What’s the ABS Certification Process for Portable Accommodation Modules in Offshore Operations?5/5/2023

Obtaining the American Bureau of Shipping (ABS) certification is an significant requirement when using portable accommodation modules to vessels. Working offshore involves a range of certifications, both personal and equipment-related, to ensure safety and suitability for the harsh marine environment. Despite the familiarity of the ABS certification name, many people may not know the exact criteria that a portable accommodation module must meet to receive it. As a leading manufacturer of offshore portable accommodations, offices, and workshop modules, TLS has experience constructing modules that meet certifications for regulatory agencies worldwide. In this article, we will explain the process of obtaining ABS certification for a portable accommodation module. To obtain ABS certification, manufacturers must follow guidelines provided by the ABS for designing and manufacturing equipment that meets their certification requirements. These guidelines are updated periodically to keep up with industry developments and improve clarity. The certification process for a portable accommodation module involves four steps: Design Review of Module, Survey During Fabrication, Review for Installation Approval, and Survey Onboard Host Vessel. These steps cover the module's life cycle, from initial design and engineering to final installation and approval on a vessel or installation. ABS Certification Step 1 – Design Review of Module Within the design review of the module section of the guide, the ABS categorizes the requirements for portable accommodation modules into twelve areas:

After the engineering team has completed detailed plans, drawings, and data that meet the ABS requirements, the manufacturer submits them to the ABS technical office for review. Once the review is finished, the drawings are returned to the manufacturer and then sent to the ABS surveyor for further inspection. If the product design meets the requirements, the manufacturer will receive a Product Design Assessment (PDA) certificate, and the product status will be updated to "Design Assessed." With this certification in hand, the manufacturer can proceed to the next step of the process. ABS Certification Step 2 – Survey During Fabrication The manufacturer begins fabrication of the module following the drawings and designs approved by the ABS technical office. Within the drawings that the technical office sent over to the surveyor are:

During the fabrication process, the ABS surveyor conducts periodic inspections of the portable accommodation module, verifying its compliance with the design plans and data package. The surveyor conducts various inspections such as visual inspections, insulation, and non-destructive testing (NDT), as well as tests of systems such as general alarms and fire detection. Upon completion of fabrication, the module is marked for identification purposes, including details like the manufacturer's name and address, the manufacturer's serial number, the number of persons to be accommodated, and the ABS approval letter. This marking enables ABS surveyors to locate all the necessary information on a module to ensure it meets the requirements of the vessel or installation it is being installed on. Subsequently, the manufacturer requests a manufacturer assessment (MA) to confirm that the ABS surveyor has verified compliance with the PDA and to audit the quality control system and manufacturing process. Upon successful completion of the audit, the module is issued an MA certificate, and its product status is updated to "Type Approved." ABS Certification Step 3 – Design Review for Installation Approval Once the product status of the module has been changed to "Type Approved," it is ready to be deployed for use on a vessel or installation. However, there are specific technical requirements that must be met when installing a portable accommodation module onto a host vessel.

This information is packaged together and sent to the ABS technical office, where ABS engineers will determine if the proposed location on the vessel is suitable for the module. When the package is approved, stamped drawings are returned to the submitter and to the ABS survey office. ABS Certification Step 4 – Host Survey Onboard The final step in obtaining ABS certification involves the Host Survey Onboard, where an ABS surveyor checks the installation of the module on the vessel to confirm that it follows the approved drawings submitted in the previous steps. Once the surveyor approves the installation, the module is considered "ABS Certified" and ready for use. Since modules can remain in service on vessels for several years, the ABS mandates annual surveys to ensure that the module remains compliant with the necessary requirements for maintaining its certification. This explanation provides a brief overview of the process for obtaining ABS certification for offshore modules. For further information on offshore module, please contact us. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. #Portable accommodation modules #Offshore accommodations #ABS certification #Marine safety #Modular construction Written by OliverAs the world continues to search for sustainable ways to meet its energy needs, one technology that is gaining popularity is energy storage containers. These containers, also known as energy storage systems, have the potential to play a key role in the transition to clean energy by helping to stabilize the grid and integrate renewable energy sources. At its core, an energy storage container is a self-contained unit that stores electrical energy in batteries or other energy storage devices. These containers can be designed to store energy from a variety of sources, including solar panels, wind turbines, and the grid. The energy stored in these containers can then be used during times of high demand or when renewable energy sources are not available. One of the primary benefits of energy storage containers is their ability to stabilize the grid. By providing energy during times of high demand or when renewable energy sources are not available, these containers can help prevent blackouts and brownouts and ensure that the grid remains stable and reliable. This is critical as more and more renewable energy sources are integrated into the grid, which can create fluctuations in energy supply and demand. Another benefit of energy storage containers is their ability to integrate renewable energy sources into the grid. By storing excess energy from solar panels or wind turbines, energy storage containers can ensure that energy is available even when the sun is not shining or the wind is not blowing. This helps to make renewable energy sources more reliable and reduces our dependence on fossil fuels. In addition to their benefits for the grid and renewable energy integration, energy storage containers also offer cost savings. By storing energy during times of low demand when energy prices are low and then using that energy during times of high demand when energy prices are high, these containers can help reduce energy costs for individuals and communities. As the world looks for sustainable energy solutions, energy storage containers are poised to play a critical role in the transition to clean energy. They offer a way to stabilize the grid, integrate renewable energy sources, and reduce energy costs. Moreover, they also offer an opportunity for innovation and entrepreneurship, as entrepreneurs develop new and innovative energy storage technologies to meet the growing demand for sustainable energy solutions. In conclusion, energy storage containers are an important technology that can help us achieve a more sustainable and clean energy future. As we continue to explore new and innovative ways to meet our energy needs, energy storage containers are poised to play a key role in the energy transition. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. Regarding the Battery Energy Storage System (BESS) container, please download Energy Storage System (ESS) Containers brochure for reference. #Energy storage containers #Renewable energy integration #Grid stabilization #Clean energy #Sustainable energy Written by OliverDNV 2.7-1 Certified Offshore Containers: Ensuring Safety and Efficiency in the Oil and Gas Industry5/4/2023

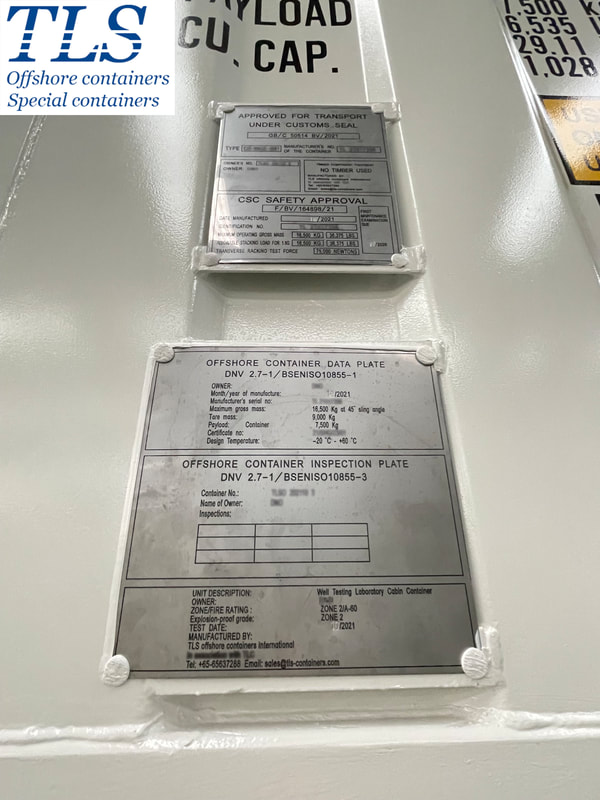

The oil and gas industry is one of the most challenging and demanding industries in the world. Operating in harsh offshore environments, the industry requires equipment and infrastructure that can withstand extreme conditions while ensuring the safety of personnel and the environment. This is where DNV 2.7-1 certified offshore containers come into play. DNV 2.7-1 is a globally recognized standard for offshore containers, developed by the international certification body Det Norske Veritas (DNV). The standard specifies the requirements for design, manufacture, testing, inspection, and certification of offshore containers for use in the oil and gas industry. DNV 2.7-1 certified offshore containers are designed to meet the highest standards of safety, quality, and efficiency. These containers are built to withstand harsh weather conditions, heavy loads, and rough handling during transport and lifting. They are also designed to protect personnel and equipment from hazards such as fire, explosion, and impact. One of the key benefits of DNV 2.7-1 certified offshore containers is their versatility. These containers can be used for a wide range of applications in the oil and gas industry, including storage, transportation, and accommodation. They can be customized to meet specific requirements, such as the need for temperature control, hazardous material storage, or equipment protection. DNV 2.7-1 certified offshore containers are subject to rigorous testing and inspection procedures to ensure compliance with the standard. This includes testing for structural strength, water-tightness, fire resistance, and lifting capacity. Only containers that meet these requirements and are certified by an accredited certification body are allowed to be used in the offshore industry. Using DNV 2.7-1 certified offshore containers can help companies to reduce risk, improve safety, and increase efficiency in their operations. By using certified containers, companies can ensure that their equipment and personnel are protected from hazards and that their operations comply with industry standards and regulations. In conclusion, DNV 2.7-1 certified offshore containers play a critical role in ensuring the safety and efficiency of operations in the oil and gas industry. These containers are designed and tested to meet the highest standards of quality and safety, and their versatility makes them ideal for a wide range of applications. By using certified containers, companies can minimize risk and improve the overall performance of their operations. TLS Offshore Containers / TLS Special Containers is a global supplier of standard and customised containerised solutions. Wherever you are in the world TLS can help you, please contact us. #DNV 2.7-1 #offshore containers #oil and gas industry #risk reduction #structural strength #water-tightness #fire resistance Written by OliverOffshore oil and gas platforms are among the most hazardous work environments in the world, and the equipment used in these environments must meet strict safety standards. One of the key challenges in offshore oil and gas production is ensuring safe containment, transportation and storage in a flammable and explosive environment. This is where positive pressure containers come into play. Positive pressure containers are designed to maintain a positive pressure inside the container at all times, preventing flammable or explosive gases from entering the container and creating a potentially dangerous environment. These containers are typically made from high-grade materials that are resistant to corrosion, extreme temperatures, and other environmental factors. TLS Offshore Containers is a leading manufacturer of positive pressure containers for use in offshore oil and gas production. Our containers are designed and manufactured to meet the highest safety standards and are widely used by some of the world's largest oil and gas companies. So, why do flammable and explosive hazardous areas, especially offshore oil and gas platforms, need positive pressure containers designed and manufactured by TLS Offshore Containers? The answer lies in the unique challenges posed by these environments. Offshore oil and gas platforms are exposed to a wide range of environmental factors, including saltwater, wind, and extreme temperatures. This can create significant challenges when it comes to storing and transporting hazardous materials. Positive pressure containers are designed to withstand these environmental factors and maintain a safe environment for workers. In addition to environmental factors, offshore oil and gas platforms are also exposed to a wide range of potential hazards, including fires, explosions, and leaks. Positive pressure containers are designed to minimize these risks by preventing flammable or explosive gases from entering the container and creating a potentially dangerous environment. TLS Offshore Containers has been designing and manufacturing high-quality containers for use in offshore oil and gas production for many years. Our containers are designed to meet the highest safety standards and are rigorously tested to ensure they can withstand the unique challenges posed by offshore environments. In conclusion, positive pressure containers designed and manufactured by TLS Offshore Containers are essential for ensuring the safety of workers in flammable and explosive hazardous areas, especially offshore oil and gas platforms. These containers are designed to withstand a wide range of environmental factors and potential hazards, and are crucial for maintaining a safe work environment in one of the world's most dangerous industries. Wherever you are in the world TLS can help you, please contact us. #Flammable and explosive hazardous areas #Positive pressure containers #Offshore oil and gas platforms #Environmental factors #Corrosion resistance #Extreme temperatures Written by Oliver |

Archives

May 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|