|

Offshore containers are specialized units used for the transport, storage, and handling of goods and equipment in the demanding offshore environment, such as oil rigs and gas platforms. They must withstand harsh weather conditions, heavy loads, and rigorous handling. To ensure safety, durability, and performance, offshore containers are built and certified according to specific standards, primarily DNV 2.7-1 and EN 12079. These standards govern the design, construction, testing, and certification of offshore containers to ensure they are fit for their intended use. DNV 2.7-1 Standard DNV 2.7-1, developed by DNV (Det Norske Veritas), is a globally recognized standard specifically for offshore containers. This standard covers the following key aspects: - Design and Construction: It specifies requirements for the design and construction of offshore containers, ensuring they can withstand the rigors of offshore use, including high stress and load conditions. - Materials: DNV 2.7-1 outlines the types of materials that can be used, focusing on their strength, durability, and resistance to the corrosive marine environment. - Testing and Inspection: It requires thorough testing and inspection of each container, including load testing, to verify that the design and construction meet the standard’s requirements. - Certification: Containers that comply with DNV 2.7-1 are certified by DNV, providing assurance that they meet the highest standards for safety and reliability. EN 12079 Standard EN 12079 is a European standard that encompasses design, manufacturing, and testing requirements for offshore containers and associated lifting sets. While it shares similarities with DNV 2.7-1, it is specifically harmonized for European compliance. Key components include: - Design and Manufacturing: EN 12079 outlines criteria for the design and manufacturing of offshore containers, ensuring they are suitable for repeated use in the offshore environment. - Testing: This standard includes specific testing requirements for both the offshore containers and their lifting sets, ensuring comprehensive safety. - Marking and Certification: Containers meeting EN 12079 standards must be properly marked and come with a Declaration of Conformity, indicating compliance with European regulations. Comparison and Compliance - Global Recognition: While DNV 2.7-1 is widely recognized internationally, especially in regions with significant offshore oil and gas activities, EN 12079 ensures compliance within European Union countries. - Harmonization: Many manufacturers aim to comply with both standards to ensure their containers are acceptable for global use. Compliance with both standards indicates a high level of safety, durability, and reliability. - Certification Bodies: Different certification bodies can issue certifications under these standards, with DNV being a leading authority for DNV 2.7-1, and various European bodies for EN 12079. Manufacturers and operators must ensure that their offshore containers meet these stringent standards to ensure the safety of operations, the protection of personnel, and the integrity of the equipment transported within these containers. please contact us for more information. 400 units 20ft open top containers ready for delivery, color/logo can be customerised, ex-stock3/22/2024

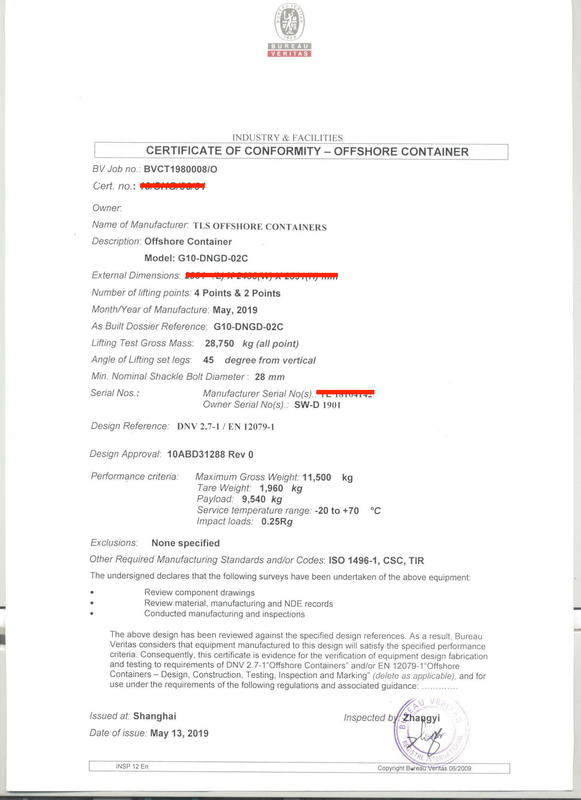

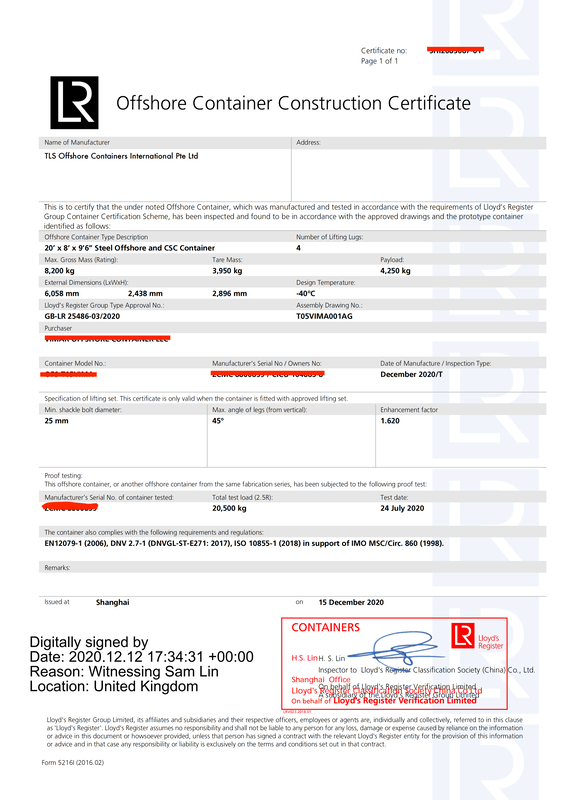

At TLS Offshore Containers, we are excited to announce that we currently have an extensive stock of 400 units of 20ft open-top containers, ready for immediate delivery. All units are certified by Bureau Veritas (BV) and Lloyd's Register (LR), ensuring they meet the highest international standards for safety, durability, and performance. This certification is a testament to our commitment to excellence and our dedication to providing products that our customers can trust. If you are interested in purchasing or wish to learn more about our 20ft open-top containers, please do not hesitate to contact us. Our team is ready to assist you with any questions you may have and guide you through the customization process to ensure your needs are met with precision and care. At TLS Offshore Containers, we are more than just a provider; we are your partner in finding the best container solutions for your business. Reach out today to secure your containers and take the first step towards enhancing your operational efficiency with our certified, customizable 20ft open-top containers. --- Introduction: In the realm of scientific research, innovation knows no bounds. However, conducting experiments and research projects often requires specialized infrastructure, which can be both expensive and logistically challenging to set up. This is where TLS Offshore Lab Containers step in to revolutionize the landscape. In this article, we delve into the transformative potential of these containers, exploring their features, benefits, and the impact they can have on various fields of study. Unraveling Offshore Lab Containers: TLS Offshore Containers International specializes in designing and manufacturing lab containers and more, meticulously crafted to customer specifications. These containers are engineered to adhere to industry-leading standards, including DNV 2.7-1, NORSOK, ATEX/IECEx, as well as SOLAS/IMO regulatory requirements. With a focus on functionality and compliance, TLS containers ensure optimal performance and safety in any environment. Features That Redefine Possibilities:

Benefits Galore:

Impact Across Disciplines: The versatility of Offshore Lab Containers makes them indispensable across various fields of scientific inquiry:

Conclusion: In an era where scientific breakthroughs are essential for addressing global challenges, Offshore Lab Containers by TLS emerge as a game-changer. By combining innovation, durability, and flexibility, these containers empower researchers to push the boundaries of knowledge, transcending geographical limitations and unlocking new avenues of discovery. Embrace the future of scientific exploration with TLS's Offshore Lab Containers. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #ATEX/IECEx #SOLAS/IMO regulations #Customization #Compliance #Climate control #Efficiency #Rapid deployment #Scientific research #Innovation #Insulation #Offshore containers #Laboratory containers #DNV 2.7-1 Written by OliverIn the realm of energy storage, Battery Energy Storage Systems (BESS) have emerged as pivotal assets for managing power grids efficiently and sustainably. As the demand for renewable energy integration grows, the importance of efficient BESS operation becomes increasingly evident. Among the critical components of BESS infrastructure is the Energy Management System (EMS), which plays a crucial role in optimizing performance and ensuring seamless integration with the grid. In this blog post, we delve into the intricacies of EMS communication within BESS containers manufactured by TLS, shedding light on its functionality and significance. What is EMS Communication? EMS communication refers to the exchange of data and instructions between the Energy Management System and various components within a BESS container. The EMS serves as the central intelligence hub, orchestrating the operation of batteries, inverters, monitoring devices, and other subsystems to achieve optimal performance objectives. Key Components of EMS Communication in TLS BESS Containers:

Benefits of Effective EMS Communication in TLS BESS Containers:

Conclusion: In the realm of energy storage, effective communication between the EMS and various subsystems is essential for optimizing performance, ensuring grid stability, and maximizing the value of BESS assets. TLS BESS containers exemplify this principle, boasting robust EMS communication capabilities that enable seamless integration, enhanced control, and superior operational efficiency. By leveraging advanced technology and innovative design, TLS continues to redefine the landscape of energy storage, empowering utilities, renewable energy developers, and grid operators to embrace a sustainable energy future. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #Battery Management System (BMS) #Inverters #Grid monitoring #SCADA systems #Performance optimization #Grid stability #Renewable energy integration #Ancillary services #Real-time data #Operational efficiency #Remote management #Predictive analytics #Maintenance scheduling Written by OliverUnveiling the Engineering Marvel: Understanding How the Inverter Works in TLS BESS Containers3/22/2024

Introduction: In today's energy landscape, the importance of sustainable and efficient energy storage solutions cannot be overstated. Battery Energy Storage Systems (BESS) have emerged as a cornerstone of this transformation, providing flexibility, reliability, and stability to the grid. At the heart of every BESS lies a crucial component: the inverter. In this blog, we delve into the intricate workings of the inverter within the BESS containers manufactured by TLS, shedding light on its functionality and significance. Understanding the Inverter: The inverter serves as the backbone of any BESS, facilitating the conversion of direct current (DC) electricity stored in the batteries into alternating current (AC) electricity, which is compatible with the grid and can power homes, businesses, and industries. This seamless conversion process is fundamental for integrating renewable energy sources, managing peak demand, and ensuring grid stability. Key Components and Technologies: Within TLS BESS containers, the inverter comprises a sophisticated array of components and cutting-edge technologies engineered to optimize performance and efficiency. These include:

Benefits of TLS Inverter Technology:

Conclusion: In conclusion, the inverter stands as a linchpin of TLS BESS containers, facilitating the seamless conversion of stored energy into usable electricity while ensuring compatibility with the grid. Through advanced technologies, robust design principles, and adaptive control strategies, TLS continues to pioneer innovative solutions that drive the transition towards a sustainable energy future. As the demand for reliable and efficient energy storage solutions escalates, the role of the inverter within BESS containers remains paramount, shaping the landscape of modern energy infrastructure. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. Key words: #Inverter technology #Energy storage solutions #Grid integration #Renewable energy #Power electronics #Grid stability #Energy conversion #Efficiency #Control systems #Modularity #Scalability Written by OliverInnovative Solutions for Sustainable Agriculture In today's rapidly evolving world, the intersection of traditional agricultural practices with cutting-edge technology has paved the way for revolutionary advancements in food production. One such groundbreaking innovation is the integration of hydroponic farming with refrigerated containers, particularly those engineered by TLS Offshore Containers. This ingenious combination creates a highly controlled and efficient environment for plant growth, offering myriad benefits that transcend conventional farming methods. Hydroponic farming, a method of cultivating plants without soil by using nutrient-rich water solutions, has gained significant traction in recent years due to its potential for increased yields and reduced resource consumption. By eliminating the need for soil, hydroponics drastically reduces water usage compared to traditional farming methods, making it an environmentally sustainable option in regions facing water scarcity. When coupled with refrigerated containers provided by TLS Offshore Containers, hydroponic farming takes on a new dimension of efficiency and versatility. These containers, renowned for their durability and precision engineering, offer an ideal environment for maintaining optimal growing conditions regardless of external climate variations. With customizable temperature, humidity, and lighting controls, these containers provide a controlled environment conducive to year-round cultivation, overcoming the limitations imposed by seasonal changes. Addressing Global Food Security Challenges The integration of hydroponic farming with refrigerated containers holds immense promise for addressing global food security challenges. By harnessing technology to create self-contained agricultural ecosystems, this approach enables food production in non-arable and urban areas where traditional farming methods may be impractical or unsustainable. Urban populations, in particular, stand to benefit from locally grown produce, reducing reliance on long-distance transportation and minimizing carbon emissions associated with food miles. Moreover, the scalability of this solution makes it adaptable to various settings, from rural communities to densely populated urban centers. TLS Offshore Containers' expertise in designing and manufacturing specialized containers ensures that farmers and agricultural enterprises have access to reliable infrastructure tailored to their specific needs. Whether used for small-scale urban gardens or large-scale commercial operations, these containers provide a flexible platform for enhancing food production efficiency and sustainability. Environmental Benefits of Hydroponic Farming in Refrigerated Containers The environmental advantages of integrating hydroponic farming with refrigerated containers are manifold. By operating in a controlled environment, hydroponic systems minimize water usage through recirculation and precise nutrient delivery, reducing the strain on freshwater resources. Additionally, the absence of soil eliminates the risk of soil erosion and contamination, preserving land quality for future generations. Furthermore, the efficient use of space inherent in hydroponic systems allows for higher crop yields per unit area compared to traditional farming methods. This increased productivity enables farmers to maximize land utilization while minimizing environmental impact, making hydroponic farming in refrigerated containers a sustainable solution for meeting growing food demands. Economic Opportunities and Technological Innovation Beyond its environmental benefits, the integration of hydroponic farming with refrigerated containers presents significant economic opportunities for farmers, entrepreneurs, and communities. By optimizing resource efficiency and crop yields, this approach enhances the profitability and viability of agricultural enterprises, particularly in regions where land availability or climatic conditions pose challenges to traditional farming practices. Moreover, the convergence of agriculture and technology fosters innovation and entrepreneurship in the agri-tech sector. TLS Offshore Containers' commitment to technological excellence ensures that their containers are equipped with state-of-the-art features, such as remote monitoring and automated climate control systems, enhancing operational efficiency and reducing maintenance costs for farmers. The Future of Agriculture: Sustainable and Resilient As the global population continues to grow and environmental pressures mount, the need for sustainable agricultural solutions becomes increasingly urgent. The integration of hydroponic farming with refrigerated containers represents a significant step towards building a more resilient and food-secure future. By leveraging innovative technologies and holistic approaches to food production, we can create a world where access to fresh, nutritious food is no longer a luxury but a fundamental human right. The marriage of hydroponic farming and refrigerated containers offered by TLS Offshore Containers holds immense promise for transforming agriculture as we know it. By combining the efficiency of hydroponics with the versatility of containerized systems, this approach not only maximizes resource utilization but also unlocks new possibilities for food production in diverse environments. As we embrace the potential of technology to address global challenges, let us work towards creating a more sustainable and equitable food system for generations to come. TLS Offshore Containers: Revolutionizing the Oil Tank Container Industry with the T4 Tank Container3/18/2024

In the ever-evolving landscape of offshore and maritime logistics, the importance of reliable, safe, and efficient transportation of liquids, gases, and pressurized dry bulk cannot be overstated. At the forefront of this industry, TLS Offshore Containers is pioneering with its state-of-the-art T4 tank containers. These containers are not just containers; they are a testament to innovation, safety, and environmental stewardship in the transportation of hazardous materials across the seas. **The Genesis of Excellence: T4 Tank Container Specifications** The T4 tank container, a product of meticulous engineering and design, adheres to stringent international standards including the International Maritime Dangerous Goods (IMDG) Code, the American Society of Mechanical Engineers (ASME) VIII-1 for the construction of pressure vessels, and various ISO standards such as ISO 668, ISO 830, ISO 1161, and ISO 1496-3. This compliance ensures the T4 tank container meets the global criteria for safety, durability, and reliability. With an overall dimension of 6058mm in length, 2438mm in width, and 2591mm in height, the T4 tank container boasts a gross weight capacity of 36,000 kg, a tare weight of approximately 4970 kg, and a maximum loading capacity of 31,030 kg. The container's volume is an impressive 30 cubic meters, optimized for the transport of a wide range of liquids and gases under the T code T4, signifying its versatility and capability to handle different types of dangerous goods. The container operates within a design temperature range of -40°C to 130°C, ensuring it can withstand extreme conditions. Its design and test pressures are 1.77 Bar and 2.65 Bar, respectively, providing an additional layer of safety during transportation. **Structural Integrity and Innovations** At the heart of the T4 tank container lies its robust construction, primarily composed of the tank body frame assembly, spillage tray, walkway, bottom outlet valve box, and heating system, among others. The materials used, such as ASTM A240 304 for the cylinder and head plates, Q450NQR1 for the corner posts, and SPA-H for additional structural components, ensure durability and corrosion resistance. The walkway, made of aluminum alloy, and the collapsible handrails and ladder, made of stainless steel, provide safe and easy access for inspection and maintenance. The innovative inclusion of a baffle with 18 holes of D100mm facilitates the stabilization of the cargo during transport, mitigating the risk of sloshing. **Safety First: Advanced Features** Safety is paramount in the design of the T4 tank container. It features two 2.5" BSP pressure-only safety relief valves set at 2.2 bar, with a negative pressure rating of 0.21bar, ensuring the container remains secure under varying pressures. Additionally, the container includes two manholes for easy access, an airline with a 1-1/2" ball valve, and both top and bottom outlet provisions for versatility in loading and unloading procedures. The heating system deserves special mention; it comprises 12 stainless steel longitudinal steam heating tubes, providing an actual heating area of 7.5m2. This system ensures the contents can be maintained or brought to the required temperature, crucial for certain chemicals or oils that need to be kept fluid during transportation. **Protecting the Environment and Contents** Insulation and cladding are critical for maintaining the internal temperature and protecting the tank's contents. The T4 container uses 40mm thick rock wool insulation and is clad with 1.8mm thick glass-reinforced plastic over the barrel and 2.0mm thick over the ends, offering superior insulation and protection. External surfaces are treated with a shot blast to SA 2½ grade and coated with a multi-layer paint system, including an epoxy zinc-rich primer, epoxy primer, and acrylic top coat, totaling 120 microns in thickness. This not only adds to the aesthetic appeal but also significantly enhances the container's resistance to corrosion and the harsh maritime environment. **TLS Offshore Containers: Leading the Way** TLS Offshore Containers has set a new benchmark in the industry with the T4 tank container. Through its commitment to quality, safety, and innovation, TLS Offshore Containers ensures that the transportation of hazardous materials is not just about compliance but about exceeding industry standards and contributing to a safer and more sustainable future. The T4 tank container from TLS Offshore Containers represents the pinnacle of engineering excellence in the offshore container industry. Its advanced features, adherence to international standards, and commitment to safety and environmental protection make it the preferred choice for companies worldwide. As we look to the future, TLS Offshore Containers continues to innovate, pushing the boundaries of what is possible in the transportation of dangerous goods and setting new standards for the industry to follow. Are you seeking unparalleled safety solutions for hazardous offshore environments? TLS presents a groundbreaking innovation: the Offshore Ex-Proof Positive Pressure Container. Engineered to thrive in Zone 1/2 areas, and compatible with ATEX/IECEx certified electrical equipment, these containers redefine safety standards in offshore operations. Join us as we explore the myriad advantages of TLS's cutting-edge containers and their transformative impact on offshore safety. Understanding Offshore Ex-Proof Positive Pressure Containers TLS's Offshore Ex-Proof Positive Pressure Containers are purpose-built for the rigors of offshore oil and gas exploration and production. Designed to mitigate the risks associated with hazardous environments, these containers offer a comprehensive solution for ensuring the safety of personnel and assets. Advantages of TLS Offshore Ex-Proof Positive Pressure Containers

Conclusion TLS's Offshore Ex-Proof Positive Pressure Containers represent the pinnacle of safety, reliability, and performance in hazardous offshore environments. With their Zone 1/2 compatibility, ATEX/IECEx certified electrical equipment compatibility, unparalleled safety features, durability, customization options, efficiency gains, and regulatory compliance, TLS's containers offer a comprehensive solution for offshore operations. Invest in TLS's Offshore Ex-Proof Positive Pressure Containers today and experience the peace of mind that comes with knowing your personnel and assets are protected in even the most challenging offshore conditions. Contact TLS to learn more about how their innovative containers can elevate your offshore operations to new heights of safety and efficiency. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Offshore #Ex-Proof #Positive Pressure Container #Hazardous Area #Zone 1 #Zone 2 #ATEX #IECEx #Safety #Reliability Written by OliverRevolutionizing Offshore Living: The Ultimate Guide to TLS Offshore Accommodation Containers3/14/2024

In the ever-evolving landscape of offshore industries, innovation is key to efficiency, safety, and comfort. Enter TLS Offshore Accommodation Containers – a game-changer in offshore living solutions. Whether you're in the oil and gas sector, maritime industry, or renewable energy fields, TLS offers cutting-edge solutions designed to elevate your offshore accommodations to new heights. In this comprehensive guide, we'll delve into the features, benefits, and applications of TLS Offshore Accommodation Containers, showcasing why they are the premier choice for your offshore projects. Introduction: Unveiling TLS Offshore Accommodation Containers TLS, with its unwavering commitment to excellence, introduces its state-of-the-art Offshore Accommodation Containers, engineered to meet the diverse needs of offshore operations. These containers redefine offshore living by integrating advanced technology, ergonomic design, and superior craftsmanship. Key Features of TLS Offshore Accommodation Containers:

Benefits of Choosing TLS Offshore Accommodation Containers:

Applications of TLS Offshore Accommodation Containers:

Conclusion: Elevate Your Offshore Living Experience with TLS Innovation, reliability, and excellence – these are the hallmarks of TLS Offshore Accommodation Containers. With their advanced features, customizable options, and unparalleled durability, TLS containers set the standard for offshore living solutions. Choose TLS and experience the difference in offshore accommodations – where safety, comfort, and efficiency converge to redefine the way you live and work offshore. Upgrade to TLS Offshore Accommodation Containers today and embark on a journey of unparalleled comfort, safety, and productivity in the vast expanse of the offshore world. Contact us now to learn more about our products and services. Your offshore adventure begins with TLS. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. Key words: #Offshore accommodation #Offshore living #TLS containers #Offshore housing solutions #Accommodation containers #Offshore industry #Oil and gas accommodation #Maritime accommodation #Renewable energy accommodations #Offshore accommodation suppliers Written by OliverIn the ever-evolving landscape of scientific research and experimentation, the demand for innovative solutions that ensure safety, efficiency, and mobility has never been higher. Enter the 20' offshore negative pressure lab container – a cutting-edge solution that is revolutionizing laboratory research across diverse fields. In this blog post, we'll explore the functionalities, benefits, and applications of these remarkable containers. Understanding Offshore Negative Pressure Lab Containers Offshore negative pressure lab containers are specialized units designed to provide a controlled environment for laboratory experiments, analysis, and research activities. What sets them apart is their ability to maintain negative pressure within the container, ensuring that hazardous materials and contaminants are effectively contained and prevented from escaping into the surrounding environment. Features and Specifications These containers typically come in a compact 20-foot size, making them highly versatile and suitable for various applications. They are equipped with state-of-the-art ventilation and filtration systems that create and maintain negative pressure, thereby minimizing the risk of exposure to harmful substances. Key features of offshore negative pressure lab containers include:

Applications Across Industries The versatility and functionality of 20' offshore negative pressure lab containers make them invaluable across a wide range of industries and research fields:

Conclusion In conclusion, 20' offshore negative pressure lab containers represent a significant advancement in laboratory safety and mobility, offering researchers a versatile and secure environment for conducting a wide range of experiments and analyses. With their advanced features, durability, and compliance with industry standards, these containers are poised to transform the way research is conducted across various disciplines. As the demand for portable and efficient laboratory solutions continues to grow, offshore negative pressure lab containers emerge as indispensable tools in the pursuit of scientific innovation and discovery. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Please download Laboratory container brochure for reference. Key words: #Offshore negative pressure lab container #Laboratory research #20-foot container #Scientific experimentation #Hazardous materials #Ventilation system #Filtration technology #Modular design #Environmental monitoring Written by Oliver |

Archives

May 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|