|

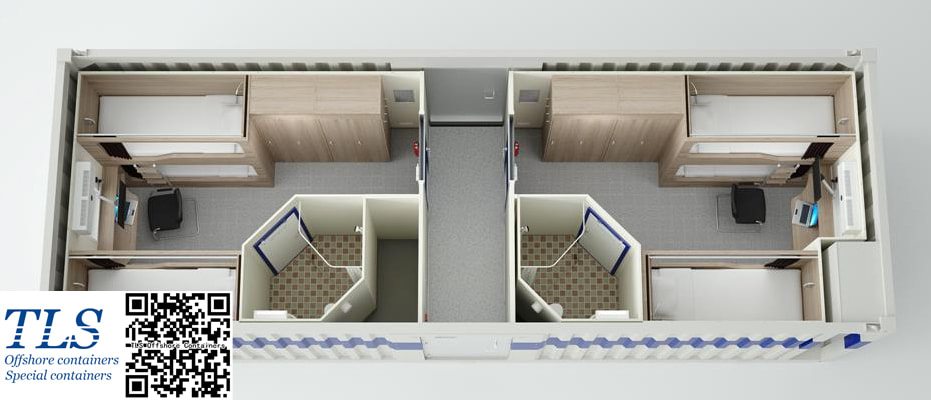

A60 offshore accommodation module offering safe and comfortable living space for 1, 2, 3, 4 or 8 personnel Description:

In addition compliance with offshore oil & gas requirements as following,

Features:

Services

Weight Less than 17.5 Tons. Lifting

Furnitures

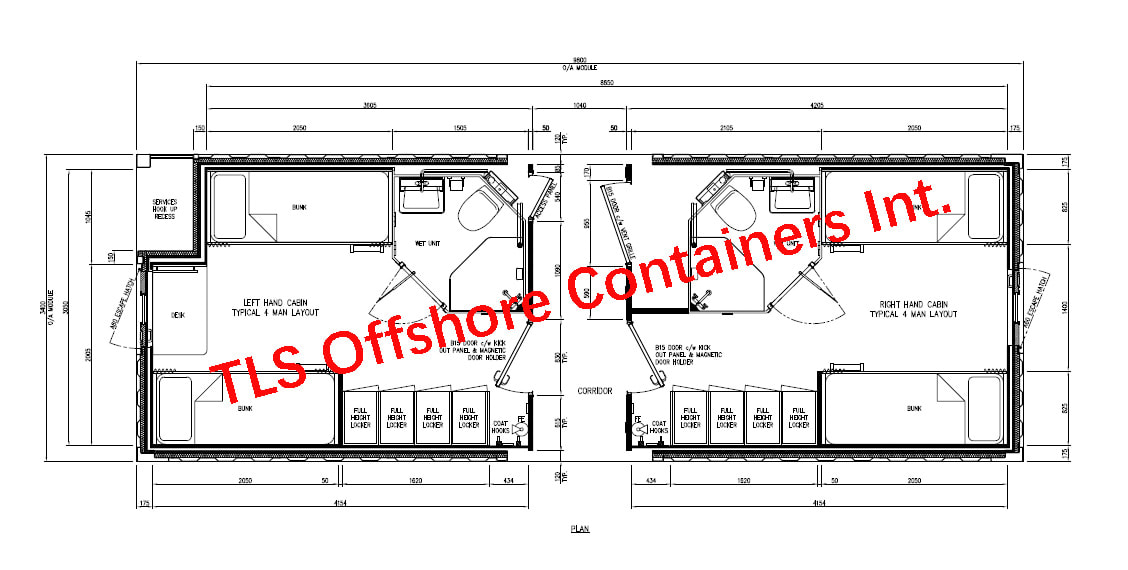

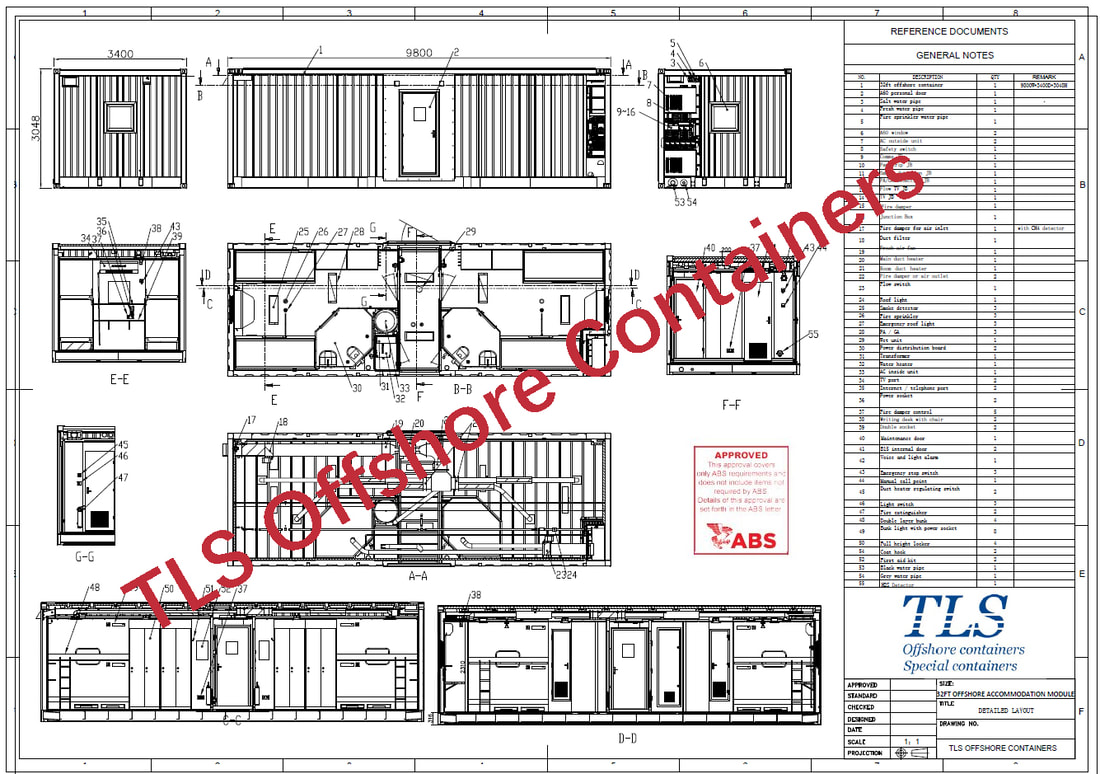

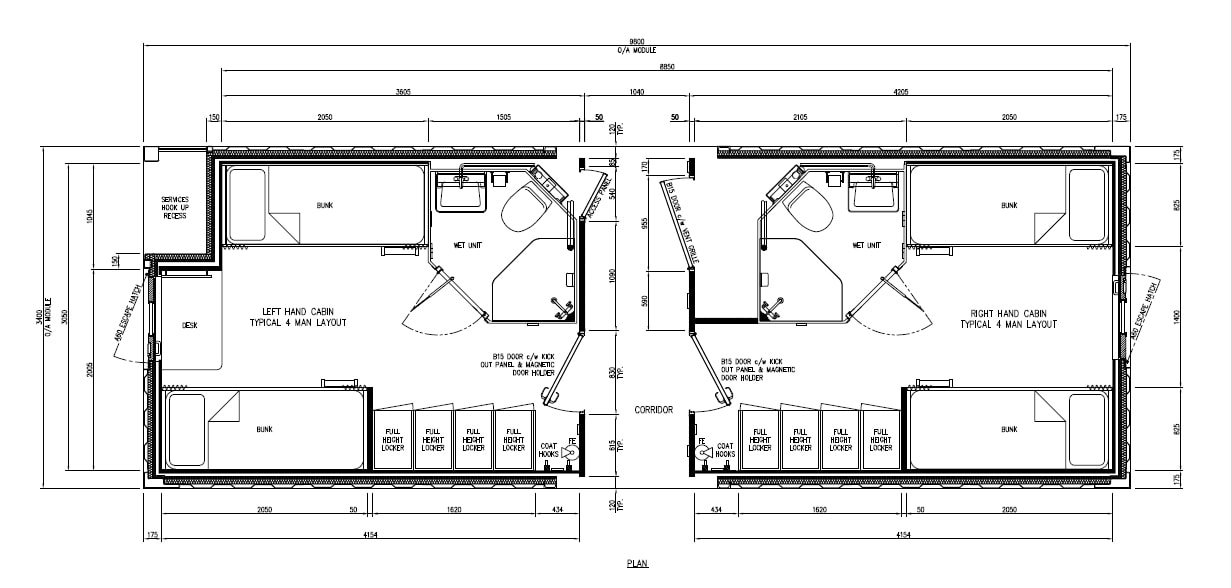

A60 offshore accommodation modules are manufactured and designed according to ABS guildline. Please download TLS accommodation modular brochure , TLS ABS approved offshore accommodation module brochure for reference. More information about accommodation modulars, offshore accommodation cabins, gallery module, mess module, etc. Please contact sales@tls-containers.com for more information.  ABS approved 8 man accommodation cabin installed on ABS classed mobile offshore drilling units, offshore barge or vessels ABS approved 8 man accommodation cabin installed on ABS classed mobile offshore drilling units, offshore barge or vessels Services Each Module has an Accessible Service Area Which Contains Hot Water Heater, Transformer & General Electrical Equipment Which Can be Easily Serviced. External Paint Specification Each Module is Shot Blasted to SA 2.5 and DNV approved, 3 Coat Paint System Applied, Giving a Total of 250 Microns Paint Thickness. Modules Shall be Painted “RAL 9003 Signal White” As Standard, However Client Can Change Color & Add Company Markings Where Required. Weight Not Exceed Weight of 17.5 Tons. Lifting All modules, as well as being DNV certified, also have certified lifting eyes included in the design structure and each module is supplied with a certified sling (included in the price). The units are designed for lifting on and off fixed platforms and other types of floating installations. Installation & Linking Each Module Comes Complete with Twist Locks & Pads for Deck Mounting & Linking Kits for Structural, Mechanical & Architectural Linking of Modules. Accommodation Module Contains 2 Cabins & Each Cabin Includes the Following Items:

In addition, compliance with offshore oil& gas requirements as follows:

Unit specification: As per ABS guideline for offshore accommodation module. modules fitness as three stacking level manned during floating / elevating condition meeting weather criteria in addition to compliance with ILO/MLC. ABS guildline for the design and survey of portable accommodation modules installed onboard ABS-classed Mobile Offshore Drilling Units (MODUs), and Mobile Offshore Units (MOUs), Offshore Installations (fixed or floating), Steel Barges, and Steel Vessels. Please don't hesitate to contact us sales@tls-containers.com |

Archives

April 2024

Categories

All

|

- Home

-

Containerised solutions

- Intelligent pressurised container | MUD logging cabin

- Battery energy storage system (BESS) container

- Flexible grid tied battery storage system

- Laboratory container | workshop container | Equipment containers

- Temporary refuge shelter | Toxic gas refuge | Safe haven

- Offshore accommodation cabin | office container

- Reefer container | Refrigerated container

- Intelligent waste water treatment container

- Fresh water generator container

- Cargo Containers

- Product photos & videos

- News & Blogs

- Contact us

|

Featured products

Intelligent pressurised container Temporary refuge (TR) shelter, toxic gas refuge (TGR) Battery energy storage system (BESS) container Containerised waste water treatment plant Fresh water generator container Reefer container Laboratory container, Workshop container Accommodation container Offshore closed container |

All Rights Reserved 2020 © TLS Offshore Containers / TLS Energy

|