|

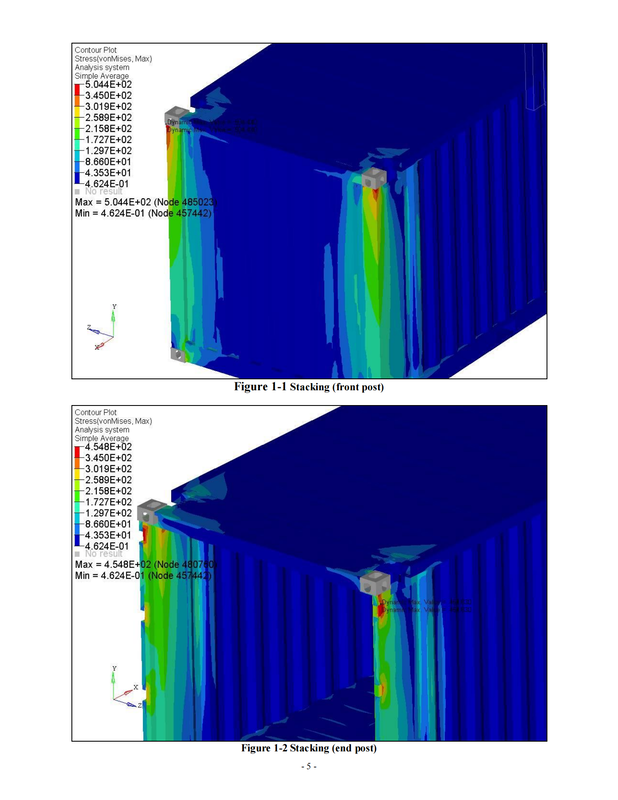

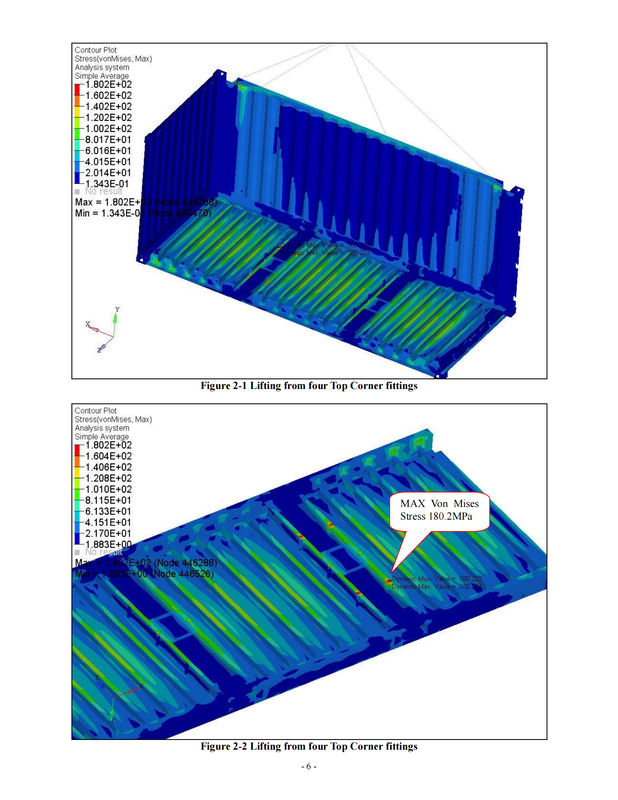

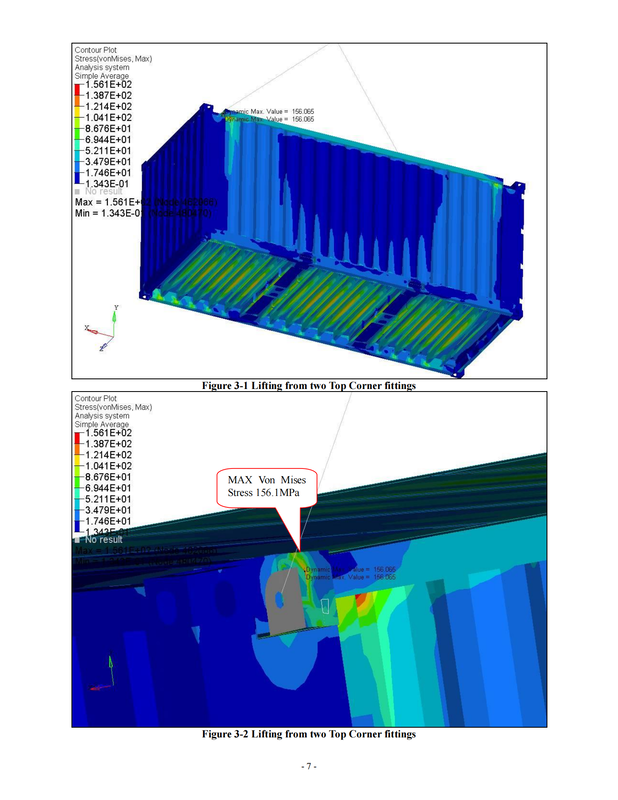

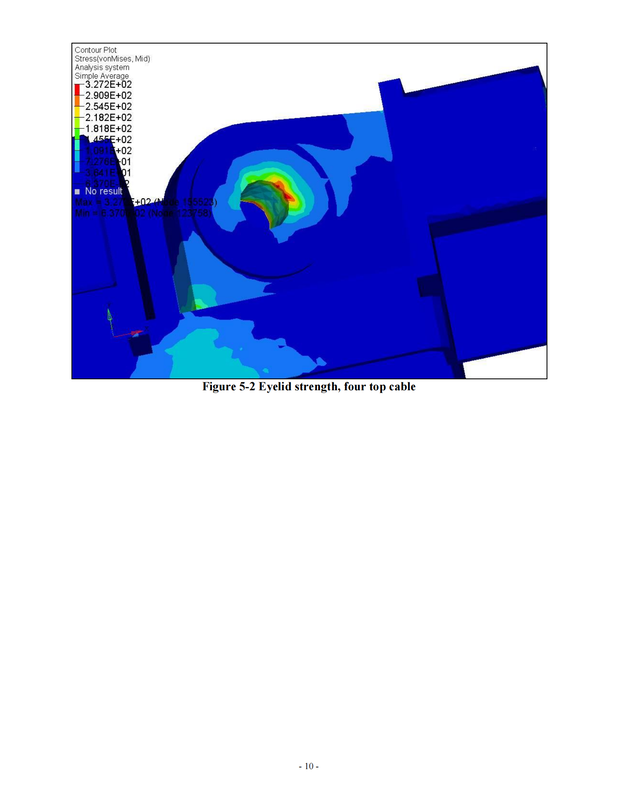

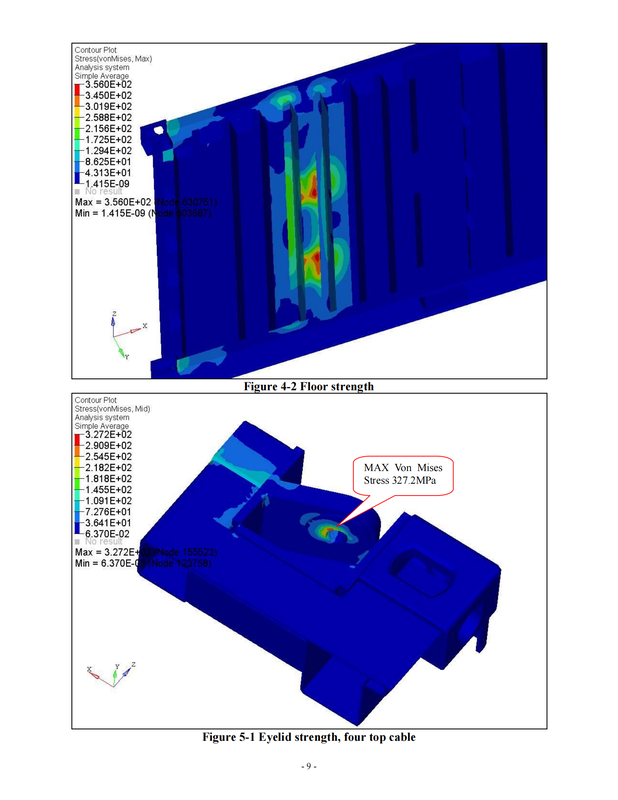

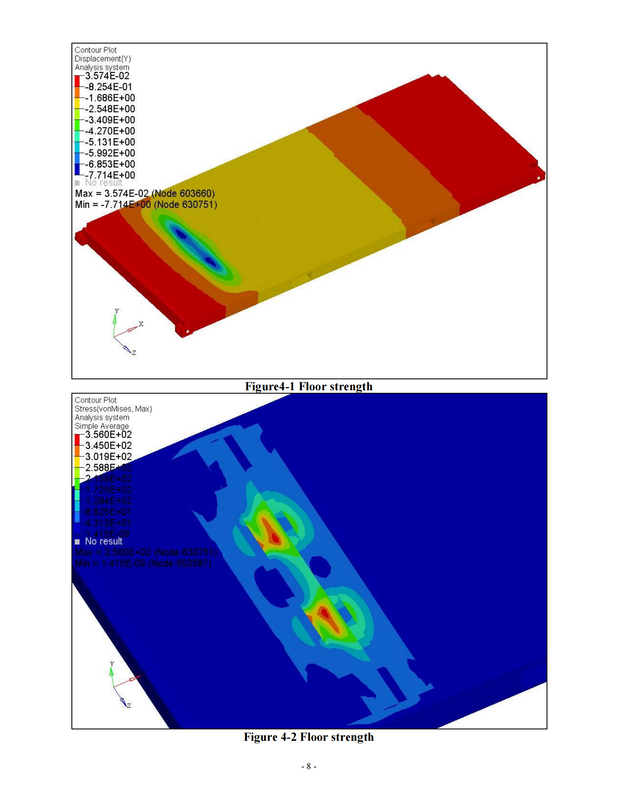

Offshore containers are used in the oil and gas industry to transport equipment, supplies, and materials to offshore platforms and drilling sites. These containers are designed to withstand harsh weather conditions, rough handling during transportation, and high loads during lifting and stacking. TLS Offshore Containers International is a leading provider of offshore container solutions, and their containers undergo rigorous Finite Element Analysis (FEA) structure analysis to ensure their safety and durability. FEA is a computational method that analyzes the behavior of structures under various conditions by dividing the structure into small, interconnected elements. Each element is analyzed individually, and the results are combined to obtain the overall behavior of the structure. FEA is widely used in engineering design and analysis to optimize designs, reduce costs, and improve performance. TLS Offshore Containers International uses FEA to analyze their offshore containers to ensure they meet the strict safety and performance requirements of the oil and gas industry. FEA enables them to evaluate the structural integrity of the containers under various loads, including lifting, stacking, and impact loads. This analysis helps them identify potential weaknesses in the design and make necessary modifications to improve the container's strength and durability. The FEA process starts with creating a 3D model of the container in a computer-aided design (CAD) software. The model includes all the components of the container, such as the frame, walls, roof, floor, and door. The model is then divided into small elements, and the material properties of each element are specified. The loads that the container is expected to experience during transportation and handling are also specified. The FEA software then solves equations based on the specified loads and material properties to calculate the stresses and deformations in each element of the container. These results are combined to obtain the overall stress and deformation of the container. The results are compared to the allowable stress and deformation limits specified by industry standards and regulations, such as DNV 2.7-1, EN 12079, and CSC. If the stress and deformation values are within the allowable limits, the container design is deemed safe and suitable for use. If the values exceed the allowable limits, modifications are made to the design to improve the container's strength and durability. These modifications may include changes to the material properties, thickness, or geometry of the container components. FEA enables TLS Offshore Containers International to optimize their container designs to meet the specific needs of their customers while ensuring their safety and durability. The use of FEA also reduces the need for physical testing, which saves time and costs in the design and development process. Furthermore, FEA allows for rapid iteration of designs, enabling TLS Offshore Containers International to quickly evaluate different design options and choose the most optimal one. In conclusion, FEA is a powerful tool that enables TLS Offshore Containers International to analyze and optimize their offshore container designs for safety and durability. The use of FEA ensures that their containers meet the strict industry standards and regulations and can withstand the harsh conditions of the oil and gas industry. By leveraging FEA, TLS Offshore Containers International can continue to provide innovative and reliable offshore container solutions to their customers. Comments are closed.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|