|

The maritime and offshore industry constantly evolves, necessitating robust and reliable solutions for various operational challenges. One such innovation is the A60 offshore workshop container, a versatile and essential asset for offshore projects. This blog explores the features, benefits, and applications of the A60 offshore workshop container manufactured by TLS, a leading provider in the industry. What is an A60 Offshore Workshop Container? An A60 offshore workshop container is a specially designed and certified container that meets the stringent A60 fire rating standards. These containers are engineered to withstand extreme offshore conditions, providing a safe and functional workspace for various activities, including maintenance, repair, and storage. Key Features of TLS A60 Offshore Workshop Containers

Benefits of Using A60 Offshore Workshop Containers

Applications of TLS A60 Offshore Workshop Containers

Why Choose TLS for A60 Offshore Workshop Containers?

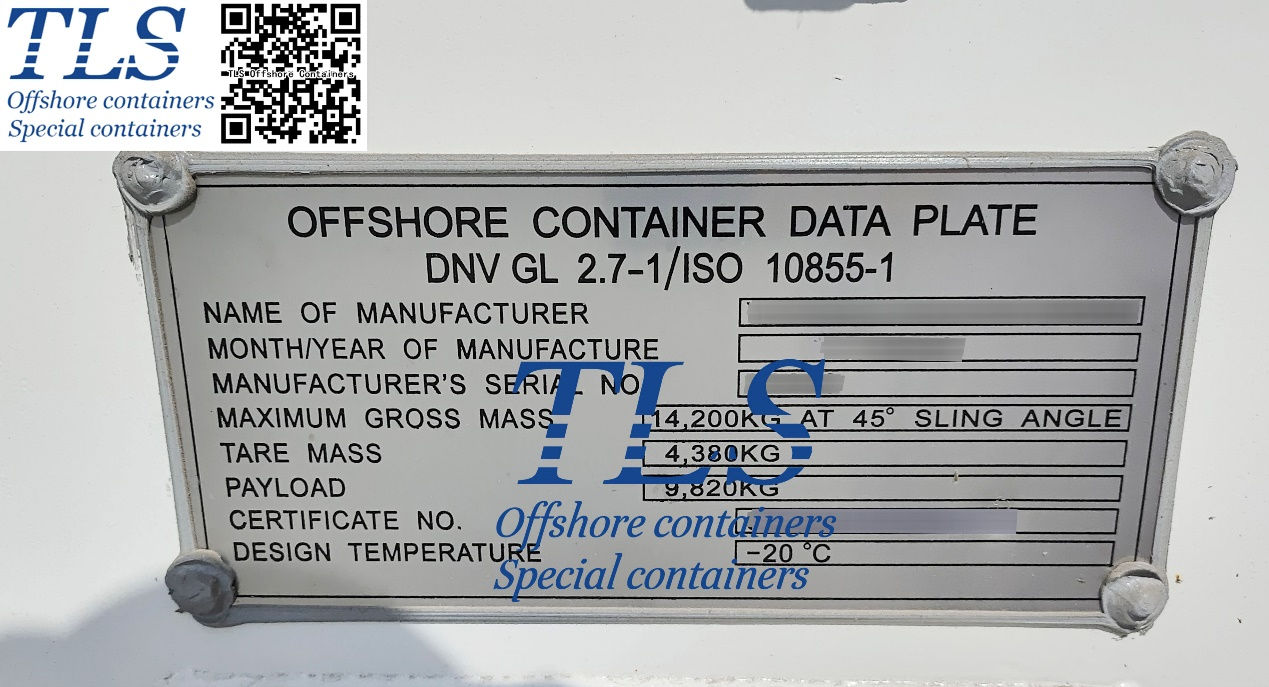

Conclusion A60 offshore workshop containers by TLS are a vital asset for the maritime and offshore industry. With their robust construction, advanced safety features, and versatile applications, these containers provide reliable and efficient solutions for various offshore needs. Choosing TLS means investing in quality, safety, and performance, ensuring the success of your offshore operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Key words: #A60 offshore workshop container #Offshore workshop solutions #Durable offshore containers #Custom offshore containers #DNV 2.7-1 containers #Marine workshop container #Secure offshore storage solutions #Offshore control room container #A60 compliant containers #Offshore living quarters containers #Modular offshore workshop Written by OliverIn the realm of offshore operations, safety and efficiency are paramount. One critical aspect that significantly contributes to these factors is the use of certified offshore containers. Among these, the DNV 2.7-1 standard stands out as a benchmark for quality and reliability. In this blog, we'll delve into what DNV 2.7-1 containers are, why they are essential, and how they enhance offshore operations. What is a DNV 2.7-1 Container? DNV 2.7-1 is a standard set by Det Norske Veritas (DNV), a leading international certification body. This standard specifically addresses the design, manufacturing, and certification of offshore containers. An offshore container is any portable unit, used for the transport and storage of goods and equipment, that is frequently handled in open seas and harsh environments. The DNV 2.7-1 standard ensures that these containers can withstand the extreme conditions encountered offshore, including rough handling, high winds, and corrosive saltwater. To meet this standard, containers must pass rigorous tests for structural integrity, safety, and durability. Key Features of DNV 2.7-1 Containers

Benefits of Using DNV 2.7-1 Containers in Offshore Operations

Applications of DNV 2.7-1 Containers

Conclusion The adoption of DNV 2.7-1 containers in offshore operations is a testament to the industry's commitment to safety, efficiency, and regulatory compliance. By investing in these high-quality, certified containers, offshore operators can ensure the protection of their personnel, equipment, and the environment, while also optimizing their operational processes. Whether for transporting goods, storing hazardous materials, or providing temporary living spaces, DNV 2.7-1 containers are the gold standard in offshore container solutions. As the offshore industry continues to evolve, the reliance on robust and certified containers will only grow, making DNV 2.7-1 an indispensable part of modern marine operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Key words: #DNV 2.7-1 containers #Offshore containers #Marine operations safety #Durable offshore containers #Marine container safety #Compliance #Offshore storage solutions #Hazardous materials storage offshore #Safety in offshore operations #Regulatory compliance offshore containers Written by OliverIntroduction In the demanding environments of the offshore industry, safety and reliability are paramount. TLS Offshore Containers International, a leader in designing and manufacturing high-quality offshore containers, ensures these needs are met, particularly in ZONE 2 areas. This blog delves into the specifics of how TLS offshore pressurized containers operate efficiently and safely in ZONE 2 hazardous locations. What are ZONE 2 Areas? ZONE 2 areas are classified as hazardous locations where explosive gases are not likely to occur in normal operation, and if they do occur, it will be for a short period. These areas require equipment that is robust, safe, and compliant with stringent safety standards. The Role of TLS Offshore Pressurized Containers TLS Offshore Containers International specializes in providing containers designed to withstand the rigors of ZONE 2 environments. Here's how our containers ensure safety and functionality:

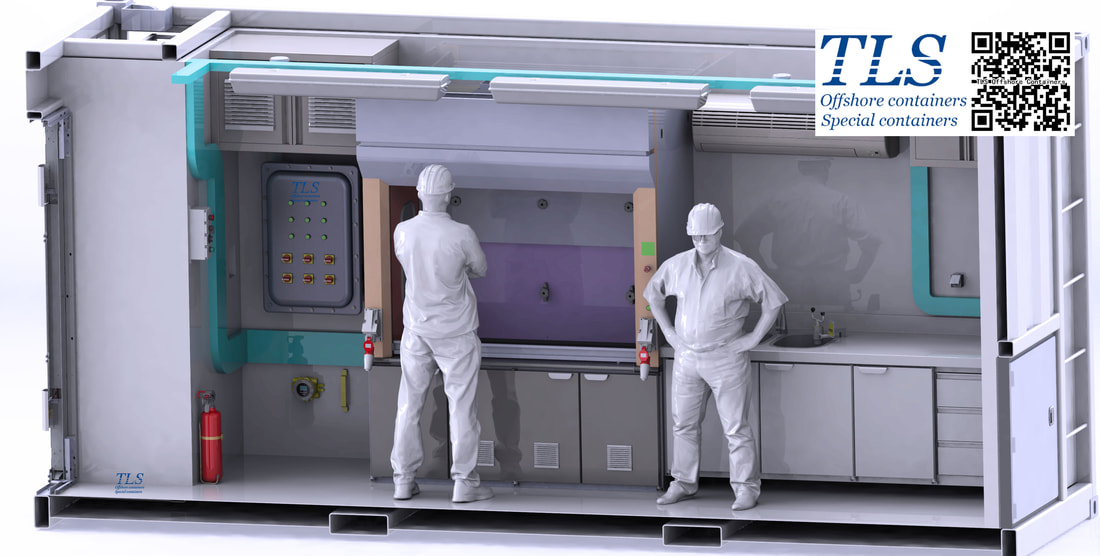

Conclusion Operating in ZONE 2 areas requires equipment that not only meets but exceeds safety standards. TLS Offshore Containers International's pressurized containers are engineered to provide maximum safety, reliability, and functionality in these demanding environments. By choosing TLS, you're investing in quality and peace of mind, knowing that your operations are supported by the best in the industry. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #TLS Offshore Containers #ZONE 2 hazardous areas #Offshore pressurized containers #ATEX certified containers #IECEx certified containers #DNV 2.7-1 containers #Offshore safety equipment #Hazardous location containers #Pressurization systems for containers #Customizable offshore containers #Explosion-proof containers #Offshore container solutions Written by OliverBattery management systems (BMS) are essential for the optimal functioning of energy storage systems, including those used in electric vehicles, energy storage stations, and base station power supplies. BMS acts as the backbone of energy storage, providing critical sensing, decision-making, and execution functions. This article explores the unique requirements of BMS in energy storage systems and highlights their vital role in ensuring system success. **High Voltage and Current Environment** Energy storage systems operate in high-voltage and high-current environments. Battery packs often reach voltages of up to 700V and currents between 100 to 300 amperes. Deep cycle batteries experience discharge and charge depths (DOD) typically around 80% or higher. These conditions necessitate a robust and reliable BMS to manage and monitor the battery pack effectively. **Unique Requirements of Energy Storage BMS** 1. **Complex System Design and Coordination:** - Energy storage systems usually have MWh-level storage capacity and power conversion rates from hundreds of kW to MW, requiring numerous batteries to be connected in series and parallel. This complex configuration demands a BMS with advanced circuit principles, anti-interference EMC design, efficient data processing capabilities, and rapid response times. Additionally, the overall system layout, wiring, and grounding must be meticulously planned to ensure safety and signal integrity. 2. **Battery Balancing:** - Consistent performance among individual cells within a battery pack is crucial for maximizing available capacity and system efficiency. BMS must feature strong battery balancing capabilities, typically using active balancing techniques with balancing currents ranging from 0.5 to 5A. This ensures uniform charge and discharge cycles, reducing discrepancies and enhancing overall performance. 3. **Thermal Management:** - Proper temperature control is vital for battery longevity. High charging and discharging currents in energy storage systems, particularly those used for frequency regulation and peak shaving, can lead to significant heating and uneven discharge rates. Effective thermal management strategies, including BMS-controlled thermal management, efficient cooling pathways, and well-designed battery module heat dissipation, are essential. Liquid cooling systems often provide superior thermal management. Monitoring battery temperature accurately is critical for preventing thermal runaway and maintaining battery health. 4. **Parallel Battery Control:** - When using multiple batteries in parallel, it's essential to manage voltage differences to prevent circulating currents and ensure balanced maintenance across all battery packs. 5. **Advanced Processing and Response:** - The complexity and scale of energy storage systems require BMS control units to possess sophisticated processing power and quick response times. The system's complexity demands high standards for processors, software architecture, and code quality. 6. **Reliability and Safety:** - Energy storage systems require exceptionally high safety and reliability standards. BMS must meet stringent functional safety and fault tolerance requirements to ensure the system's long-term reliability, typically designed for a lifespan of 15 years. 7. **Preemptive Safety Measures:** - One of the main challenges in the energy storage industry is ensuring system safety. BMS plays a crucial role in early warning and safety state analysis of batteries. While current BMS technology can monitor voltage and temperature in real-time, improvements in accuracy and computational capacity are necessary. Enhanced interference resistance and precise monitoring of individual cell temperatures are essential for effective thermal runaway prevention. **Conclusion** The development and design of BMS for energy storage systems must be tailored to meet the evolving demands of longer lifecycle, larger size, and increased complexity. A well-designed BMS ensures the safety, reliability, and efficiency of energy storage systems, making it an indispensable component. As the industry continues to advance, the role of BMS in managing battery safety and performance becomes increasingly critical, underscoring its importance in the success of energy storage systems. Explosion-proof control boxes are essential for ensuring safety in hazardous environments where explosive gases or dust may be present. Various explosion-proof methods are designed to prevent ignition and protect equipment and personnel. This article explores the primary explosion-proof methods for control boxes, their applications, advantages, and considerations for choosing the right type for specific environments. ### 1. Flameproof Type (Ex d) **Description**: The flameproof method involves enclosing electrical components within a robust housing designed to withstand an internal explosion. The housing contains any explosion that occurs inside, preventing it from spreading to the external environment. **Applications**: This method is commonly used in electrical equipment such as motors, transformers, and switchgear. **Advantages**: - Provides high-level protection in environments with frequent explosive atmospheres. - Suitable for a wide range of electrical equipment. **Considerations**: - The housing must be robust and well-sealed, which can increase the weight and size of the equipment. - Maintenance and inspection can be more challenging due to the need to maintain the integrity of the enclosure. ### 2. Increased Safety Type (Ex e) **Description**: The increased safety method enhances the safety features of the equipment to prevent the occurrence of arcs, sparks, or high temperatures under normal operating conditions. **Applications**: Suitable for motors, lighting fixtures, junction boxes, and other electrical apparatus. **Advantages**: - Reduces the risk of ignition by enhancing the equipment's safety design. - Often lighter and less bulky compared to flameproof enclosures. **Considerations**: - Best suited for equipment that does not produce sparks or arcs during normal operation. - Requires careful design and manufacturing to ensure enhanced safety features. ### 3. Intrinsic Safety Type (Ex i) **Description**: Intrinsic safety limits the energy within electrical circuits to prevent the generation of sparks or heat that could ignite an explosive atmosphere. Even in fault conditions, the energy is insufficient to cause ignition. **Applications**: Commonly used in control circuits, instrumentation, and signaling devices. **Advantages**: - Highly effective for low-power devices and control circuits. - Simplifies maintenance and inspection since there are fewer restrictions on opening equipment in hazardous areas. **Considerations**: - Limited to low-power applications. - Requires detailed analysis and design to ensure all potential ignition sources are controlled. ### 4. Pressurization Type (Ex p) **Description**: The pressurization method involves creating a positive pressure within the enclosure by introducing clean air or an inert gas. This prevents explosive gases from entering the enclosure. **Applications**: Suitable for larger equipment and systems, such as control rooms, analyzers, and motor control centers. **Advantages**: - Can be applied to a wide range of equipment sizes and types. - Allows the use of standard industrial equipment within the pressurized enclosure. **Considerations**: - Requires a continuous supply of clean air or gas and a reliable monitoring system. - May involve higher operational costs due to the pressurization system. ### 5. Oil Immersion Type (Ex o) **Description**: This method immerses electrical equipment in insulating oil to prevent the entry of explosive gases and to suppress any arcs or sparks. **Applications**: Used in transformers, circuit breakers, and other equipment where insulation and arc suppression are critical. **Advantages**: - Provides excellent arc suppression and insulation. - Effective for high-power equipment. **Considerations**: - Requires maintenance to ensure the oil remains clean and effective. - Potential for oil leaks, which need to be managed carefully. ### 6. Sand Filling Type (Ex q) **Description**: The sand filling method involves filling the enclosure with quartz sand or similar material to quench arcs and sparks, preventing the spread of ignition. **Applications**: Suitable for electrical apparatus where arc suppression is necessary, such as control units and junction boxes. **Advantages**: - Simple and effective method for arc suppression. - Can be used in various types of electrical equipment. **Considerations**: - Adds weight to the equipment. - Maintenance and inspection can be challenging due to the sand filling. ### 7. Non-Sparking Type (Ex n) **Description**: The non-sparking method ensures that the equipment is designed and manufactured in a way that prevents the generation of sparks, arcs, or high temperatures under normal operation and defined fault conditions. **Applications**: Suitable for low-risk environments and equipment like lighting fixtures, small motors, and control devices. **Advantages**: - Lightweight and less bulky compared to other explosion-proof methods. - Suitable for lower-risk areas where explosive atmospheres are less likely. **Considerations**: - Not suitable for high-risk environments with frequent explosive atmospheres. - Requires careful design to ensure non-sparking operation under all conditions. ### Choosing the Right Explosion-Proof Method When selecting an explosion-proof control box, it's crucial to consider the specific requirements of the environment and the nature of the equipment being protected. Here are some key factors to consider: 1. **Hazardous Area Classification**: Determine the classification of the hazardous area (e.g., Zone 1, Zone 2) to ensure the chosen method meets the required safety standards. 2. **Type of Explosive Atmosphere**: Consider whether the environment contains gases, vapors, or dust, as this will influence the choice of explosion-proof method. 3. **Equipment Type and Function**: Different methods are better suited to specific types of equipment. For example, intrinsic safety is ideal for control circuits, while flameproof enclosures are better for larger electrical equipment. 4. **Maintenance and Inspection**: Consider the ease of maintenance and inspection for the chosen method. Some methods, like intrinsic safety, allow for easier maintenance without compromising safety. 5. **Cost and Operational Considerations**: Evaluate the cost and operational requirements, including the need for continuous pressurization or oil maintenance. ### Conclusion Understanding the different explosion-proof methods for control boxes is essential for ensuring safety and efficiency in hazardous environments. Each method offers unique advantages and is suited to specific applications, making it crucial to choose the right method based on the specific needs of the environment and equipment. Investing in the appropriate explosion-proof control boxes not only ensures compliance with safety standards but also enhances operational efficiency and protects valuable assets. Whether you need a flameproof enclosure, an increased safety solution, or an intrinsically safe circuit, selecting the right explosion-proof method is a critical decision that contributes to the overall safety and success of your operations. Offshore operations often occur in hazardous environments where the presence of flammable gases or vapors poses significant risks. To mitigate these risks, specialized equipment such as Zone 2 applied offshore pressurised containers is essential. These containers are designed to operate safely in environments classified as Zone 2, where an explosive atmosphere is not likely to occur in normal operation and, if it does occur, will persist for a short period. This article delves into the applications, features, and benefits of these pressurised containers, particularly focusing on their use as Measurement While Drilling (MWD) units, laboratory containers, and Motor Control Center (MCC) shelters. ### What is a Zone 2 Area? Zone 2 areas are defined by the presence of an explosive atmosphere that is unlikely to occur in normal operation and, if it does occur, will do so infrequently and for a short duration. These areas require equipment that meets specific safety standards to prevent ignition and ensure the safety of personnel and equipment. Zone 2 equipment, including pressurised containers, is built to withstand these conditions, providing a safe working environment even in the presence of flammable gases or vapors. ### Key Features of Zone 2 Applied Offshore Pressurised Containers 1. **Pressurisation System**: A critical feature of these containers is their pressurisation system, which maintains a positive internal pressure to prevent the ingress of hazardous gases. This system is typically supported by continuous monitoring and alarm systems to ensure constant safety. 2. **Robust Construction**: Built from high-grade materials, these containers are designed to withstand harsh offshore conditions, including extreme weather, corrosive environments, and physical impacts. 3. **Compliance with Standards**: Zone 2 containers comply with international safety standards such as ATEX, IECEx, and others relevant to offshore hazardous areas. This ensures they meet stringent safety and performance requirements. 4. **Flexible Configurations**: These containers can be customized to suit various applications, including MWD units, laboratory setups, and MCC shelters. They are equipped with necessary utilities such as HVAC systems, fire suppression systems, and explosion-proof lighting. ### Applications of Zone 2 Pressurised Containers #### 1. Measurement While Drilling (MWD) Units MWD units are essential in the drilling process, providing real-time data on the wellbore's conditions. Zone 2 applied pressurised containers offer a safe and controlled environment for housing sensitive MWD equipment, ensuring continuous operation without the risk of explosion. These units can be equipped with advanced telemetry systems, data acquisition modules, and monitoring equipment, all protected within the pressurised container. **Benefits**: - **Safety**: Ensures safe operation in hazardous areas. - **Reliability**: Protects sensitive equipment from harsh offshore conditions. - **Efficiency**: Allows for continuous data collection and transmission, improving drilling accuracy and efficiency. #### 2. Laboratory Containers Offshore laboratories require a controlled environment to conduct various tests and analyses. Zone 2 pressurised lab containers provide a safe and stable environment for scientific work, equipped with all necessary laboratory equipment and safety systems. These containers can be customized with workbenches, storage cabinets, fume hoods, and other laboratory necessities. **Benefits**: - **Controlled Environment**: Maintains necessary conditions for accurate scientific work. - **Safety**: Ensures that hazardous gases do not enter the laboratory space. - **Mobility**: Easily transportable to different offshore locations as needed. #### 3. Motor Control Center (MCC) Shelters MCC shelters house critical electrical equipment used to control motors and other electrical devices in offshore installations. Zone 2 pressurised containers ensure these components are protected from hazardous gases, moisture, and other environmental factors. These shelters are equipped with climate control systems, fire suppression systems, and explosion-proof electrical installations. **Benefits**: - **Equipment Protection**: Shields critical electrical components from harsh conditions. - **Operational Safety**: Prevents the risk of ignition in hazardous areas. - **Efficiency**: Ensures reliable operation of motor control systems, reducing downtime. ### Advantages of Using Zone 2 Applied Pressurised Containers Offshore 1. **Enhanced Safety**: The primary advantage of these containers is the enhanced safety they provide. By preventing the ingress of flammable gases and ensuring a controlled environment, they significantly reduce the risk of explosions. 2. **Operational Efficiency**: These containers enable continuous and reliable operation of critical equipment, minimizing downtime and enhancing overall operational efficiency. 3. **Customizability**: The ability to customize these containers for specific applications makes them highly versatile, suitable for various offshore needs. 4. **Compliance**: Using Zone 2 pressurised containers ensures compliance with international safety standards, which is crucial for maintaining operational licenses and avoiding regulatory penalties. 5. **Durability**: Constructed to withstand extreme offshore conditions, these containers offer long-term durability and reliability. ### Conclusion Zone 2 applied offshore pressurised containers are indispensable for ensuring safety and operational efficiency in hazardous offshore environments. Whether used as MWD units, laboratory containers, or MCC shelters, these containers provide a robust and reliable solution for protecting critical equipment and personnel. Their ability to maintain a safe internal environment, coupled with their compliance with international standards, makes them a vital component of offshore operations. Investing in high-quality Zone 2 pressurised containers is a strategic decision that enhances safety, ensures compliance, and boosts operational efficiency, making them an essential asset for any offshore installation. Comprehensive Lifecycle Planning and Design Analysis of Containerized Energy Storage Systems5/31/2024

Containerized energy storage systems encompass all stages from planning, design, construction, and operation to final decommissioning. This process involves not only the technical implementation but also considers economic feasibility, environmental impact, and social responsibility. ## Lifecycle Stages of Energy Storage Systems The lifecycle of an energy storage system can be divided into seven key stages: planning and design, manufacturing, packaging and transportation, installation, commissioning, operation, maintenance and inspection, and decommissioning. Safety analysis for these systems can be categorized into electrical/electronic safety, thermal safety, mechanical safety, and chemical safety. A comprehensive safety plan should be implemented at each stage to ensure the product meets all safety requirements. ### 1. Planning and Design Stage **Needs Analysis:** Determine the application scenarios, scale, and performance requirements of the energy storage system. This includes identifying whether the system will be used for grid stabilization, renewable energy integration, backup power, or other purposes. **Battery Selection:** Choose the appropriate energy storage technology based on the identified needs. Options include lithium-ion batteries, lead-acid batteries, and flow batteries. Each technology has its advantages and suitability depending on the specific application. **System Design:** This includes layout design, electrical design, structural design, and thermal management design. The layout should ensure efficient use of space and ease of maintenance, while electrical design should focus on reliability and safety. Structural design must consider the robustness and durability of the system, and thermal management should prevent overheating and ensure optimal performance. **Safety Design:** Consider the safety of the system, including fire prevention, explosion protection, and overheat protection. This involves incorporating safety features such as fire suppression systems, thermal insulation, and emergency shutdown mechanisms. ### 2. Manufacturing Stage **Material Selection:** Select appropriate materials to ensure the system's performance and lifespan. This includes choosing materials that can withstand the operational environment and have minimal environmental impact. **Quality Control:** Implement strict quality control measures throughout the manufacturing process. Each component must meet established standards to ensure overall system reliability. **Assembly Testing:** Conduct preliminary functional tests after assembling the components to ensure they work correctly. This includes electrical tests, mechanical integrity checks, and safety feature verification. ### 3. Packaging and Transportation **Packaging and Labeling:** Use appropriate packaging materials and methods to protect the batteries during transportation. This includes shock-absorbing materials and secure enclosures to prevent damage. **Labeling:** Clearly label the packaging with information such as battery type, weight, and special handling instructions to ensure proper handling by transport personnel. ### 4. Installation Stage **Site Preparation:** Ensure that the installation site meets the requirements for the energy storage system. This includes evaluating the site for structural integrity, electrical infrastructure, and environmental conditions. **Equipment Installation:** Install the equipment according to the design blueprints. This involves positioning the containers, securing them, and connecting all necessary components. **Connection and Commissioning:** Complete the electrical connections and perform system commissioning to ensure everything operates correctly. This includes running initial tests to verify functionality and safety. ### 5. Commissioning Stage **System Inspection and Testing:** Conduct a comprehensive inspection and testing of the installed system. Verify that all connections and functions are correct and that the system is safe and reliable. **Electrical System Verification:** Ensure that all electrical connections are accurate and secure to prevent issues such as short circuits or leakage. This involves checking wiring, circuit breakers, and protective devices. ### 6. Operation Stage **Monitoring and Maintenance:** Continuously monitor the system's operational status and conduct regular maintenance and inspections. Use monitoring tools to track performance metrics and detect potential issues early. **Performance Optimization:** Optimize the system based on operational data to improve efficiency and reliability. This might involve adjusting settings, upgrading components, or implementing new software updates. **Fault Handling:** Promptly address any system faults to ensure stable operation. This includes diagnosing issues, performing repairs, and replacing faulty components. ### 7. Maintenance and Inspection Stage **Regular Maintenance Plan:** Develop a regular maintenance plan that includes cleaning, tightening connections, and checking battery status. This ensures the system remains safe and reliable over its lifespan. **Battery Status Monitoring:** Regularly check the battery status, including capacity and internal resistance, to prevent aging, damage, or abnormal conditions. Use diagnostic tools to assess battery health and predict replacement needs. ### 8. Decommissioning Stage **Decommissioning Assessment:** Evaluate the system for decommissioning when it reaches the end of its designed lifespan or when its performance significantly declines. This includes assessing whether components can be repurposed or recycled. **Disassembly and Recycling:** Safely disassemble the equipment and recycle key components such as batteries to minimize environmental impact. Follow proper disposal guidelines to handle hazardous materials. **Environmental Impact Assessment:** Assess the environmental footprint of the entire lifecycle, including carbon emissions and resource consumption. Implement measures to mitigate negative impacts and promote sustainability. In conclusion, the lifecycle of containerized energy storage systems is complex and multifaceted, requiring careful planning and execution at each stage. By addressing technical, economic, and environmental considerations, we can ensure the safe, efficient, and sustainable operation of these systems. This comprehensive approach not only maximizes the benefits of energy storage but also aligns with broader goals of environmental stewardship and social responsibility. In the realm of offshore operations, where every element must withstand the rigors of the sea, accommodation solutions play a pivotal role. Enter TLS Offshore Containers, a pioneering force in revolutionizing offshore living experiences. Let’s delve into how TLS containers are reshaping the landscape of offshore accommodations, blending innovation, durability, and efficiency. Introduction: Offshore projects demand accommodations that are not only robust and secure but also flexible and efficient. TLS Offshore Containers stands tall as a beacon of innovation in this domain, offering modular living solutions that cater to the unique needs of offshore operations. From oil and gas platforms to renewable energy installations, TLS containers are engineered to deliver unparalleled performance in the harshest marine environments. Advantages of TLS Offshore Containers:

Applications:

Conclusion: TLS Offshore Containers epitomizes innovation and reliability in the realm of offshore accommodations. With their durable construction, modular flexibility, safety compliance, cost-effectiveness, and sustainability initiatives, TLS containers set a new standard for offshore living solutions. As offshore operations continue to evolve, TLS remains steadfast in its commitment to delivering superior accommodation solutions that meet the ever-changing needs of the industry. Choose TLS for offshore accommodations that redefine comfort, efficiency, and durability on the high seas. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. Key words: #Offshore living #Modular accommodation #Offshore operations #Marine environments #Efficiency #Safety compliance #Sustainability #Innovation #Remote locations #Oil and gas platforms #Renewable energy installations #Modular design #Rapid deployment Written by OliverIntroduction: In the realm of deep-sea exploration, safety and innovation are paramount. TLS Offshore Containers, a pioneering company renowned for its commitment to excellence, has introduced a groundbreaking solution to revolutionize underwater exploration: the ROV Pressurized Cabin. In this SEO blog post, we delve into the significance of this innovative technology and its transformative impact on underwater expeditions. Unveiling the ROV Pressurized Cabin: TLS Offshore Containers' ROV Pressurized Cabin is a marvel of engineering, designed to redefine the possibilities of deep-sea exploration. This cutting-edge cabin offers a secure environment for human operators, enabling direct occupancy in the depths of the ocean. Equipped with advanced safety features and state-of-the-art technology, it ensures unparalleled protection and comfort for operators during underwater missions. Safety at the Forefront: Safety is the cornerstone of TLS Offshore Containers' design philosophy, and the ROV Pressurized Cabin exemplifies this commitment. Constructed with robust materials and equipped with stringent safety protocols, it shields occupants from the extreme pressures and environmental hazards of the deep sea. TLS prioritizes the well-being of operators, providing peace of mind in the most challenging underwater conditions. Empowering Exploration: The ROV Pressurized Cabin transcends the limitations of traditional remote-operated vehicles (ROV) by facilitating direct human interaction with the underwater environment. This human presence enhances the scope and quality of exploration, allowing operators to conduct intricate tasks and make real-time observations with unprecedented clarity and precision. TLS empowers exploration teams to push boundaries and unlock new discoveries beneath the waves. Adaptability and Versatility: TLS Offshore Containers' commitment to innovation extends to the adaptability and versatility of the ROV Pressurized Cabin. Whether navigating complex underwater terrain, conducting scientific research, or inspecting offshore infrastructure, this versatile technology rises to the challenge. Its modular design enables seamless customization to suit the unique requirements of diverse exploration projects, ensuring maximum efficiency and effectiveness. Sustainable Exploration: TLS Offshore Containers recognizes the importance of responsible environmental stewardship in deep-sea exploration. The ROV Pressurized Cabin facilitates non-invasive observation and data collection, minimizing disturbance to fragile underwater ecosystems. By promoting sustainable exploration practices, TLS contributes to the preservation and conservation of marine environments for future generations. Conclusion: The ROV Pressurized Cabin by TLS Offshore Containers represents a paradigm shift in underwater exploration technology. With its unwavering focus on safety, empowerment, adaptability, and sustainability, it heralds a new era of discovery beneath the ocean's surface. As exploration teams embark on voyages of exploration and scientific inquiry, TLS's innovative cabin serves as a beacon of progress and possibility, driving forward the frontiers of human knowledge and understanding in the depths of the sea. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #ROV Pressurized Cabin #TLS Offshore Containers #Deep-sea exploration #Underwater technology #Safety features #Exploration capabilities #Innovation #Versatility #Adaptability #Environmental conservation #Sustainable exploration #Modular design #Underwater observation Written by OliverIn the dynamic landscape of offshore industries, efficiency, and safety are paramount. With the demand for reliable equipment that can withstand harsh environments, TLS introduces the A60 Offshore Pressurized Container, revolutionizing offshore operations. In this blog post, we delve into the features, benefits, and significance of this innovative solution in enhancing productivity and mitigating risks in offshore settings. Understanding the A60 Offshore Pressurized Container The A60 Offshore Pressurized Container by TLS is a cutting-edge solution engineered to meet the rigorous demands of offshore environments. Designed to withstand extreme conditions such as high pressure, corrosive elements, and adverse weather, this container sets a new standard in reliability and durability. Key Features and Benefits

Applications in Offshore Industries The versatility of the A60 Offshore Pressurized Container makes it indispensable across a wide range of offshore applications, including:

Conclusion In the ever-evolving landscape of offshore industries, the A60 Offshore Pressurized Container by TLS emerges as a game-changer, combining innovation, reliability, and safety to optimize operations and mitigate risks. With its robust construction, advanced features, and customizable configurations, this container offers unmatched versatility and performance in demanding offshore environments. Embrace the future of offshore operations with TLS and experience the difference with the A60 Offshore Pressurized Container. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Product brochures: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Key words: #Offshore industry #Oil and gas #Marine engineering #Subsea operations #Rigging solutions #Containerization #Hazardous materials #Seismic exploration #Remote locations #Modular design #Environmental protection #Logistics management Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|