|

Temporary Refuge Shelter (TR), safe haven cabin, toxic gas refuge shelter (TGR)

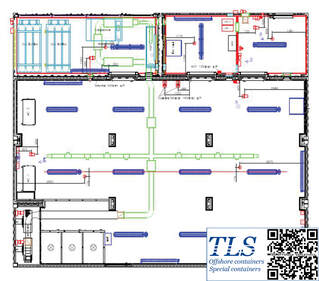

Temporary refuge shelter is a containerised module designed for persons for hours time duration in case of emergency such as toxic gas leakage, explosion, etc. which includes complete of air-lock, HVAC system, breathing air system (emergency pressurisation system), stand-alone electric system (UPS + batteries), F&G systems, facilities (medical kit, water and toilet) and accessories. Containerised or blast resistant structures are designed to protect persons in order to give possibilities of installation in safe area or explosion risk zone. HVAC running in Emergency mode for TR This kind of SURVIVAL MODULE is designed as "Modularised container/shelter" ready for the use as a “Stand alone package” meeting the following requirements: * High resistance to the adverse climatic and atmospheric conditions (corrosive marine conditions, high temperature and solar radiation in desert environments, industrial /oil gas aggressive chemical atmospheres) * Easy transport via land (road or railway) or sea. * Easy assembly of the entire Survival Module by simple bolting or (if required) welding. * Easy management and maintenance of the HVAC, Breathing Air and Electric systems. HVAC stopped in Emergency situation The fresh air intake is 100% redundant and it is sized in order to prevent the ingress of gas before the F/G system detection close the dampers. Under certain outdoor conditions, the CHEMICAL FILTER assure acceptable indoor conditions but when the maximum ppm vales are measured inside the Safe Area, the system switch to a full recirculation mode. In this particular emergency condition the HVAC system recirculate only the indoor air and provide for a first de-contamination by POLISHING FILTER. After this stage will be the CO2 SCRUBBER to be activated in order to keep breathing air atmosphere inside the room. In full recirculation mode, the pressurisation and the additional breathing air for all the people inside the refuge will be assured by dedicated HP Breathing air system composed by BA Cylinders Storage Racks (typically at 300 bar of storage pressure), reduction groups and nozzles for air diffusion. Overpressure system Overpressure systems for Electrical Substation or TR- Protection from weather/dust/toxic gas. The engineering of HVAC system or Emergency Pressurisation System start from the idea of personnel and equipment protection from critical outdoor conditions like extreme weather, dust or sand storm, H2S, HCL or other toxic gasses contamination. The first solution is to keep the projected indoor condition adopting a correct overpressure system with the necessary outdoor protection. IECEx and ATEX rating One of the most important focus point of HVAC engineering and construction in the Oil gas sector or in other difficult environmental conditions is to keep attention to the atmosphere composition. Due to this condition it is possible that all the components of HVAC equipment shall be IECEx & ATEX certified. We have planned, designed and realised solutions to prevent H2S and other hydrocarbon gases from entering the buildings in Oil & Gas complexes. The HVAC fresh air intake is projected in order to give the necessary closure time to Fire & Gas Dampers before the entry of toxic gases in the Electrical Substation. All the outdoor equipment are ATEX Zone 1 IIB T3 rated. Please contact us [email protected] for more information. Comments are closed.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|