|

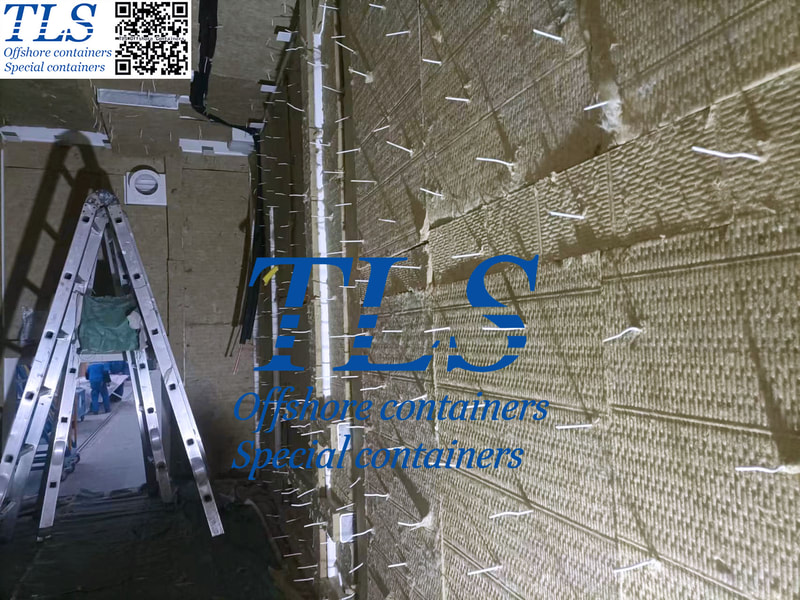

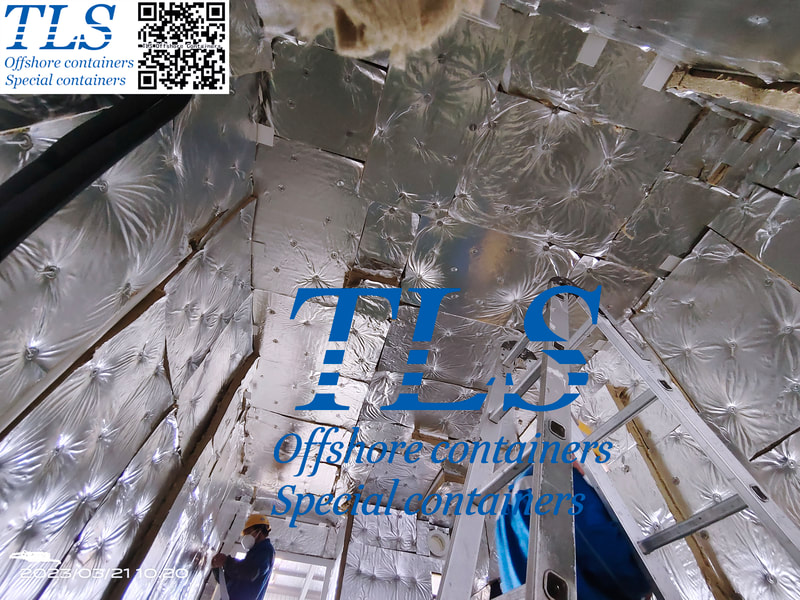

Container heat insulation and fire protection design refers to designing a set of heat insulation and fire protection system inside the container to protect the goods in the container from the influence of external temperature and fire. Commonly used insulation materials include rock wool, glass wool, polyurethane, etc., while fireproof materials include fireproof boards, fireproof coatings, etc. TLS offshore containers can meet the A60 fire protection standard and usually use rock wool as an insulating material, which is made of basalt or lava mineral fibers. It has the following characteristics: High temperature stability: rock wool can maintain stable insulation performance at high temperature, and can be used for thermal insulation of high temperature equipment. Good thermal insulation performance: rock wool has low thermal conductivity and high thermal insulation performance, which can effectively reduce energy loss and reduce energy consumption. Good fire performance: rock wool is a non-combustible material that will not burn or melt, and can effectively isolate the fire source and reduce the occurrence of fire. Good sound absorption performance: The fiber structure of rock wool can effectively absorb sound waves, reduce noise transmission, and improve indoor comfort. Environmental protection and health: rock wool products do not contain harmful substances, do not produce harmful gases, and are harmless to the environment and human health. Using rock wool as a container insulation material can provide good thermal insulation performance, fire performance, sound insulation performance and environmental protection performance. When designing the insulation scheme, factors such as insulation requirements, cost and durability need to be considered comprehensively to determine the appropriate thickness and density of rock wool, and attention should be paid to the installation of rock wool and compliance with relevant fire protection and environmental protection standards. In the heat insulation and fire protection design of containers, several aspects of design should also be considered: Designing the insulation and how to insulate: The location of the insulation and how to insulate need to be determined. Generally speaking, the heat insulation layer can be designed on the inner wall, roof and ground of the container. At the same time, you can choose to use double-layer structure or single-layer structure for heat insulation. Design fire protection layer and fire prevention method: need to determine the position and fire prevention method of fire protection layer. Generally speaking, the fireproof layer can be designed on the inner wall, roof and ground of the container. At the same time, you can choose to use fireproof boards, fireproof coatings and other materials for fire prevention. Fire protection system design: The design of the fire protection system needs to be taken into account. This includes fire water sources, fire sprinklers, smoke detectors, etc. Operator Safety: Operator safety needs to be considered. This includes things like lighting and ventilation systems inside the container. Container heat insulation and fire protection design is a complex project, which needs to consider multiple aspects such as heat insulation, fire protection, fire protection system and operator safety. During the design process, it is necessary to comprehensively consider factors such as the nature of the cargo inside the container, the characteristics of the container itself, and the budget to determine the most suitable heat insulation and fire protection scheme. Written by Mandy TLS Offers Offshore Lab Containers Built to DNV 2.7-1 Standards for Maximum Safety and Durability2/20/2023

TLS provides offshore lab containers that conform to the rigorous DNV 2.7-1 Standards for offshore use. These specialized lab containers are designed to withstand the challenging conditions of offshore environments, including exposure to saltwater, high winds, and extreme temperatures. The DNV 2.7-1 Standard is a certification requirement for all types of offshore containers used as transport units. This standard covers all aspects of offshore container design, including structural integrity, lifting points, ventilation, and access to the container. Containers designed and certified according to this standard possess enough strength to withstand the normal forces encountered in offshore operations and can withstand more extreme loads. There has been a growing demand for offshore mobile laboratories in recent years, particularly in the fields of research, environmental testing, and healthcare. Portable labs offer scientists and researchers the flexibility to conduct experiments and analyze samples in remote or hard-to-reach locations. Lab containers have become increasingly popular in this area. Offshore lab containers are converted shipping containers that can be customized to meet the user's specific needs, including specialized equipment, ventilation systems, plumbing, and electrical outlets. They can also include safety features, such as fire suppression systems and hazardous material containment. Offshore lab containers have the advantage of mobility, allowing them to be transported to any location via truck, train, or ship. This makes them particularly useful in remote areas where traditional laboratories may not be accessible. Lab containers are also cost-effective, as they can be delivered and set up in a matter of weeks, saving money and enabling researchers to begin their work sooner. Furthermore, lab containers are environmentally friendly, as they can be repurposed, reducing waste, and can be fitted with solar panels to reduce reliance on external power sources. TLS offshore lab containers are highly durable and equipped with specialized equipment and safety features to ensure maximum safety for personnel working in and around the lab. They are corrosion-resistant and able to withstand damage from the elements, with fire suppression systems and gas detection sensors installed to prevent accidents. In addition to their safety features, TLS offshore lab containers are highly customizable to meet the unique requirements of offshore research and experimentation. They can be designed with specialized equipment, lighting, and ventilation systems to meet the specific needs of offshore work. TLS offshore lab containers are an ideal choice for offshore applications in the oil and gas industry, providing maximum safety and durability for personnel and equipment in harsh offshore environments. These specialized lab containers offer maximum safety and durability, ensuring that experiments and analyses can be conducted safely and efficiently in remote offshore locations. Please download laboratory container brochure for reference. Safety and Efficiency for Offshore Operations with TLS Intelligent Pressurized Containers"2/18/2023

TLS Offshore Containers offers intelligent pressurized containers that are designed and constructed to meet the specific needs and requirements of the customer. The containers are designed to provide a safe environment for personnel and equipment, with built-in HVAC and power control systems. One of the key features of TLS intelligent pressurized containers is the incorporation of state-of-the-art safety monitoring systems. These include integrated fire and gas detection, pressurization and emergency shutdown systems, making them suitable for use in Zone 1/Zone 2 hazardous areas. This ensures that personnel and equipment are protected at all times, even in the most challenging environments. TLS intelligent pressurized containers are also designed for easy connection and rapid mobilization. The company is able to integrate data communication networks, fire suppression systems, air conditioning systems, and other systems to ensure that the container is ready for use as soon as it reaches its destination. The containers are designed, manufactured, and certified to the latest DNV 2.7-1, EN 12079 offshore container standards, ATEX, IEC 60079-13, and/or SOLAS standards, ensuring that they meet the highest industry standards and are built to withstand the harsh conditions of offshore operations. The design of the pressurized containers is based on a combination of engineering principles and customer requirements. The containers are typically designed using 3D modeling software, allowing the customer to visualize the design and make any necessary modifications. The containers are then manufactured using high-quality materials and state-of-the-art welding techniques to ensure maximum durability and longevity. Some of the main features of TLS intelligent pressurized containers include A60 or A0 passive fire protection, hazardous area ratings for Zone 1/Zone 2, and DNV 2.7-1/EN12079 structural design codes. The containers are also equipped with an intelligent combined pressurization fire and gas panel (CPFG), automatic fire dampers, and ex-proof pressurization fans. Other safety features include fire and smoke detectors, flammable gas detectors, and H2S detectors. In addition to safety features, TLS intelligent pressurized containers are also designed for easy installation and mobilization. The containers are equipped with air conditioning systems that are ATEX compliant or ex-proof, and they feature emergency lighting and automatic fire extinguishing systems. The containers are fully load/drop tested and are certified by the Container Safety Convention (CSC). TLS offshore pressurized containers are trusted by esteemed clients such as ADNOC, ENSP, Sonatrach, Halliburton, SNF, Perenco, and many others who demand the highest level of safety and efficiency for their offshore operations. With advanced safety features, easy installation and mobilization, and industry-standard certifications, TLS intelligent pressurized containers provide peace of mind and ensure the safety of personnel and equipment. Offshore container modules are primarily used to store and transport various materials and equipment during the operation of offshore platforms, including food and living materials, fuel chemicals such as oil and gas, tools, and spare parts for offshore operations, etc. It can also be used for temporary offices, workshops and living quarters to provide basic working and living facilities for offshore workers. The offshore container module is a container specially designed for offshore platforms, which has the characteristics of anti-wave, windproof, anti-corrosion, and durable. The containers are typically made of high-strength steel and are detachable and reconfigurable to suit different transportation needs. Offshore containers are highly specialized, and each type of container has its specific purpose. According to different uses, offshore containers can be divided into the following 3 categories:

TLS specializes in providing customized offshore container modules that comply with international standards DNV2.7-1/ IEC60079-13. We always follow the principles of safety, reliability, and efficiency to escort your offshore operations. Written by Mandy TLS Company Overview and Featured Products: pressurised containers, BESS containers, TR shelters2/14/2023

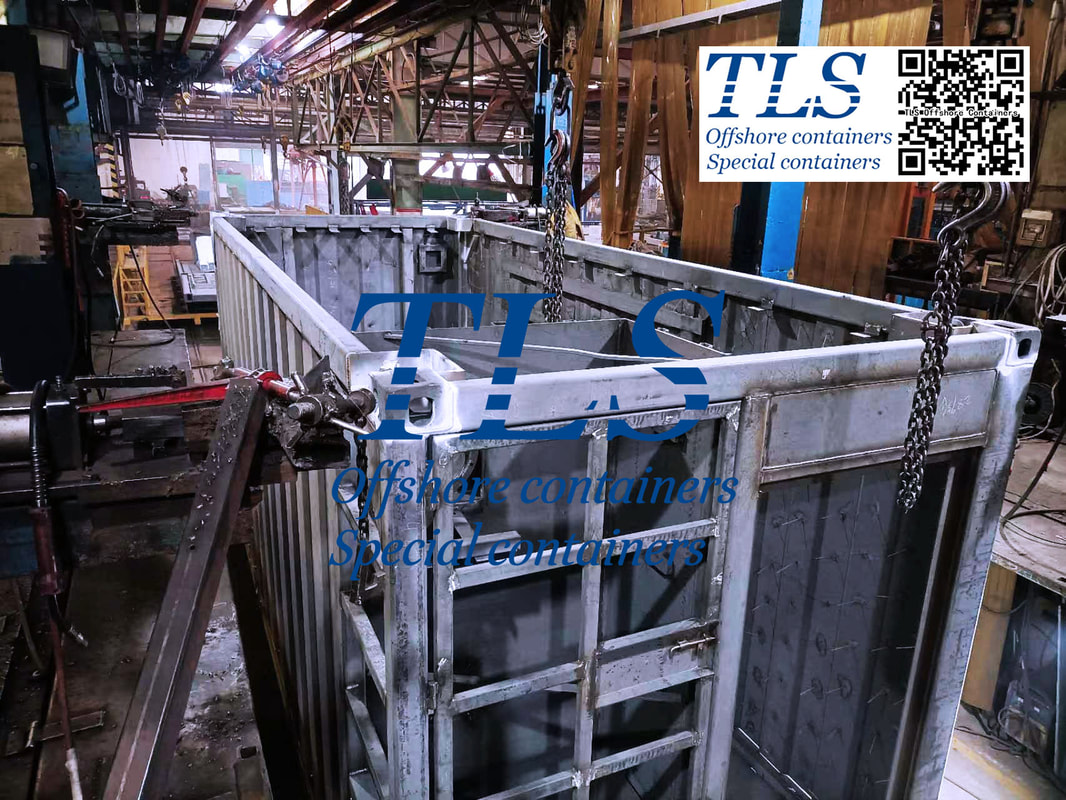

TLS is a global leader in the design and manufacture of specialized containers for a range of industries. The company's mission is to provide high-quality, innovative solutions that meet the needs of clients around the world. With a focus on safety, efficiency, and sustainability, TLS has become a trusted supplier of pressurized containers, TR shelters, and BESS containers. Pressurized containers are a key product for TLS, providing a safe and secure environment for equipment and personnel in hazardous environments. These containers are designed to withstand high pressures, ensuring that their contents remain intact in a range of conditions. TLS pressurized containers are commonly used in the oil and gas industry, chemical processing plants, and other industries where hazardous materials are present. TR shelters are another important product from TLS, providing a temporary refuge for personnel in the event of an emergency. These shelters are designed to withstand the impact of blast events, providing a protective environment for personnel to wait until it is safe to evacuate the area. TLS TR shelters are available in a range of sizes to meet the needs of clients in various industries, from offshore oil rigs to chemical processing plants. BESS (Battery Energy Storage System) containers are a newer addition to the TLS product lineup, offering a sustainable energy storage solution for clients in a range of industries. These containers are designed to store large amounts of energy in batteries, which can be used to power a range of equipment and applications. BESS containers are becoming increasingly popular in renewable energy industries, such as wind and solar power, where they provide a reliable and efficient way to store energy. All TLS products are designed with safety and efficiency in mind, using the latest technologies and materials to ensure high-quality and reliable solutions. The company works closely with clients to understand their needs and customize products to meet their specific requirements. With a focus on sustainability, TLS products are also designed to minimize their environmental impact, using energy-efficient technologies and materials wherever possible. In addition to its product lineup, TLS also provides a range of services to support its clients, including installation, maintenance, and repair. The company's global network of service centers ensures that clients can access support and assistance wherever they are in the world. Overall, TLS is a trusted supplier of specialized containers, providing high-quality, innovative solutions to clients in a range of industries. With a focus on safety, efficiency, and sustainability, the company is well-positioned to meet the evolving needs of clients around the world. Main structure: Mainly divided into two categories 1. Important and non-redundant primary structures, which are the basic components that transfer the resultant load of the cargo to the crane hook or forklift (i.e. form the transfer path from the payload to the sling load), include at least: Top and bottom side beams, top and bottom end beams, corner posts, lifting lugs, fork grooves 2. Non-basic main structure. Examples include floors and other components with major functions other than those described for basic components. Baffles, stacking corners and end plates on hollow sections fall into this category. In addition non-essential primary structures also include protective framing members. Secondary structure The non-loaded parts that do not need to be considered in design calculations are called secondary structures, including 1. Door, wall and roof panels, non-slip cover 2. Reinforced plate and corrugated plate 3. Parts used only to protect tank structure 4. Internal fixed points TLS is an international supplier that can customize onshore | offshore special containerised solutions,Any requirements, please contact us directly: E-mail: [email protected] Hotline: +65-65637288; +65-31386967 DNV stands for Det Norske Veritas, an independent and self-governing foundation dedicated to the protection of human life, the property and the environment both onshore and offshore. DNV Shipping Containers or Offshore Containers are certified containers for the oil and gas industry. This portable unit can be used many times, thus increasing its worth and viability. When transporting large components to a drilling rig or FPSO (or storing products on site), you require containers that can endure harsh weather and movement. Due to certain hazards that may exist in the oil industry, DNV containers must comply with safety regulations in order to be certified for application on oil rigs, on oil tankers and in the environment. DNV Shipping containers are divided into three main types: Offshore freight containers:Suitable for carrying large loads and cargoes. Offshore service containers:Can be customized to specific projects such as control centers, laboratories, power plants or workshops. Offshore waste skip containers: Suitable for holding rubbish with an open or closed top.

Due to the harsh environment at sea and the frequent lifting of offshore containers, there are strict requirements on the lifting lugs of offshore containers.

DET NORSKE VERITAS (DNV) is an autonomous and independent foundation whose goal is to protect life, property, and the environment at sea and on land. DNV undertakes classification, certification and other verification and consulting services related to the quality of ships, offshore equipment and facilities, and onshore industries worldwide, and conducts research related to these functions.

The DNV 2.7-1 certified offshore container is specifically designed for dynamic hoisting with eye pad devices and DNV certified slings fitted with shackles. They are checked during the design phase, material procurement, production, and final loading and NDE testing. Not only are prototypes tested, but a specific number of units are randomly selected from each batch for testing at a rate five times the rate of ISO standard container testing. The containers have a solid steel structure, including floors. They weigh almost twice as much as an ISO container of the same size, which is critical to their ability to maintain an upright position while being transported in rough seas. They must be equipped with DNV approved slings, stronger steel, stricter production specifications and have all the test documentation to prove their reliability in harsh offshore conditions. Classification societies certify containers

Offshore containers should be inspected regularly every year. Regular inspections should be performed on the inside and outside of the container when it is empty. TLS has prepared tips for you to check including:

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|