|

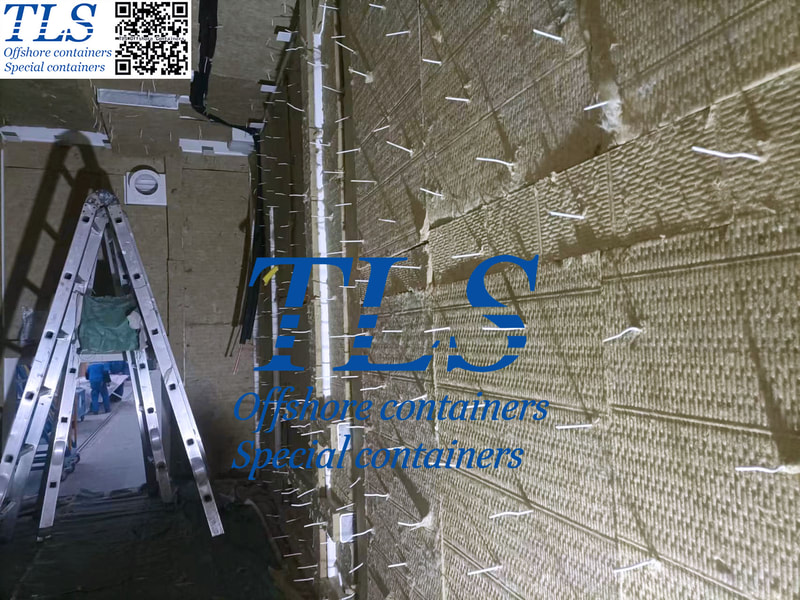

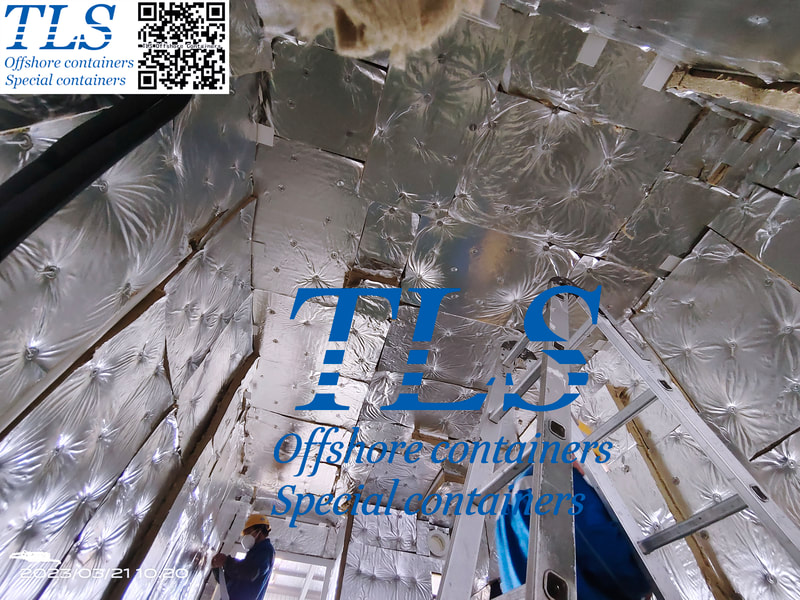

Container heat insulation and fire protection design refers to designing a set of heat insulation and fire protection system inside the container to protect the goods in the container from the influence of external temperature and fire. Commonly used insulation materials include rock wool, glass wool, polyurethane, etc., while fireproof materials include fireproof boards, fireproof coatings, etc. TLS offshore containers can meet the A60 fire protection standard and usually use rock wool as an insulating material, which is made of basalt or lava mineral fibers. It has the following characteristics: High temperature stability: rock wool can maintain stable insulation performance at high temperature, and can be used for thermal insulation of high temperature equipment. Good thermal insulation performance: rock wool has low thermal conductivity and high thermal insulation performance, which can effectively reduce energy loss and reduce energy consumption. Good fire performance: rock wool is a non-combustible material that will not burn or melt, and can effectively isolate the fire source and reduce the occurrence of fire. Good sound absorption performance: The fiber structure of rock wool can effectively absorb sound waves, reduce noise transmission, and improve indoor comfort. Environmental protection and health: rock wool products do not contain harmful substances, do not produce harmful gases, and are harmless to the environment and human health. Using rock wool as a container insulation material can provide good thermal insulation performance, fire performance, sound insulation performance and environmental protection performance. When designing the insulation scheme, factors such as insulation requirements, cost and durability need to be considered comprehensively to determine the appropriate thickness and density of rock wool, and attention should be paid to the installation of rock wool and compliance with relevant fire protection and environmental protection standards. In the heat insulation and fire protection design of containers, several aspects of design should also be considered: Designing the insulation and how to insulate: The location of the insulation and how to insulate need to be determined. Generally speaking, the heat insulation layer can be designed on the inner wall, roof and ground of the container. At the same time, you can choose to use double-layer structure or single-layer structure for heat insulation. Design fire protection layer and fire prevention method: need to determine the position and fire prevention method of fire protection layer. Generally speaking, the fireproof layer can be designed on the inner wall, roof and ground of the container. At the same time, you can choose to use fireproof boards, fireproof coatings and other materials for fire prevention. Fire protection system design: The design of the fire protection system needs to be taken into account. This includes fire water sources, fire sprinklers, smoke detectors, etc. Operator Safety: Operator safety needs to be considered. This includes things like lighting and ventilation systems inside the container. Container heat insulation and fire protection design is a complex project, which needs to consider multiple aspects such as heat insulation, fire protection, fire protection system and operator safety. During the design process, it is necessary to comprehensively consider factors such as the nature of the cargo inside the container, the characteristics of the container itself, and the budget to determine the most suitable heat insulation and fire protection scheme. Written by Mandy Comments are closed.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|