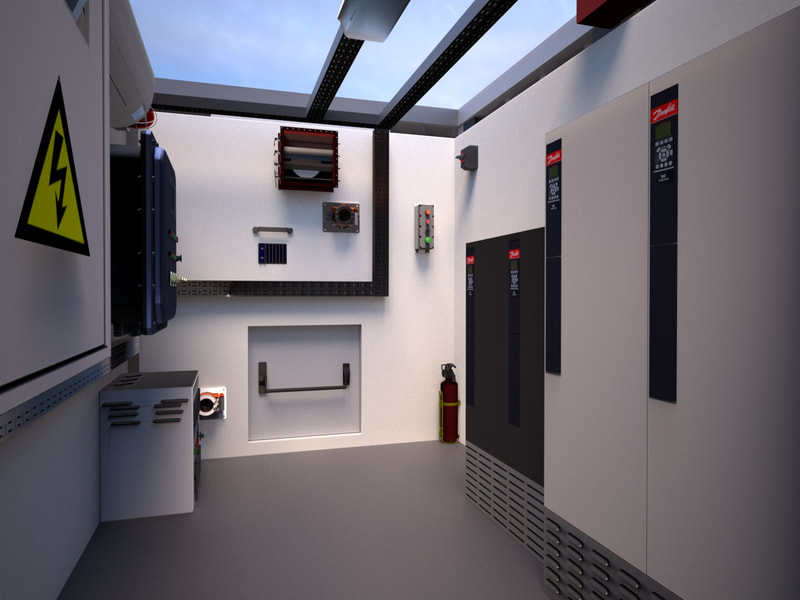

Conclusion: Offshore container shell insulation is a critical aspect of maintaining the integrity and safety of offshore operations. Insulating the outer shell of these containers helps protect against extreme temperature variations, humidity, and other environmental factors that can cause damage. The benefits of offshore container shell insulation include protecting the contents of the container, reducing energy consumption, enhancing the lifespan of offshore containers, improving safety, and ensuring compliance with industry regulations and standards. By investing in offshore container shell insulation, offshore operators can enjoy greater safety, efficiency, and cost savings in their operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Written by OliverOffshore container HVAC systems are a critical component of the oil and gas industry, providing essential temperature regulation, humidity control, and ventilation in offshore locations. What’s the importance of HVAC Systems in Offshore Containers? Offshore container HVAC systems are crucial in ensuring the safety and well-being of personnel working in offshore locations. These systems regulate the temperature within the container, preventing heat stress and hypothermia. They also control humidity levels, preventing corrosion and damage to equipment stored in the container.

Temperature regulation is also important for personnel working in offshore locations. Extreme temperatures can cause heat stress, leading to fatigue, nausea, and dehydration. On the other hand, low temperatures can cause hypothermia, which can be life-threatening.

Humidity control is also important for personnel working in offshore locations. High humidity levels can cause discomfort, making it difficult for workers to perform their tasks. Low humidity levels can cause dry skin, eye irritation, and respiratory problems.

Ventilation is particularly important when storing hazardous materials in the container. These materials can release harmful gases, which can be dangerous if inhaled. Proper ventilation can prevent the buildup of these gases, ensuring the safety of personnel working in the container. What’s the benefits of HVAC Systems in Offshore Containers? Offshore container HVAC systems offer several benefits, including energy efficiency, durability, and customization.

Energy-efficient HVAC systems use less energy to regulate the temperature within the container, which reduces the amount of fuel required to power the system. They also use advanced technologies such as variable speed drives, which adjust the speed of the system based on the temperature requirements. This reduces energy consumption and increases the efficiency of the system.

Durability is important in offshore locations where the environment can be unpredictable. Offshore container HVAC systems must be able to withstand the elements and continue to operate even in adverse conditions. This ensures that personnel working in the container are protected and that equipment stored in the container is safe from damage.

Customization is important in offshore locations where the needs of the company may vary depending on the project or location. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Writted by OliverOffshore container painting is a critical maintenance task that ensures the safety and longevity of offshore containers used in the oil and gas industry. Offshore containers are used to transport equipment, tools, and materials to and from offshore drilling rigs and other offshore structures. These containers are subject to harsh environmental conditions, such as saltwater, UV radiation, and extreme temperatures, which can lead to corrosion, damage, and deterioration over time. Therefore, offshore container painting is essential to protect the containers from these elements and prevent them from becoming a safety hazard. Offshore container painting involves the application of a high-performance coating system that is designed to withstand the harsh marine environment. The coating system includes a primer, intermediate coat, and topcoat, each with specific properties to ensure the optimal protection of the container. The primer is used to prepare the surface and provide adhesion for the intermediate coat, which provides further protection and durability. The topcoat is the final layer, which adds color and gloss to the container, as well as additional protection against UV radiation and other environmental factors. Offshore container painting offers several benefits that are crucial for the safety and durability of the containers. Some of these benefits include:

In conclusion, offshore container painting is an essential maintenance task that is crucial for the safety and longevity of offshore containers used in the oil and gas industry. By applying a high-performance coating system, companies can protect their containers from harsh environmental conditions, extend their lifespan, enhance their safety, and improve their appearance. Therefore, it is important for companies to invest in offshore container painting to ensure the optimal performance of their equipment and operations. Written by OliverThere are obvious differences between offshore containers and ordinary containers in terms of structural design, size and volume, usage, and safety requirements. They need to meet more stringent safety standards and regulations to ensure the safety of personnel and equipment. They must be expertly designed and tested to withstand the harsh offshore environment and extreme weather conditions. At the same time, offshore containers also need to meet the safety standards and regulations of international maritime transportation. Offshore containers have multiple functions, mainly including the following aspects: Storage of equipment and supplies: Offshore containers can be used to store a variety of equipment and supplies such as drilling equipment, tools, spare parts, fuel and food, etc. These materials usually need to be stored for a long time, so a reliable and safe storage space is required. Provide accommodation and offices: Offshore containers can be used to provide accommodation and office space, providing a comfortable and safe working and living environment for offshore workers. These containers are usually equipped with facilities such as air conditioning, toilets, showers and kitchens. Control and monitoring equipment: Offshore containers can also be used to place equipment control rooms, monitoring rooms and communication rooms, etc., to monitor the operating status of the platform, control equipment operation and communication, etc. Disposal of garbage and wastewater: Offshore containers can be used to treat pollutants such as garbage and wastewater generated by the platform to protect the marine environment and ecosystem. Offshore containers play an important role in the construction and operation of offshore facilities, which can improve work efficiency, ensure personnel safety and maintain the sustainability of the marine environment. TLS Offshore Containers is a global provider of standard and custom container solutions. No matter where you are, please feel free to contact us if you are interested in our products. E-mail: [email protected] Hotline: +65-65637288; +65-31386967 Written by Mandy The International Organization for Standardization (ISO) Container Technical Committee (ISO/TC104) has set specific conditions that containers must meet to be considered suitable for use. These conditions include:

Offshore containers have evolved from standard containers and are widely used in the offshore oil industry as supporting equipment. However, there are significant differences between standard and offshore containers in terms of their operating environments and lifting methods. Standard containers are typically transported by container liners to ports and secured using box guideposts or stacking fixings. In port terminals, they are hoisted using container cranes and twist lock devices. In contrast, offshore containers are exposed to the harsh marine environment and are subject to single-point lifting on supply vessels or oil platforms. They require higher structural strength and protection due to potential collisions with adjacent containers or hulls. Offshore containers are not allowed to be stacked on ships during transport, and stacking fixings are not used for lifting. The certification and production of offshore containers are subject to strict requirements compared to standard containers. The certification process includes evaluation and certification, manufacturing process inspection, and sample box testing, which involves four-point lifting, two-point lifting, inclination testing, and drop testing. During production, the material and welds of the main structure undergo rigorous quality control. Therefore, it is essential to differentiate and identify between standard and offshore containers in terms of procurement, design, display, and operation to better manage offshore container business. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

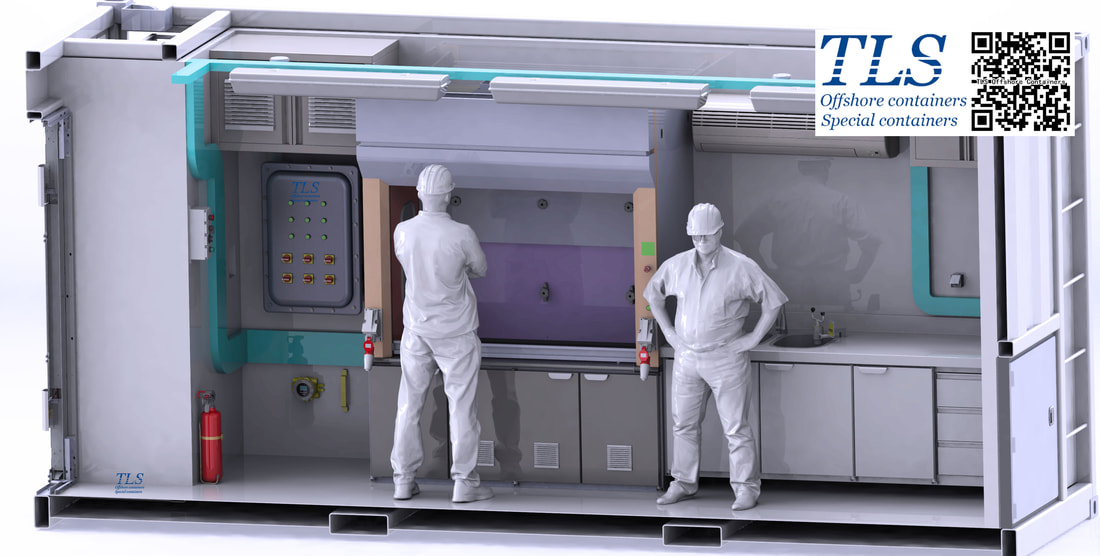

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|