|

To facilitate the loading and unloading of the cargo, the bottom of TLS offshore containers is usually designed with fork pockets, which are required as follows:

1. If provided, the fork pockets shall be arranged in the bottom structure with the top closed to penetrate the bottom and prevent the offshore container from overturning from the fork tine. 2. The net opening size of the fork pocket of the offshore container shall not be less than 200mm×90mm. 3. Considering the length, height, width, and rated weight of the offshore container, the position of the fork pocket should ensure the stability of the container when it is transported by the forklift. The fork pockets should be as far apart as possible, generally not less than 900 mm from the center, but not more than 2,050 mm. 4. The bottom plate of the fork pockets can be closed completely, but openings are recommended for maintenance and to reduce the risk of loose items being left in the fork pockets, thereby preventing items from falling during the lifting process. Where openings are provided, the size and position of the opening should be set to avoid jamming or being damaged by the tines The opening at the bottom of the fork pockets are not allowed at the bottom side rails, and the distance between the opening and the bottom side rails should not be less than 200mm. 5. The weakening of vertical shear strength of bottom side rails by fork pockets opening should be taken into account when calculating the bottom side rails strength. In general, a reinforcement plate should be attached to the top of the bottom side rail. The reinforcement plate should be in the same plane as the bottom side rails web. The reinforcement plate should be extended by at least 100mm at both ends. At this point, the weld between the reinforcement plate and the bottom side rail should be completely melted through. Visual inspection and non-destructive testing are commonly used to inspect container welds. Magnetic particle inspection is one of the types of non-destructive testing. Magnetic particle inspection is a method of observing defects using magnetic powders as a display medium. After the ferromagnetic material workpiece is magnetized, as the existence of discontinuity, the magnetic field lines on the surface and near the surface of the workpiece are locally distorted to generate a leakage magnetic field, which adsorbs the magnetic powder applied on the surface of the workpiece and forms a visible magnetic field under suitable illumination,and the location, size, shape, and severity of the discontinuities are shown. TLS normally uses black magnetic paste for flaw detection. This method has high sensitivity to detect small defects on the surface of the workpiece. The steps are:

Any requirements about specialized shipping containers, please feel free to contact us. Containers are no longer a traditional transport tool that can only be used to carry goods. More and more container types are known to us. In order to meet the needs of different container types, the correct selection of doors has also become an important step in the design process. Before choosing, please answer the following questions: What does this container need to be used for? Do large-sized items need to be placed in the container? Are containers used as offices or homes? Do we need to go inside the container frequently? 5 Basic Types of Container Doors for Your Reference 1. Cargo door "Original" doors for shipping containers. Usually installed at the end of the container. These heavy duty doors are weatherproof and very secure. They open outward, and the secure cam and locking system are robustly designed to deter theft and reduce the risk of damage from inclement weather and other environmental threats. Applicable environment:Large objects need to be easily placed in the container Features: Affordable, no modification or installation required. 2. Personnel door Use in case of storing smaller items or as a laboratory, office, house etc. They are usually installed on the end face of the container and have good sealing performance. According to the different use environments, there are doors that meet the level of B30 and A60. Applicable environment: It is frequently used for easy entry and exit of people, (movable office building, portable office station, laboratory shipping container) Features: Easy to use, various styles and standards to choose from 3. Roll-Up Doors Sometimes referred to as overhead doors, they are welded to the container walls, are usually rolled up from the bottom, can be locked, are easy to maneuver and are relatively lightweight. Applicable environment: Used to store large objects or equipment Features: Save space, easy to operate 4. Glass door Sliding glass doors are the same height and width as double-width personnel doors, but they are made of durable glass with a vinyl frame. These doors come with safety locks to protect the interior, although they shouldn't be considered as secure or durable as the alternative doors mentioned above, since they are transparent. Applicable environment: Office, storefront |shop or living space. Features: Create better lighting for the interior in accordance with the environment, and the design is more fashionable 5. Combination door For containers with larger space or special needs, it is usually also considered to design multiple channels The design of any container building should be tailored to the specific needs of each project.

Feel free to contact us ,we customize special containers as you need. What are the common container structures? Different containers usually have different shapes and structures due to different uses. Let's take a look at the common container structures. The common dry box structure is often used to transport common cargo and is the most common type of container.

In addition to containers used to transport goods, do you know what types of special containers there are?

Key words: #Dry Containers #Flat Rack Containers #Open Top Container #Tunnel Container #Side Opening Container #Tank #Half Height Containers| Cutting Skip #Reefer Container #Refrigerated Container #Positive Pressure Container #Negative Pressure Container #Energy Storage System (#ESS) #Lab Container|Workshop Container #Accommodation Container #Temporary shelter #Temporary #refuge shelter ( #TR) #Sewage Treatment Container HOW MANY MODE SELECTIONS IN TLS'S CPFG SYSTEM AND WHAT CONDITIONS WILL BE USED THESE MODES?4/28/2022

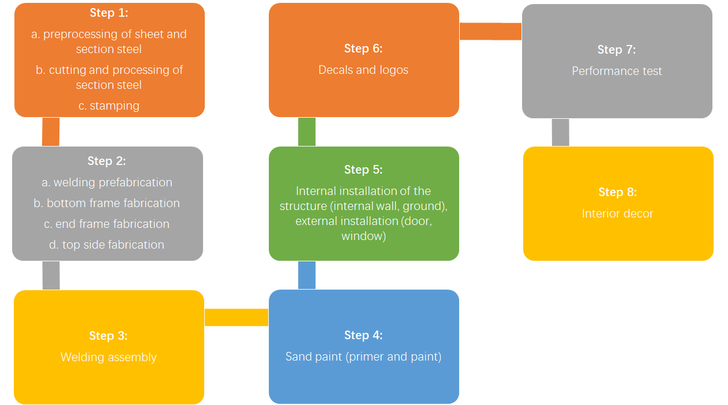

CPFG is divided into three working modes: manual mode, bypass mode and automatic mode. Turn the mode selector switch to the corresponding mode, at the same time, HMI face change will switch to the corresponding mode. The operation instructions of each mode are as follows: Manual mode: only for emergency use, only the HMI "STOP" button/ESD signal/Cut-off signal can stop the output of safety power supply. Bypass mode: Only can be used in safe area, make sure no dangerous gas and fire alarm start the safety power supply. Auto mode: Can be used for normal use in dangerous area. Any requirements, please contact us directly: E-mail: sales@tls-containers.com Hotline: +65-65637288; +65-31386967 Key words: # CPFG # ESD # Manual mode # Bypass mode # Auto mode #A60 fire rating #explosion-proof #LAB # workshop container #TLS offshore containers #laboratory containe The specially designed ultra-wide explosion-proof lab container|workshop container| Pressure container is about to be delivered. Our technicians are cooperating with various inspections from the end customer and SGS to ensure that the performance of the container meets customer standards and industry standards. TLS provides DNV2.7-1 standard | explosion-proof | which can be used in hazardous areas (ZONE 0, ZONE 1, AND ZONE 2) | special containers that meet A60 fire rating, we provide the independent certification from DNV | BV | LR | ABS | SGS. Any requirements, please contact us directly: E-mail: sales@tls-containers.com Hotline: +65-65637288; +65-31386967 Key words: #DNV #BV #LR #ABS #SGS #DNV2.7-1 #ESS #BESS #A60 fire rating #explosion-proof #LAB # workshop container #TLS offshore containers THE PROCESS OF CONTAINER MANUFACTURING Step 1: a. preprocessing of sheet and section steel b. cutting and processing of section steel c. stamping Step 2: a. welding prefabricationb. bottom frame fabrication c. end frame fabricationd. top side fabrication Step 3: Welding assembly Step 4: Sand paint (primer and paint) Step 5: Internal installation of the structure (internal wall, ground), external installation (door, window) Step 6: Decals and logos Step 7: Performance test Step 8: Interior decor The customized ultra-wide laboratory container is being assembled, we will follow up every process in real time, and we will take every detail seriously. Rest assured, products tailored to your needs are sure to satisfy you. |

Archives

April 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|