|

Motor Control Centers (MCCs) are essential facilities that control and monitor electric motors and associated equipment. They serve as centralized control systems, incorporating motor starters, protection devices, control circuits, and instrumentation. To protect MCC equipment from harsh environmental conditions and external interferences, MCC shelters are deployed.These enclosed and fortified rooms or enclosures provide an ideal working environment, safeguarding the MCC systems and ensuring their uninterrupted operation.

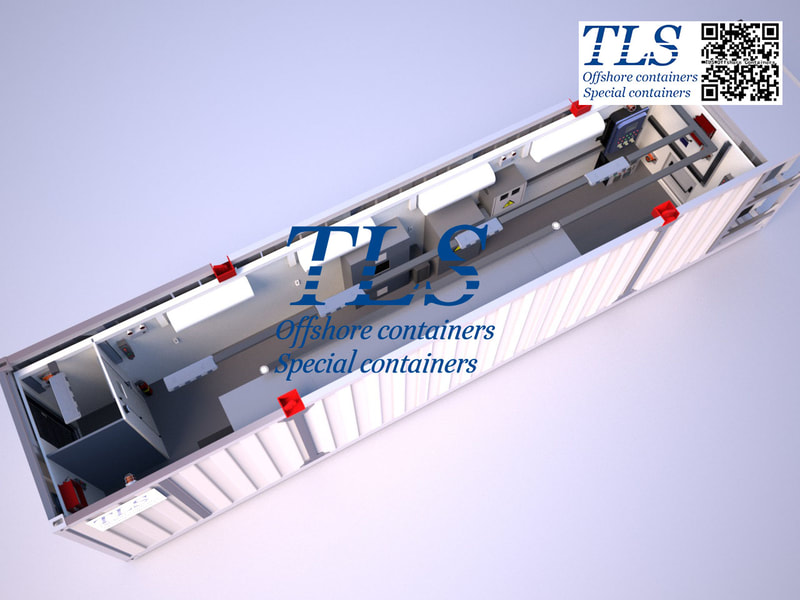

MCC shelters play a vital role in ensuring the safety, reliability, and efficiency of motor control centers. By providing physical protection, temperature control, safety measures, and sound isolation, these shelters create an optimal operational environment for MCC systems.With their ability to shield against environmental hazards and external disturbances, MCC shelters offer a secure, dependable, and efficient control center for electric motors. They serve as essential components in protecting and supporting the smooth operation of motor control systems, enabling optimal performance and prolonged equipment lifespan. TLS switchgear, MCC (motor control centre), MCP (motor circuit protection), VFD (variable frequency driver),VSD (variable speed driver) pressurised shelters are built from the containerized module to protect electronic controls and switch-gear safe from harsh climate, and the gas hazardous atmosphere,especially when the equipment is non explosion proof. The shelter solution will have the equipment (switchgear, MCC, MCP, etc)enclosed in a weatherresistant container with the entrance door for walk-in operation. Modular and flexible design make the shelter available to diverse requirements about the equipment, and the site installation. Standard or customized ISO standard or DNV2.7-1 standard container, sea worthy packing, easily transported by road and sea, to provide better support to overseas customers. Comments are closed.

|

Archives

July 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|