|

Offshore container HVAC systems are a critical component of the oil and gas industry, providing essential temperature regulation, humidity control, and ventilation in offshore locations. What’s the importance of HVAC Systems in Offshore Containers? Offshore container HVAC systems are crucial in ensuring the safety and well-being of personnel working in offshore locations. These systems regulate the temperature within the container, preventing heat stress and hypothermia. They also control humidity levels, preventing corrosion and damage to equipment stored in the container.

Temperature regulation is also important for personnel working in offshore locations. Extreme temperatures can cause heat stress, leading to fatigue, nausea, and dehydration. On the other hand, low temperatures can cause hypothermia, which can be life-threatening.

Humidity control is also important for personnel working in offshore locations. High humidity levels can cause discomfort, making it difficult for workers to perform their tasks. Low humidity levels can cause dry skin, eye irritation, and respiratory problems.

Ventilation is particularly important when storing hazardous materials in the container. These materials can release harmful gases, which can be dangerous if inhaled. Proper ventilation can prevent the buildup of these gases, ensuring the safety of personnel working in the container. What’s the benefits of HVAC Systems in Offshore Containers? Offshore container HVAC systems offer several benefits, including energy efficiency, durability, and customization.

Energy-efficient HVAC systems use less energy to regulate the temperature within the container, which reduces the amount of fuel required to power the system. They also use advanced technologies such as variable speed drives, which adjust the speed of the system based on the temperature requirements. This reduces energy consumption and increases the efficiency of the system.

Durability is important in offshore locations where the environment can be unpredictable. Offshore container HVAC systems must be able to withstand the elements and continue to operate even in adverse conditions. This ensures that personnel working in the container are protected and that equipment stored in the container is safe from damage.

Customization is important in offshore locations where the needs of the company may vary depending on the project or location. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Writted by OliverOffshore container painting is a critical maintenance task that ensures the safety and longevity of offshore containers used in the oil and gas industry. Offshore containers are used to transport equipment, tools, and materials to and from offshore drilling rigs and other offshore structures. These containers are subject to harsh environmental conditions, such as saltwater, UV radiation, and extreme temperatures, which can lead to corrosion, damage, and deterioration over time. Therefore, offshore container painting is essential to protect the containers from these elements and prevent them from becoming a safety hazard. Offshore container painting involves the application of a high-performance coating system that is designed to withstand the harsh marine environment. The coating system includes a primer, intermediate coat, and topcoat, each with specific properties to ensure the optimal protection of the container. The primer is used to prepare the surface and provide adhesion for the intermediate coat, which provides further protection and durability. The topcoat is the final layer, which adds color and gloss to the container, as well as additional protection against UV radiation and other environmental factors. Offshore container painting offers several benefits that are crucial for the safety and durability of the containers. Some of these benefits include:

In conclusion, offshore container painting is an essential maintenance task that is crucial for the safety and longevity of offshore containers used in the oil and gas industry. By applying a high-performance coating system, companies can protect their containers from harsh environmental conditions, extend their lifespan, enhance their safety, and improve their appearance. Therefore, it is important for companies to invest in offshore container painting to ensure the optimal performance of their equipment and operations. Written by OliverWhen it comes to offshore containers used in the oil and gas industry, DNV2.7-1 is a widely recognized standard. However, selecting the right paint standard for these containers can be challenging. Two options to consider are C3 and C5 standards. The C3 standard is suitable for containers used in general marine environments, with coatings having medium durability and anti-corrosion properties. The minimum paint thickness should be 75μm. On the other hand, the C5 standard is suitable for containers used in highly corrosive environments, with coatings having high durability and anti-corrosion properties. The minimum paint thickness should be 150μm. It's important to consider the specific usage environment and requirements when selecting the paint standard for DNV2.7-1 compliant containers. For general marine environments, the C3 standard is typically sufficient. However, if the container will be exposed to highly corrosive environments, the C5 standard should be used. Proper surface preparation, primer application, intermediate coats, and topcoat thickness are also crucial factors in ensuring the longevity and durability of the paint on DNV2.7-1 compliant containers. In conclusion, choosing the right paint standard is essential to ensure the safety and longevity of DNV2.7-1 compliant containers. By understanding the differences between C3 and C5 standards and considering the specific usage environment, you can make an informed decision and select the appropriate standard for your container. The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system. This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power. Here's an overview of the design sequence: 1. Requirements and specifications: - Determine the specific use case for the BESS container. - Define the desired energy capacity (in kWh) and power output (in kW) based on the application. - Establish the required operational temperature range, efficiency, and system lifespan. 2. Battery technology selection: - Choose the appropriate battery technology (e.g., lithium-ion, flow batteries, or advanced lead-acid) based on the requirements, cost, efficiency, and availability. 3. System architecture and layout design: - Develop a high-level system architecture, including battery modules, inverters, transformers, power distribution units, and control systems. - Design the container layout, considering factors like thermal management, accessibility, and maintenance. 4. Thermal management and HVAC design: - Design the cooling and heating systems, considering the battery technology and its thermal requirements. - Select appropriate HVAC components (e.g., air conditioners, fans, heaters) based on the container's size and cooling/heating requirements. 5. Electrical and control system design: - Design the electrical system, including wiring, protection devices, grounding, and power distribution. - Develop the control system for monitoring and managing the BESS container, including battery management systems (BMS), energy management systems (EMS), and communication interfaces. 6. Safety and regulatory compliance: - Ensure compliance with local and international safety standards, such as UL, IEC, and IEEE. - Implement necessary safety measures, including fire suppression systems, alarms, and emergency shutdown procedures. 7. Container selection and structural modifications: - Select an appropriate container size (e.g., 20-foot or 40-foot) based on the system layout and required capacity. - Make necessary structural modifications to the container, such as ventilation openings, cable entry points, and door reinforcements. 8. System integration and assembly: - Assemble the BESS components within the container, following the designed layout. - Install and connect the electrical and control systems. 9. Testing and commissioning: - Perform thorough testing of the BESS container, including functional, performance, and safety tests. - Commission the system and verify that it meets the specified requirements and operates as intended. 10. Transportation and deployment: - Transport the container to the installation site and deploy the BESS system. - Connect the BESS container to the grid or other intended energy sources and loads. 11. Operation and maintenance: - Monitor the performance and health of the BESS container during operation. - Perform regular maintenance and inspections to ensure the system operates efficiently and safely. The Importance of Air-Lock Compartments in Positive Pressure Containers in the Oil and Gas Industry4/7/2023

Positive pressure containers are a critical component in various industries, including the oil and gas industry, where maintaining a sterile environment and preventing contamination is essential for safe and efficient operations. These containers utilize a specialized mechanism known as an air-lock compartment to ensure that the air inside remains under positive pressure. An air-lock compartment is a small chamber located between the outside environment and the positive pressure container. This chamber features two airtight doors that prevent air from passing through when they are closed. The first door faces the external environment, while the second door faces the positive pressure container. The air-lock compartment's purpose is to enable people and objects to enter and exit the positive pressure container without compromising the sterile environment inside. The process of entering the air-lock compartment begins by closing the first door. The chamber is then pressurized to match the positive pressure inside the container, preventing any air from the outside environment from entering the container. Once the air-lock compartment is pressurized, the second door facing the container can be opened, allowing a person or object to enter. Upon entry, the second door is closed, and the air-lock compartment is depressurized, removing any contaminants that may have entered the chamber. In addition to providing a safe and sterile entry and exit point for people and objects, the air-lock compartment also serves as a means of removing objects and waste from the positive pressure container without contaminating the outside environment. When an object or waste is removed from the container, it is placed inside the air-lock compartment, and the second door is closed. The compartment is then pressurized, and the first door is opened, allowing the object or waste to be removed from the air-lock compartment and into the external environment. In the oil and gas industry, positive pressure containers with air-lock compartments are essential for safe and efficient operations. They are used to maintain a sterile environment when drilling or performing other operations that require strict contamination control measures. Additionally, these containers are used to store hazardous materials and waste safely, reducing the risk of environmental contamination. In conclusion, air-lock compartments are a critical component of positive pressure containers, enabling safe and sterile entry and exit points for people and objects while maintaining a contamination-free environment. In the oil and gas industry, these containers play a crucial role in ensuring safe and efficient operations, minimizing the risk of environmental contamination and protecting workers from hazardous materials. Written by OliverAs the world increasingly shifts towards renewable energy, the importance of energy storage solutions cannot be overstated. One such innovative and versatile solution is the TLS Battery Sea Container - a mobile energy storage unit that is capable of being easily transported and deployed. At its core, the TLS Battery Sea Container is a standard shipping container that has been converted into an energy storage unit by integrating it with batteries, inverters, and other electrical components. These units are particularly useful for storing energy from renewable sources such as solar and wind, and can be conveniently transported by truck, train, or ship. The advantages of utilizing the TLS Battery Sea Container as an energy storage solution are manifold.

The application of the TLS Battery Sea Container is wide-ranging and diverse. They can be used to provide energy storage solutions for remote communities without access to the grid, as well as in emergency situations where power outages may occur. Moreover, battery shipping containers have the potential to revolutionize remote mining operations that currently rely on diesel generators for power, providing a more sustainable energy source. Additionally, they can be utilized to provide temporary power solutions at construction sites, thereby increasing their flexibility and convenience. While the TLS Battery Sea Container offers a compelling solution for energy storage, it is vital to consider its environmental impact. The production of batteries requires the extraction of raw materials, which has a negative impact on the environment. Furthermore, the disposal of used batteries can pose environmental risks if not managed appropriately. However, the use of renewable energy sources like solar and wind to charge batteries can help mitigate these environmental impacts. With proper maintenance and management, the overall environmental footprint of battery sea containers can also be minimized, extending the lifespan of batteries and reducing waste. Moreover, the deployment of battery sea containers can help reduce greenhouse gas emissions by providing a clean and sustainable energy source. This is particularly critical in regions heavily reliant on fossil fuels for energy. Governments and organizations can play a vital role in mitigating the environmental impact of battery sea containers by encouraging the use of renewable energy and promoting proper battery management and disposal practices. In conclusion, the TLS Battery Sea Container offers a promising solution for energy storage. By utilizing renewable energy and appropriate management practices, the overall environmental footprint of these containers can be minimized. As governments and organizations continue to prioritize sustainability, the deployment of battery sea containers is expected to become more common. With their portability, expandability, and durability, they are poised to become a critical part of the energy infrastructure as renewable energy continues to grow. Written by OliverMud logging cabins are an essential part of the oil and gas exploration process. These cabins are mobile units that are usually stationed at the drilling site and are responsible for collecting and analyzing geological data during the drilling process. Mud logging is an important process that helps determine the viability of a well and the potential for oil and gas production. Mud logging cabins are typically located near the drilling rig and are designed to provide a comfortable and safe environment for the mud loggers to work in. These cabins are usually equipped with the latest technology and equipment to ensure that accurate data is collected during the drilling process. They are usually made of durable materials such as steel or aluminum to withstand the harsh conditions of the drilling site. One of the most critical aspects of a mud logging cabin is the communication and data transfer capabilities. Mud loggers need to be able to communicate with the drilling team and relay data in real-time. This ensures that the drilling team can make informed decisions based on the data collected by the mud loggers. Mud logging cabins are equipped with advanced communication equipment such as satellite phones, radios, and computers to ensure that the data is collected and relayed efficiently. Mud loggers are responsible for collecting data on the formation being drilled, the drill cuttings, and the drilling mud. The drilling mud is analyzed for various parameters such as density, viscosity, and pH levels. The mud loggers also collect drill cuttings that are analyzed for their mineral content and texture. This information helps geologists and drilling engineers determine the potential for oil and gas production. In addition to collecting data, mud logging cabins also provide shelter and safety for the mud loggers. These cabins are usually equipped with HVAC systems to provide heating and cooling, depending on the weather conditions. They also have safety features such as fire extinguishers and emergency exits in case of an emergency. Mud logging cabins play a critical role in the oil and gas exploration process. They are an essential component of the drilling operation, providing real-time data and analysis to the drilling team. Without mud logging cabins, it would be challenging to collect accurate data and make informed decisions about the potential for oil and gas production. Mud logging cabins are a testament to the ingenuity and innovation of the oil and gas industry, providing a safe and efficient way to explore for new resources. Please download our product brochure for your reference: Offshore pressurised mud logging cabin brochure MCC | Switchgear | VFD | VSD pressurised shelter Don’t hesitate to contact us for more information about the offshore pressurised container. Written by OliverOffshore Pressurized Container: The Ultimate MCC Shelter by TLS Offshore Containers International4/4/2023

The offshore industry continually seeks innovative solutions to ensure safe and efficient operations in challenging environments. One such solution is the Offshore Pressurized Container, specifically designed as a Motor Control Center (MCC) shelter. TLS Offshore Containers International, a leading provider of high-quality offshore containers, is the company behind the production of these state-of-the-art pressurized containers. This article will explore the unique features, applications, and benefits of the Offshore Pressurized Container, showcasing its role as a game-changer in the offshore industry. Offshore Pressurized Container: What is it? The Offshore Pressurized Container is a specialized container designed to serve as a Motor Control Center (MCC) shelter in offshore environments. These containers are built to withstand extreme weather conditions, high pressures, and harsh working environments that are common in offshore operations. They provide an ideal solution for housing MCCs, electrical equipment, and control systems, ensuring safety, efficiency, and reliability. TLS Offshore Containers International: The Company Behind the Innovation TLS Offshore Containers International is a globally renowned manufacturer of offshore containers and equipment. With over two decades of experience, the company has earned a reputation for delivering high-quality, durable, and innovative products to clients across the globe. The Offshore Pressurized Container is another testament to their commitment to excellence in the offshore industry. Key Features of the Offshore Pressurized Container The Offshore Pressurized Container comes with several unique features that set it apart from other MCC shelters: a. Pressurized environment: The container maintains a pressurized environment to protect sensitive equipment and personnel from harmful substances, such as toxic gases and vapors. b. Customizable design: The container can be customized to meet specific client requirements, such as dimensions, layout, and technical specifications. c. Robust construction: Made from high-quality materials, the container is built to withstand harsh offshore conditions, including extreme temperatures, corrosive elements, and heavy loads. d. Safety features: The container is equipped with numerous safety features, such as fire detection and suppression systems, gas detection systems, and emergency escape routes. e. Compliance with industry standards: The Offshore Pressurized Container meets international offshore container standards, including DNV 2.7-1, EN 12079, and ISO 10855. Applications of the Offshore Pressurized Container The Offshore Pressurized Container is ideal for a wide range of offshore applications, including: a. Offshore oil and gas platforms: The container serves as a safe and secure MCC shelter on drilling rigs, production platforms, and floating production, storage, and offloading (FPSO) units. b. Offshore wind farms: The container can be used as an MCC shelter in wind farm substations, ensuring reliable control and monitoring of wind turbines. c. Marine construction projects: The container can be utilized in various marine construction projects, such as bridge construction, underwater tunneling, and port infrastructure development. d. Offshore research facilities: The container can provide a safe and secure environment for scientific research and data collection in offshore locations. Benefits of the Offshore Pressurized Container Investing in an Offshore Pressurized Container from TLS Offshore Containers International offers several advantages: a. Enhanced safety: The container's pressurized environment and safety features protect both equipment and personnel from potential hazards. b. Cost-effective solution: The container's durable construction and ability to withstand harsh offshore conditions lead to lower maintenance costs and extended service life. c. Customization options: The ability to customize the container to meet specific client requirements ensures a tailor-made solution for each project. d. Improved efficiency: The container's design allows for easy installation, operation, and maintenance of MCCs and other electrical equipment, streamlining offshore operations. e. Compliance with industry standards: By meeting international offshore container standards, the Offshore Pressurized Container ensures compliance with regulatory requirements and reduces the risk of non-compliance penalties. How to Get Your Offshore Pressurized Container To learn more about the Offshore Pressurized Container and how it can benefit your offshore operations, visit the official TLS Offshore Containers International website at https://www.tls-containers.com/pressurised-container.html. Here, you can find detailed information about the product, as well as contact information to get in touch with the company's expert team who can assist with your specific needs and requirements. The Offshore Pressurized Container by TLS Offshore Containers International is an innovative solution that provides a safe, efficient, and customizable MCC shelter for various offshore applications. Its unique features, such as the pressurized environment, robust construction, and compliance with industry standards, make it an ideal choice for offshore operators looking to improve safety and efficiency in their operations. By investing in an Offshore Pressurized Container, businesses can reap the benefits of enhanced safety, reduced operational costs, and streamlined operations while ensuring compliance with international standards. Visit the TLS Offshore Containers International website today to learn more about this game-changing product and how it can revolutionize your offshore operations. The offshore industry is continuously evolving, and with this expansion comes the need for safe, comfortable, and high-quality accommodations for the professionals working in these demanding environments. To meet these requirements, TLS Offshore Containers International is proud to offer their state-of-the-art ABS approved offshore accommodation cabins, designed to provide the ultimate in safety, durability, and living comfort. As a world-renowned manufacturer of offshore containers and cabins, TLS Offshore Containers International is dedicated to providing top-notch products and services to its global clientele. With years of experience, a strong commitment to quality, and a deep understanding of the unique challenges faced by the offshore industry, our ABS approved accommodation cabins stand out as a testament to our expertise and dedication to excellence. What Are ABS Approved Offshore Accommodation Cabins? Offshore accommodation cabins are specialized living quarters designed specifically for personnel working in the offshore oil and gas, renewable energy, and maritime sectors. These cabins must adhere to stringent safety standards and regulations to ensure that the occupants are protected from the harsh conditions and potential hazards of their surroundings. ABS, or the American Bureau of Shipping, is a globally recognized classification organization that sets safety and environmental standards for the marine and offshore industries. An ABS-approved offshore accommodation cabin is a testament to its superior quality, as it has met or exceeded the rigorous requirements set forth by the ABS. Features and Benefits of TLS Offshore Containers International's ABS Approved Offshore Accommodation Cabins: 1. Superior Quality and Safety StandardsOur ABS approved offshore accommodation cabins are manufactured using the highest quality materials and components, ensuring maximum durability and resistance to corrosion, even in the harshest offshore environments. By adhering to ABS standards, our cabins provide a safe, secure, and comfortable living space for offshore personnel, giving them peace of mind knowing they are protected from the elements and potential hazards. 2. Customizable SolutionsWe understand that the needs of each project and client may vary, which is why we offer a range of customizable options to suit individual requirements. From cabin size and layout to additional features and amenities, our team of experts will work closely with you to design and manufacture an accommodation solution tailored to your unique needs. 3. Enhanced Comfort and LivabilityOur ABS approved offshore accommodation cabins are designed with the comfort of the occupants in mind. With features such as ergonomic furniture, temperature control systems, sound insulation, and ample storage, our cabins provide a comfortable and functional living space that helps to boost morale and productivity for those working offshore. 4. Easy Installation and IntegrationOur offshore accommodation cabins are designed for easy installation and integration with existing offshore platforms and vessels. With a modular design and standardized connection points, our cabins can be quickly and efficiently installed on site, minimizing downtime and disruption to your operations. 5. Comprehensive After-sales SupportAt TLS Offshore Containers International, we pride ourselves on providing exceptional customer service and after-sales support. Our team of skilled technicians and engineers are available to assist with any maintenance, repairs, or modifications that may be required, ensuring your accommodation cabins remain in optimal condition throughout their lifespan. 6. Environmentally Friendly SolutionsWe recognize the importance of environmental stewardship and strive to minimize our ecological footprint throughout the entire manufacturing process. Our ABS approved offshore accommodation cabins are designed to be energy-efficient and compliant with international environmental regulations, helping to reduce emissions and promote a sustainable future for the offshore industry. When it comes to offshore accommodations, safety, comfort, and durability are of the utmost importance. With TLS Offshore Containers International's ABS approved offshore accommodation cabins, you can rest assured that you are investing in a product that has been meticulously crafted to meet the highest industry standards. Our commitment to quality, innovation, and customer satisfaction sets us apart as the leading manufacturer of offshore accommodation solutions. By choosing TLS Offshore Containers International for your accommodation needs, you are not only selecting a superior product but also partnering with a company that is dedicated to supporting your operations and ensuring the well-being of your personnel. Our team of experts is ready to collaborate with you to design and manufacture the perfect ABS approved offshore accommodation cabin that meets your unique requirements and exceeds your expectations. In an industry that demands the highest levels of safety, reliability, and performance, TLS Offshore Containers International is the name you can trust. Contact us today to learn more about our ABS approved offshore accommodation cabins and discover how we can help to enhance the comfort and safety of your offshore personnel. With our expertise and commitment to excellence, we are confident that our offshore accommodation solutions will not only meet your needs but also contribute to the success of your operations. Together, we can create a safer, more comfortable, and more sustainable future for the offshore industry. Choose TLS Offshore Containers International's ABS approved offshore accommodation cabins for your next project, and experience the difference that our dedication to quality, innovation, and customer satisfaction can make. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please contact [email protected] for more information. Container modular living quarters have emerged as a popular option for those seeking affordable and sustainable housing. These homes are made from repurposed shipping containers, which provide a sturdy and durable structure that can withstand harsh weather conditions and rough handling. The modular design of these living quarters allows for flexibility and versatility, making them an ideal choice for people who need a housing solution that can easily adapt to changing circumstances. A container modular living quarter is essentially a prefabricated housing unit made from shipping containers. The containers are remodeled with electrical, plumbing, heating systems, insulation, and other necessary amenities to create a comfortable living environment. The interior can be customized with a choice of different floor plans, finishes, fixtures, and appliances to suit your preferences. One of the main advantages of container modular living quarters is their affordability. Compared to traditional houses, these homes are cost-effective because they are built using recycled materials and a modular design, which reduces construction and maintenance costs. Additionally, they are environmentally friendly and sustainable, as they use recycled shipping containers and energy-efficient systems and materials that help reduce your carbon footprint and save on utility bills. Customization is another key benefit of container modular living quarters. You can choose from a variety of floor plans, finishes, fixtures, and appliances to create a living space that meets your specific needs and preferences. Moreover, these homes are highly flexible and can be easily relocated or expanded, making them suitable for people who need a temporary or semi-permanent housing solution. When choosing a container modular living area, you should consider factors such as size, location, customization options, quality, and cost. The design scheme of these homes can vary widely, with options such as open living spaces, outdoor areas, energy-saving features, and modern decor. The possibilities are endless, and you can create a home that truly reflects your personal style. In summary, container modular living quarters are an innovative and eco-friendly housing solution that offers many benefits. They are affordable, sustainable, customisable, flexible, and stylish. Whether you're looking for a starter home, a vacation home, or a home that can grow with your changing needs, container modular living quarters could be the perfect choice for you. Written by Oliver |

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

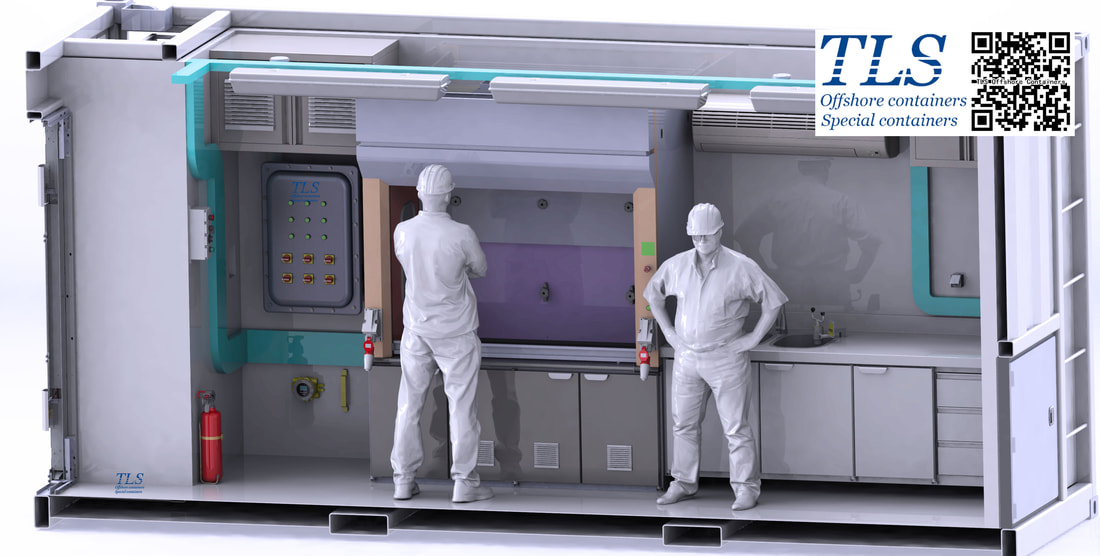

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|